By Philip H. Dater, MD

For the past 30-plus years, the name Curtis Higgins and S&H Arms of Oklahoma, Inc., have been at the forefront of quality machine gun conversions of Heckler & Koch (HK) semi-auto rifles and carbines. The business started in 1986 manufacturing thousands of registered HK autosears prior to the May 19, 1986, ban on new machine guns and conversions. Since the 5/19/86 Day of Infamy, Curtis and his company have converted innumerable HK 93, 91 and 94 rifles into fully transferrable select fire versions of the models 33, G3 and MP5 (for more info: curtis@sandharms.com). While several other manufacturers also made the autosears, the S&H conversions were coveted due to the flawless cosmetics and functioning of the weapons. S&H was also known for its autosears for the FNC and, to a lesser extent, autosears for the Ruger 10/22. To this day, S&H is known as the premier gunsmithing facility for HK machine guns.

1986 also was the year S&H entered the suppressor market with MP5 muzzle suppressors, HK MP5SD integral suppressors and a variety of integral rimfire suppressors for Ruger .22LR weapons, the Ruger 77/44 and the Marlin .45 Camp Carbine. Curtis licensed his integral Ruger rimfire designs to John’s Guns.

Small Arms Review recently received S&H’s latest suppressed weapon, an integrally suppressed upper receiver chambered for the popular AAC .300 Blackout cartridge, an improved version of the SSK .300 Whisper originally designed by J.D. Jones.

Designed for a 9-inch barrel, the .300BLK’s popularity has risen dramatically due to the simple conversion of the AR-16/M16 weapons simply by changing the barrel with its associated gas block. Even the M249 belt-fed machine gun is set up for this cartridge. For many purposes, the .300BLK cartridge is ideal: .30 caliber bullet, short barrel, subsonic and supersonic loadings with bullet weights ranging from 110 grains to 220 grains. The loadings using bullets 150 grains or less are supersonic while those with the heavier bullets are generally subsonic.

The S&H Model 30 is a complete assembly consisting of an integrally suppressed upper receiver with an overall length of 28.8 inches and a ported 16-inch, 1:5 barrel. The ports bleed excessive propelling gas into a sealed chamber in the rear of the suppressor. It weighs 89.7 ounces (5.6 pounds). It utilizes the bolt, charging handle and lower receiver of the user’s AR-15 or M16. For our evaluation, we used a Bushmaster select fire AR-15 lower receiver with a standard buffer intended for 5.56 weapons.

The unit is a conventional direct impingement gas system which mounts easily on an AR-15 or M16 lower receiver using the bolt assembly and charging handle from the host weapon. The handguard has a full-length Picatinny rail and has as standard equipment easy-to-use, flip-up sights. The 1.5-inch-diameter suppressor outer tube extends rearward over the barrel over 15 inches back to the gas block and approximately 5.5 inches forward of the muzzle. The baffle stack in this forward section contains five conventional baffles. The exit hole in the front end cap is configured to use a standard 3/8-inch hex wrench for disassembly. The large chamber surrounding the barrel is fed by four ports in the barrel several inches forward of the gas port. This permits proper usage of this chamber rather than relying on reverse gas flow at the muzzle.

The entire suppressor can be disassembled by the user for cleaning and maintenance. The only tools needed are a 5/32-inch hex wrench for the handguard and a 3/8-inch hex wrench for the front end cap. For total disassembly, a special spanner wrench from S&H is needed to loosen the retaining nut that tightens the suppressor outer tube onto the threaded barrel end. Removal of the baffles and spacers from the front section is somewhat tedious. Unlike firearms with moving parts, suppressors generally perform better if they are not cleaned (with the exception of rimfire suppressors). From the writer’s experience examining suppressor designs, it is estimated that performance degradation will not become apparent for many tens of thousands of rounds, and cleaning is not recommended.

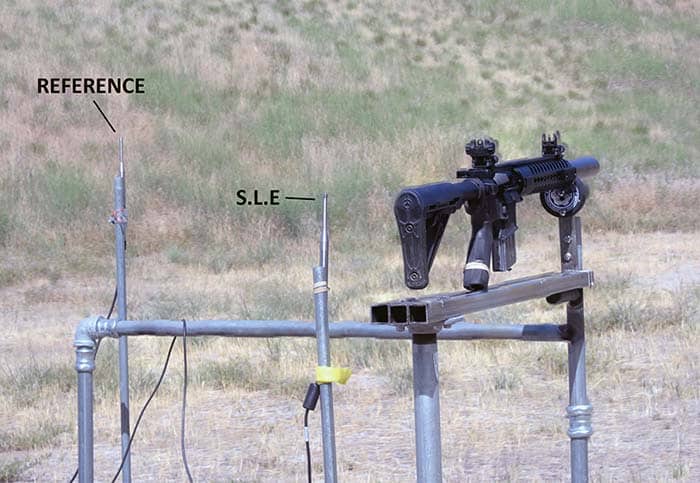

Of major interest to users is the sound performance of the system. Sound measurements were made in compliance with MIL-STD-1474D (Section 5). Two Larson-Davis model 800B sound level meters were used, each with its Larson-Davis model 2530 random incidence ¼-inch instrumentation microphones. These are compliant with rise/response times less than 20 microseconds. Measurements were made at the reference location (one meter left of the muzzle 90º to bore axis, 1.6 meters above grass) and at the simulation of the shooter’s left ear (SLE, 8cm rearward of the receiver, 18cm left of bore axis). By using two sound meters, it is possible to obtain both location readings for each shot. Because MIL-STD permits the use of weighting and because weighting is the industry standard, measurements were made utilizing C-weighting.

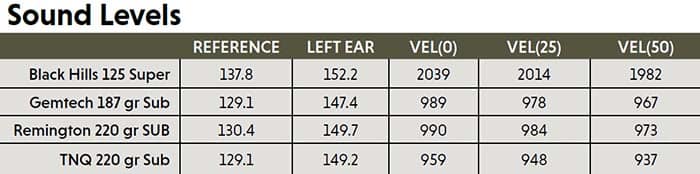

Five rounds of 125-grain Black Hills supersonic, five rounds of Gemtech 187-grain subsonic, five rounds of TNQ 220-grain subsonic and five rounds of Remington 220-grain subsonic ammunition were used, and the results averaged. In addition, velocity was measured both at the muzzle and at 25 yards using a Labradar radar chronograph. Velocity at greater range was not possible due to constraints of the range used. Sound levels and velocities are shown in Table 1.

While performing sound testing, several malfunctions were noted with the Gemtech 187gr, the TNQ 220gr and the Remington 220gr subsonic ammunition. The 125gr Black Hills supersonic functioned flawlessly. Because of malfunctions with the subsonic ammunition, high-speed video was taken, concentrating on the ejection port to document actual bolt travel and rearward bolt velocity. Video tests were performed on a 3-shot burst with the camera operating at 10,000 frames/second. The TNQ 220-grain subsonic was not photographed due to having only enough ammunition to perform sound and velocity measurements. The high-speed video of the bolt opening showed normal rearward travel with the supersonic ammunition but only approximately 66%–75% rearward travel with the subsonic ammunition. Opening bolt velocity was 3750mm/second with supersonic ammunition and less than 2,000mm/second with subsonic. The subsonic bolt travel was enough to permit case ejection at the 4 o’clock position but not enough to feed the next round from the magazine.

Sound levels with all varieties of ammunition tested were below 140dB at the reference location with the subsonic ammunition showing averages around 130dB. Readings at the shooter’s left ear location were in the upper 140dB region, probably due to some ejection port noise and gas leakage in the region of the gas block. Supersonic readings were somewhat higher than subsonic. The reference location is a good indicator of perception by the target in the far field.

Velocity readings were as anticipated for the ammunition used. All subsonic ammunition had a muzzle velocity just under 1,000 feet/second, and all exhibited a drop of approximately 50 feet/second at 50 yards. The Remington 220gr subsonic exhibited the greatest round-to-round variation in velocity with a standard deviation of around 30. The TNQ 220-grain subsonic showed the least variation.

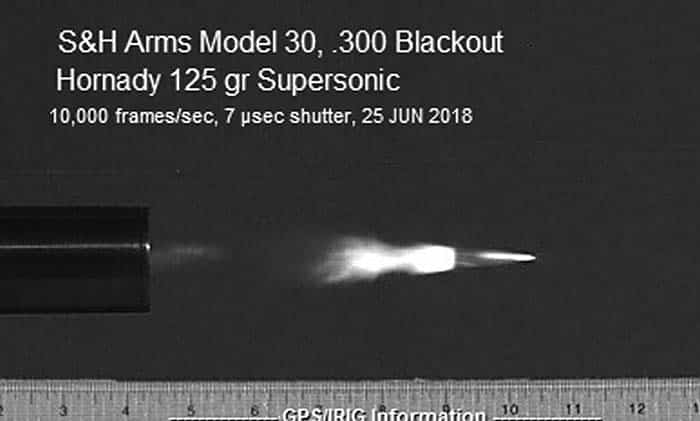

Quantifying flash requires a light meter capable of holding the intensity of the single brightest light peak. Lacking access to such a meter, there are two methods of evaluating flash: long camera exposure (about 1 second) on a dark night or high-speed video. High-speed video offers the option of performing filming in daylight with a black background for contrast. It also offers the option of looking at bullet stability. With a ruler in the field of view, a reasonable estimation of the intensity can be made. Figure 5 is the single frame showing the greatest amount of flash.

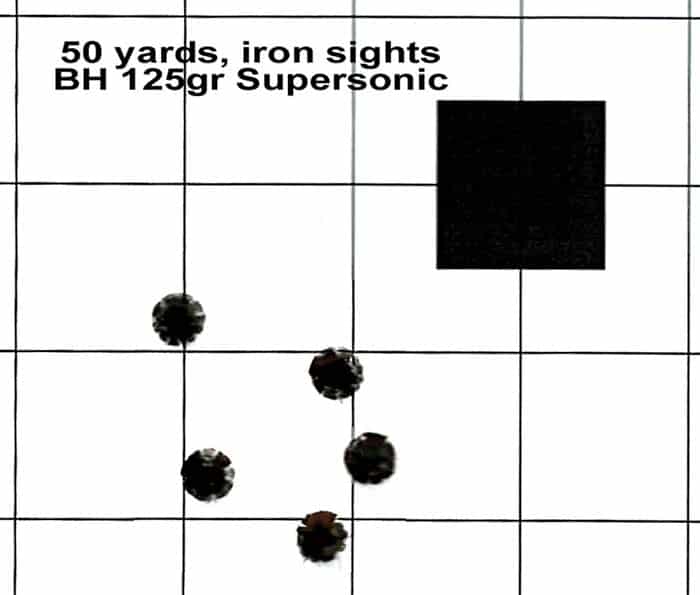

Firearms have little value if they are not accurate. A lead-sled was used as a bench rest, and a target was shot at 50 yards. It was decided to utilize the Black Hills 125gr supersonic ammunition because its greater kinetic energy is most likely to be used for neutralizing targets. The supply of this load was limited without enough to zero accessory optical sights. As a result, the flip-up iron sights on the weapon were used. The front post (.058 inch) is approximately 6MOA wide. The group size is under 3MOA (target grid is one inch).

In all, SAR’s testing of the S&H M30 integrally suppressed upper receiver was very positive. While it is a larger suppressor, it is also very successful for 300BLK suppression and accuracy. Curtis should be proud of his continued success in providing a good product for the end users.

This article first appeared in Small Arms Review V22N9 (November 2018)