The year 1994 will be remembered by many as the dark cloud that brought the dreaded “Assault Weapon” ban in the paramilitary market among civilian shooters. This controversial law killed importation of sporterized military type weapons and their rimfire look-alikes. The fallout soon affected many independent aftermarket accessory producers solely dedicated to the development and production of hi-capacity magazines, folding stocks and dress up kits for sporting arms to eventually close their doors after their pre ban hardware was depleted. Owners of sub guns and hi-capacity guns and look-alikes saw the value of their wares climb sky high overnight and lasted for a decade. The Clinton ban finally sunset in 2004 marking the beginning of yet another era in the hi-tech weapons development geared for both military and civilian market. Back once again are the high capacity magazines for short and long arms, dress up kits and folding stocks as well as few rimfire look-alikes of the golden 80s. Regretfully, the big difference this time is that not all states have been freed from this bureaucracy as legislators in anti-gun strongholds opted to live with the restriction and are likely to stay with it for an indefinite period of time.

When hi-tech exotic weaponry first entered the scene back in the 80s, its primary goal was to fill the enormous demand in transforming semi-auto sporting arms to military format. Aftermarket accessories for the very popular Ruger 10/22 self-loading carbine undoubtedly stirred more money-making innovations among independent manufacturers than any other models ever produced in the American market. Hi-capacity magazines for this gun became the hottest selling item to date followed by folding stocks and dress up kits. Bill Ruger’s masterpiece self-loader is unquestionably one of the most advanced and sophisticated U.S. made rimfire carbine in the world. With nearly five million produced to date, no other model in its class will ever come close. This gun is as hot a seller today as it was when it was first introduced 42 years ago. Out of the box, the 10/22 can be best described as a subtle cross-breed between a sporter with just a slight dash of the famed M1 .30 Carbine with the absence of the clip sticking out below the gun. Perhaps, the hottest selling point of the gun is its unmatched reliability and ruggedness as compared to other models in its class that are many times more expensive. The ten-round rotary magazine of the 10/22 is a masterpiece of design as well as reliability. However, for a more serious defensive application, its limited firepower becomes an issue. It is a pure fun gun that barely encounters any malfunction; but its limited capacity keeps the fun a bit too short, especially when used by paper punchers and plinkers. In today’s standard, a ten-round magazine is considered a handicap, particularly for a self loading carbine designed to be a work horse. Selling the 10/22 is no problem and is always the first one to leave the dealer’s shelves. The maker has a hard time catching up with the demand of seemingly never ending orders. The main problem confronting the dealers is supplying their 10/22 customers with the demand for a truly reliable large capacity magazine that can equal the factory produced magazine in overall reliability. Whether Ruger ignored the idea of developing this device for their bread and butter gun or simply hadn’t time for it, still remains a mystery. One thing for sure however, it has left an open market for a very desirable item.

The mid 80s opened the door to many private entrepreneurs who entered the race in the development and production of hi-capacity magazines for this hot selling little carbine. The first contender to enter the market was the ill fated Condor. In its first month, the 25-shot plastic magazine was a sensation. A month after, customers who bought it cursed it to the moon. In a desperate bid to calm down the complaining buyers, the manufacturer enclosed a small instruction sheet, suggesting that the buyer has to throat the barrel until it works. Nice try, but this didn’t solve the problem. A few months later, the company closed. The Condor was followed by the Sanford-50, a drum type magazine boasting an impressive 50-shot firepower. This magazine was marketed by Eaton Supply. This item was also offered by Arcadia Machine & Tool Company (AMT) as an optional accessory for their “Lightning,” a stainless steel clone of the 10/22. The Sanford-50 gives the gun and awesome look and feeling of confidence seeing the large number of rounds neatly stack around the rim of the clear plastic housing. The Sanford drum is the first 10/22 magazine to feature a see-through viewing using clear Lexan plastic for its exterior casing. The magazine also features a loading gate wherein the ammo spool can be manually turned while loading. This excellent feature makes for easy loading advantage by simply dropping the rounds into the feed lips, while turning the spool. The magazine lip is made of cheap cast zinc oxide material that is somewhat fragile and out of dimension. The Lexan plastic easily cracked in its rear half casing when accidentally dropped to no higher than a foot on a wooden floor.

Did the Sanford 50 work? Unfortunately this is another matter. During the test, this awesome looking drum proved to be a great pretender. It develop multiple loading problems with hang-ups leaving the chamber empty because the next round for battery got stuck halfway below the feed line and was not scooped up by the bolt during the loading cycle. It was also plagued by ejection problems with empties barely clearing the ejection port. When the magazine is loaded to capacity, the spool is slower than a turtle walk, leaving no round positioned in the magazine lip when the bolt passes through resulting in an empty chamber. With just about ten rounds remaining in the magazine, the tension of the clock-type spring becomes erratic, causing the top round in the magazine lips to occasionally jump out of its seat. This causes a loading jam with the cartridge caught between the breech face and barrel chamber in an almost vertical position, with the tip of the bullet lodge in the chamber mouth. As much as the quick and easy loading feature of the Sanford drum was a big plus, it failed miserably with every type of ammunition used. A few years later a new version of the Sanford drum was produce and marketed by Pro-Mag. Gone was the see-through Lexan material being replaced by what appears to be an unbreakable material. Externally, the Pro-Mag drum appears solid and impressive. This first impression quickly changed during the actual test firing. Pro-Mag made the same mistake as on the first Sanford construction by using a soft metal instead of steel in the magazine lips. After the last round is fired, the bottom section of the breech face that pushes the cartridge to the chamber is hitting the top of the magazine feed ramp and deforming quite easily. Another fatal flaw of the design is the very short protrusion of the round metal in front of the magazine that connects to the receiver. When the gun is fired, the magazine tends to disengage and fall off the gun since this part of the magazine is barely engaging the gun. The magazine connection to the receiver is loose and it tends to rock back and forth when it is seated to the gun. The overall reliability of the gun is acceptable when using solid point cartridges; however the magazine must be supported by the non-shooting hand while the gun is being fired to prevent the magazine from falling off. The forward racking action of the magazine as the bolt moves forward when not supported by hand tends to jam the cartridge nose against the edge of the chamber as it is being pushed out of the magazine lips. The Pro-Mag 50 is far from being perfect. It definitely needed more refinements on the above noted areas of concern. Next in the market was the Black Dog 50-shot polymer drum magazine for the 10/22. This magazine looks promising and is very well made as compared to both the Sanford and Pro-Mag drums. The Black Dog version appears to have borrowed some features from the Sanford employing a back window to access the winding mechanism as well as its clock-type spring. However, its inherent reliability can be attributed to the features borrowed from the Italian made Bingham PPS-50 steel drum design incorporating plastic dummy cartridges as part of the magazine follower system. The PPS-50 drum magazine is possibly the finest 50-shot drum magazine ever made and Black Dog certainly made a great choice in employing its design characteristics. The Black Dog drum works best with solid point ammo. When hollow points are used there is an average of 3-4 jams per mag.

The quick demise of the old Condor magazine was quickly followed by yet another 25-shot all plastic banana magazine called the Eaton. Both the Condor and Eaton are virtually identical except the Condor utilized steel feed lips while the Eaton is an all plastic construction. Is this the improved Condor? During testing, three Eaton banana-type magazines were used. For a while, the magazines seemed to work fine but after 300 rounds were fired, malfunctions started to appear. The follower started to get tight and loading problems become frequent. The ejector shoulder on the magazine lip started to wear out fast causing frequent ejection problems. It appears that the plastic material used is not geared for this type of device. One time during the test, a rim blow-up occurred while firing a Remington Yellow Jacket hi-velocity cartridge. The unsupported section below the breech face diverted the exploding gas towards the magazine forcing it to disengage from its seat. As a result, the small protruding section that engages the magazine catch at the back of the magazine broke off, rendering the magazine totally unserviceable. As the Eaton magazine fell off the gun, it split into two halves as it hit the ground scattering the remaining ammo during impact. The two halves appear not to be bonded together. The Eaton 25-shot magazine is a standard item for the AMT Lightning when it entered the commercial marketed in the 1980s. Interestingly, Black Dog resurrected the Eaton magazine design as one of the primary offering in the banana type magazine market. While the early Eaton magazine are made to 1980’s standard, the new Black Dog version is much refined employing unbreakable polymer materials in their overall construction.

The new and much touted Butler Creek 25-shot “Steel Lips” magazine appears to bear a strong heritage to the old Condor magazine in overall design and construction. The difference between the two is that the Steel Lips works and the Condor doesn’t. By close examination, there are subtle differences between the original Condor and Steel Lips primarily in the feed lip and follower design. The exterior format is virtually identical between the two, however, the Butler Creek magazine proved to be far superior to the Condor in both quality of workmanship and reliability. The Steel Lips works reliably as long as it is kept clean. However, once the inside is exposed to heavy powder residue built up after prolonged use, the follower tends to hang up and will not push the cartridges upward leaving an empty chamber. The Steel Lips was also offered in all plastic format called the Hot Lips (clear plastic) and are both available in ten and 25-shot capacity. Three ten-shot version can be clipped together to form a unique “Star” shape configuration for a 30-shot firepower. In addition to its excellent magazines, Butler Creek also produced and marketed a very compact loading device for their magazines. Unfortunately, this loader will not work with other brands due to their different magazine lip opening.

Yet another 50 rounder entered the scene. This one has a unique teardrop type configuration. This magazine was originally marketed by Mitchell Arms designated as the 50/22. It was given good advertising and publicity when first introduced. Class II manufacturers for the 10/22 were also at its peak during this period. It was hoped that the Mitchell magazine was the final answer to the long search for a reliable hi-capacity magazine in their full auto wares. Two magazines were ordered with the same expectation. Unfortunately, after few try outs, the enthusiasm towards the Teardrop magazine quickly faded away. This device does not load to capacity without jamming. The drive belt is prone to hang-ups, just like the spool design of the Sanford drum. Worst of all, the Mitchell magazine has the shallowest ejector shoulder of all the hi-cap contenders tested. As expected, ejection problems plagued this magazine next to feeding hang-ups, caused by frequent stopping action of the drive belt. The Mitchell 50/22 has good possibility to be a top contender in the 50-round category once all the bugs are ironed out.

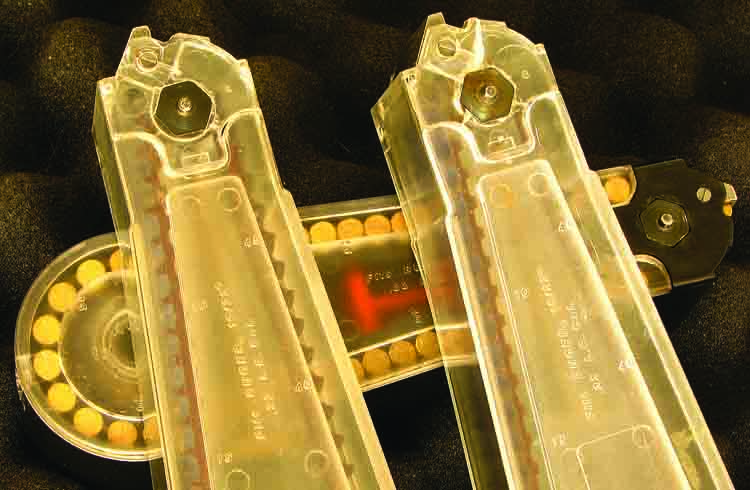

Twenty two years after its initial introduction, the Mitchell teardrop magazine once again came to life in the form of the new MWG 50-Rounder. This author was quite skeptical whether the MWG version was any better than the original despite the flowery advertising. The MWG is not cheap retailing at $80 but was not as expensive as the Pro-Mag drum which at one time sold for $100. Nevertheless, two of this new version was purchased for testing. As usual, prior to the actual reliability test, a visual comparison between the old and the new was made. The first thing noticed was the belt clip on the old Mitchell magazine was omitted on the MWG. The new version sported an all clear plastic construction in its shell casing versus the two-tone plastic of the old. Further examination revealed that the new MWG incorporated identical steel feed lips to the factory rotary magazine, while the Mitchell design had a narrow ejector and slightly different cutouts in the release point of the lip area. Internally, everything seemed to be identical except for the new type of material used in the loading belt. The old type has some sort of strands coming off the belt while the new one is clean. Range testing consisted of 500 rounds of Stinger and two 10/22s for heavy duty workout. Out of the 500 rounds fired, only three malfunctions were experienced which occurred only when the magazines were fully loaded. One of the 10/22s has an extra power recoil spring purchased from Brownell’s. The other has the standard factory recoil spring, which is basically tailored to work with their magazine. The bolt seems to have difficulty pushing the top round from the magazine lip, which is under heavy tension with the factory standard recoil spring. However, with the heavier recoil spring, the magazine worked flawlessly with 300 rounds fired. That is quite impressive. Finally, a 50-round magazine for the 10/22 that really works. MWG has indeed done their homework on this one. So what makes the MWG work and not the Mitchell? After stripping both the Mitchell and MWG magazines, the only valid explanation as to why one works and the other don’t is the difference in magazine lips. To test my theory, I switched the magazine lips on both magazines and retested both. The MWG, now having the lips of the old Mitchell, did not work. The Old Mitchell, now with the new magazine lips of the WMG, worked very well. Now on the right track, the metal lips were borrowed from two factory magazines and installed them on the old Mitchell magazines. They fit perfectly, and at last, worked perfectly. Puzzle solved. Why Mitchell did do not use identical lips as the factory rotary magazine to begin with is a mystery. Unfortunately, such good things do not last. Barely two months after getting the new MWG magazines, with just over 1,000 rounds being used in each mag, cracks started to appear on the top of the magazine just around the cap nut that controls the tension of the upper half of the belt. In addition, the bottom of the magazine housing also exhibited multiple cracks now rendering this expensive magazine totally unserviceable. Nevertheless, the old Mitchell mags are very much intact and still working great after their defective magazine lips were replaced with original Ruger parts. If MWG changes the housing with a better material that does not crack easily, I may but them again. For now, they work, but they don’t last very long.

Just at the time when more and more large capacity magazines were starting to flood the market for the 10/22, Bingham Ltd. of Norcross, Georgia introduce an all steel 30-shot banana type magazine of Italian manufacture. Bingham at this time was busy promoting its upcoming PPS-50, a rimfire clone of the famed WW II Russian PPSh burp gun. The Bingham magazine is very well made. A magazine adapter was utilized to compensate for the wide opening of the stock’s magazine chute for the factory rotary type magazine. The Italian magazine produces only marginal reliability, however. It also suffered multiple ejection and loading problems when fully loaded. It worked best with only 25 rounds loaded to give the spring and follower more leverage for movement. The magazine lip appears easily deformed and needs to be re-adjusted from time to time, especially the built-in ejector to minimize ejection problems. The magazine also tends to disengage accidentally from its adapter during firing. To correct this drawback, the writer installed built-in spring loaded plungers positioned on both sides of the adapter. The protruding ends of the plungers locks securely on their corresponding detent holes at the front of the trigger housing.

For few years, the Sanford, Eaton and Mitchell magazines dominated the 10/22 hi-capacity market despite their shortcomings. In the later part of the 80’s Ram-Line and Eagle International, both based in Colorado at that time, set to compete in this open market. Eagle International introduced a very attractive 30-shot banana type polymer magazine in both smoke and black color. The Eagle has a few interesting design features not found in any magazine in its class. It features a built-in magazine catch activator that is more convenient to operate than the factory flush-in catch if a high capacity magazine is used. The bottom of the magazine had a sliding trap door that would allow internal cleaning if needed. There were notable malfunctions experienced with the Eagle that occurred mostly after several thousands of rounds had gone through it. The magazine lips appeared to have opened up and caused the top round to jump out of its seat when firing hi-velocity rounds, particularly Stingers. A custom nylon buffer will help alleviate this problem by softening the recoil impact. When new, this magazine worked quite well with very few malfunctions noted. The Eagle magazine is available again and now offered in various colors ranging from black, smoke, orange and clear. This magazine not only proved to be one of the more reliable 30-rounders available in the market today, it is also one of the cheapest with some retailers selling them for as low as $10.

Perhaps, among the half dozen or more independent aftermarket accessory producers, no one can claim the top spot in the development and manufacture of hi-capacity magazines in the banana type category than Ram-Line. Famous for their extensive line of fixed and folding stocks made of indestructible polymer material and dress up kits, the Colorado based company has undoubtedly offered more selections of banana-type magazines than anyone else in the industry. Their first 30-round single stack magazines are the most reliable in their lineup. I still have five of these which I have extensively used in the past 20 years and they still work as good as when they were new. These magazine were soon followed by the more sophisticated double stack versions that were offered in 15, 20, 30, and 50-shot capacity, as well as a 25-shot single stack magazine called “Truncator” designed to work primarily with truncated type ammo such as the Remington Yellow Jacket. Ram-Line can be credited to the final breakthrough in creating a double column type magazine, something thought impossible at one time with .22 rimfire ammunition. These double stack format magazines however are very hard to load due to their very powerful dual clock type springs. To solve this problem, the company developed an autoloader device that can load the magazine almost as fast as you can shoot it. Unfortunately, as good as it sounds, the loader does not always work reliably. Their double stack magazines are also subject to this type of criticism. I have a dozen of this magazine that I acquired back in the late 80s. Out of twelve, half actually worked as long as they were not loaded to capacity and with certain type of ammo. Winchester Super-X appears to work best with these mags. The others have varying problems that I can attribute to excessive spring power of the follower. The most common problems encountered with this type of magazine is the tendency of the top round’s front end to lift itself up to almost 50 degrees as the bolt hits the back of the receiver during recoil. As the bolt comes back to battery, the lower end of the breech face that normally scoops the cartridge will miss the rim (now below the feed line) and instead glides over the lifted front end of the bullet, scraping it and finally stopping as the breech face dug deeper into the bullet nose. Another frequent malfunction using this magazine is the tendency of the bullet nose to hit the upper section of the chamber mouth as it is being pushed by the bolt towards the chamber. Again, the excessive magazine spring power appears to be the culprit here. There seems to be imbalance in the distribution of spring tension with much of the pressure directed to the front end of the follower. It is this author’s opinion that Ram-Line should have combined a full power spring and a half power spring rather than using two full power springs to make the system work reliably – and it would also make loading easier.

| This article first appeared in Small Arms Review V14N7 (April 2011) |