By Robert Bruce

“From the first days of the war we were convinced that an unpardonable error had been committed. The German Army attacked with extremely varied and far-from-first-class tanks, including the captured French Renaults and outdated German T-1 and T-II tanks whose participation in the war had not initially been anticipated.” Boris Vannikov, People’s Commissar of Armament (From Vannikov’s memoirs, quoted in D.N. Bolotin’s 1995 book, Soviet Small Arms and Ammunition, published by Finnish Arms Museum Foundation)

Vannikov’s admission of this near-fatal error carried a host of implications as Operation Barbarossa, Hitler’s mechanized blitzkrieg, blasted into Russia on June 22nd 1941, steamrolling over an ill-prepared and poorly armed Red Army. The problem was particularly acute in a lack of anti-armor weapons; both shortages of artillery and an almost complete lack of infantry weapons suitable to stop even lightly armored enemy vehicles.

Pre-war planning by Soviet generals and armaments chiefs had overestimated the armor thickness of what would prove to be the actual types of tanks that would be used by the German invaders. At the same time they rejected the need for antitank rifles and underestimated the need for increased quantities of conventional artillery.

Thus, German forces quickly and relentlessly penetrated hundreds and hundreds of miles into “Mother Russia.” This caused Josef Stalin, the ruthless and remorseless Soviet dictator who was well known for ordering executions as remedial action, to turn his wrath on top bureaucrats.

Armament Commissar Boris Vannikov reports being angrily confronted by Stalin in a high level meeting in July of 1941. Why, he demanded, were his soldiers reduced to using hand grenades and “Molotov Cocktail” gasoline bottles in desperately attempting to stop even light tanks when a suitable antitank rifle had been developed but not fielded in anything but paltry quantities?

Rukavishnikov

While there were lesser-known contenders along the way, the “suitable” rifle Stalin was referring to was Nikolay Rukavishnikov’s semi auto design, adopted in late 1939 and firing a demonstrably powerful 14.5mm cartridge. Although proven capable of penetrating 20 mm of armor at 500 meters, a catalog of problems in performance, production, bureaucratic inefficiencies, and high-level Army indifference delayed fielding of more than a handful.

Vannikov nervously and hastily cited these factors in his defense, winning at least a temporary reprieve from the firing squad. But Stalin, told that debugged Rukavishnikov rifles would not be rolling off the assembly line for more than a month, upped the pressure.

Such was the urgent need as Germany’s armored forces continued to race toward Moscow, that the dictator demanded a crash program to develop alternatives. Not just one but two simultaneous efforts were to begin at once, produce guns in the shortest time, and they had both damn well better be good. Or else it would be cigarette and blindfold time…

22 Day Wonders

In what has to have been an “honor” they’d prefer not have, two of the Soviet Union’s most talented gun designers were put under Stalin’s fearsome orders and immediately set to work around the clock. Vasiliy Alexeyevich Degtyarev, best known at the time for several well-regarded machine guns, and Sergey Gavrilovich Simonov, creator of the clever but flawed AVS-36, are said to have produced firing prototypes in an astonishingly brief 22 days.

Degtyarev’s gun used a relatively simple bolt action, albeit fancied up a bit with a recoiling barrel and automatically unlocking bolt to help minimize high energy stress on the parts and to speed up manual feed of subsequent shots. Robust, relatively light, simple to operate and to manufacture using mostly lathe-turned parts, it was a strong contender.

Simonov, on the other hand, took a bigger chance by making his rifle a gas operated autoloader. But, hedging the bet somewhat, its action was wisely derived from his previous invention, the 7.62x54R Simonov 1938 rifle. Although heavier and somewhat more difficult to make, its fast, reliable semiautomatic function and five round capacity were compelling advantages over the rival bolt gun.

Both weapons tested well and were deemed superior to the still-struggling Rukavishnikov that was summarily scrapped. Then, testifying to the dire need for weapons of this exact kind, both were officially adopted on August 29, 1941 and rushed into production.

An interestingly ironic side note to quantity manufacture of the PTRS comes from having to make an emergency move of its entire factory operation from Tula to Saratov. Seems the rapid German advance, against which the antitank rifles were so sorely needed, threatened to overrun the factory.

Anatomy of the PTRS

Since the focus of this feature is on live firing Simonov’s “Protivotankovoe Ruzhe Sistemy Simonova,” let‘s take a close look at what he came up with in just over three weeks of grueling, nonstop, trial-and-error design and fabrication.

With apparent faith in his 7.62mm 1938 rifle despite it earlier losing out to rival Fedor Tokarev’s SVT-38 and 40, Simonov used its essence as the basis for his considerably more powerful tank-buster. With a top-mounted gas piston to actuate a sturdy bolt carrier, its locking in the beefy machined steel receiver was achieved by simple tipping action.

Taming the mechanism-destroying and case-separation propensity of the powerful 14.5mm cartridges was achieved by building in “dwell time” during movement of the gas piston and unlocking the bolt carrier. The proper milliseconds delay – calculated and achieved on the run with no sophisticated engineering apparatus – allowed the relatively brittle cartridge cases to “deflate” inside the firing chamber, easing extraction and ejection without undue instances of sticking and rim separation.

Recognizing the many handicaps of mass-manufacturing operational weapons under the most dire wartime circumstances and shortages of materials, machine tools and their operators, Simonov’s design was efficiently simple to make and not unnecessarily critical in its tolerances. Its thick, conventionally machined upper receiver was mated with a mandrel rifled barrel. Underneath, a trigger housing group and protruding magazine assembly were made mostly from stampings.

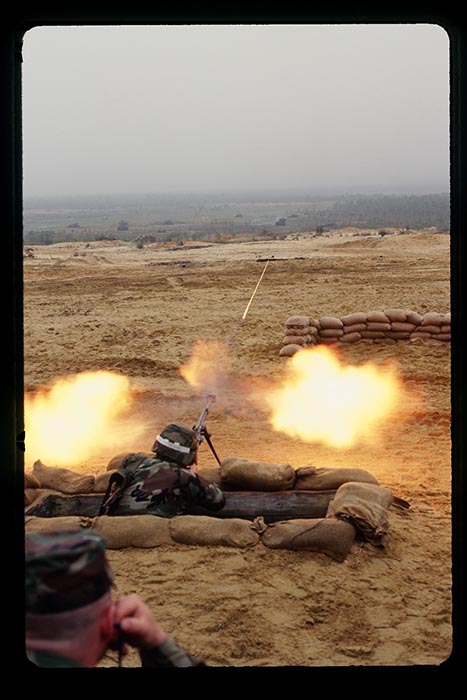

Weighing more than reasonable for one man to carry on the march, the long and heavy barrel assembly could be quickly separated from the receiver. Its well positioned bipod allowed necessary movement for gunner position and efficient aiming, and sights were configured in the same manner as most other Soviet shoulder weapons. The gun was “soldier friendly” – quick and easy to load, aim, fire, strip, and clean. Equally important, the PTRS was effective for gunners with steely nerves whose best bet was to wait for enemy tanks to close to well within 500 meters.

Reduction of recoil wasn’t just a concern in minimizing stoppages as well as parts stress; effects on gunners had to be considered as well. Because too much kick would cause flinching and inaccurate shooting, not to mention pain and suffering, both Degtyarev’s bolt gun and Simonov’s semi auto featured prominent muzzle brakes. These simple and effective blast deflectors channeled propellant gas at a slight rearward angle, pulling the whole gun forward with each shot. And, while the PTRD’s tubular steel buttstock contained a sturdy spring that compressed with each shot, Simonov’s considerably heavier rifle with recoil-absorbing semi auto action needed only to have a simple butt pad on its fixed wooden stock.

First Blood

Less than three months after adoption and start of manufacture, the first of the new antitank rifles went into battle with the Red Army, fighting a desperate action to block advance of the Germans on Moscow.

As reported by Western Front Artillery Commander (initial tactical doctrine called for the big rifles to be deployed with the artillery), “The first experience in using antitank rifles occurred on 16 November 1941 in the 1075th Infantry Regiment… in the region of Petelino – Shiryaevo, where eight rifles were used in the battle. They were fired at enemy tanks at 150-200 meters. In that battle, two medium tanks were destroyed.”

Combat experience undoubtedly increased the ability and confidence of the gunners because target engagement ranges quickly lengthened. The same commander, Lieutenant General Ivan Kamara, wrote to superiors, “In subsequent battles, the antitank rifles were successfully used against light and medium enemy tanks. Fire was usually laid out to 250-400 meters.”

Production ramped up quickly and by the end of 1942 more than 248,000 of both types are said to have been produced with the PTRS accounting for about 63,000 of this impressive number. As more and more of the two types of rifles reached the front lines tactical doctrine was refined and matured.

In his invaluable reference book, Soviet Small Arms and Ammunition, D.N. Bolotin reports, “By 1943, the demands of the Red Army were completely satisfied; there were antitank platoons in every battalion, antitank companies in every infantry regiment and every tank-fighting division. In addition, the artillery, beginning with the antitank regiments, also received antitank rifles on the scale of one for every gun. According to approved practices, each infantry regiment was to have 54 rifles.”

Heroes of the Great Patriotic War

PTRS and PTRD rifles and the men who used them in battle quickly entered Red Army combat mythology through a vigorous and comprehensive propaganda campaign intended to inspire soldiers on the front as well as civilians back at home and in factories. Bolotin cites one colorfully worded leaflet among many representing countless true stories of heroic antitank riflemen in action against the hated invaders.

Recounting actions of Vasili Zverev, a former tractor driver turned platoon commander, it notes, “The line defended by a handful of his men was attacked by tanks. The enemy vehicles surged ahead, pouring fire at the soldiers from their cannon and machine guns, threatening to crush the defenders with their tracks. Nervously, the soldiers awaited the commander’s instructions. Zverev simply let the tanks come nearer, then opened fire with other antitank rifle teams. Tanks started burning, then exploding. Six had been destroyed by the riflemen.”

Room for Improvement

PTRD and PTRS rifles were strong, serviceable and deadly in the right circumstances but they still had shortcomings. While some sources contend that the harsh Russian winter was the source of the bulk of problems, Bolotin directly refutes this. “Though they operated faultlessly in wintertime, spring thaws brought jams caused by dust and mud; stoppages were caused by violent extraction (of the powerful rounds), together with partial ruptures of the cartridge. These flaws could be explained by minor design imperfections, impossible to eliminate within the short time in which the weapons had been developed.”

Bolotin reports that both Degtyarev and Simonov personally visited soldiers on the battlefront, carefully listening and taking to heart their concerns. A comprehensive remedial program was carried out in the latter part of 1942, addressing shortcomings in “technical documentation, roughly finished chambers and sliding parts, and mishandling by the soldiers.”

It is reported that one remedy to sticking cases came with instructing gunners to lightly lubricate the cartridges. But this can be tricky as the inevitability of oiled surfaces attracting grit could quickly make the extraction problem even worse.

PTRS Technical Specifications

Armaments designer Sergei Gravilovich Simonov designed, built and fired a prototype in the astonishing period of just 22 days. While the simpler PTRD went on to be made in vast numbers, it is said that more than 250,000 of both types were made before production ended following defeat of Germany in 1945. Although replaced by RPGs in first-line postwar use, they soldiered on for decades later, supplied to various communist armies and insurgent forces around the world.

The 14.5mm Cartridge with BS-41 Projectile, adopted in August 1941, was most commonly used in the PTRS and PTRD rifles in WW2. Carried in a brass alloy jacket, its penetrator core – variously described as tungsten carbide or metal-ceramic – is said to be capable of punching through some 40 mm of armor when hit flat-on at ranges under 300 meters. More powerful and versatile versions evolved and are still in use with the Russian Army and others in various heavy machine cannon, most notably the KPV/ZSU.

Nomenclature: 14.5mm Protivotankovoe Ruzhe Sistemy Simonova, Obrazets 1941 g

Origin: Soviet Union

Caliber: 14.5 x 114 mm

Operation: Semiautomatic only, gas activated piston

Locking: Bolt carrier tilts to lock in receiver recesses

Feed: 5-round internal magazine with rounds loaded individually or with enbloc clip

Overall length: 86.6 inches/2200 mm

Sights: Hooded post front and tangent U notch rear. Adjustable to 1,500 meters

Barrel: 48 inches/1,220 mm long, 8 grooves rifling, right twist. Operator removable for two-man carry.

Weight unloaded: 46 pounds/20.8 kilograms

Muzzle velocity: 3,320 feet/1,012 meters per second

Armor penetration: 1.57 inches/40mm at 90 degree angle, target engaged under 300 meters

PTRS and 14.5mm Update

Recent correspondence with Mr. J. D. Jones in preparation of this feature reveals that he has since parted with the rare and undoubtedly pricey gun seen in the live fire photos. But his appreciation for its big bore ammo has led him to make and offer the 14.5mm JDJ, yet another exotic and interesting development in SSK’s distinguished line of unique wildcat cartridges and custom tailored launch platforms:

The 14.5mm JDJ cartridge is based on the .50 BMG case. The neck is opened to accept the SSK 1,173 grain bullet loaded over 235 grains of 5010 to fire form the case. Other bullets may become available in the near future.

Important Note: SSK has non Destructive Device exemption for a 14.5mm (.585?) cartridge

In the test rifle, 100 yard accuracy hovers between .3 and .5 inches with this fire form load. Velocity is chronographed at 2,600 – 2,700 feet per second with the 1,173 grain bullet. This author’s worst 300 yard three shot group with it is 1.509 inches. The 750 Barnes is a real performer at 3,000 FPS. Dies are in stock.

Actions suitable for the .50 BMG are the ONLY ones that will take this cartridge. We recommend McMillan actions. Guns are all custom built according to customer preferences. It is doubtful that it will be possible to build one for less than $8,000. Please do not email questions – if seriously interested call.

SSKINDUSTRIES.COM

590 Woodvue Lane

Wintersville, Ohio 43953

Phone: (740) 264-0176,

FAX: (740) 264-2257

http://sskindustries.com

| This article first appeared in Small Arms Review V18N5 (October 2014) |