By Mark White

The Use of Sound Suppressors on High-Powered Rifles: Semester 1

It should be stated at the outset that the phrase high-powered will cover those fairly efficient, non-magnum cartridges bracketed between the .223 and the .308 – the workhorses of the law-enforcement and military community. If one is going to suppress a sniper rifle, that rifle should be totally dedicated to suppressed fire. Using a rifle which is only occasionally silenced is an invitation to either a lawsuit or to poor field shooting, as any rifle will carry a different zero without a suppressor, as opposed to its zero with one.

A suppressed rifle should be stored and carried in its assembled, ready-to-go configuration. Many of us have seen movies in which a fitted case full of components (stock, action, barrel, forearm, scope, mount and silencer) was assembled in the field, and then used to complete an important assassination. Pure Hollywood. No enforcement officer in his right mind would ever assemble a rifle on the spot on a callout at a crime scene and expect the weapon to hold its zero. It might, but such an occurrence would be an abnormality. And what would be the moral and legal consequences of a botched shot in a hostage rescue attempt? By the same token, some suppressors cause shots to stray with various degrees of tightness or looseness on a rifle’s barrel.

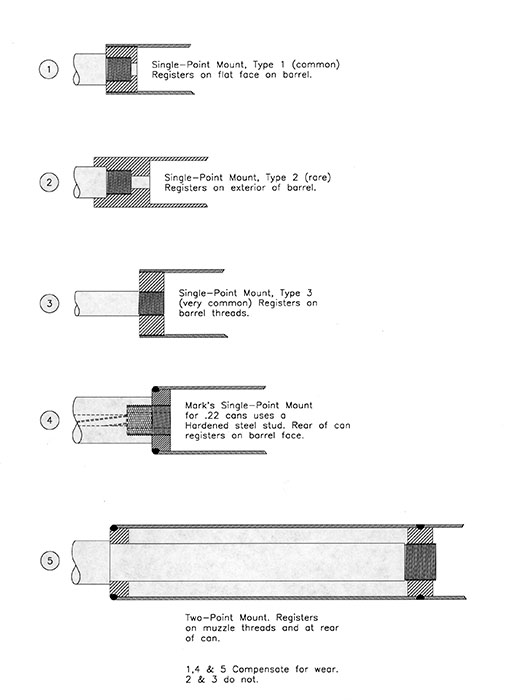

The Single-Point Mount

The muzzle and a massive outpouring of high-pressure propellant gas are the last things a bullet feels before it leaves the control of the shooter. The joint between suppressor and barrel should be as rigid as that between barrel and action. Often, the suppressor/barrel interface is conceived as an afterthought. The muzzles of most military barrels are fitted with small, steel flash hiders, weighing but 2 or 3 ounces. Many manufacturers try to use the same kind of short, 1/2 inch diameter, threaded muzzle sections to mount suppressors that might weigh up to 4 pounds. It may be convenient to use flash hider threads, but such a tiny joint is very fragile, and lacks the strength and stability expected of a military or enforcement weapon. A small error in machined accuracy on a single-point mount can result in a disastrous misalignment problem near the muzzle of a suppressor.

A suppressor that is held at the rear by a single collet, or by a single section of threads, is said to be held by a single-point mount. If the threaded section is only 1/2-inch in diameter the strength factor is very low. If a heavy target barrel is used, the threads can be as large as 3/4 or 7/8 inch in diameter. In this case, the strength and stability factor is much improved. Unfortunately, many suppressed rifles with single-point mounts suffer from a wandering zero. There is, however, a better way.

The Two-Point Mount

The two-point mount usually attaches a barrel to its suppressor with threads at the muzzle, and with a collet, O-ring, or conical joint about 8 or 10 inches behind the muzzle. It is a vastly superior way to mount a muzzle can to a rifle barrel. The resulting joint is many times stronger than any single-point mount could ever be. Because of the geometry of a two-point mount, a small error in alignment will not progress into a much larger error at the suppressor’s muzzle.

The common configuration has threads at the barrel’s muzzle, and the step for the rear of the can near the middle of the barrel. Tightening puts the suppressor in compression, and the barrel in tension – which we feel is the most conducive to accuracy. Another configuration has a threaded section in the center of the barrel, while the unthreaded muzzle stubs or jams into a socket in the middle of the suppressor. We feel that this configuration (with the barrel in compression) is not as conducive to accuracy, although it may ease manufacture of the suppressor. However, to our great surprise, we have seen suppressed .308 systems (with compressed barrels) that appeared to be fairly accurate.

Yet another benefit exists with the two-point mount. Space behind the muzzle exists inside the rear chamber of the suppressor. That extra volume can be used for more effective suppression, without adding greatly to the overall length of the weapon in front of the muzzle.

Barrel Torque

Most rifles have barrels that impart a right-hand spin to their projectiles. Since most calibers accelerate their bullets to between 2,500 and 3,400 fps, and since most of this acceleration takes place within the first few inches, there is a sudden and violent twisting of the barrel in an opposite (left-hand) direction. This torque tends to cause a barrel held into its action with RH threads to screw itself ever more tightly into its action with each shot. One can screw a barrel lightly into an action by hand. After several shots are fired the barrel will have driven itself tightly into its action, and it will take quite a bit of force to remove that barrel with a wrench.

That same torque tends to cause a suppressor to loosen if the suppressor is held in place with RH threads, which seem to be the norm. One must be constantly vigilant to make sure that a rifle’s suppressor remains tightly screwed in place. Especially before a critical shot. All Russian and German flash hiders (and some suppressors) are attached with LH threads. Those made in the U.S. are usually held on with RH threads.

Our testing has indicated that a rifle with a suppressor held in place with a properly executed, two-point, conical, tensioned barrel mount will remain in zero. This zero remains even after the suppressor has been removed for cleaning and replaced. As long as the replacement torque is about the same, the zero will be unaffected. We are talking about no discernable, cold shot shift after a day, week or year, at 200 yards.

Suppressor manufacturer Don Wagenknecht, of Grandview, MO (DAW-Phone-816-765-2539) uses a threaded muzzle and an unusual rear collet to hold his high-powered rifle suppressors in place. Don is a skilled and extremely precise machinist. His work is so accurate that he allows a mere .007 (7/1,000ths) of an inch of clearance on each side of his bullets as they pass through a stack of symmetrical baffles. Clearances on baffle stacks of other manufacturers are often significantly greater.

Bullet contact with any one baffle in a suppressor usually results in tumbling, with severe consequences for those baffles that remain downrange of the event. Since the smallest possible passage hole results in the greatest level of suppression, the pressure is on to keep internal baffle clearances to a minimum. More than one suppressor (held with a single-point mount) has been ripped free of its threads, and then violently launched downrange when baffle contact has caused internal bullet tumbling. Damage to the suppressor in such an instance is usually substantial. If this happens in the field the rifle may be undamaged, but it will have to be rezeroed before it can be used effectively.

Moisture Accumulation and Weapon Storage

Water is a major byproduct of gunpowder combustion. A good suppressor will capture and retain a considerable amount of the liquid. Twenty shots from a .308 will cause about a teaspoonful of water to be captured. Whenever possible, the weapon should be carried and stored with the muzzle pointing straight down. The bolt or action should remain open to allow accumulated water to evaporate and vent. If the suppressor is removed as soon as the shooting stops, heat in the suppressor will rapidly dry most of the internal components.

Unfortunately, most rifles are traditionally stored muzzle-up. This causes water and trapped particulates to slowly release, where they will fall and lodge in the chamber area and bolt face. Burned gunpowder is quite dirty, and the inside of a suppressor is usually filthy. Cleaning is best accomplished by flushing the can in solvent, draining, and blowing the unit out with compressed air. One should get in the habit of storing a suppressed rifle by hanging it, muzzle-down. Even stainless steel components will rust if trapped water is not allowed to vent. This may result in a suppressor rusted tightly to its barrel. A bore with rust near its muzzle may lose its accuracy. Corrosion can occur quickly in a warm, moist environment. This is not an aspect to be ignored.

The Blast Baffle and Its Effect on Accuracy

The most critical moment in a bullet’s flight path is just after it exits the barrel, where the highly elastic and more rapidly moving gasses overtake it and press upon its base. The first baffle in a suppressor is called, appropriately, the blast baffle. This is the most critical component in the entire baffle stack. The blast baffle is subject to a great deal of heat, stress and impact. Many baffles have asymmetrical surfaces, and these can bounce the blast of high-pressure gas around in a way that disturbs the stability of an exiting bullet. When we first started experimenting with asymmetrical S, Z and K style baffles this phenomenon became painfully obvious. Keyholing, tumbling and baffle contact were common because the bottle-shaped blast of muzzle gas overtook the exiting bullets, deflected off the asymmetrical surfaces, and then deflected the bullets. Accuracy was not good. Some manufacturers haven’t learned this lesson yet, and their suppressors are plagued with inherent instability and resultant accuracy problems.

The blast baffle must have a perfectly symmetrical, coaxially aligned surface and bore. It must be made of fairly tough steel, stainless steel or inconel. If it is made of a soft material like copper, brass, titanium or aluminum, the high-velocity impact from unburned grains of powder will peen the surfaces – eventually reducing the size of the bore orifice to the point where destabilizing bullet contact results.

A properly designed blast baffle will strip and deflect much of the bottle-shaped blast of high-pressure gas that envelops and pursues the departing bullet. For this reason, one can logically expect an increase in practical accuracy when a properly designed suppressor has been installed. Also, the weight of a heavy steel unit tied to both the center and end of a rifle barrel does beneficial things for harmonic barrel vibration – dampening out much of it. These two factors greatly increase the practical accuracy potential of a suppressed rifle. The properly suppressed rifle becomes very stable and reliable. Larger internal clearances reduce the likelihood of baffle contact in the event that the suppressor or barrel get slightly damaged or bent.

The Supersonic Crack

Any projectile moving through the air at a velocity greater than the speed of sound (1,089 to 1,114 fps in dry, 65 degree F air, depending on who one listens to) will create a supersonic crack. Temperature, humidity and atmospheric pressure variations play a role in raising or lowering the speed of sound by a small percentage. In a firearm which lacks a substantial muzzle report (being fired over an open field) the sound resembles the loud tearing of a bed sheet. Two sounds are actually created, one from the front of the bullet, and one from the rear. Near trees and buildings the sound waves come back as a distinct crack or pop each time the speeding bullet passes some object with a vertical, reflective surface. Once the muzzle report has been diminished the supersonic boom becomes dominant. Curiously, the sound will now appear to come from the target area, rather than the rifleman’s position. Sound moves through our atmosphere at a relatively fixed rate. A sound wave will typically strike one ear a bit before the other. The human brain is capable of detecting the difference in time between sound impacting one ear and then the other — in an increment of as little as one/six-millionth of a second. With time and practice we soon learn to use this ability to pinpoint the source of a sound very accurately. Because a suppressed muzzle report is relatively quiet, the uninitiated will automatically home in on the loudest sound, which in this case is a sonic boom reflecting from the target area. The sound of the bullet’s passage will seem much louder than the muzzle report to someone close to the flight path. Indeed, a rapidly moving .308 bullet will sound louder than a .22 LR pistol, to someone who is positioned a few feet from its flight path.

Smaller diameter bullets make less noise than larger diameter bullets. Supersonic is supersonic. A bullet traveling 1,200 fps will make about the same noise as one traveling 4,000 fps. Projectiles that are .308 inch in diameter will be somewhat louder than .223 bullets. There is no technology which can remove the sound of a supersonic projectile, no matter what claims are made to the contrary.

Sound Level and Recoil

Even though the supersonic crack remains, the overall sound level is greatly diminished. The report sounds like a rapid hiss of compressed air as the slowed gasses issue from the muzzle of the suppressor. The suppressed .223 and .308 rifles become quite comfortable to shoot without hearing protection. Since propellant gas is responsible for about half of a rifle’s recoil, and since that gas is captured and released slowly, the recoil level will be about half that of an unsuppressed rifle. A .308 has a propellant charge weighing about 50 grains. This is of course converted to 50 grains of gas, and this gas only moves forward about 2 feet before the suppressor baffles intercept it. The fact that the gas doesn’t leave the muzzle of the suppressor at high speed is responsible for much of the reduction in recoil. The interception of forward momentum (which results when that gas is captured in the can) is responsible for much of the remainder of the reduction in felt recoil. In addition, the weight of the heavy can on the rifle’s muzzle acts as a pendulum, limiting muzzle rise and swing as the rifle recoils, and then pivots around the shooter’s body mass. We have said all of this about recoil only because many people have a hard time understanding how 50 grains of gas can be responsible for as much felt recoil as 168 grains of rapidly departing bullet. The answer of course is that the bullet, being heavy and inelastic, issues forth at a relatively slow speed when compared to the lighter and (we are told) perfectly elastic gas. Since energy is a product of mass times the square of velocity, it can be seen that the gas doesn’t have to exit many times faster than the bullet to equal its energy. Empirically, we know that recoil from a suppressed rifle carrying a high powder charge is much gentler with a suppressor than without. All theoretical argument stops after that point. If a rifle hurts you to shoot it before suppression, it becomes quite comfortable to shoot after it’s been suppressed.

It should be mentioned that (if a rifle was first sighted in, and then suppressed) the point of impact will be much lower and a bit to the left for a right-handed shooter. We need to say that again. The point of impact will not be the same if the previously zeroed rifle is used with (or without) its suppressor. A rifle simply cannot be zeroed in one mode and then used in the other. This is a serious liability issue for law enforcement snipers. Litigation specialists (lawyers) will hammer this point to exhaustion in a courtroom if a hostage rescue situation ever goes bad as a direct result of a botched shot, or if innocent bystanders are wrongfully injured. The rifle, scope and suppressor must be regarded as a unit, and they must remain as a unit. If a number of suppressed rifles exist in an armory, they must be numbered, and the respective pieces must remain married, so that suppressors stay with their assigned rifles. Identical suppressors on identical rifles may be interchangeable without affecting cold shot zero, but an officer of the law should not take that chance.

| This article first appeared in Small Arms Review V1N7 (April 1998) |