By Michael Heidler

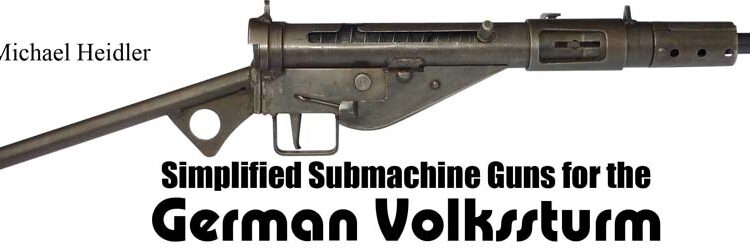

In the course of the war, the submachine gun proved indispensable for urban warfare. Compact and portable, with a high rate of fire and a sufficient magazine capacity, it had advantage over the standard carbine on short distance. For this reason it was decided that the Volkssturm should be equipped with submachine guns.

But how? The manufacturers of the standard MP40 were totally busy and could not even meet the needs of the army. Even if the MP40 was easier and faster to produce than its predecessor MP38, it was still a quality weapon. Only minor simplifications had been implemented during serial production, and since becoming aware that the submachine gun would soon be replaced by the new Sturmgewehr 44, no more improvements were made.

At the beginning of 1942, Erma ceased the production of model 98k carbines that had run since 1935. The company had been ordered to focus their production entirely on the MP40. The complete machinery for carbine production, as well as all prefabricated parts were then handed over to the Gustloff-Werke in Weimar. Although the MP40 was never discharged and could not be replaced by the Sturmgewehr 44 as planned, their production ended in 1944 after more than 700,000 pieces were made. Haenel stopped production in 1942 in favor of the assault rifle, followed by Erma at the end of 1943. Finally Steyr in Austria continued their production until autumn 1944. From then on the production was concentrated on Sturmgewehr 44 and MG42. With more than 300,000 pieces, almost half of all MP40s came from the production of Steyr.

Since the production of assault rifles could not keep up with the demand and the losses at the front increased during the war, a noticeable lack of submachine guns arose soon after the end of the MP40 production. In adversity, the decision was made to use the Italian Beretta model MP 38A/42 as a stopgap and it received the German designation MP738(i). Between mid-1944 and the end of the war some 150,000 Berettas were used in German service.

The Gerät Potsdam

With the Wehrmacht’s fading fortunes of war and the approaching Allies, the partisan movements in the occupied countries became stronger. As their operations tied up a large number of German troops for security tasks, the Allies attempted to support these underground fighters with supplies. The British, for example, sent containers with firearms, ammunition, explosives and other useful equipment that were dropped to the French Résistance from the air. In the area of Beauvais alone about 1,205 containers and 11 agents were dropped between the 1st and 5th of March 1944. However, only a small part of it reached the right receiver – a large part was collected by the Germans. The weapons were mainly British Sten submachine guns. These were cheap to produce and space-saving for packing in airdrop containers. Also the Résistance could use captured German 9mm ammunition with these guns.

The Sten gun was developed by Colonel V. Shepperd and engineer H. J. Turpin. From the initial letters of their names and the production site Enfield the name Sten was created. The official introduction took place in June 1941. Until then, Britain, which did not have much submachine gun development in the years before, had been dependent on costly aid deliveries (Thompson) from the United States. But now a mass production started with the involvement of other companies and industry workshops all over the country. From the first model and the following variants (Mark II, III, IV, V, VI) more than 3.5 million pieces were produced before the war ended. The production of a Sten Mk.III only took 5 hours.

On the German side, a large stock of air-dropped Sten guns was collected. These were put into storage in the Reichssicherheitshauptamt “RSHA” (Reich Security Main Office) in Paris. After the Allied landings in Normandy a lot of captured weapons came in addition. In view of the shortage of their own submachine guns, the police and SS filled up their stock from this booty storage. Soon after the failed commando raid at Dieppe in August 1942 the Reichsführer-SS Heinrich Himmler had instructed the head of the SS-Waffenamt, SS-Oberführer Gärtner, to examine one of the captured British submachine guns. Now, after thousands of these weapons were stored in the RSHA, their distribution as “MP748(e)” to various organizations and units of the SS in Germany and the occupied territories began. So in April 1944, the Gauleiter of Lorraine (Lothringen), Josef Bürckel, got more than 3,000 Stens for further distribution. Also SS-Obersturmbannführer Otto Skorzeny, well-known for his commando raids, received a shipment of weapons in October including 100 Stens. This way the storage in Paris emptied, while the inflow of captured weapons was getting lower. Additionally, the support of the Résistance was much easier since the Allies had gained a foothold in France and the supply by air-drops could be reduced significantly.

In the meantime, the successful use of the Sten seems to have convinced many skeptics on the German side. Initially regarded as “English sheet metal junk” the gun served its purpose. Still today it’s a mystery who eventually had initiated the following development. In literature, the most fantastic stories can be found, from special forces through the werewolf units that should fight like partisans against the allied occupiers on German territory. Also the repeatedly mentioned English markings (for example the Broad Arrow) to deceive the enemy could not be found on original Potsdams.

In autumn 1944, the Mauser company received an order for the production of 10,000 exact copies of the Sten Mk.II. As a codename “Gerät Potsdam” (device Potsdam) was chosen. In an interrogation after the war, Dr. Harnisch (chief engineer in rifle, machine gun and pistol production) said that the production was only done because of a lack of their own submachine guns. He did not mention any particular use.

In the monthly reports by Mauser, the Gerät Potsdam was mentioned for the first time in September 1944. Due to changes in the aircraft program, the work on the MG215 (V.7077) by the special commission “Automatic Cannons” was discontinued the month before. Soon after that the involved employees were appointed to the new project “Gerät Potsdam” (V.7081). They made good progress and already in October the monthly report of the Weapons Research Institute says, “Two new sets of drawings were drawn up, one for the manufacture by arms factories and one for a manual production in small workshops. The first named set was handed over to the production company, where a series of 10,000 pieces is in preparation. The other set was handed over to the department. Prototypes must now be made to check the drawings.”

Immediately after delivery of the drawings, Mauser began with serial production and by November, 5,300 weapons were finished. In December, 5,100 pieces followed and then the order was completed. According to a survey of Mauser showing the monthly output of weapons, only the actually ordered 10,000 weapons were shipped. What happened to the 400 surplus weapons is not known.

Because the Gerät Potsdam is a copy of the Sten Mk.II, only magazines of the Sten and the German MP28/II could be used. The magazines of the MP38/40 did not fit. They are 6mm too narrow and wobble in the magazine well, since the magazine release does not engage. The magazines of the MP28/II can therefore easily be used because the weapon had once been copied by the British as the Lanchester, and in turn the Sten magazines are based on them. After the war the company Haenel stated in a document for the Russians that they had made 39,300 magazines for the Gerät Potsdam: 16,800 pieces in 1944 and 22,500 pieces in 1945. Since Haenel already had the tools for making MP28/II-magazines, it was no problem to make the new magazines for the Gerät Potsdam. The original British Sten magazines and the German ones only differ in the style of the bottom-plate. This is identical to the bottom of the MP28/II-magazines.

According to the documents from Mauser, the Gerät Potsdam should have been made in small local workshops scattered throughout the Reich. But this never happened. Even before the production at Mauser was set into operation correctly, the company received an instruction by the Sonderkommission Infanteriewaffen (Special Commission infantry weapons) to simplify the Gerät Potsdam and to reduce the manufacturing requirements to a minimum.

The Gerät Neumünster (MP 3008)

The Gerät Potsdam still had potential for simplification. Since at the beginning only an exact copy of the Sten Mk.II was requested, Mauser had not made any changes to the weapon’s design. Now, however, the design could be made more simple.

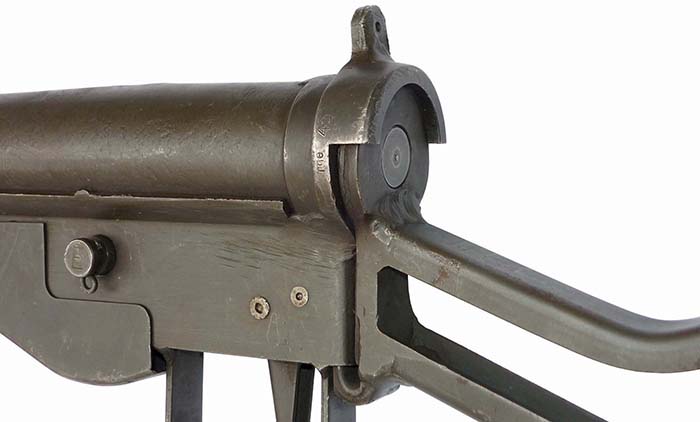

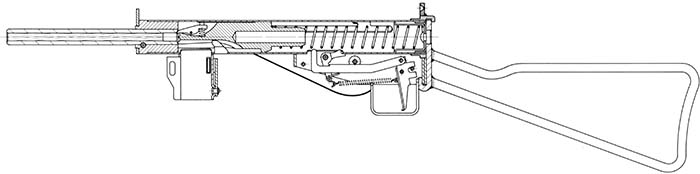

The most noticeable change is the omission of the rotatable magazine well. The Gerät Potsdam was fed by a magazine inserted from the left side. When not in use, the magazine well could be pivoted downwardly so as to prevent an ingress of dirt. Now Mauser replaced it with a solid metal well welded on vertically from below. This type of magazine well was already known to German soldiers because of the submachine guns MP38 and 40, where the magazine well also served as a front grip. The vertical magazine well is a hindrance to the soldier in the prone position, but the production is thus considerably simplified. Because of the changed magazine well, Mauser also had to remodel the bolt accordingly and relocate the opening for the ejected empty cases to the right. The receiver of the new weapon was lengthened. Instead of a barrel nut, the barrel was now pinned in the front of the receiver. The trigger assembly, fire selector and other parts of the Potsdam retained in shape. By the change of the dimensions of the magazine well it could now accept the standard magazines of the MP40.

In November 1944, Mauser finished the blueprint set for the now called “Gerät Neumünster” (V.71083). Based on this set, two models were made and handed over to the Hauptausschuß Waffen (main committee for weapons) of the RmfRuK (HAW) and the Heereswaffenamt. Since both offices asked for some minor modifications, two more models had to be produced and handed over again for examination. This time both weapons were found to be good. Immediately thereafter, production began in some small workshops, because the Mauser monthly report says: “Enquiries from manufacturers (workshops) are answered regularly.”

Based on the mention of the Gerät Neumünster in the secret regulation D.97/1+ “Geräteliste” (list of devices) of 2 November 1944 under the number 1-3-3008, the submachine gun got the unofficial name “MP3008.”

That same month, on paper, the distribution of the weapons began. On 15 November 1944, the Feldzeuginspektion (Ordnance Inspection) ordered the utopian quantity of 1,000,000 pieces Gerät Neumünster with accessories and spare parts. Until March, every month 250,000 weapons should be delivered to the arsenals in Güstrow, Ingolstadt and Prague. Two weeks later, after a meeting with the Reichsministers für Rüstung und Kriegsproduktion on 30 November the Volkssturm also demanded its share. SS-Obergruppenführer Gottlob Berger placed the order for delivery of Sten guns: “Subsequent to the meeting mentioned above, I hereby place an order to the Main Committee for the delivery of 50,000 Sten – pistols 9mm for the German Volkssturm. I ask for notification, in which time and where the Sten-pistols 9mm will be available for acceptance, so that I can arrange the distribution in the individual Gaue (districts).”

After the completion of the development, Mauser was still busy with the requests by the manufacturers. Mauser also provided 150 Geräte Neumünster from their own production for distribution as a pattern. Some weapons, manufactured according to this pattern, were sent back to Mauser for examination of function and quality. Minor problems led to some improvements, so that in February 1945 another five pieces were ordered by Wa.Prüf.2. In the monthly report of February is mentioned: “As difficulties arose at the production facilities, these should prove again that the weapons made according to the drawings have a flawless function and durability.” The revised model of the Gerät Neumünster got the new Mauser project number V.71091.

The forecast list “Sten Pist.” of the Waffenamt dated 1 March 1945 indicates that no Sten-guns had yet been delivered to the Waffenamt. From January on, 10,000 pieces should have been made every month. The reason is mentioned as “initial difficulties” that should be eliminated by the improved model. For April a production of 20,000 pieces was planned. Another forecast for the time from March to August 1945 shows a monthly production of 100,000 pieces. The paper-shufflers in Berlin were probably living in a different world.

Manufacturing

Only a few documents exist about the production of the MP3008 alias Gerät Neumünster. A list of the companies that had received the drawings from Mauser is not yet known. According to Dir-Ing. K. Weissenborn the jobs were distributed to 30 subcontractors and 14 companies for finishing the weapons. Few of them have been unequivocally identified so far.

At least of one company an American report on its investigation has survived: Carl Eickhorn. After the arrival of American troops in Solingen on 17 April 1945, the search of the local industry for interesting technical achievements began. In the course of this search Captain Phillip B. Sharpe (U.S. Army Ordnance Technical Intelligence Unit) visited the well-known Carl Eickhorn factory, where he found several MP3008s among other things. In his report of 14 June he wrote: “Specimens of a new German 9mm. Machine Pistol were recovered in the Karl Eickhorn Plant, in Solingen, Germany, together with drawings and proof records indicating that the German designation “M.P. 3008” has been applied to this weapon. It appears to be a simplified version of the British Sten 9mm. Machine Pistol, designed with economy and speed of manufacture in view, stampings assembled by welding being used. The gun cannot be disassembled, and accordingly was probably regarded as highly expendable.”

In his interrogation of employees he found out that only 26 weapons were finished before the occupation. They were not yet distributed. Capt. Sharpe concluded that there must have been other manufacturers, since some of those weapons had been captured in the field.

Depending on the origin, the submachine guns vary considerably. The drawings of Mauser should have served only as a basis on which the manufacturers could orientate themselves. Due to the different manufacturing facilities and the often inadequate supply of raw material not all the parts could be made in the exactly same way by each manufacturer. Many small workshops had to improvise. What was important was that the parts were suitable for their purpose – no matter what they looked like.

With a few exceptions, such as barrels and bolts, all parts of the MP3008 were manufactured in a simple way. Some receivers were made from seamless drawn tubes, others were rolled out of stamped steel and welded together end to end. Eickhorn in turn had punched out the receivers from sheet metal and then rolled them so that it overlaps at three points (before and after the empty case ejection port and behind the slot for the cocking handle). The overlaps were then spot welded and smoothed. A metal block was inserted in the front of all receivers in which then the barrel was pressed in. A driven in crosspin secures the barrel in place. Most barrels have 8 grooves with right-hand twist. Finally the trigger assembly and the magazine well were welded to the receiver.

The sight was adjusted to 100 meters. The exact sequence is not known. Neither the peep-hole rear sight on the end of the housing nor the stamped sheet metal front sight can be moved. On the Gerät Potsdam the front sight sits in a dovetail groove and could be slid sideways for adjusting, before it was spot-welded in place. On the Gerät Neumünster both sights had to be fixed by welding right during adjustment.

To facilitate the adjustment and test firing, Mauser designed a special device for their submachine guns. A factory photo from November 1944 shows the device with a fixed Gerät Potsdam ready for testing. However, since at this time the development of the Gerät Neumünster was already completed, the base plate got a cut-out to accommodate the vertical magazine.

Supply With Ammunition

A monthly increase by 250,000 submachine guns could not have been coped with by the ammunition supply situation at that time. In the entire year 1944, the consumption of 9mm cartridges was 450 million rounds. With the planned three magazines (each 32 rounds) for each MP3008, the demand increased by 96 million rounds. Without an increase in production, the supply of the additional Volkssturm-MPs was impossible.

Therefore on 9 December Lieutenant Colonel Haymann of the OKH wrote to Gen.Qu./Abt.III/planning group and Gen.Qu./Abt.I/ammunition to point to the increasing ammunition demand: “Subject: Sten-pistols. It has been reported that In 2 has issued a production order for 1 million Sten-pistols. The General of Infantry requests to be oriented about the concept of the operational sequence of this demand for manufacture. In regard to this it must be pointed out that in connection with the production of so large a number of Sten-pistols it will become necessary to increase the monthly production of the Pist.Patr. 9mm by a total of 150 million cartridges per month.”

Finally the ammunition supply for the Volkssturm submachine guns was no longer relevant.

(The author wants to thank Jan Skramoušský of the Military Museum Prague (www.vhu.cz/cs/stranka/armadni-muzeum) and Richard D. Jones of the National Firearms Centre (Royal Armories) in Leeds/England.)

| This article first appeared in Small Arms Review V17N1 (March 2013) |