By Rob Krott & Dan Shea

During World War II Soviet Arms designers were responsible for a number of innovative weapons designs. During the war against Nazi Germany and its lackluster allies new and largely innovative weapons such at the Tokarev Semi-automatic rifle, the PPD submachine gun, and the PPSH-41 submachine gun were produced in large quantities. Other weapons, such as the SKS rifle and the Kalashnikov series of weapons, were produced as a result of design programs begun during the war. The Rushnol Pulemet Degtyareva (RPD) was fielded in the early 1950s and would become the Red Army’s standard issue light machine gun and squad automatic weapon. An evolution of other designs by design engineer Vasily Alexseyevich Degtyarev, the RPD is a gas operated, open-bolt, locked-breech design. The first machine gun to chamber the innovative M1943 7.62x39mm cartridge (influenced by the German 7.92x33mm kurz round) the RPD light machine gun was first tabled for design during World War II in 1943. Degtyarev’s other light machine gun design, the Degtvarev Pakhotni (DP)) adopted in 1928, was already in general use by the Soviet Army. An improved version, the DPM, was adopted in early 1945 in the closing days of World War II. Because of this, production of the RPD did not begin until after “The Great Patriotic War.” The first RPD was issued to the Soviet infantry in 1953. It would prove to be Degtyarev’s final weapons design and one that would undergo progressive improvements and changes throughout its long and faithful service with the Soviet Army. It was produced in the People’s Republic of China as the Type 56 and in North Korea as the Type 62.

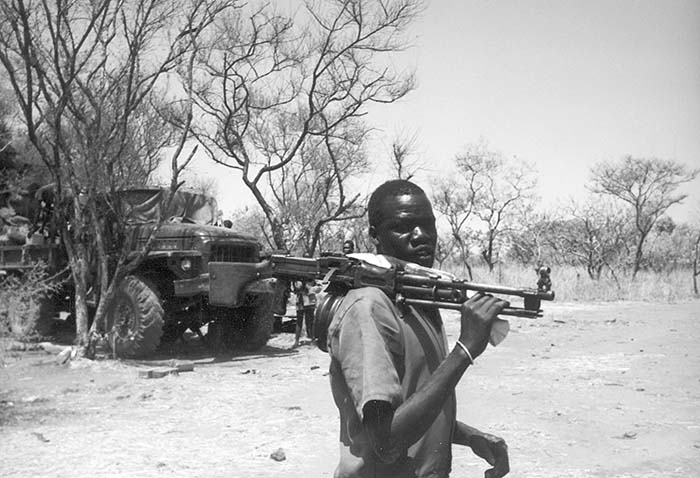

The overall length of the RPD is 41 inches and it weighs 15.43 pounds (7 kilograms). Its rate of fire is 700 rounds per minute. The RPD, like most LMGs of its era, is capable of only full automatic fire although skilled operators will be able to touch off three-round bursts and even single shots. The M1943 cartridge when fired from the RPD generates a muzzle velocity of 2,410 feet per second. It’s an easy enough weapon to operate and maintain though it necessitates a special wrench for proper adjustment of the gas cylinder. I’ve had the opportunity to fire the RPD in combat in Africa and have fired another on a range in Afghanistan. I’ve also been on the receiving end of RPD fire – and can’t say I liked it much. While manuals might give the RPD’s maximum effective range at 800 meters, I feel it’s closer to 600 meters unless firing tracer ammunition with the aid of a good assistant gunner as my observer. You really can’t expect much more given the trajectory and relatively low velocity of the 7.62x39mm “intermediate” cartridge. Because of this and its 16 pound weight it straddles the fence between squad automatic weapon and light machine gun.

RPD First Model, Russian manufacture, left side. RPD First Model, Russian manufacture, left side. Cleaning rod location. Photos by Dan Shea,

courtesy MOD Pattern Room.

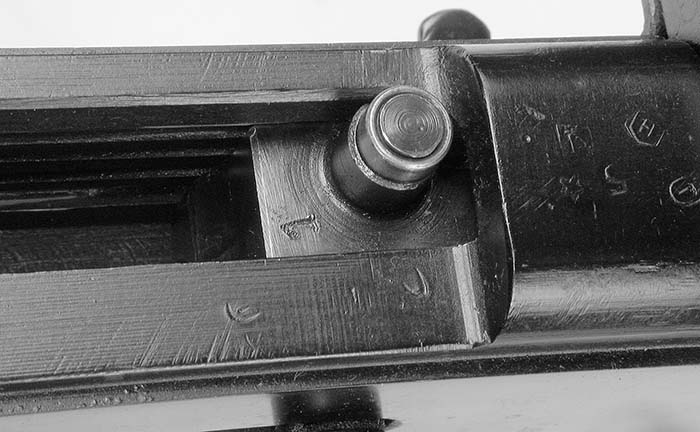

RPD First Model, Russian manufacture, cup style gas piston that surrounds the tip of the gas release vent.

RPD First Model, Russian manufacture, top right view- showing the single roller on the bolt carrier. Photo by Dan Shea, courtesy MOD Pattern Room.

RPD First Model, Russian manufacture, right side. RPD First Model, Russian manufacture, right side. Note: there are no dust covers, the charging handle is a fixed one, and the rear sight has a right side control. Photos by Dan Shea,

courtesy MOD Pattern Room.

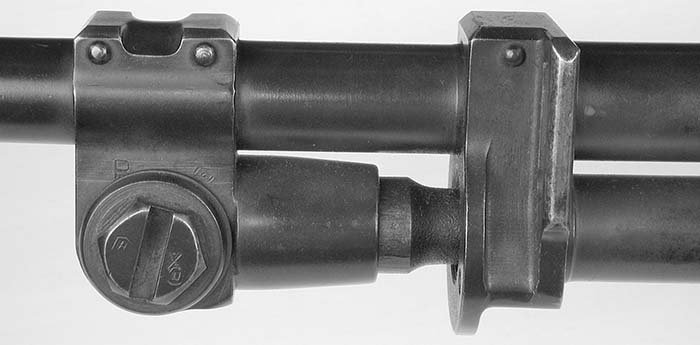

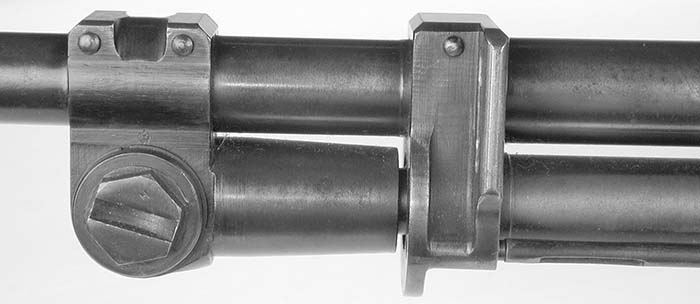

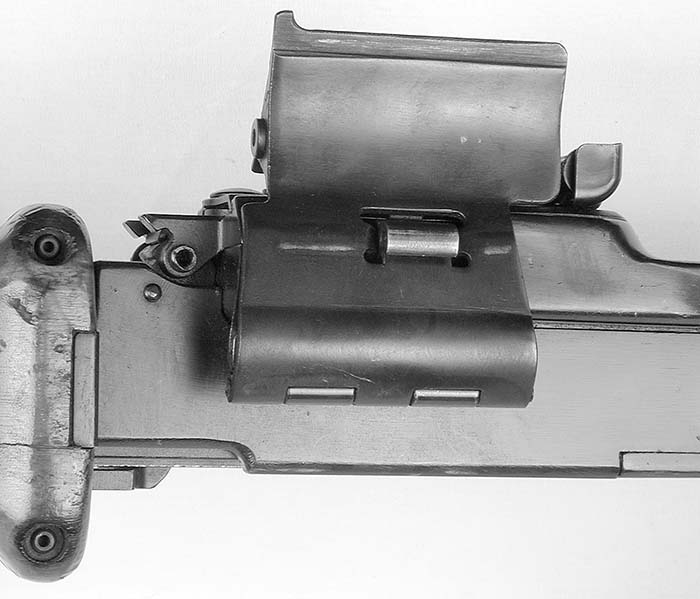

There are five distinct models of the RPD fielded in its lengthy service life. The first model had a cup type piston, no dust-cover, a right-hand windage knob and a straight reciprocating operating handle (which oscillated somewhat irritatingly back and forth during firing). The second model replaced the cup type piston with a plunger type gas piston and the right hand windage knob became a left-hand windage knob. The lack of a dust-cover and the straight reciprocating handle remained. There were variations to the second model RPD: some had a sliding dust-cover and others had a bracket attached (by rivets) to accommodate a non-reciprocating operating handle. The operating handle may either fold forward or up. The third model, which was also copied and produced in large quantities by the People’s Republic of China as the Type 56, was an improvement with dust-covers on the feed mechanism and a folding, non-reciprocating operating handle. The new cocking handle which remained still during firing was especially appreciated by those machine gunners who were disconcerted by a charging handle rattling in from of them during firing. The fourth model of the RPD is known as the RPDM with the “M” standing for modernniy (modern). The design was significantly improved with a longer gas cylinder, a buffer assembly in the buttstock, and an additional roller on the piston slide. These were all in response to increasing complaints of controllability due to the relatively light weight of the weapon and reports of problems with the belt feeding. But no great changes were made; certainly nothing to deserve the change in nomenclature. The fifth and final modification of the RPD (manufactured in the PRC as the Type 56-1) was very minor adding a folding magazine bracket / dust-cover and a sectional cleaning rod which is carried in the buttstock.

RPD Second Model, Russian manufacture. Left side. RPD Second Model, Russian manufacture. Cleaning rod location. Photos by Dan Shea, courtesy MOD Pattern Room.

RPD Second Model, Russian manufacture. New style gas piston, where the cup has been changed to the gas release vent and the piston is a more standard piston.

RPD Second Model, Russian manufacture, top right view- showing single roller on the bolt carrier. Photos by Dan Shea, courtesy MOD Pattern Room.

RPD Second Model, Russian manufacture. Right side. Inset: RPD Second Model, Russian manufacture. Note: there are no dust covers, the charging handle is a fixed one, and the rear sight has a left side control with protecting ears. Photos by Dan Shea, courtesy MOD Pattern Room.

The RPD’s front sight post is a standard front post arrangement with a protective shroud. Elevation and windage sighting adjustments are made by moving the front sight. The wrenches in the RPD buttstock tool kit are required for sight adjustments. Once the weapon is zeroed (which can be a painstakingly laborious process) further elevation adjustments during operation or while firing are made using the rear tangent sight mounted on the receiver cover. The rear tangent sight is a protected open U notch. The rear sight is a sliding ramp graduated in 100 meter increments from 100 meters to 1,000 meters.

RPD Third Model, Russian manufacture. Left side. RPD Third Model, Russian manufacture. Cleaning rod location. Photos by Dan Shea, courtesy MOD Pattern Room.

RPD Third Model, Russian manufacture. New style gas piston.

RPD Third Model, Russian manufacture. Top right view- showing single roller on the bolt carrier. Photos by Dan Shea, courtesy MOD Pattern Room.

RPD Third Model, Russian manufacture. Right side. RPD Third Model, Russian manufacture. Note: new dust cover on belt chute (Closed), the charging handle is a new folding model (Retracted), and the rear sight has a left side control with protecting ears. Bottom: Dust cover on belt chute open. The charging handle is open for charging. Photos by Dan Shea, courtesy MOD Pattern Room.

Regarding the design ergonomics, Degtyarev’s human engineering was superior for the time. The weapon is handy and well-balanced. The top and bottom wood handguard make it comfortable to fire from the hip assault position, but not without possibly burning the hand. The handguards are un-insulated and supposedly will catch fire if the weapon is fired continuously at the cyclic rate. I have seen an RPD gunner wrap a rag around the handguard so he could fire rapid bursts from the hip with sling support while in the assault. Firing offhand with the heavy drum magazine is difficult, but braced against the hip, and with the aid of the sling, it’s not a problem. The buttstock is heavy and provides a good buffer in firing. Its peculiar squared-off shape is readily recognizable and is based on the clubbed buttstock on the DP light machine gun. The buttstock configuration is ideally suited to the European machinegun firing technique of cupping the non-firing hand under the bottom of the buttstock for support. The pistol grip is, to my hand, set at a bit too acute an angle. But perhaps that’s due to the American method of firing an LMG in the prone or my experience with the M60. Maybe the Russians angle their arms differently when firing.

The feed mechanism must lift and feed the belt from beneath the gun. Reportedly this strains the feed pawl mechanism and under field combat conditions would frequently cause problems with the gun’s functioning. But, I believe this is a fallacy. Having fired the RPD and observed others firing one in adverse combat conditions it feeds well, especially on the first two gas regulator settings. Though it’s quite possible that poor operator maintenance, dirty belts, and a worn feed pawl could cause feed problems that would then be blamed on the RPD’s inherent design features. I don’t believe the Soviets would have continued to produce the RPD in its basic design envelope without making significant design modifications to the feed mechanism if there were genuine problems.

The modifications to the RPD did not incorporate the changeable barrel as used on the DP. The barrels were threaded to the receiver and pinned into place. Lack of a quick-change barrel makes gunners limit their cyclic rate firing and long burst firing. Soviet gunners were taught not to fire a belt (100 rounds) in less than a minute. The chrome-lined 20.5 inch RPD barrels have four-grooves with a 1 in 10 twist. If a gunner burns out a barrel the weapon has to be sent to the rear for re-fitting by a competent armorer.

RPD Drum Magazine

The RPD feeds a 100 round belt from a cylindrical drum attached beneath the weapon (positioned well at the gun’s center of gravity). The RPD loads two fifty-round metal non-disintegrating belts (of 7.62x39mm ammo) which are snapped together before loading into the RPD’s metal drum magazine. The starter belts (50 rounds) have a loading tab which will feed the belt without requiring the operator to open the top-cover. There are 50-round end belts and 25-round middle belts which can be linked together. The links are connected by a small steel spring. There were two distinct types of links. The first was patterned after the German MG-34 and MG-42 metal link design (the Russians didn’t mind copying an enemy’s design). The second type of link introduced has a nub which fits against the cartridge base whereas the first version used a tab which engaged the extractor groove above the cartridge case rim. Most RPD machinegunners will tell you that the second type of link is harder to load.

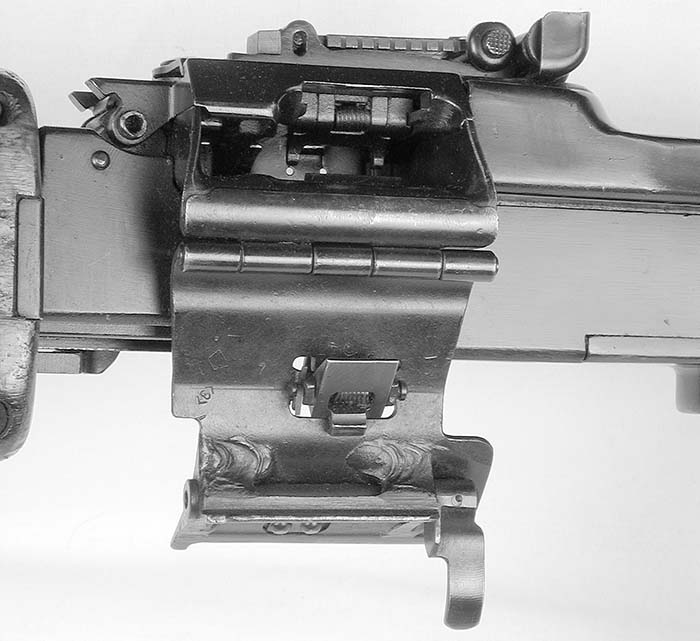

Fourth Model, (RPDM) Russian manufacture. Left side. RPD Fourth Model, (RPDM) Russian manufacture. Cleaning rod location. Photos by Dan Shea, courtesy MOD Pattern Room.

RPD Fourth Model, (RPDM) Russian manufacture. Gas piston cup on the vent has been extended to cover the piston more fully.

Second roller has been added to the bolt carrier. This significantly smoothed out the action, and reduced wear. Photos by Dan Shea, courtesy MOD Pattern Room.

RPD Fourth Model, (RPDM) Russian manufacture. Right side. Inset: Note: new dust cover on belt chute (Open), the charging handle is a new folding model (Retracted), and the rear sight has a left side control with protecting ears. Photos by Dan Shea, courtesy MOD Pattern Room.

Belts are joined by matching up links and inserting a loose cartridge. The bottom hooking section of the link snaps into place in the cartridge extractor groove. Two belts are linked together by slipping the tongue of the end link on one belt into the slot of the starting link on the other belt. Putting a cartridge through the link locks the two belts together. Loading the drum with a 100-round belt takes practice and fortunately there is a loading machine which makes it much easier. The ammunition belts sit loosely enough in the drum that a loaded drum will rattle when the weapon is being carried. The drum is attached to the weapon by sliding the top dovetail onto the corresponding connection below the receiver. On the later models of the RPK the drum attaches to the ejection port dust cover which can be snapped down and locked into place as a mounting bracket. The belt’s loading tab protrudes from a spring-loaded trap door on the drum magazine. In Vietnam U.S. Navy SEALs occasionally adapted captured North Vietnamese RPD drum magazines for use with their 5.56mm Stoner light machineguns. The RPD drum magazine is an all together better arrangement than the cardboard box and cotton bandoleer method of ammunition supply used with the contemporaneous M-60 machinegun.

Mechanical Functioning / Operation

The RPD fires from an open bolt: a good feature for a light machine gun as it precludes cookoffs. The RPD’s locking system is very similar to the modified Kjellman Frijberg locking system used by Degtyarev’s DP-DPM series of light machine gun. The gas-operated RPD functions as such: When the weapon’s trigger is pulled the compressed recoil spring is unlocked. The slide assembly then moves forward powered by the expanding recoil spring. The slide assembly (piston and bolt group) rides in milled slots on the RPD’s receiver. A round is stripped from the belt and loaded in the chamber. The bolt stops forward with the extractor over the round. The bolt is then locked when the slide continues its forward travel and engages two locking lugs and the rear of the bolt strikes the firing pin. During firing some of the expanding gases are forced through the gas port, driving the gas piston and slide assembly to the rear. Bolt unlocking is delayed and the locking lugs pressed against the bolt. As the slide assembly is driven rearward the ejector draws the cartridge out of the chamber. The ejection port is in the bottom of the receiver.

The slide assembly utilizes an actuating cam roller like that found on the M60. But unlike the M60’s top-mounted cam, it is on the left side of the slide and slots into a spring loaded spring rail on the bottom-side of the receiver top-cover. As the feed rail is moved right by the actuating cam roller it moves the feed pawl to the left. As the bolt goes forward chambering a round, the actuator roller moves down along the straight section of the feed rail. When the cartridge is stripped from the belt by the bolt the actuating cam pushes the feed rail to the right. The feed slide and pawl are moved left out of the feed-tray cover. The spring-loaded stop on the feed tray keeps the belt from being pulled left as the feed pawl moves to the next cartridge in the belt. As the weapon recoils the belt and the next cartridge are engaged and pulled right.

Loading and Firing

To load: 1) load and attach a loaded drum magazine; 2) insure the belt loading tab protrudes from the drum’s trap door; 3) pull down the drum lock on the underside of the receiver; 4) pull the operating handle to the rear, cocking the weapon; {note: on the older RPKs the non-folding operating handle will remain rearward while the folding handle on the newer guns should be pushed forward after cocking}; 5) push forward on the feed-tray cover latch and open the top-cover; 6) place the belt on top of the feed-tray with the first round against the cartridge stop; 7) close the cover. The RPK is now loaded and ready to fire. The safety catch on the right side of the pistol-grip / trigger group may be applied. Forward the trigger is “safe.” Snap the safety catch to the rear to fire. To unload the gun; push forward on the feed-tray cover catch and lift the cover. Remove the belt and close the cover.

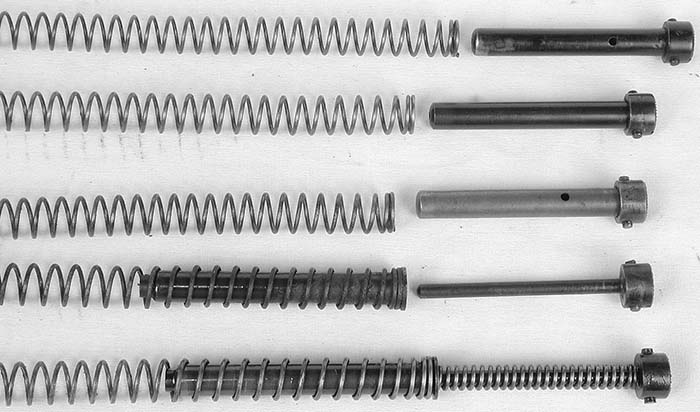

RPD Fifth Model, (Type 56-1) Chinese manufacture. Left side. Cleaning rod has been changed to a sectional stored in the buttstock, and the rod well has been left out. Bottom: Buttstock well typical of RPD series, showing plate turned to the side to remove recoil/ return spring, and well for cleaning kit. Photos by Dan Shea, courtesy MOD Pattern Room.

RPD Fifth Model, (Type 56-1) Chinese manufacture. Gas piston cup on the vent has been extended to cover the piston more fully, same as Fourth model.

Second roller on bolt carrier. Photos by Dan Shea, courtesy MOD Pattern Room.

RPD Fifth Model, (Type 56-1) Chinese manufacture. The drum hanger has been included with the dust cover. When locked in the “Cover” position, the hanger is out of the way. When the drum is attached, the dust cover is open. Cover closed.

Cover open, hanger down. Photos by Dan Shea, courtesy MOD Pattern Room.

RPD Fifth Model, (Type 56-1) Chinese manufacture. Note: new dust cover on belt chute (closed), the charging handle is a new folding model (Retracted), and the rear sight has a left side control with protecting ears. Photo by Dan Shea, courtesy MOD Pattern Room.

Disassembly

To disassemble the RPD: 1) Remove the belt and clear the weapon; 2) pulling the trigger let the slide go forward while under control; 3) push the spring-loaded top cover locking latch forward and lift the receiver cover; 4) to remove the cover, drift the pivot pin out to the right; 5) turning the butt trap cover over at a right angle to the butt 6) with a screwdriver turn the recoil spring and buffer plug assembly on-quarter turn (either left or right); 7) remove the buffer assembly, recoil spring, and guide rod; 8) push the buttstock retaining pin and remove the pistol grip, trigger assembly, and buttstock; 9) pull the operating handle to the rear to remove; 10) remove the slide assembly; 11) remove bolt and locking lugs from the slide assembly.

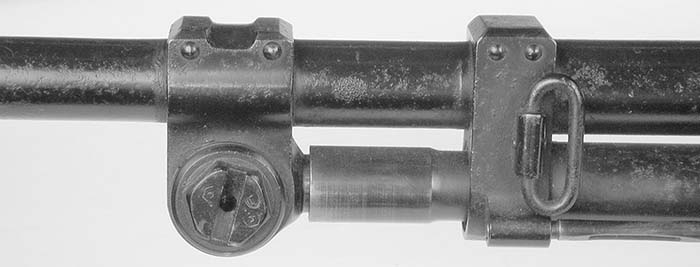

The 3-Position Gas Regulator

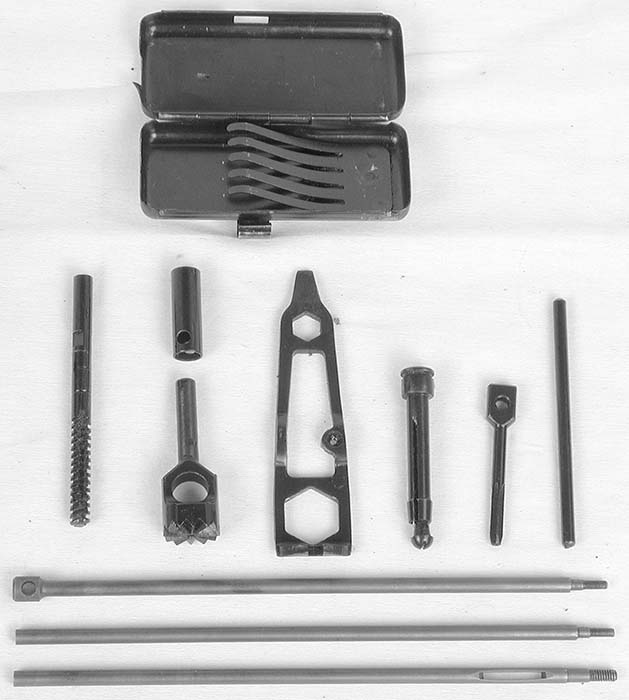

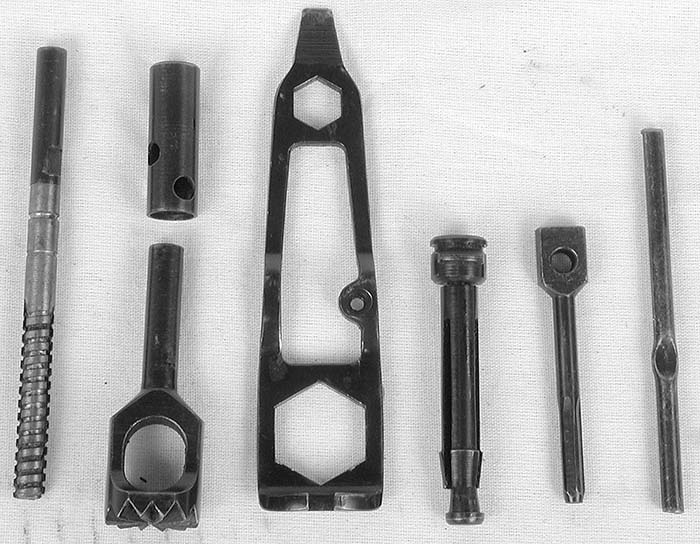

Like the Bren Gun and the BAR, on the RPD the weapon’s gas cylinder is adjustable. The RPD gas block and cylinder are permanently pinned to the barrel. The gas block incorporates a three-position variable gas regulator. The gas regulator settings are each lined up on an index pin and are marked “1”, “2” and “3”, respectively. The first position is referenced in the Soviet Army RPD operating manual as “standard use” however field operation seems best accommodated by position setting #2. Adjustment of the gas regulator is carried out by loosening and removing the regulator’s retaining nut (found on the left side) with the combination take-down tool located in the buttstock maintenance kit. The regulator must be pressed down to the right to disengage it from the index pin. This task has been found to be difficult under the best of conditions and all but impossible in the field when the gas regulator is dirty and the weapon is hot from firing. Add to that quotient the stress and confusion of combat (or worse, nighttime and / or winter conditions) and you’ve got a real problem. That’s if you can even find the combination tool.

Replacement

The RPK (rushnoi pulemet kalashnikova) a heavy barreled bipod equipped AKM replaced the RPD as the Soviet squad automatic weapon. Not the best idea and something I’ve never agreed with as the RPK, while streamlining ammunition and parts logistics at the small unit level and simplifying weapons training, is less than auspicious as a squad or platoon level weapon. It lacks a quick change barrel and can not be used for sustained automatic fire. It must also be fired using pre-loaded 75-round drums or 40-round “banana” box magazines. The 40-round magazine is difficult to use in the prone.

The RPD, although considered obsolete in the Warsaw Pact nations, is still occasionally see in combat in the internecine squabbles of the breakaway republics of the former USSR. Examples exist in the special operations armories of many nations. The RPD also found favor with military units outside the communist bloc including the U.S. Navy SEALs in Vietnam and the Rhodesian Selous Scouts. Numbers of captured weapons were pressed into service both by the Rhodesians and by the South African special forces. Captured UAR (Egyptian) weapons evaluated (and pressed into use) by the Israeli Defense Force performed well and some of the weapons were used later by their southern Lebanese falange allies. RPDs can still be found in use by several armies (especially in Africa) and numerous Guerrilla factions around the world where it continues to serve in an active frontline role.

| This article first appeared in Small Arms Review V5N3 (December 2001) |