By Robert G. Segel

As collectors and shooters of automatic weapons know, keeping and maintaining these machine guns in working order is no easy task, particularly the classic, tired pre-1945 models. And with the rarity of some models, physical external appearance is just as important in determining collectors value as is the operational aspect. How many times have we all seen the results of improper tools applied and used on guns which ultimately scar and mar the gun’s finish, strip screw heads and break key parts? How many Thompson submachine guns have we seen with screwdriver scratches and pry marks on the frame and pivot plate assembly where well meaning, but ignorant, people thought they could completely disassemble the gun using common household tools? How many barrels have we encountered that show the ugly tell tale scars of vise, channel lock or just plain old pliers marks forever deeply gouged into the metal? Horror stories abound. As ridiculous as it sounds, the common household screwdriver (one size fits all), the steel claw hammer and pliers are the tools of choice and convenience in the majority of do-it-yourself styled hobbyists. This is truly a recipe for disaster in devaluing your expensive and rare weapon.

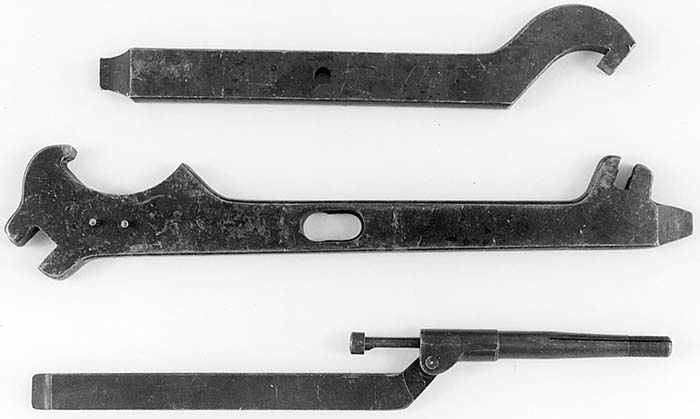

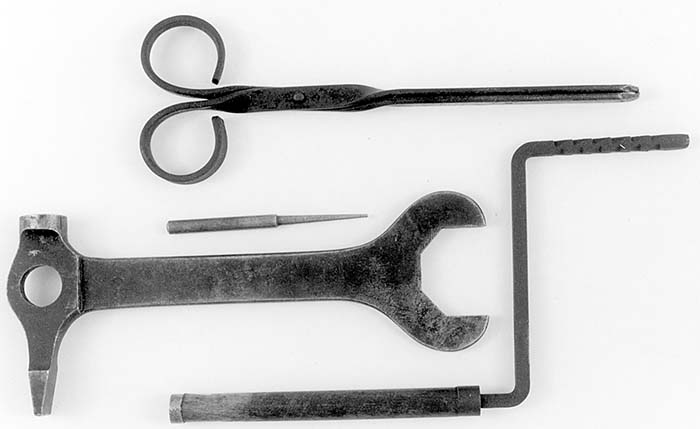

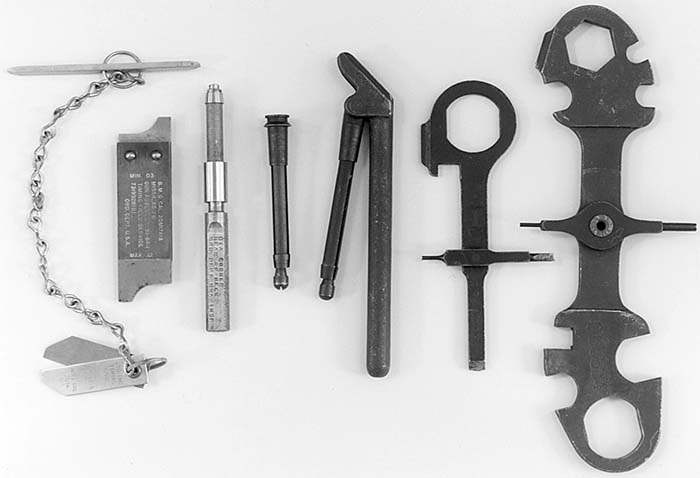

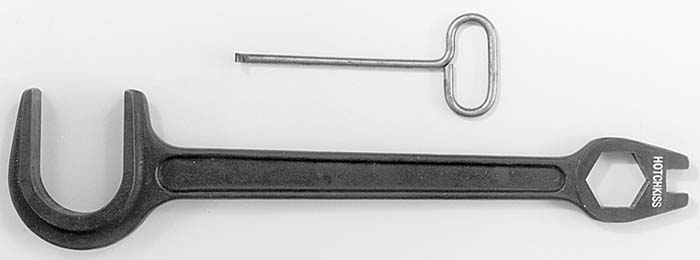

Manufacturers of these firearms produced a number of specialized tools to support the take down and maintenance of these weapons. Sometimes extremely simple such as a specific sized wrench to the more elaborate combination tools that utilized a number of specific tools “combined” into one unit. These often had such tools as exact sized screwdriver, barrel wrench, muzzle gland wrench, flashider wrench, pin punch and gas regulator key. These tools provided a quick and easy means of servicing the weapon for either routine maintenance or expedient field repairs. These tools were meant to be used in the field by the soldiers. Depot tools, gages and jigs are another subject and for use by only truly qualified gunsmiths or armorers.

Other simple but necessary field tools include ruptured case extractors of various designs, oil cans or bottles, gauges for measuring headspace, timing and chambers and, of course, the lowly but very important cleaning rod. Headspace and timing gauges are particularly important for Browning type heavy machine guns since the headspace and timing can be adjusted by the gunner particularly after field stripping. Woe to the shooter who fires his Browning out of battery. Proper lubrication is also an absolute necessity to keep wear and tear to a minimum. It is wise to keep all working parts well oiled but remember that too much oil can be just as harmful as no oil at all. Too much oil can attract and retain dirt and grime which acts like sandpaper to grind your moving parts down to unacceptable tolerances.

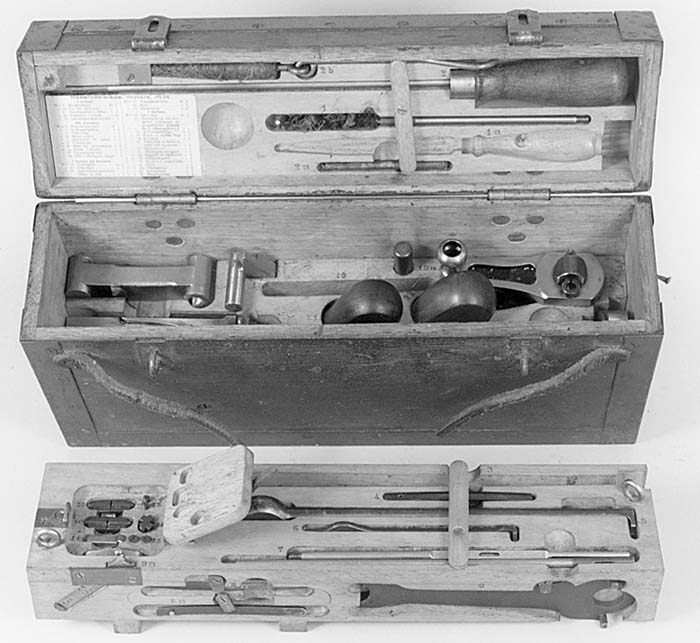

While the tools mentioned are carried by the machine gunner for expedient repairs in the field, there were also elaborate armorer kits that contained even more specialized tools to patch holes in water jackets or repair cloth belts as well as containing some spare parts that were likely to wear out after heavy use or were prone to loss or breakage.

The old adage “Proper tools will produce proper results” is very true. Changing a barrel with a properly sized and function specific barrel wrench on a Colt Model 1914 “Potato Digger” or a Model 1909 Benet-Mercie is a snap versus the all to often disastrous results of using a pair of vise grips. Most of these weapons are pretty tired after all these years. They have had hard use and abuse in the military and in many cases have survived actual combat usage. Treat them with respect and take care of them. Using the proper tools will help keep the value of your gun and not turn it into a piece of junk. Try and find the proper tool or combination tool for your treasured machine gun. It may take a little work but they are there. And by all means invest in a set of quality gunsmith screwdrivers. You will never be sorry you did.

| This article first appeared in Small Arms Review V3N3 (December 1999) |