By Ronaldo Olive

From the window of my plane in the commercial flight en-route to Lima, the sight of the dark blue waters of Lago Titicaca (the world’s highest navigable lake, right on the border between Bolivia and Peru) was one more breathtaking scene of the equally majestic Andes Mountains that I tried to record in my mind. Photographs alone could hardly match the sensation of actually being there, and I couldn’t help imagining how it would have been in the time of the native pre-Columbian civilizations which existed for over 5,000 years. Their Apogee was reached by the Incas in what is now Peru around the year 1500, only to be drastically brought to a bloodstained end, following the arrival of Spanish “Conquistador” Francisco Pizarro in 1532.

Although a great portion of the passengers on my flight from Brazil were clearly foreigners eager to visit such traditional places as the ruins of Machu Picchu, the cities of Arequipa and Cusco, and the intriguing Nasca Lines (colossal figures of animals and constellations traced on the ground and only clearly perceptible when you fly above them!), the purpose of my visit was not so touristic and/or esoteric. Pretty much on the contrary, my objective was to test fire and learn about submachine guns of indigenous design and manufacture. Yes sir, the Peruvians do have a local small arms production capability!

For the record, domestic firearms construction in that South American nation had already been tried in the early 1950s, when American designer Gordon B. Ingram (better known by his compact, fast-firing M-10/M-11 series SMGs) established the local “Fábrica de Armas Los Andes”. The aim was to series-produce his .45 ACP caliber Model 6 submachine gun under license from Los Angeles-based Police Ordnance Company. It’s not clear how many examples were actually assembled in Peru.

It would take about twenty more years for the Peruvians to think about making guns again, and that time they decided to go ahead and contrive a national product. Oddly enough, incentive for this effort came in the mid-1970s at what was then the “Departamento de Armas del Arsenal Naval” (Weapons Department of the Navy Arsenal), at the Callao Naval Base, adjacent to the capital city of Lima.

That establishment was primarily in charge of maintaining and repairing Peruvian Navy armament of all types. Its CO at the time, one Captain Benvenuto, boldly decided they should contemplate actual manufacture of small arms. A project group was put together, and this allegedly also included an Italian and an Argentine designer. As it has frequently happened in countries deciding to establish a domestic firearm production capability, a subgun was chose as the initial product. This comes from the fact that this type of weapon is intrinsically simpler to design and cheaper to make than, say a good revolver or rifle.

A prototype was ready for testing by 1979, and later showed to be good enough to justify series manufacture. At about the same time, the SIMA-CEFAR organization was established, SIMA standing for “Servicios Industriales de la Marina” (Navy Industrial Services), and CEFAR for “Centro de Fabricaciones de Armas” (Weapons Manufacturing Center), whose responsibility would be making and marketing the guns.

As it should be expected, moving from a couple of working prototypes into series production status is no simple task, much more so in a country with very limited financial and industrial resources. Skilled technicians had to be trained and adequate tooling procured from different sources, and all this resulted in the production of the first domestic Peruvian submachine gun, the MGP-79, starting around 1983. Something like 16,000 guns were made through about 1985, all being supplied to the local Police and Armed Forces.

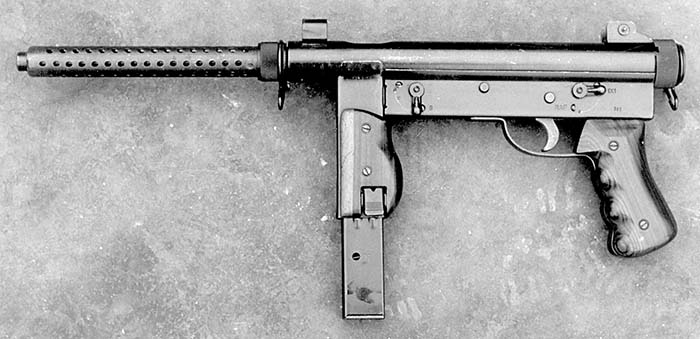

The MGP-79

MGP stands for “Marina de Guerra del Peru” (Peruvian Navy), and this first model is a stockless weapon which operates by conventional blowback action and, like all subsequent members of the family, is chambered to fire the popular 9 x 19 mm cartridge. The receiver is a conventional tubular structure, to the fore end of which is fastened the 240 mm-long barrel (12 micro-grooves, RH twist) by the collar of a perforated jacket. The similarly-cylindrical bolt with a fixed firing pin and its corresponding recoil spring assembly (guide rod and buffer) are inserted into the receiver from the rear end, which features a screw-on cap.

Following a configuration common to many of the so-called second-generation SMGs, pioneered by the German MP38/MP40 series of WWII fame, the long magazine housing is well forward under the receiver, and doubles as a vertical fore grip. Wooden panels, with a marked protuberance at the rear, were originally employed here, but later examples featured straight synthetic panels. The magazine catch, found on the lower left side of the housing, is a square button fashioned after the one used in the Uzi family of SMGs. The 20- and 32-round box magazines also come from the Israeli design, being of the staggered-row, two position feed type.

The firing mechanism proper is contained within a stamped, rectangular lower body affixed to the receiver. The pistol grip is an integral part of this assembly, and may also be encountered with wooden or plastic panels, both types with conspicuous finger grooves.

Shooting Impressions

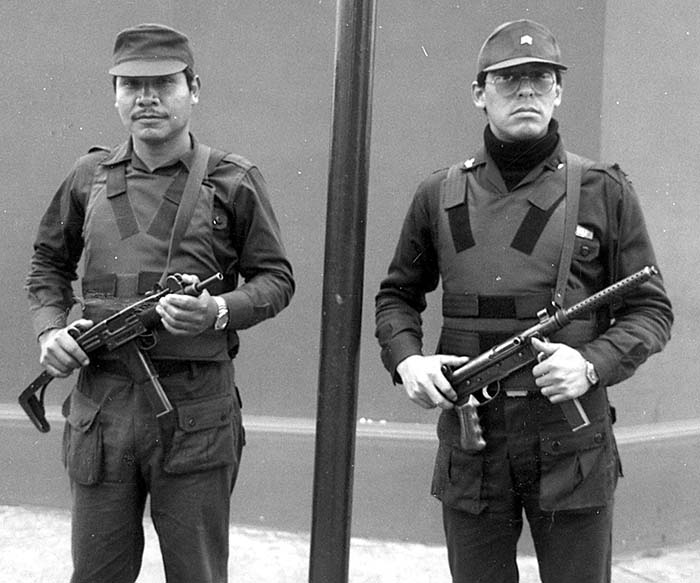

The most cooperative staff of SIMA-CEFAR was kind enough to allow me to carry out a hands-on evaluation of the MGP-79, an event which took place at one of the many combat training ranges at the Callao Naval Base. My host for the occasion was Captain Daniel Quiróz, then Marketing Officer of that organization. On our way to the test site he drove past several training areas where I could see a number of “Marina de Guerra” (Navy) and “Infanteria de Marina” (Marine Corps) combat teams hard at work. Instructors and trainees alike displayed an outstanding degree of professionalism, which should come as no surprise to anybody in view of the fact that both the local Military and the Police share responsibilities in anti-terrorist and anti-drug operations. The guys I saw there were not merely following a course schedule, but rather, learning or drilling how to survive in real-life combat and assure their opponents … don’t!

At 3.3 kg with a loaded 32-round magazine in place, the MGP-79 is well within the weight range of typical second-generation SMGs. My individual taste does not favor inserting the magazine into a housing too far forward in the gun, I favor those just ahead of the trigger guard (H&K MP5-style) or, even more, within the main grip (Uzi-style). As usual, tapping the bottom of the magazine after insertion makes sure that it is in place and held by its catch.

Applied safety and fire control are performed by two distinct levers on the left side of the gun body, which leaves a lot to be desired in terms of ergonomics. A single lever is certainly preferred, mainly under the usual stress of combat. Just above the main grip and within satisfactory reach of the right hand’s thumb lies the fire selector. In a 90-degree arc, settings are semi-auto (curiously marked “1×1”), to the rear, and full-auto (marked “RAF” for “Ráfaga”, or Burst). The applied safety lever, which blocks the bolt either in the closed or open position, is located on the left side, near the magazine housing. It can be flawlessly manipulated with the thumb of the left hand, and settings are “F” (“Fuego”, or Fire), forward, and “S” (“Securo”, or Safe), down.

The cocking piece is a knob protruding 90 degrees to the right side of the weapon, so if you are right-handed and don’t want to lose your grip when actuating it, just turn the gun slightly towards its left side, and use the supporting (left) hand, instead. As an additional precaution against accidental discharges, the retracting handle can be pulled to the rear and hooked up into a vertical notch in the receiver, a simple and long-established method.

As mentioned earlier, the design parameters for the MGP-79 surprisingly did not call for any kind of buttstock, which might well be an indication that its intended operational use was only CQC (close-quarters combat) or any other actions (I wonder what) not requiring too-accurate fire. In contrast, however, decent adjustable sights are provided. The rear unit is a flip-type, two-position (100 and 200 meters) V-notch, while the front sight is a hooded blade, radius being a reasonable 260 mm.

The example I used in my test was in excellent condition and was marked with serial number “383” (definitely an early production weapon) and “FAP” (“Fuerza Aérea del Perú”, or Peruvian Air Force). Although it came with sling swivels at the rear and forward ends, regretfully the sling itself was missing, as it would have made a good additional support for more precise shooting. Anyway, the “opposition forces” at hand were simply empty plastic bottles, soda cans, and broken wooden crates spread around the sand bank I was shooting at … and, most fortunately, they didn’t return fire!

Range was in the region of 50 meters, more than realistic for submachine gun use, and the stockless MGP-79 still allowed me to concentrate most of my semi-automatic and automatic fire on the “enemy” in such a way that heavy casualties among them would have been expected. Firing from the waist, assault-style, shot convergence both with short and long bursts was pretty much satisfactory.

The supporting hand was alternately used to hold the vertical fore grip (magazine housing) and to grasp the barrel sleeve well near the muzzle end, the latter proving more effective for speedier turn-around movements, like would have been required for the engagement of multiple targets. The insulation provided by the perforated jacket was barely enough to protect my hand from the moderate barrel heating generated by my brief scuffle with the bottles.

But there’s a trick with the MGP-79: its ejection port is located right on top of the receiver. Although the “formal” ejection path should take the empty cartridge cases up and forward, I had the annoying experience of seeing (and feeling!) some of them hitting my shooting glasses a number of times, mainly when I fired the gun from a lower position. Were it shouldered (had it a stock!), the brass would probably fly inoffensively over the shooter’s head. That is one design snag.

Cyclic rate of fire averages about 700 rounds per minute, a reasonable figure, and proper trigger manipulation allows one to squeeze out two- and three-round bursts (and even single shots, with a little more familiarization time) in full-auto setting. I tried some single-handed firing, as this may eventually be required in an emergency, but found it not practical, mainly as a result of the main grip being too far back from the gun’s center of gravity. For my small build, it was far from effective beyond short ranges, but maybe Rambo and others of his species would find it a piece of cake…

Design improvement

The shortcomings I noticed during my relatively brief shooting session at Callao obviously also called the attention of the MGP-79 users as time passed and operational experience accumulated. Although the weapon’s reliability as a whole was generally praised, there were complaints regarding the barrel’s limited resistance to high volumes of fire. What would in our days be called a PIP (Product Improvement Program) was eventually carried out by SIMA-CEFAR, the result being the MGP79A/MGP-87 series of buzzguns, which entered production in 1987.

MGP-79 Technical Specification:

Cartridge: 9 x 19 mm

Operation: Blowback, selective fire

Feed: 20- or 32-round detachable box magazine

Weight: no magazine: 2.65 kg, 32-rd magazine: 3.25 kg

Overall length: 526 mm

Barrel length: 240 mm

Cyclic rate of fire: 700 rounds/min

| This article first appeared in Small Arms Review V2N3 (December 1998) |