By N.R. Parker

In 1943, Russell S. Robinson started the design and development of what many would consider to be a proper machine pistol, i.e. a pistol that would fire automatically yet having recoil so low as to be controllable in this mode of fire. The Model 11 is not a true Constant Reaction gun in which the barrel, extension and bolt are used to pre-absorb recoil, but uses the slide or jacket to provide all of the inertia. This is a unique approach to solving the problems of firing in full automatic with a weapon the size of a Colt M1911A1.

The Model 11 employs two distinct principles: firstly to smooth out the rearward recoil kick and secondly, to smooth out the torque impact resulting from spinning the projectile to about 1,500 rpm which disturbs aim in a light hand held weapon. The second principle involves rotating the barrel while the slide is moving forward, with the rotation of the barrel in the same direction as the spinning projectile. While we will examine in detail the operation and design of the Model 11 later on, we will first take a look into the history of its development, and what role Russ Robinson had in mind for the Model 11 when designing and developing it. It turns out that this was the role of a Personal Defense Weapon (PDW) long before the concept of a PDW came into vogue.

Inspiration from the Gatenby .45

In 1942, an Australian named Gatenby submitted to the Australian Army Inventions Directorate (A.I.D.) for evaluation a very unusual .45 caliber Machine Carbine/Pistol. Intrigued, the A.I.D. sought a version in 9mm for evaluation and Robinson, at the time involved in firing-range tests of his Model 5 Cal. .50 machine gun, was contracted by the A.I.D. to design a version in 9mm.

The Gatenby gun fed rearward out of the magazine, with a fixed buttress on the pistol grip having a fixed firing pin. A sliding barrel was used with about 1.5 inches of movement. When a round was chambered and fired, the force of engraving and friction of the bullet in the rifling carried the barrel forward against a stiff spring, with a spring-biased extractor in the buttress holding the fired case against the breech face. A fixed ejector spun the empty case off the breech face after the barrel had moved forward about 1.25 inches. Hitting a forward stop at its forward limit of movement, the barrel returned rearward, with a fixed finger under the barrel striking the point of the next cartridge in the magazine. This thrust the cartridge rearward against a ramp that guided it upwards, and, simultaneously, the recoiling barrel pushed the point of the cartridge upward and chambered.

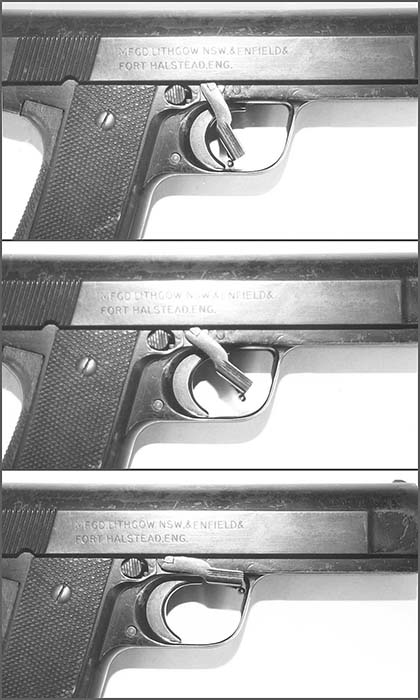

Center -Combination safety and fire selector in semi-auto position Bottom – Combination safety and fire selector in full-auto position. Photo Credit: N.R. Parker

Problems with feeding reliably due to insufficient support of the cartridge while the barrel moved rearward, as well as the heavy recoil, made the Gatenby very difficult to control in a full-auto burst mode. The heavy recoil was due to a combination of the simultaneous recoil shock of ignition and the shock of the returning barrel hitting the fixed breech face.

Robinson designed two variants of the 9mm Gatenby, these being known as the Models 8 and 10. While the Gatenby did not continue any further, it did impress Robinson with some aspects of the design. He initially considered that the Constant Reaction principle was only applicable to .30 caliber and larger, but the Gatenby concept inspired him to apply a variation of the principle to a light weight gun. He felt that a cyclic rate of 600 rpm, with continuous recoil of 5.2 pounds, with the recoil varying about 1.75 pounds, would result in an accurate one-hand held machine pistol. The end result was the S.R. Model 11 9mm Machine Pistol.

Development and design of the Model 11

Conceived in early 1943, the drawings were finally completed by March 1944, and construction was approved in November 1944. Major modifications to the design were necessary due to Russ Robinson’s failure to realize that when the slide struck the barrel via the chambered case, substantial energy was lost in getting the six ounce barrel up to slide speed. As a result of this failure, six ounces had to be added to the slide weight at the rear to compensate. These modifications and redesign were finished by mid February 1945. By early September 1945, major components had been fabricated at the Small Arms Factory (SAF), Lithgow and the prototype gun had fired some 1600 rounds in tests.

The S.R. Model 11 9mm Machine Pistol was designed to initially meet some 13 specifications laid down in 1943 following the advice and assistance of Major J.E.M. Hall, then chief of the Army Small Arms Branch, Directorate of Artillery. One requirement that could not be met was the weight, as the slide alone had to weigh one pound. Additional recommendations and suggestions were made by Australian Army and R.A.A.F. service personnel returning from fighting overseas and later by the Canadians. In this revised list of specifications, numbering 24 in total, the weight was increased.

While some of the 24 specifications laid down have been examined in an article from the now defunct Fighting Firearms, (Summer 1996, Constant Reaction Guns II), let us look again at some of the more interesting. These are as follows:

- Cyclic Rate of 500-600 rpm;

- Weight not to exceed 2.5 pounds;

- Provision for automatic ejection of empty magazine from gun;

- Safety and fire-selection controls must be conveniently located and designed for immediate operation by right and left trigger finger only;

- Recoil force to be smoothed out to permit accurate auto or semi-auto fire single handed;

- Except for pushing home successive magazines, no handling or operational function to require a second hand;

- The action to be kept in a cocked mode upon termination of burst fire as well as ejection of the magazine; and

- Magazines to be made as expendable as possible.

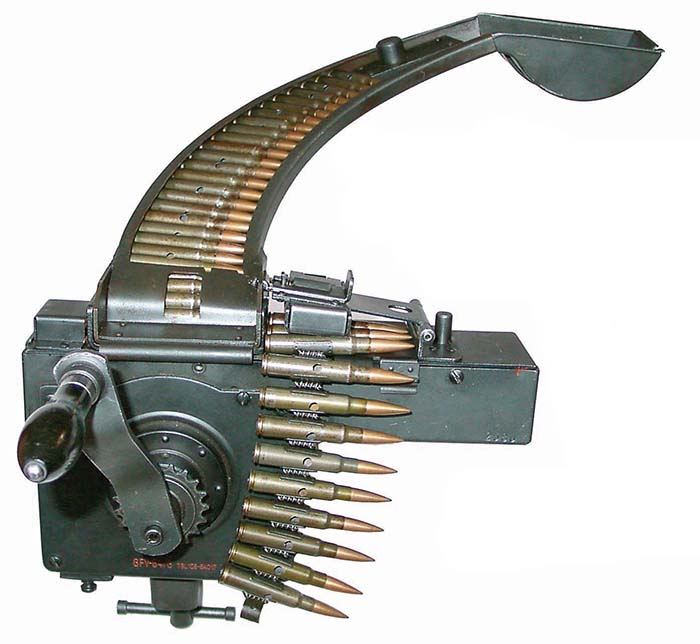

Some of these requirements and features had never been seen before such as the automatic ejection of magazines when empty. Alternative feed systems were mentioned in place of the magazine. For example, a flexible feed system was proposed feeding through the pistol grip though nothing came about from this proposal. The auto-ejection of empty magazines, coupled with the retention of the gun in a fully cocked position, allowed for a very short time break in firing estimated to be about 0.5 second. The only movement required to re-commence firing was the pushing home of the new magazine. This feature resulted from advice from Australian soldiers fighting in the jungles of New Guinea.

During a trip to Canada, on the way home from the UK in 1945, Russ Robinson visited Small Arms Ltd. and John Inglis Co., Ltd., the latter being manufacturers of the GP35 Pistol and the BREN. Both of these manufacturers expressed a great deal of interest in the Model 11. Colonel Jolley, the Manager at Small Arms Ltd., suggested that a light holster or combination holster/shoulder stock be developed, similar to that of the Mauser Broomhandle and the FN GP35, to enhance the effective range of the Model 11. However, a simple tubular telescoping stock was eventually designed and manufactured, which was attached to the pistol via a tapped hole in the frame. The holster ended up being made of canvas with a separate slip to accommodate the telescoping stock.

When Russ Robinson returned to the UK in the latter part of 1945, he took with him a number of S.R. Model 11 Machine Pistols complete with tubular stocks and canvas holsters. These guns were then later modified after tests in 1946. While these tests were carried out by the UK Ordnance Board, in another ironic twist, the trial report was signed by Major J.E.M. Hall, the Australian Army officer whose advice led to specifications for a 9mm machine pistol being laid down in Australia and ultimately resulted in the development of the S.R. Model 11. Major Hall had been transferred to the UK to work on various small arms projects, and was in charge of a design team working on the .280 rifle project.

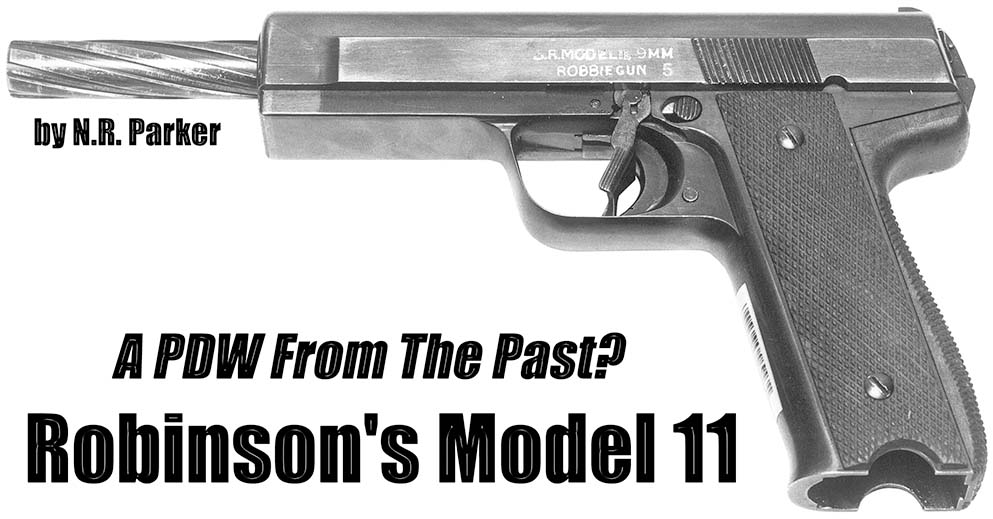

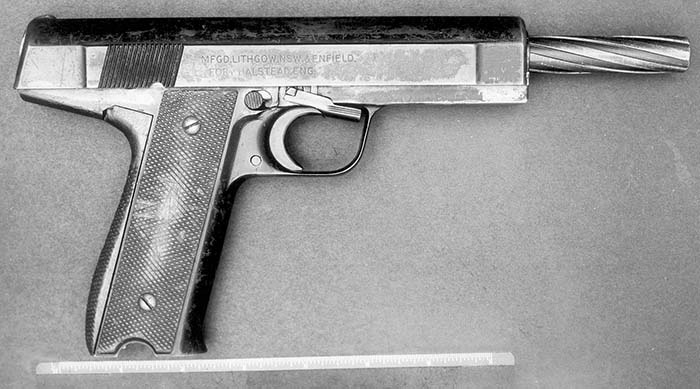

The S.R. Model 11, in its initial form, resembled a normal semi-automatic pistol, with the exception of the grooves machined into the exterior of the long barrel. Conducting further research for this article proved the old adage that “hands-on” research provides new insights into a subject. Up until now, it was commonly believed that only four S.R. Model 11 9mm Machine Pistols, including the prototype, were manufactured at SAF Lithgow, though there were some references in official files to a fifth gun being manufactured for spares only. The fifth gun was recently discovered in an official collection in Australia, and it is in an unmodified condition, unlike the other existing Model 11 guns that were modified in England. With the number 5 marked on the slide, it appears that this gun was assembled at SAF Lithgow, and somehow ended up in this official collection along with a modified Model 11 that is now in another official collection within Australia. This discovery allows us to view for the first time what the original Model 11 looked like prior to being modified in England. The markings on this fifth gun match those shown in the original drawings, and the differences between the unmodified and modified specimens are quite striking. The most obvious difference is the extended tang on the pistol grip while the modified slide is longer, heavier and has different markings.

Trials and Tests in the UK

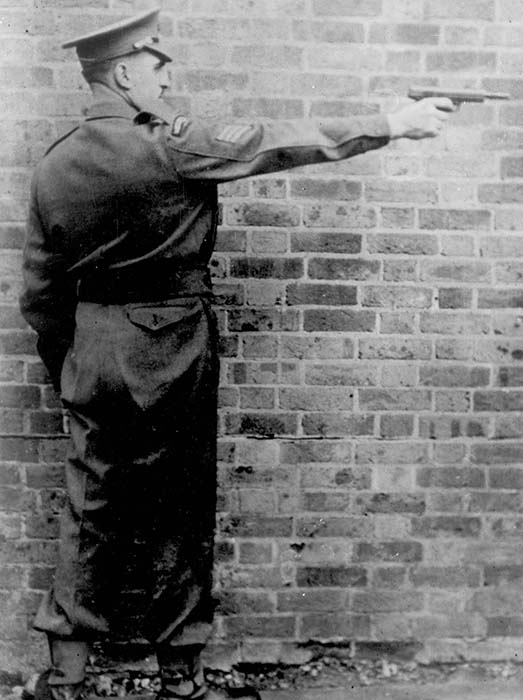

In 1946, the Model 11 underwent sand and mud tests at Enfield held in conjunction with accuracy tests. Major Hall ran these trials, and the accuracy tests produced some interesting results. The Model 11 was found to be more accurate in full-auto fire than the Sten Mk V and the Polish-designed Machine Carbine Experimental Model (MCEM), which is believed to be the MCEM 2. Both the Sten Mk V and the MCEM 2 were used as controls in both the accuracy and sand/mud tests. The accuracy tests showed that the Model 11 was not as accurate as the two control guns in semi-auto fire. The sand and mud tests showed some problems with the change lever and also clearance between the magazine and the housing had to be increased slightly.

Russ Robinson’s work for the British at the time concentrated more on machine guns so the Model 11 received only spasmodic attention to improve the design. After carrying out their initial tests, the Ordnance Board (OB) felt that if it looked like a pistol, was carried like a pistol in a holster, was used like a pistol, and its weight was like a pistol, then it should shoot like a pistol in semi-auto fire. The OB advised Robinson that the gun should be re-designed so that it would provide accurate semi-auto fire but at the same time maintain the accuracy levels achieved with full-auto fire. This was easier said than done, as it would require a major re-design of the Model 11 to allow semi-auto fire from a front sear position, and a change from a fixed firing pin to a more conventional floating firing pin. Robinson looked at this, and this re-design was known as the Model 16. Unfortunately, the Model 16 was never built, with the exception of some firing fixtures.

In 1948, Robinson experimented with heavy alloy metals to try and increase the weight of the slide without making the gun more bulky. Using an alloy made by General Electric Company known as “Heavy Alloy”, which was 50% heavier than steel, new slides were manufactured which were slightly thicker and longer than the original slides. Modifications to the frame included welding an extension to the tang of the frame. Slides were manufactured and fitted to the Model 11 guns that Robinson had brought with him from Australia, and it was envisaged that further tests would result in a total re-design and lead to further manufacture. These tests never occurred because Russ Robinson moved to the United States, and the British had by then adopted the Patchett submachine gun.

Operation of the Model 11

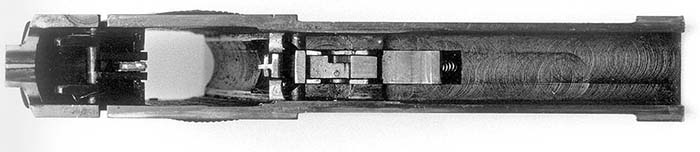

The S.R. Model 11 is a very simple gun with a total of just 22 parts including checkered wooden grips and screws. It has a floating barrel that is the secret of the low recoil force in the various machine pistols designed by Russ Robinson. The floating barrel enabled the forward momentum of the slide to be fully harnessed to pre-absorb almost half of the recoil. The automatic ejection of the magazine is accomplished by an ejection system that is triggered when the rising magazine follower strikes the magazine retainer when it rises to the top of the magazine. The release of the magazine retainer permits the magazine ejector to thrust the magazine downward and out of the butt. At the same time, a heel on the ejector rises and holds the slide slightly to the rear of the sear position. When a loaded magazine is thrust in place, the magazine ejector is rocked upward by the rear wall of the magazine and its heel is withdrawn allowing the slide to move forward .025 inches to rear (cocked) position, and the gun is ready to fire.

When the trigger is pressed, the slide is accelerated forward by the driving spring, the rear end of which bears rearward against the barrel and holds it against its rear stop. As the slide moves forward, it forces the barrel to rotate at a fairly constant angular speed by the grooves in the slide nut engaging the external grooves on the barrel. By the time the slide reaches forward or firing position, the rotational energy of the barrel is about one half that of the fired bullet. When the fixed firing pin of the slide strikes the primer and ignites the charge, a very slight delay occurs while combustion fully develops. At the speed the slide is moving, it wants to move about .030 inches before the recoil is sufficient to arrest and then reverse the motion of the slide. Because of this delay, the slide is arrested in 9mm weapons not by recoil, but by the slide striking the fixed barrel and frame via the fully chambered cartridge case. The greater part of the forward energy of the slide is dispersed into the frame or pistol grip. In order to make the forward energy or movement of the slide fully available to pre-absorb almost one half of the recoil, the barrel of the Model 11 is allowed to slide forward with the slide.

As the bullet leaves the muzzle it has about twice the rotational energy as that of the rotating barrel, so the barrel rotation is arrested and reversed by the rotating bullet. But as the slide moves rearward, the barrel’s rotation is decelerated so that the decelerating torque is in the same sense as the accelerating torque when the slide is going forward. Thus the heavy torque impulse to spin the bullet is replaced by a continuous very small torque which is applied throughout the entire cycle of fire, and which is too small to affect aim during automatic firing.

Each cycle of fire in the Model 11 is followed by a small cushioned blow of the slide against the rear buffer of the pistol grip, which represents a reserve of energy to provide for elevated firing or firing under foul conditions. The blows against the buffer can be felt, but they are very small compared with usual 9mm recoil. The Model 11 was not a true constant reaction gun but it employed a combination of the constant reaction principle with rotating the barrel in the direction of projectile spin, and recoil was reduced greatly by this unique combination. Robinson found that the rapid firing of the gun produced a succession of reactive torque impacts upon the gun, thus affecting accuracy. There is a tendency for such a firearm to react with non-axial twisting pulses. And if these impacts could be cushioned so that the impact is applied to the gun over a long time, then the effects on accuracy due to imparting bullet spin in a very light weapon can be virtually eliminated. The selector mechanism used with the Model 11 is a simple three-position system. The selector is ambidextrous and can be used with either trigger finger. The full-auto position is when the selector lever is fully up and parallel with the slide. Moving the selector lever downwards about 20 degrees clicks it into semi-auto position; and in the safe position the selector lever is fully down and blocking access to the trigger while internally locking the sear.

Ejection of empty cases is via an ejection port in the top of the slide. With the exception of a magazine change, all operations necessary to use the gun require only one hand, thus meeting a major specification laid down back in Australia. Magazine capacity was 14 rounds for the initial holster friendly magazine, and 30 for the subsequent magazines.

The Model 11 U.S. Patent

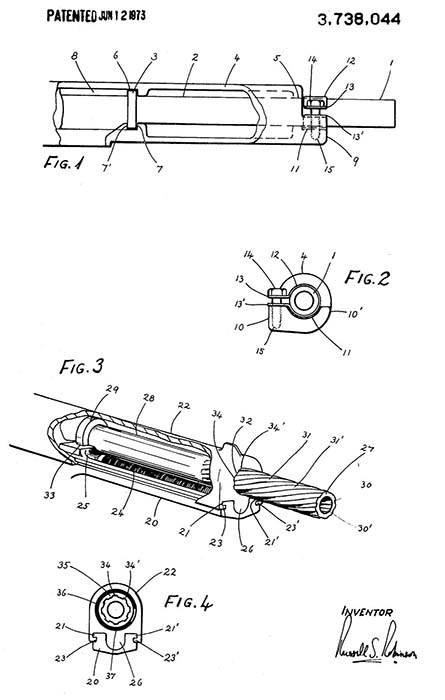

In 1970, Russ Robinson applied for a U.S. Patent on the concepts he developed with the original Model 11, with the U.S. Patent Office granting the patent on June 12, 1973. The patent disclosed two different approaches to the original ideas as used in the original Model 11, and the additional approach is worthy of some discussion.

The original approach is disclosed though with some differences from the actual Model 11. Rather than have the recoil spring positioned around the barrel as in the actual Model 11, the patent disclosed having the recoil spring being positioned below the barrel. It is believed that this approach was used in the design of the later Model 16. Another difference disclosed in the patent involved the addition of a ring of a resilient material, such as synthetic rubber, to the forward bearing surface between the slide and the external helical grooves in the barrel. This feature was included specifically for the Model 11 as a “…type of firearm…in which a short dwell time occurs in the movement of the slide after it has completed its counter recoil movement and before it receives its recoil movement…”

The alternate embodiment disclosed in the patent was for a firearm with a rotating barrel and two bearings, one at the front of the barrel and the other at the rear, the rear bearing being positioned in the receiver of the firearm. The design allowed for the barrel to be restrained from longitudinal movement, but allowed for the unobstructed rotation of the barrel within the receiver and within the constraints of the two bearings. The receiver included a saddle at the front of the receiver with a friction clip or clamp as a part of the saddle. The friction clip or clamp utilized a simple tension screw that was threaded into a threaded hole in the saddle.

Tightening the screw increased the clamping action of the friction clip and increased the torque resisting the rotation of the barrel with respect to the receiver. When correctly adjusted, the firing of a shot resulted in the barrel being reactively spun by the projectile to an angular velocity in which its angular momentum, less the losses generated by friction, was equal to but opposite to that imparted by the projectile. This resulted in the clamping torque being applied to the barrel so that the barrel was brought to a rest in a period considerably longer than the period of projectile travel in the barrel. Reduction of the torque level and its application to the receiver resulted in the cushioning of the reactive torque impact on the receiver.

Research into the various guns developed by Russ Robinson has failed to find any particular firearm that utilized this version of the invention, and it is believed that this approach was a theoretical design and concept that was never proven in an actual firearm.

The Model 11/16 as a PDW

Examination of personal and official files has shown that, if the problem of semi-auto fire could have been solved quickly, the British would have seriously considered adopting the Robinson gun for use in a multi-purpose role replacing the pistol and the machine carbine. This is the role that Russ Robinson envisioned right from the start for the Model 11, a role now known as a PDW or Personal Defense Weapon.

Initially, the S.R. Model 11 was designed as a standard holster weapon for officers, NCOs, drivers, jungle artillerymen and such, but the fact that it was so light and able to be used with one hand opened up many possibilities for use by other military personnel. Robinson felt that a 2.5-pound 9mm carbine that is normally carried in a holster would be extremely valuable for street and jungle fighting, and night operations. He envisioned that, combining the use of such a weapon with the standard infantry rifle, there would appear to be little requirement for the orthodox type carbine.

The OB was of the opinion that a combination of the self-loading pistol and the machine carbine would be very interesting, but weight would be a major factor. The weight would have to compare favorably with other self-loading pistols for it to be seriously considered. While the weight factor was easily achieved, it was the semi-auto requirement that was awkward to achieve without a major re-design of the gun.

The Model 16 still kept many of the highly desirable features of the Model 11, including one-handed operation, ejection of empty magazines, selective-fire capability, and most critical, a projected weight of 2 pounds 4 ounces unloaded.

The story of the Model 11 finished when Russ Robinson moved to the US, and no further development of the Model 11 or Model 16 occurred. However the specifications laid down for the Model 11 so many years ago mirror, in many aspects, current requirements and operational roles for a PDW/OPW.

Perhaps we do need to reflect upon what has occurred in the past, take heed, and start to break out of the circle that continues in small arms design. Many of today’s so-called advances in small arms have their roots in the past, when lessons were not heeded. Just imagine what would have happened if the British had adopted the Model 11 or 16. Much time, money and effort would not be expended today trying to create a solution that may already exist. In a conversation with Russ Robinson in 1995, he indicated that he would be glad to undertake the design of an improved Model 16 if a firm requirement arose from a responsible source. Regrettably, following his passing away in late 1998, this will not occur. But, perhaps we may still see such a gun incorporating Russ Robinson’s concepts and ideas.

The author wishes to acknowledge the assistance of the following: Australian Army Engineering Agency (A.A.E.A.), (formerly A.T.E.A., Army Technical & Engineering Agency), Maribyrnong, Victoria, Australia; MOD Pattern Room, Nottingham, United Kingdom; the late Mr. Herb Woodend, and the late Mr. Russell S. Robinson in the preparation of this article. Their assistance is gratefully appreciated.

| This article first appeared in Small Arms Review V7N12 (September 2004) |