By Charles Q. Cutshaw

Automatic grenade launchers (AGL) have been a mainstay of light infantry support weapons since the Vietnam War when the US Navy’s 40x53mm Mark 19 was introduced for use in riverine warfare operations in the Mekong River delta. Since then, there has been a number of first generation 40mm AGLs produced. All are similar in concept, are relatively heavy with an overall system weight of 50 kg or more and all have relatively simple optical sights. Saco Defense, however, is in the final stages of development of what promises to be the next generation of AGL. This new AGL, called Striker, is presently under consideration for adoption by US special operations forces and will shortly be available for international sales. SAR’s intrepid reporter was recently afforded the opportunity to be the first journalist to actually fire the Striker at Crane Division, Naval Surface Warfare Center, where the weapon is undergoing test and evaluation by the US military.

The Striker was developed as a private venture by a consortium consisting of Saco Defense (gun and overall system integration), Computing Devices Canada (fire control) and NAMMO Bofors (programmable ammunition). The overall design goals for the weapon were to develop a new generation 40mm AGL that provided improved lethality and suppression capability, significantly lighter weight, enhanced reliability and increased lethality, combined with reasonable cost. It was with these goals in mind that we approached our informal evaluation of the Striker.

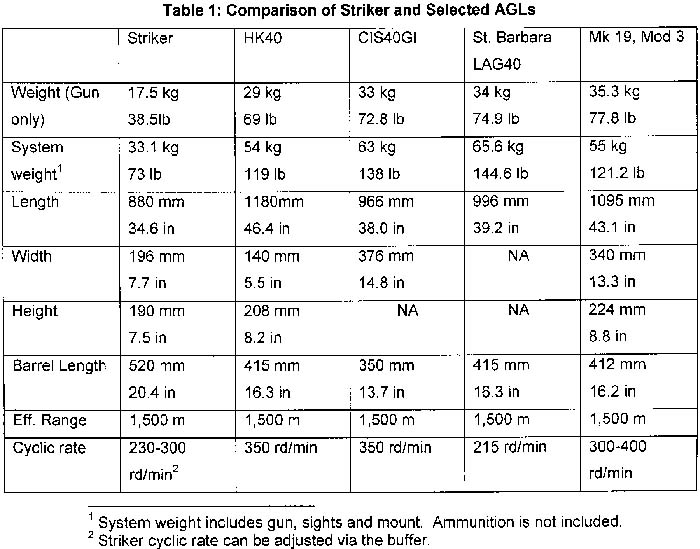

There are several features that differentiate the Striker from all other currently available AGLs. The Striker is considerably lighter than any other currently available AGL. The Striker has a computer controlled fire control system developed by Computer Devices Canada that not only automatically sets superelevation and windage, but also programs the air burst munition developed by Nammo Bofors and significantly enhances the probability of a first burst hit. We will discuss these features in detail below. Table 1 provides a comparison between Striker and currently available 40mm AGLs.

The Striker operates via delayed blowback using a toggle mechanism to delay bolt opening sufficiently long for pressures to drop to a safe level. Saco did not allow photography of the interior of the Striker at this point due to patent sensitivities. We were, however, permitted to examine the gun’s interior and field strip it. The overall simplicity of the Striker and its ability to be field stripped, to include barrel removal, without the use of tools is impressive. The Striker fires from the closed bolt and is fed from a standard disintegrating link belt via a sprocket driven by the recoiling parts. Ejection is straight down. The round counter on the gun we tested indicated that it had fired nearly 20,000 rounds. According to Saco representatives and Crane personnel, overall weapon performance has been excellent and will equal or exceed that of the Mark 19.

The reader will note that the “full-up” Striker with fire control and tripod in place weighs less than the gun alone in some other available systems and weighs dramatically less than any other currently available AGL configured with sights and tripod. Striker’s weight saving has been accomplished in several ways, while at the same time reducing recoil by 60 per cent compared to that of the Mark 19. The toggle link delayed blowback system, for example, allowed bolt weight to be reduced by 11lb (5kg) in comparison to that of the Mark 19. Toggle link delayed blowback has been widely used in the past and is in itself no great technological breakthrough, although its use in Striker is an ingenious application of the technique. A second factor that reduces recoil is the bi-directional hydraulic buffer that operates in both recoil and counterrecoil to reduce felt recoil and stabilize the gun. The buffer, which acts as in internal soft mount, can also be adjusted to vary the Striker’s cyclic rate from approximately 230 to 300 rounds per minute.

All unstressed components of the Striker are made of either light alloy or polymer. The receiver of the Striker, for example, receives little stress and is made of aluminum, while the top cover receives no stress whatsoever and thus is of polymer. The reciprocating components ride on steel rails in the receiver. In comparison to the Mark 19, the total number of parts in the Striker has been reduced by 33 per cent. Essentially, the entire Striker system was developed by innovative application and integration of existing technologies. This not only helped to achieve the weight and reliability goals, but also enhanced the achievement of cost goals. The Striker is light enough that the entire system can be easily carried and placed into action by a two-man crew, although a third man is desirable to carry the 40mm ammunition. The lightweight tripod collapses into a very compact and convenient package for transportation. Extending or collapsing the tripod takes only a matter of seconds.

The Striker is fully STANAG compliant and fires all standard 40x53mm ammunition, although the system is optimized for the programmable air burst munition. The Striker is made to be as safe as humanly possible for the user. The manual safety is configured in such a way that its position can be determined by touch. The weapon will not fire if the barrel or buffer are incorrectly installed. The backplate cannot be removed if there is a round in the chamber. Since removal of the backplate is necessary to field strip the Striker, the gun thus cannot be disassembled while loaded. In addition, the firing pin is blocked until the bolt is in the fully closed position. Short recoils are precluded by a ratchet mechanism. As previously stated, the gun has a built in round counter to indicate scheduled maintenance.

Another innovative element of the Striker is the weapon’s computer controlled fire control system, which allows the gunner to achieve a high percentage of first burst hits, rather than having to “walk” rounds onto the target as required with other AGLs. The 8x-magnification sight uses video image processing and ballistic computer technology to enhance target acquisition and first round hit probability. The sighting system also allows Striker to achieve a greater effective range than current systems. All current systems have an effective range of approximately 1,500 meters, but Striker’s effectiveness is multiplied by its accuracy. The sight incorporates a Gen III Image intensifier for night operations. The computer provides a full ballistic solution, can be used with virtually any 40x53mm cartridge, has air temperature and barometric pressure sensors, automatically compensates for ammunition temperature, senses cant and angle and is self-testing. In practice, all the gunner has to do is range the target using the sight’s laser range finder to designate his target. He then moves the corrected sight aim point to coincide with the target he has designated and the weapon can then be fired with virtual assurance of a first burst hit. The computer automatically computes superelevation, the weapon’s elevation angle above the line of sight to ensure that the projectile hits the target. Not only is this system simpler to use, it allows targets to be engaged much more quickly than with any existing system. In addition to rapid target engagement, the ballistic computer provides the ability to predesignate up to eight targets and store them in the computer’s memory. These targets may subsequently be engaged regardless of optical conditions. The ballistic computer further allows the gunner to prepare electronic range cards with lateral limits to automatically prevent engagements outside the range “fan,” although this feature can be manually overridden. Future upgrades to the computer fire control system include automatic calculation of the speed of moving targets and incorporation of a global positioning system into the fire control computer to allow automatic indirect firing.

The ballistic computer also provides a direct interface with the programmable ammunition developed by NAMMO Bofors. The programmable ammunition, while extremely innovative, again is manufactured using a maximum number of available components. The warhead, for example, was designed by Diehl with Bofors fuzing that provides air burst, point detonation and self-destruct, while the propulsion element is a standard NICO component. As ammunition is an integral element of accuracy, along with the gun itself, NICO’s propulsion system is specifically designed for low dispersion. The NICO cartridge case to projectile interface is threaded rather than crimped to provide a consistent release at a predetermined pressure to reduce dispersion. The air burst warhead is electronically programmed by the ballistic computer just prior to firing as the rangefinder determines the range and computes the trajectory and time of flight to the target. Use of an air bursting munition allows engagement of targets in defilade or behind obstacles. The lethal area of the 40mm air burst round is approximately 100 square meters.

Our overall firing impressions of the Striker were extremely favorable. We fired the weapon from a pedestal mount and found it to be easy to control and pleasant to shoot. We were able to use the computer fire control to quickly engage targets after only a few minutes’ orientation and “dry firing” practice. The cyclic rate was set to approximately 230 rounds per minute, allowing easy burst control or even single shots if desired. We were consistently able to achieve first round hits with the Striker by simply engaging the range finder, matching the gun to the sight’s indicated point of aim and pressing the trigger. With very little additional training, we could easily have made use of the remainder of the fire control unit’s sophisticated capabilities. We fired two containers of 48 rounds each without incident. The first rounds in each burst hit precisely where we aimed, with the remainder of the burst clustered closely around the initial hit, consistent with Saco’s dispersion claims. Had we been firing high explosive rather than training rounds, we could have easily destroyed hardened targets with very few rounds. We did not notice any appreciable recoil through the “hard” pedestal mount; had we been firing any other AGL, an external “soft mount” would have been a virtual necessity. Striker’s inherent low recoil and light weight will assuredly simplify adapting the weapon to vehicle mounts. We did not fire the Striker from the lightweight tripod ground mount, but given the lack of felt recoil on the rigid pedestal mount and Striker’s internal soft mount, we believe that the eight pound (3.6kg) tripod will sustain the weight and recoil of the gun.

In sum, we liked the Striker. We tend to approach all manufacturers’ claims with a very jaundiced eye, but in the case of the Striker, our “hands on” experience, albeit brief, indicates that the weapon will probably live up to its claimed performance levels. In closing, we should point out that the Striker is not yet a fielded system. It is undergoing final developmental testing and is currently scheduled to enter production in late 2000 with initial deliveries shortly thereafter. In Europe, the Striker is sold by Bofors/Carl Gustav as the CG40. In the remainder of the world, except Canada, it is sold by Saco under the Striker name. Canadian sales are handled by Computing Devices Canada. Those seeking further information on this system should contact one of these firms.

| This article first appeared in Small Arms Review V3N6 (March 2000) |