By Gary E. Reisenwitz

Whenever someone mentions the term “Kit Gun”; visions of partially finished Kentucky rifles come to mind. If you are very patient, possess a few files and some sand paper, you could “finish” the collection of parts and quite possibly be proud of your newly created firearm. I’ve never built one of those “Kit Guns”, mainly because I never really wanted a Kentucky rifle to begin with. If I had wanted one, there was simply a much easier way to get one, and the cost appeared to be about the same. Times have changed, and the term “Kit Gun” has taken some new meanings. The ads for M16 “kits” abound, and the plethora of “parts kits” continues to amaze me. However, most of the parts kits are for guns that will never be built, because the receivers are not available, and most likely, never will be. There is one “Kit Gun” that does not fit into any of these categories. This particular one enables the clever hobbyist to construct something that cannot be easily bought, and mimics a firearm that is beyond the affordable range of all but the most serious of collectors. This is a kit that enables the construction of a semi-automatic version of the US M60 General Purpose Machine Gun.

HISTORICAL BACKGROUND

This “Kit” is the brainchild of Eugene Peruski . He began developing the design for a semi-auto M60 back in 1990. This was about the same time that Dave Reese, from Springfield Armory, was working on their own ill-fated SA1 (which, unfortunately, will probably never see the light of day). Eugene worked on the prototype for a good three years, and finally got the design down to a point where it was time to fish or cut bait. At the opportune time, John Weaver came into the picture and bought the design, the prototypes and the good will of Eugene. John knew (or at least he thought he knew) the proper method for obtaining BATF approval for manufacturing something that might be perceived as “questionable”, and sent a rough working model to BATF in May of 1993. In September of 1993, he received a letter back form BATF telling him that his model was NOT approved as a semi-automatic, because the receiver dimensions were too close to those of the M60. They told him that the receiver, as he designed it, was too easily convertible back into a fully automatic configuration. The letter they sent John included a list of design changes that would be required in order for BATF to agree to accept his design as a semi-auto. Most of these design changes were to the internal dimensions of the rails within the receiver assembly. Of course, to add insult to injury, the BATF classified John and Eugene’s working model as a machine gun (post-ban) and were very reluctant to return it to them. (It later had to be destroyed.) John made extensive changes to the internal receiver rails, crafted another prototype and sent it to BATF in May of 1994, for review and approval. A letter of approval from BATF was received in August of 1994, and they got their prototype back a few weeks later. John had still underestimated how long his lead times would be to tool up for actual series production of the receiver components, and was not able to start really putting parts out until June of 1996, nearly two years later. However, by the summer of 1997, the parts were in inventory and JRW Sports, Inc. has been shipping parts, receivers, kits and even a few fully assembled guns. (John has also found himself to be the only real source for newly produced full-auto receiver components for the M60. He is even making some replacement parts out of stainless steel. He hopes to have a post-sample stainless steel M60 receiver built soon. A sideline of JRW Sports is the rebuilding of substandard aftermarket M60 receivers with properly dimensioned and hardened components. He can bring any transferable M60 receiver up to true Mil-Spec quality.)

JRW Sports, Inc. has produced a true receiver kit that will enable a hobbyist with no more than a vise, drill press, dremel tool and small hand tools, to build a working semi-auto M60 belt fed rifle. They have labeled it the “SAR-60”. It is Kalifornia legal and is not classified as an “assault weapon”. (Note: In order for the SAR-60 to be completely “ban-compliant”; the muzzle must not have the screwed on flash suppresser. JRW can help here with slip over and welded on false muzzle appendages that look like flash hiders, but are completely ban-compliant.) The semi-auto “Kit Gun” has been in production for nearly a year and has shipped quite a few units for customers to complete. The kit is available in several forms and states of completion. The least expensive version of the kit consists of just the semi-auto internals and the frame components, that when combined with standard M60 receiver components and weapon parts, can be assembled into a working gun. JRW Sports also offers complete semi-auto receivers, and if you are very patient, complete working firearms.

One of the key features of the SAR-60 is that it can be built with truly quality made parts. The trunnions are machined from AISI 4140 alloy steel and then properly heat treated for long life. The rails are made from pre-hardened 4140 bar stock so they can be produced without warpage. The receiver channels are made from 1075 sheet steel with the ports laser cut so the edges are hard and highly wear resistant. The components to the SAR-60 are a lot closer to Mil-Spec quality than a lot of the transferable M60 machineguns out there.

It appears that this is a product for which the time has come. Owning an operational M60 machinegun has gotten to be an expensive luxury for the select few. The cost is just prohibitive to all but the most serious of collectors. So if you want an M60, but just can’t justify spending the $10K+ for a decent shooter (that doesn’t look like a botched shop project from the local tech school’s Welding 101); this may be a practical alternative. The full-auto may remain a distant dream, but with a quick trigger finger and a lot less cash, you can come pretty close to the real thing.

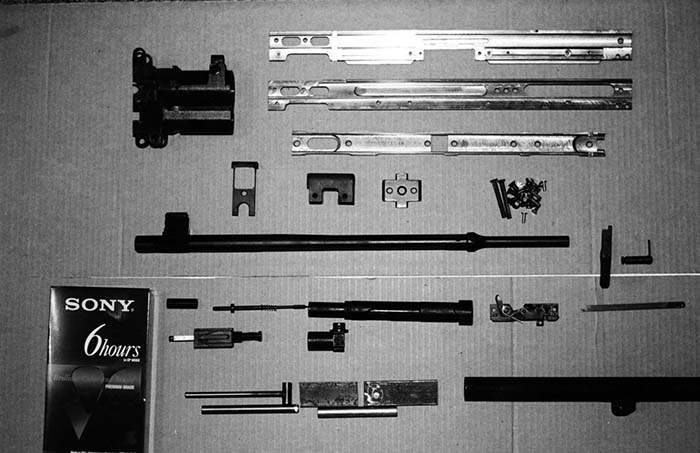

The first sight of the receiver components can be very intimidating. Just looking at them does not help one to envision a workable gun, no matter how they seem to fit together. Patience and confidence help a lot here. What also helps a lot is the instructional video that accompanies the receiver kit. This video is a little on the rough side, but it does show how the parts are mated, and covers the assembly in a very detailed manner. If you got into a fix, I’m sure that JRW Sports, Inc. offers Tech. Support. Past experience has indicated that most of the customers do manage to get these things together and get them to go bang.

These semi-auto variants work a little differently than the full-auto guns. Instead of firing from an open bolt; they fire from a closed bolt. Pulling the stock M60 trigger releases a striker that fires the gun, rather than releasing the bolt, as on an M60 machine gun. But, even though the gun fires from a closed bolt, the newer top cover is not needed. There is no external linkage on the gun’s receiver to make the semi-auto work. The gas system is pure M60, without any modifications whatsoever. It is a physical clone of the M60 machinegun. The differences are perceptible, if a semi is placed very close to the real thing. But even a trained eye could probably not be able to spot the differences from an arm’s length away.

We took a sample of a completed kit to the range, to get a feel of how a semi-auto M60 feels and shoots. All the participants agreed that this thing was a Hoot!. The stock M60 has a pretty slow cyclic rate, and you can pull the trigger on a semi-auto nearly as fast. It works better with the 100 rd cloth assault bag attached, but you can still drape a belt across your forearm and blaze away at waist level. I’m not sure there is a better way to recycle water filled milk jugs!

For more information on the price and availability of the SAR 60 kit, just contact JRW Sports, Inc. at (904) 423-9914 (Voice) or (904) 423-9915 (FAX). Their mailing address is : JRW Sports, Inc., 1401 South Ridgewood, No. 4, Edgewater, FL 32132.

| This article first appeared in Small Arms Review V1N6 (March 1998) |