By Phil Kline, Esq.

Here is another of the series of “Making your MAC Shoot Better” articles from SAR. We believe that the tinkers and innovators out there will continue to work with these small SMG’s and make the inexpensive bullet hoses more functional, as well as much more economical.

The M-11/9 submachine gun may be a bullet hose, but it’s a fun little bullet hose. If you own an M-11/9, then you might as well take the trouble to make it both fun and reliable.

Although this article is about an upgrade to the M-11/9, the replacement of the stock was instigated by an unavoidable side-effect of a previously reported upgrade.

CAUSE OF THE PROBLEM

As reported in the August ’95 issue of MGN, a replacement magazine housing is available from Craig Wheatly at Tactical Innovations, to convert the gun from those unfashionably soft (and currently expensive) Zytel plastic magazines to the sturdy and proven (and currently cheap) Sten or Lanchester magazines. As was also reported in that article, the conversion has the side-effect of using up more of the interior of the receiver, thereby decreasing the width available for the twin rails of the factory sliding stock. The magazine can’t be inserted if the factory stock is in the closed position.

THREE OPTIONS

After the conversion to Sten magazines, you have three viable options: (1) You can leave the slide rails as-is, forcing you to retract the stock before inserting a Sten magazine; (2) You can carefully shave the interior width of each stock rail, which allows a magazine to be inserted with the stock closed or open, but causes an unacceptable degree of wobble when open; or (3) you can replace the stock entirely. OK, maybe four options: you can shoot it without a stock; fine for unintended duck hunting, maybe, but lacking in style. I went for option (3), stock replacement M-11. Fixed stocks have been discussed in other magazines (MGN Mar. ’94; Feb. ’95). I wanted the option of closing it up to a compact SMG, so I decided to go with a folding stock.

FUTILE SEARCH OF THE MARKET

A search of gun shows and published ads was unsuccessful. I tried to locate one of the Choate side-folders designed for the MAC-10 which I had seen in an old FIREPOWER magazine, but neither Choate nor any of the Choate distributors whom I contacted had any on hand. Examination of other Choate and Butler Creek folding stocks revealed that they all folded to the right side, and that the configuration of each of the stocks would interfere with a right-handed shooter’s grip and/or block the ejection port. Besides, the Crime Bill has seriously affected the price and availability of most folding stocks.

CRITERIA FOR AN M-11/9 FOLDING STOCK

What I wanted was a side-folding stock which added minimally to the overall length when folded, which was steady when open, and which didn’t interfere with ejection or a firm grip on the weapon when the stock was closed. I preferred the sturdy look of the .308 Galil folding stock.

STOCK OPTIONS AK SIDE-FOLDER

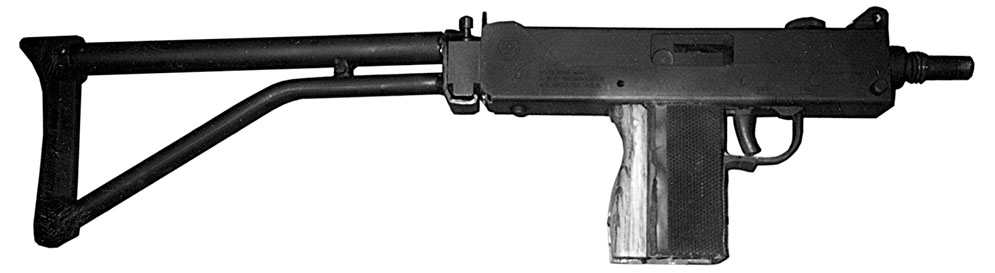

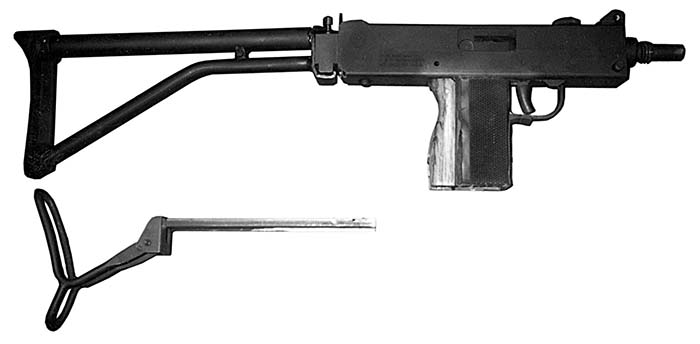

I was experimenting with the arm of a South African R-4 folding stock without much success, when I saw an ad for the Stock Options (now succeeded by “American Made Stocks”) AK-series folding stock kit. This stock folds to the left side (away from the ejection port), locks either open or closed, and attaches to a flat, vertical base plate only 3/4 of an inch thick. In appearance, it looks much like the Galil or FN-paratrooper stocks. Although designed for the AK-series, its flat attaching plate makes it adaptable to any receiver with a flat, vertical surface like the M-11/9.

I promptly ordered two of the stock kits. They retailed for about $130 each, but I’m told that significant dealer discounts are available. When they arrived, I was pleased. The stock arms are sturdy. Both stocks locked up rigidly when open (although one of them wobbled slightly when folded). The buttplates are unpadded black plastic. While I prefer rubberized steel buttplates for traction and recoil absorption, the minimal kick of the M-11/9 doesn’t require them.

ATTACHING THE STOCK

One attachment option would be to weld a set of short, notched rails to the stock base plate, (shorter versions of the factory sliding stock rails). This would allow quick stock removal, and avoid permanent alteration of the receiver. This may be the best approach, and perhaps the manufacturer (or some enterprising gunsmith) will do this in the future if there’s enough interest.

In my case, lacking ready access to welding equipment (as well as any sentimental attachment to the receiver’s virgin status) I opted to drill the back of the receiver for a quick, cheap and solid attachment.

Inside the receiver, at the back, there is a “dead space” running the width of the receiver, starting at the floor and rising up about 5/8” high, between the stock block (the fixture holding the stock release button) and the receiver wall, where a pair of nuts can be inserted without risk of interference with the bolt or recoil assembly. This is where I drilled two 13/64” holes, spaced 19/32” apart and centered on a line 9/16” up from the bottom of the receiver. These holes must be high enough to keep the base plate firmly on the flat portion of the receiver, but low enough for the nuts to stay within the dead space.

DRILLING THE BASE PLATE

On the replacement stock base plate, I opted not to use the existing holes. I drilled two new holes just below those holes. Each hole is 13/64” in diameter, countersunk to 5/16” to accommodate the set screws supplied with the kit.

SLING SWIVELS

A threaded hole in the top of the base plate matches the threads on a standard Uncle Mike’s-type Q.D. sling swivel. Clearance is pretty tight against the iron sight plate, but I managed to contrive a workable configuration.

CHEEK PIECE

Finally, I took a piece of 5/8” I.D. rubber tubing, slit it lengthwise, and wrapped it over the top tube of the stock for comfort.

FINISHED CONVERSION

The end result is an attractive stock which folds out of the way for transportation, storage or concealment, allows insertion of magazines at all times, and yet locks up better than the original wire sliding stock. The resulting height is probably better suited for use with a scope or red-dot sight. It’s a little high for use with the iron sights, but those iron sights were semi-functional at best.

SOURCE:

American Made Stocks

Info: (714) 549-3901

Orders: (800) 213-4227

| This article first appeared in Small Arms Review V1N7 (April 1998) |