By George E. Kontis, PE

Try to name a firearm that doesn’t use at least one spring? I can’t think of a single one, and it’s likely that none exist. The reason for considering the question is that springs are not reliable when used in weapon systems, so the guns with fewest springs tend to be the most reliable. The reason for this is not because springs are difficult to design correctly, hard to make properly or prone to failure. In fact, the opposite is true. Consider, as an example, a typical helical spring you might find in a ball point pen or one of those huge springs under your car’s chassis that cushion the ride. Those springs give reliable performance over many cycles, and are rarely broken. While they are the same kinds of springs found in guns, there are important reasons why those in a weapon system are less reliable.

In order to design a helical spring properly, the spring designer calculates the stresses at maximum spring compression and compares this stress level with what is recommended for the wire material. It’s all pretty easy if there is adequate space, but for gun systems there is usually not enough room. This is because the firearm needs to be as small and light as possible, forcing the designer to complete the design with at least a few overstressed springs.

Another step in the spring design process is to check the stress level at solid height – that is the point of maximum deflection when all the spring coils are touching. Some designers skip this step, thinking that they have designed the mechanism in such a way that the spring will never be compressed to solid height. This is a big mistake. The shock, or impact loads, from firing cause spring surge waves to travel back and forth on the spring. These surge waves can cause adjacent spring coils to touch or come very close to touching, which is precisely the same effect as compressing the spring to its solid height. In a study performed by Mauser in Germany, the life of impact loaded springs was determined to be in the range of 3,000 to 10,000 cycles before failure, compared to 100,000 cycles in a normally loaded spring.

You can get the feel of spring surging from a simple experiment using any of the AR-15 series (M4/M16, etc.). First, check the weapon to assure there is no ammunition or magazine present. Draw the bolt & bolt carrier to the rear and latch it there using the hold back latch. Shoulder the weapon with your cheek firmly against the buttstock. Point the weapon in a safe direction, depress the release button on the hold back latch and allow the bolt assembly to fly forward. After the bolt slams home, you’ll hear and feel the surge waves traveling up and down the main drive spring housed below your cheek.

Shock loads from firing are highest when they are in line with the firing barrel, so spring orientation on weapons is important. High shock loads can affect the spring so that it doesn’t give the right load at the right time and, as Mauser found, these springs are also more prone to failure. You may agree this is all common sense, but all too often springs are aligned with the gun barrel when the mechanism could have been designed with the spring perpendicular to it.

When springs are highly stressed beyond what is termed the elastic limit of the material, they have reached the point where the deflected metal does not spring back completely to its original shape. Springs that reach the elastic limit become noticeably shorter and are unable to reach the same level of performance as when they were newly installed. Springs that have shortened in this manner have taken what is known as a permanent set and should be replaced to maintain peak performance.

Safety is another consideration that should not be ignored. Springs by their nature store energy. That same energy that is useful in operating the weapon also represents a safety risk during assembly/disassembly. Care should be taken to design the mechanism so springs can’t launch components or themselves to endanger the maintainer. The drive spring of the M1911 pistol, for example, can easily be launched and become dangerous during disassembly and assembly. It is primarily the potential danger from these spring-induced hazards that Operator and Armorer’s manuals carry a warning that safety glasses should be worn during maintenance.

Many firearms are designed with little consideration as to how they will eventually be maintained. For military and law enforcement weapons, where trained armorers will be disassembling the weapon and replacing components, it is unwise to use springs of the same diameter in different lengths. Doing so makes it far too easy for the soldier or maintainer to mix them so they end up in the wrong place. Along these lines, springs that are not symmetric should only be able to be assembled one way—the correct one.

So far we have confined our discussion to helical compression springs since they are the most common and most reliable types used in guns. Round wire torsion springs (mousetrap type) have firearm applications, but are prone to failure from their highly stressed ends. Leaf springs and flat springs are found on guns but also have issues as they are easily deflected to the failure point, either by a snag hazard or by operator carelessness. Generally considered the worst choice among common spring types is the extension spring, or “screen door spring” due to its high failure rate at the loop or hook at the ends. Besides using springs as energy storage devices in gun systems, they are also used to dissipate energy. Buffer springs are purposely designed to convert kinetic energy of motion into heat. Here are some spring types commonly found in firearms:

Helical Compression Springs

To best understand how a helical compression spring works, first consider the torsion bar. A torsion bar is a long straight piece of metal, usually steel, that is held at one end while the other end is twisted. The greater the twist angle, the greater the spring force. The longer the bar, the less torque it takes to twist it. As long as the bar has even dimensions, there will be an even twist all along its length. A helical compression spring works exactly the same way. It is simply a torsion bar wound into a helix and its “springiness” comes from the wire twisting as the spring is compressed.

Provided they are able to be designed to work within reasonable stress levels, helical compression springs are likely to be the most reliable type spring for a gun application. They must be sized and used properly, which includes providing spring guidance. This is to prevent buckling – where the spring moves sideways and longitudinally as it is being compressed. Springs are very prone to buckling when their length is more than four times their diameter. Springs should be supported by a rod or confined to work in a hole to minimize buckling.

Recognizing that most gun springs are overstressed, a good design engineer or reliability technician should take note of the progressive shortening of the springs during endurance testing in order to establish a replacement rate. This information can eventually be incorporated into the operator’s and armorer’s manuals. If maintainers are aware of when they should replace springs, there is a better chance that they’ll do it.

Nested Springs

Another way to maximize the energy capability of a helical spring is by nesting two or more springs, placing one inside the other. For a nested pair, the designer will size the inner spring to take 1/3 the load with the outer spring designed to take the remainder. To avoid interference between coils, one spring is wound left hand and the other right hand. These springs may even touch during use, but a little bit of friction between them is useful in dampening spring surge. Nested springs introduce a maintainability risk because the maintainer must be trained that the application requires more than one spring. By itself, a single spring will not have the required force and system reliability suffers.

Shaped Springs

Helical compression springs in guns are not always made of round wire. In applications that require the spring provide the maximum travel before all of the coils touch at the solid height; a flat wire spring is sometimes used. These usually have to be custom made from specially drawn wire. Shaped springs are prone to buckling and should always be used with an internal guide rod or in a hole.

Stranded Wire Springs

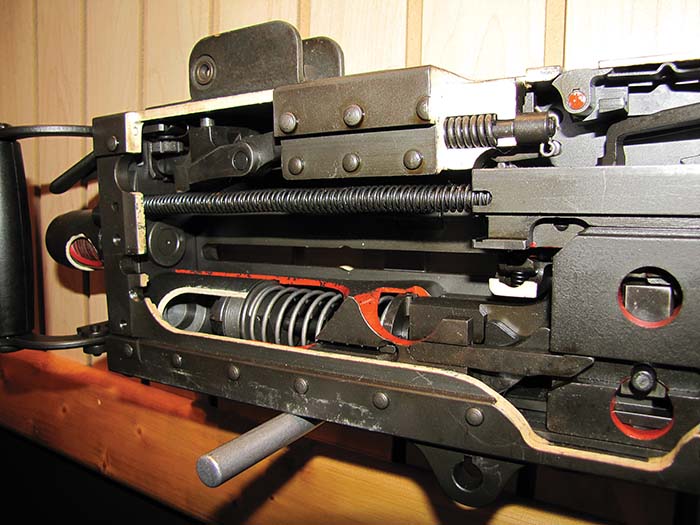

Of the springs discussed thus far, the design objective has been to deflect the spring to store energy and then to gain back as much of that energy as possible. There is a special kind of spring used in guns that is specifically designed to give back slightly less than the full amount of energy, with the balance going into friction. These are called stranded wire springs as they are formed into a helix from a wire made from three or more wires twisted together. During use, the twisted wires develop friction and that friction energy is used to dampen the effect of spring surge. The damping effect is more pronounced at high velocity. Stranded wire springs were first found on the battlefield in Russian machine guns used in the Spanish Civil War in 1936 at a time in history when Spain was receiving aid from Russia. Observers noted these machine gun springs lasted three to five times longer than comparable single wire springs. For a proper stranded wire spring to work correctly, the strands must be wound in the opposite direction to the coils of the spring. If they are not, the twist that develops in each coil will unwind the strands. If there are four or more strands, a center wire is required for the strands to wrap around or else the wrap is unstable.

Extension Springs

Extension springs, or “screen door springs” as they are sometimes called, are rarely used in guns for a very good reason. The coiled ends of these springs are normally folded perpendicular to the spring coils in order to connect the ends to the items being drawn together under the spring load. The stresses are much higher at the ends of the spring, making failure at this point common. Additionally, extension springs are easy to overstress if pulled too far apart, and it’s the operator or maintainer, who is generally responsible for this failure mode.

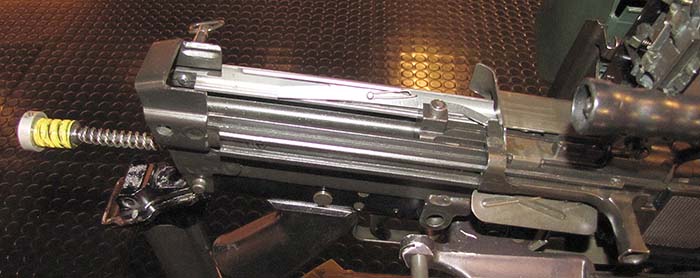

With all of the above in mind, there are some successful applications. The M107 .50 Caliber sniper rifle uses four extension springs as the recoil spring for the barrel. Ronnie Barrett ignored the spring design experts and figured out how to make these work. In his M107, the extension springs don’t have the hooks at the end, but use a separate metal end that is retained by a set screw. A second set screw is used like a jam nut to prevent loosening and loss. Oddly, the screws don’t fall out much and the springs are pretty reliable. The Harris Bipod is another application where extension springs also survive the rigors of combat.

Torsion Springs

The free arm on the helical torsion spring can reach out far from the spring centerline to perform a load or retaining function. The helical torsion spring is also useful in storing energy for rotating components or to sometimes to cushion shock loads in them. Torsion springs are often used in small arms for trigger return springs, and if they are not overstressed and wound carefully they often survive without problems. When they do fail, it’s usually the highly stressed tail of the torsion spring that goes. There are other design peculiarities. The motion to wind these springs must always be in the direction that tends to wind up (tighten) the coil, otherwise the ends coils bend outward and fail because they end up carrying the entire load.

Flat or Round Wire Leaf Springs

In a well-deserved last place for desirability in small arms and medium cannons are the round wire and flat leaf springs. Since they can be overstressed by the user, they are sometimes designed with limit stops to prevent this failure mode. Heavy shock loads from firing can sometimes reach a level to disengage these springs from what they are intended to retain, so care must be taken to minimize their weight.

Non-Circular Helical Compression Springs

Anyone who has ever disassembled a rifle magazine knows that helical compression springs don’t have to be round. Magazine springs are usually formed into a rectangle with round ends and are all too often designed by cut and try. This is unfortunate because it’s relatively easy to design these with the normal design equations for round springs. One need only to calculate the distance around one spring coil of a non-circular spring and determine an equivalent round wire spring with the same circumference. Use the proportions of this imaginary spring with spring design equations to yield final results for the odd shaped springs. Accuracy is generally within 5 to 10% of the actual loads and stresses.

Belleville Springs (Also Called Belleville Discs or Washers)

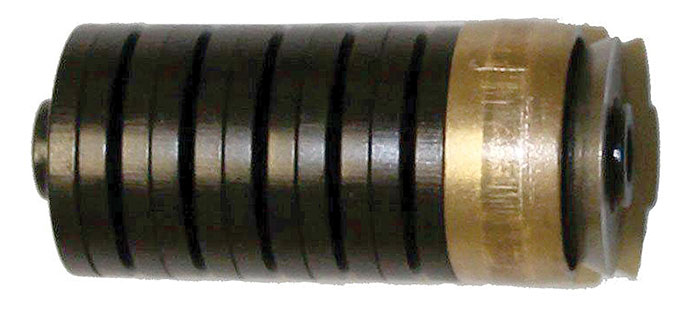

These cone discs are usually stamped from high carbon steel. They are usually held on a rod via a central hole and used for buffering high loads or for taking up a small amount of tolerance (slack) in clamping adjustments. These springs are stiff, having such a high spring rate (stiffness) that most applications require several of them. Since they can be stacked two ways – parallel or series – here’s what happens. When they are in parallel – that is, all the washers stacked in the same direction – they yield double the load of a single washer for the same amount of deflection, triple the load for three washers and so on. When two washers are stacked in opposite direction – or series – the result is double the deflection of a single washer for the same load. Three washers give triple the deflection and so on. Washers can also be stacked in both parallel and series patterns permitting the designer to tailor the properties of the spring stack for the desired combination of load and travel.

Belleville springs are often used as buffers with the friction between the mating surfaces converting spring energy to heat, dampening the load. They are relatively reliable but do have features that make them undesirable for gun systems. Due to their nature, Belleville washers are heavy. This is not only because of the large number of springs needed, but also because of the rugged support housing and guide rod required. Belleville springs are subject to metal fatigue and failures are usually slow but sure. Realizing the Belleville pack is not functioning because of a failure is generally after other gun parts have already been damaged. Since Bellevilles are normally housed and well-secured in a rugged tube that is packed with grease, it’s not easy or pleasant to inspect them. Belleville springs are also a nuisance to service. The armorer must be trained to stack these springs correctly when replacing them; otherwise the spring rate will be totally incorrect. Since there are always multiple stacking possibilities, this translates into a lot of ways of replacing them incorrectly.

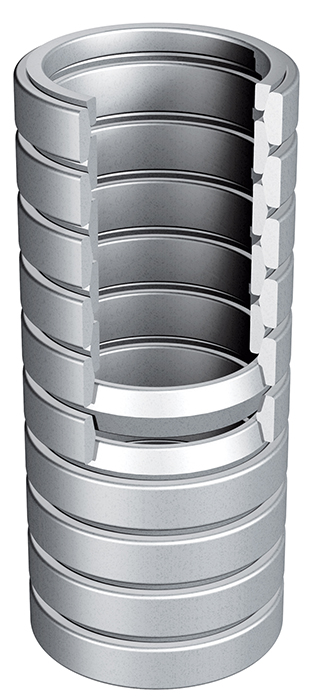

Ring Springs

Patented in the 1920s by German inventor Ernst Kreissig, the ring spring is an unusual design, with limited weapon applications in recoil buffering systems of aircraft cannons and heavy machine guns. The ring spring is so efficient in absorbing energy; it gives back only about 1/3 of what it takes in.

Ring springs work in pairs, with an inner ring spring that nest in an outer ring spring. The inner ring has an angled surface on the outside diameter and the outer ring has a mating angled surface on the inner diameter. When an axial load is applied, the mating angled surfaces cause the inner ring to get smaller while the outer ring grows larger. The tremendous amount of friction generated between them is responsible for the large amount of energy transformed into heat.

Ring springs are designed to be well-lubricated as they work, so they are usually packed in a sealed housing. They are easy to design correctly and failures are rare. If they do break, they can continue to function, but with much less energy absorption. A stack of ring springs can easily tilt in the assembly if the load is removed fully, so for that reason they are always used with a preload – a fixed amount of compression that exists even when these springs are not in use. This preload amount is at a minimum 4,000 pounds (1,800 kg), so extreme care must be taken during disassembly and maintenance. Ringfedern, a manufacturer of ring springs, and the brand most commonly used in gun designs, has this warning in their manual:

Rings in spring cartridges without pretension components must only be transported and stored when protected in a casing. To prevent jammed rings from being forced apart explosively by the stored energy (Caution, Danger), they can only be released within a safety enclosure by hitting the rings with a hammer stroke, after the rings have been carefully tied up with a strong rope.

Design Considerations/Conclusions

It is difficult and sometimes impossible to correctly design a spring for a gun, and every time a new one is introduced, it lowers the overall reliability of the system. Experienced engineers minimize the number of springs and approach their design with caution. Mr. Bob Chiabrandy, Staff Engineer at GE’s Armament Systems Department, had a knack for producing simple gun designs with minimal parts and few springs. During one design project I recall him telling me: “When I’m forced to use a spring, I make sure it does more than one job.” It would take Bob a little bit more time to think through his design approach, but when he would specify a bolt drive spring, for example, you could be sure this spring was also serving to retain a takedown latch, anchor the backplate, or perform some other task. All of Bob’s gun designs were like this – a minimum number of springs, the same spring used in multiple locations, and size variations that left no doubt in the operators mind as to their proper location in the design.

| This article first appeared in Small Arms Review V17N3 (September 2013) |