By Christopher R. Bartocci

The last company in the industry this author would suspect would manufacture a direct gas impingement rifle would be Patriot Ordnance Factory (POF). This company has built their reputation and, in fact, lead the industry on the short stroke tappet operating system in the AR15/AR10 platform. You would think this company loathed the legacy operating system. After speaking with POF CEO Frank DeSomma, that is clearly not true. According to Frank he likes the direct gas system just fine but when he went into business he wanted to fill a new niche where he could stand out and not do the same thing everyone was doing. He liked the merits of the short stroke tappet system and went with it. He wanted to diversify his product line. He also looked at several ways to improve the system making it more durable and reliable. Just like those who swear by the external piston operating system, you have that part of the industry who are die hard direct gas system supporters. POF answered that call to the industry with the Old School rifle chambered in .308 Win/7.62x51mm NATO. Later he introduced the 5.56mm version called the Renegade but that, is a different story. DeSomma would take all of the enhancements of his firearm design and apply them to the legacy gas system making it one to stand out from the pack. The POF Old School was released at SHOT Show 2015.

The POF Old School is chambered in 7.62x51mm NATO/.308 Winchester caliber. The unloaded weight is 8.0 to 8.2 pounds. Barrel length is 16.5 -inches but it is also offered with a 14.5 or 20-inch barrel. The overall length with the stock closed is 34 inches and extended fully is 39.5 inches. MSRP for the Old School is $2649.99 for the black model and $2689.99 for the NP3 coated rifle.

Starting with the lower, the receiver extension has 7 positions for the stock. Most rifles in this category have 4 to 6 positions making this extremely modular to custom fit a soldier with or without body armor and allow for various thicknesses. The receiver extension is made from a 7075 T6 impact extrusion material per Mil-Spec. The tube also has anti-tilt technology. This prevents the bolt carrier from ever coming out of alignment with the receiver extension. The bolt carrier end is already in the receiver extension when the receivers are closed. The stock chosen is the Magpul CTR stock which has a locking lever to keep the stock from unintentionally moving. This is a durable and lightweight stock assembly. There is a Quick Detach mounting point on each side of the stock as well as traditional slots for a cloth sling. The lower receiver is precision made from a billet of 7075 T6 aircraft grade aluminum. The T&E rifle lower was flawless with no machining marks. The safety is ambidextrous. The bolt catch is also ambidextrous just behind the magazine release button. In front of the trigger is another useful gadget, this one allows the operator to push upward on a lever to engage the bolt catch. This allows you to manipulate and lock open the bolt with the use of your trigger finger. Regardless if you are left or right handed, it does not matter in using this bolt catch. The trigger guard is part of the receiver and is large enough to accept heavy winter gloves. The magazine well has a very nice flare making it easier to insert magazines in low level to no light. On the left side of the receiver there is an ambidextrous magazine release that is parallel with the one on the right side. The bolt catch has an enlarged paddle on the lower portion making it easier to manipulate. The pistol grip chosen is the very comfortable Magpul MOE pistol grip with no finger swell. The trigger group is held in place by KNS Precisions anti-rotation hammer/trigger pins. The trigger mechanism is also designed and manufactured by POF. It is there drop in trigger system which is factory. The T&E trigger broke at 5 pounds. The trigger group is assembled in an aluminum housing which drops into the receiver. Standard hammer and trigger pins will not hold this unit properly. The hammer, trigger and disconnector are heat treated to 70 Rockwell, case hardened and Nitride coated. It should be noted that POF helped to develop the Timney Trigger. Looking down at the inside of the lower receiver are two polymer hex screws located just behind the rear takedown pin. This allows the user to tighten the receivers so there is no movement.

The charging handle is also manufactured by POF. It is also manufactured from a billet of 7075 T6 aircraft grade aluminum. There are knurled edges on the rear of the handle as well as the latch itself. This helps the shooter grip under adverse conditions such as mud, water and so on.

The upper receiver is manufactured from a billet of 7075 T6 aircraft grade aluminum, It has the traditional forward assist, fired cartridge case deflector and ejection port cover. When open, the ejection port cover reads “God Bless America” on the left and an American flag on the right. This is sort of a POF calling card.

The handguard is the POF designed M.R.R. or Modular Railed Receiver. The one piece rail has a continuous top rail that attaches to the top of the upper receiver and also under the barrel nut. This is a complete free floating rail. The 6 and 12 o’clock rail have a two inch Mil-Std-1913 rail. The rest are made up of removable rail sections that are placed at the operator’s discretion. The top rail will sit higher than a standard Mil-Spec upper receiver flat top. The rail is 11-1/2 inches long.

The barrel is held on by a special barrel nut that doubles as a heat sink over the camber of the barrel. This heat sink draws heat out of the chamber to increase cook-off time substantially. The combination barrel nut/heat sink is 2 1/2 -inches long and fluted around the entire diameter of the outer surface. Giving 5x more surface area compared to the standard barrel nut and aluminum. This permits 17 times more heat dissipation over steel. This barrel nut ensures that if the rail is flexed with use of a vertical grip, it will only flex at the front of the barrel nut which is 3 inches from the most critical item on the rifle, the bolt and its lock up.

The T&E rifle was provided with a 16.5-inch barrel that is manufactured from chrome vanadium (Mil-V-11595) steel. Then the barrel is Nitride heat treated and case hardened to 68 to Rockwell . The rifling is a 1 turn in 10-inch right hand twist with 5 lands and grooves. The threads on the muzzle are 5/8×24 enabling a various array of flash suppressor, muzzle brake and sound suppressors to be attached. The rifle comes standard with the POF triple port muzzle brake. POF has found this muzzle brake permits flat shooting, low recoil and allows fast follow up shots. POF guarantee sub-MOA accuracy out of the box. Of course ammunition and shooter ability are a major factor

in this guarantee.

One of the real standout features found on all POF firearms is the E2 dual extraction technology. This consists of four channels cut into the neck portion of the chamber which permit gas from combustion of the propellant to follow the channels back and impart force on the shoulder of the cartridge case. This gives initial separation of the cartridge case from the chamber when the bolt unlocks. With this system, the extractor itself has very little work to do during the extraction process. The combination of the extractor and E2 technology gives the weapon a push/pull dual extraction rather than just a pull. This is a major improvement to rifles that are known to have extraction issues due to higher cyclic rates as well as extreme adverse conditions. There are four lines visible on the neck of the cartridge case but this will not affect reloading of the cartridge case. As of this writing, POF is offering this service to customers who have 5.56mm and 7.62mm caliber barrels as an upgrade for $179.99.

Introduced on this rifle is the DIctator low profile gas block. This was just released by POF in June of 2015. The operator dictates total control of how the weapon system operates. This is specifically designed for direct gas impingement rifles. On the rifle, the gas block was drilled and pinned. Any serious combat or duty type rifle should have this drilled and pinned. Clamp-on and screw secured gas blocks are known to move forward causing short stroking, and if not fixed complete gas shut offs can occur. Rifles, especially with sound suppressors, have an inconstant port pressure that over-gasses the system causing extremely high cycle rates. This can cause issues of premature parts wear and failures to extract. The DIctaor offers the shooter 9 positions to fine tune the rifle system. Whether the operator is shooting suppressed, unsuppressed, with heavy or light buffer, the DIctator regulated gas block allows the operator complete control for smooth operating. This increases reliability and durability while having a consistent cyclic rate of fire. The DIctator was designed as a low profile adjustable gas block that will fit inside a free floating rail with an inner diameter of 1.375-inches. The first run of the DIctator will be set up for .750-inch barrels in both carbine and midlength gas systems. Each DIctator comes with a stainless steel straight gas tube. Bends in the gas tube restrict and collect higher heat in those areas of the gas tube. Those restricted areas are failure points during high volume or sustained fire. Straight gas tubes are less restrictive than standard Mil-Spec bent ones. In fact the POD gas tube is an Inconel straight tube (alloy of nickel containing chromium and iron, resistant to corrosion at high temperatures) which will withstand nearly double the amount of heat as the Mil-Spec gas tube. Each DIctator assembly comes with an adjustment wrench to move carboned up gas valves. Also, the DIctator is available for sale as an upgrade to your rifle in both screw-on and pin-on configurations. The MSRP for the DIctator upgrade assembly is $179.99.

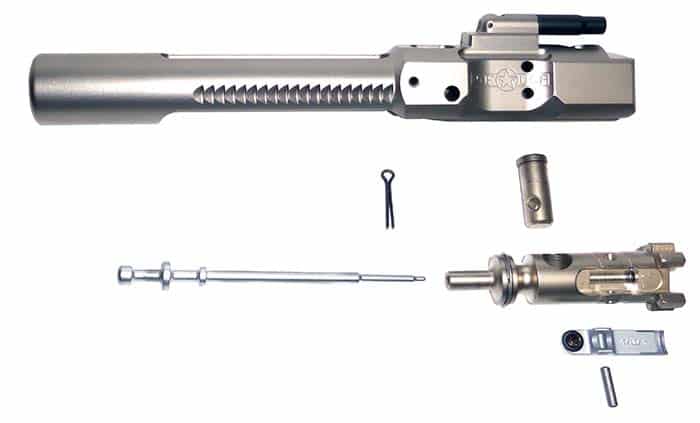

Another feature of the Old School is the enhanced direct gas bolt carrier group designed and manufactured by POF. This is also available as a drop-in for most AR10 type rifles, with an MSRP of $324.99. Also available is a .223 version of the bolt carrier for an MSRP $274.99. The NP3 plated carrier group has three major design improvements. First, the bolt carrier is one piece. The steel gas key screws into the face of the “tombstone” of the carrier and is pinned in place. What does this do? There are basically two places you get gas loss in a direct gas rifle. One is the front sight base and the second is the carrier key. If the carrier key was to break, the carbon seal is broke between the carrier key and the bolt carrier gas leaks and the rifle will short stroke. The POF carrier design completely eliminates the possibility of gas loss through the bolt carrier. The second major improvement is the use of the POF NP3 coated Roller Cam. The standard cam is square in shape. Some have the edges rounded, others do not. The square shape scrapes along the inside of the upper receiver which will cause wear on the aluminum receiver. This happens anytime two pieces of metal scrape and one is harder than the other. The roller cam eliminates the steel edges scraping the inside of the receiver, drastically reducing internal wear. This is even more prevalent in piston operated rifles. You will see a cut in the inside of the upper receiver just behind the cam notch. This is prevented for the most part with Roller Cam. This is also offered as an upgrade for all .308-type carriers. It is also offered for 5.56mm carriers. The kit comes with a carrier key (with notch cut to allow removal of Roller Cam) and Roller Cam. The third major improvement is the material the bolt is manufactured from; 9310 steel which is a 7% improvement over Carpenter 158 steel (Mil-Spec). The extractor has enhanced geometry for better support of the extractor.

The scope chosen is the NightForce BEAST. BEAST is an acronym for Best Example of Advanced Scope Technology. The BEAST is a 5-25 x 56 F1 with a tube diameter of 34mm/1.34 -inches. The objective outer diameter is 65mm with an exit pupil diameter of 5x 8.3mm and 25x at 2.3mm. The eyepiece outer diameter is 46mm. The field of view at 100 yards is 5x@18.7 ft and 25x@ 4.92 feet. Eye relief is 3.35 to 3.54 -inches. The internal adjustment range for elevation is 120 MOA and windage 80 MOA. Each click is .50 and .250 MOA. The parallax adjustment is 45 yd-∞. The optics are crystal clear. This would be a standard of excellence in long range rifle optics.

At the same time this T&E rifle arrived, so did a box of the new D&H Tactical SR25-type steel magazines in both 10 and 20 round capacities. D&H Tactical is out of Oconomowoc, Wisconsin and is the former LaBelle Industries who manufactured magazines in the early 1980’s. It was first sold to General Stampings and now D&H Tactical. Up until around 2010, D&H Tactical only offered 5.56mm AR15/M16 magazines. In the next five years D&H Tactical added SCAR16 & SCAR17 SOCOM magazines, 6.5 SPC magazines, 1911 45 Auto magazines, 300 Blackout specific magazines, SR25 pattern magazines, 7.62x39mm AR-type magazines, blank only magazines, free float handguards for AR-platform with more on the way. D&H Tactical has OEM contracts with Remington, Bushmaster, DPMS, Sig Sauer, O.F. Mossberg, Del-Ton, BCM, Windham Weaponry, Alexander Arms as well as CZ USA. They also have numerous US government and Law Enforcement contracts. They have a long standing 16-year relationship with the Israeli army as well. The magazines received were very high quality steel magazines with a non-reflecting flat black finish. There are witness notches indicating 5, 10, 15 and 20 rounds on the right side of the magazine and on the 10 round magazines there is a witness window for 5 and 10 rounds.

The ammunition tested in the rifle was manufactured by HPR (High Precision Range). This is a .308 Winchester Match 168gr Hornady boat tail hollow point projectile. The ammunition is manufactured by Advanced Tactical Armament Concepts, LLC out of Payson, Arizona. The ammunition was loaded in Winchester 7.62x51mm NATO brass with a muzzle velocity of approximately 2700 feet per second.

Approximately 200 rounds of Federal XM80 7.62x51mm FMJ was fired in the Old School for function. All ammunition was fired in two D&H Tactical magazines with no malfunctions of any sort. The gas valve was not changed from the factory setting due to 100% reliability. Recoil was moderate and extremely manageable, especially for a rifle in this caliber. The muzzle brake did its job well though the guy on the bench to my right was not happy about the muzzle blast! Accuracy tests were shot at 100 yards off of a bench vice. There were 4 groups of five rounds each of the HPR ammunition and the best group measured approximately .70 -inches in diameter.

There are many options out there in AR10 type rifles. Some tout theirs as Mil-Spec even when the only rifle out there in the US Government to have a Mil-Spec is the M110. Many rifles bought are commercial off the shelf. Many get hung up on the term Mil-Spec. The reality is this is a minimum standard the weapon must meet. Many weapons in the industry today meet and exceed Mil-Spec. They have actual improvements made to them to aid in reliability and durability of the weapon platform. The POF Old School is one of them. Major improvements to the bolt carrier group, trigger, gas system (for using suppressed ammo and fine tuning), ambidextrous controls, E2 Enhanced Extraction Technology to name a few. Most of the components on this rifle are designed and manufactured by POF to make a more durable and reliable rifle than the standard AR10-type rifle. If you are looking for a rifle that far exceeds the minimum standards and has all the major components improved, the Old School is an excellent choice.

| This article first appeared in Small Arms Review V20N4 (May 2016) |