By Frank Iannamico

Soviet sound suppressor development began during World War II, after it was discovered that “silencers” were being fielded by German snipers. Seeing the great psychological and tactical value, the Soviets soon began to field their own suppressors. They basically copied their design from captured German weapons for use on their bolt-action 1891/30 Mosin–Nagant sniper rifles. After World War II ended, there was little interest in the further development of suppressors. As the world entered the Cold War era, the Soviets once again became interested in silent weapons. During 1955, work began to develop an efficient suppressor for 7.62x39mm weapons at the Scientific Research Institute 61, located in the city of Klimovsk.

The PBS

Sound suppressors, also known as “silencers,” were developed for various models of the AK rifle. The PBS (Pribor Besshumnoy Stryelbiy) or “Device for Noiseless Shooting” was designed for use on 7.62x39mm SKS, AK and RPD weapons.

Lieutenant Colonel Makarenko, an engineer at the Scientific Research Institute 61, was one of the individuals involved in the silencer development project. The Soviet sound suppressor was quite simple and primarily designed to cool and slow down the gases expelled by a fired cartridge. One of the early PBS suppressors was a steel “clam shell” design with a hinge at the front of the unit, allowing it to be opened for easy cleaning and maintenance; inside was an expansion chamber, a rubber plug and 10 baffles. A locking mechanism was used to keep the suppressor from loosening during firing. Approximately 100 units were manufactured before production was transferred over to the Izhevsk Machine Building Plant in 1962.

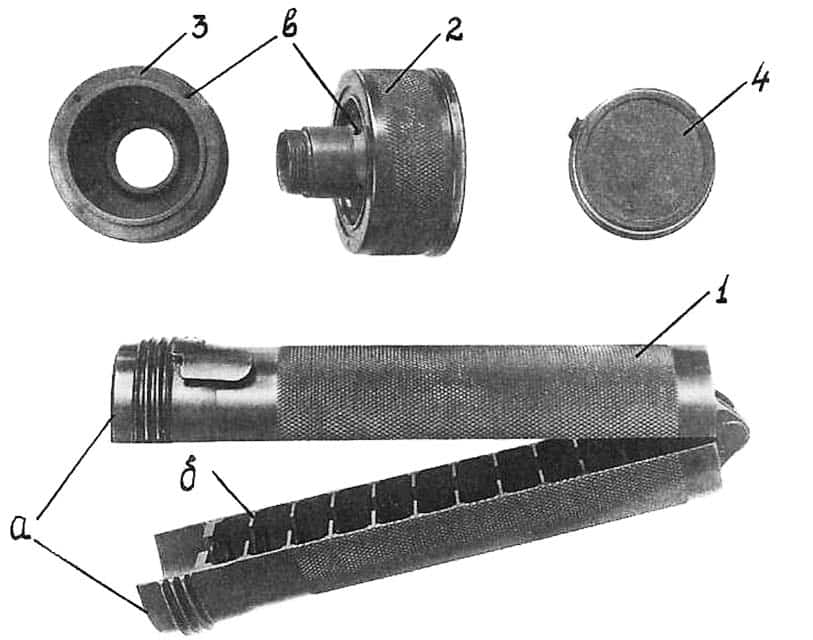

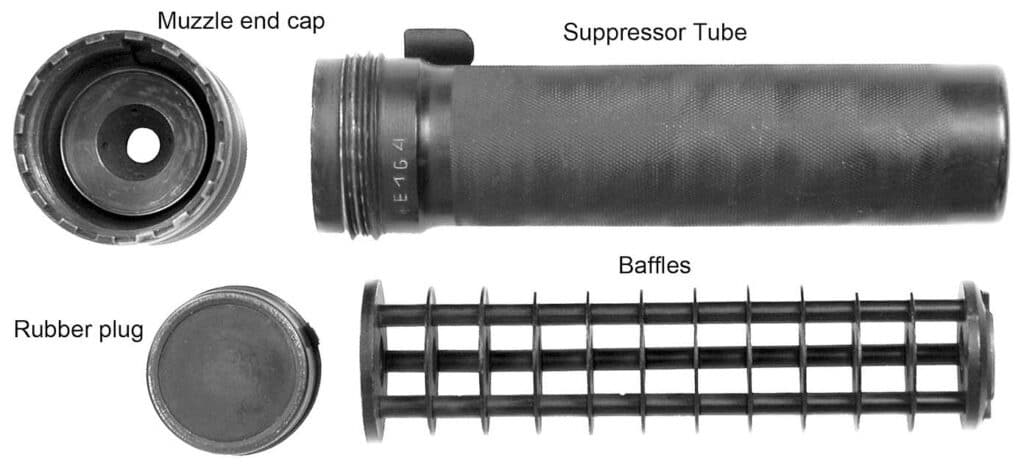

Disassembled PBS-1 Soviet Pribor Besshumnoy Stryelbiy. The suppressors used a rubber “wipe” that required replacement after firing only a few hundred rounds.

A Soviet soldier with an AKMS fitted with a PBS-1 sound suppressor.

The PBS-1

During 1962, the engineers at the Izhevsk plant changed the original PBS design to a more conventional tube-style, which proved to be far more durable. A new soft rubber “wipe” was used, which was designed for better durability in cold temperatures. The new suppressor was designated as the PBS-1.

The PBS-1 sound suppressor, like the earlier PBS, was a rather simple design. The internal components were encased inside of a steel tube. At the muzzle end of the tube was a threaded expansion chamber, followed by a cone-shaped chamber, with four 2.2mm radial bleed holes and a 20mm thick self-sealing rubber plug. The rubber plug, or “wipe,” was designed to create back-pressure to operate the weapon’s action with special down loaded ammunition and to keep hot, high-pressure gas from rapidly escaping from the suppressor. Located forward of the expansion chamber section were 10 baffles aligned on three rods, with a central hole for the bullet to pass. After firing each round, the hole in the rubber “wipe” would gradually enlarge, each time degrading the effectiveness of the device and eventually requiring replacement after approximately 200 rounds.

The PBS-1 has an overall length of 8.15-inches (207mm); the main tube has an outside diameter of 1.57 inches (40mm). The device weighs 1.6 pounds (.73kg).

Sound suppressors are not especially effective on rifles that fire supersonic cartridges, as a rather loud noise is produced when the bullet exceeds the speed of sound after leaving the suppressor. The speed of sound is approximately 1,116 feet per second (340.29m/s) at sea level, with low humidity and an ambient temperature of 68 degs Fahrenheit. The problem is usually addressed by reducing the bullet’s velocity by using a heavier bullet and a downloaded powder charge, but this greatly reduces the range and effectiveness of the weapon.

Subsonic 7.62x39mm Ammunition

Russian subsonic 57-N-231U 7.62x39mm ammunition uses a long, heavy bullet with a slightly larger diameter, which results in an altered trajectory with the bullet dropping 200mm (7.87 inches) every 100m (109 yards). To be effective, specially calibrated sights were fitted to weapons with sound suppressors; the maximum range was 400m. The subsonic ammunition was developed at Scientific Research Institute 61, by M.A. Kuzminov and L.I. Golubevu, under the supervision of the original designers of the M43 cartridge. The final design of the new cartridge was successfully tested from January through March 1955. Manufacture of the subsonic cartridges was initially undertaken by the Scientific Research Institute 61 but was later transferred to the Novopodolsky Punching Plant (renamed the Klimovsk Stamping Plant Number 711 in 1960). The subsonic ammunition was packed in two tins, 1,200 rounds to a case, with six spare rubber suppressor “wipes.” After production began at the Klimovsk Plant, the cartridges were packed 1,360 per case with six replacement rubber “wipes” for the PBS-1. The rounds were sealed in two tins and packed inside of a wooden crate.

The PBS-2

During the 1970s, the PBS-2 sound suppressor was designed for the 5.45x39mm AK-74 and AKS-74 rifles. Again, special subsonic ammunition was required to keep the bullet from exceeding the speed of sound. The PBS-2 uses a baffle/wipe system that is similar to that used in the PBS-1. The

PBS-2 was deemed unsuccessful due to the length of the AK-74’s barrel. The long barrel caused the subsonic bullets to exceed supersonic speeds, which causes unacceptable noise. Downloading the powder charge to reduce the velocity often resulted in the bullets getting lodged in the barrel.

The PBS-3

The PBS-3 sound suppressor is similar in design to the PBS-1 and PBS-2, except that the PBS-3 was designed for the 5.45x39mm AKS-74U. The AKS- 74U was more successful than the standard AK-74 when fitted with a sound suppressor, due to its short barrel and reduced muzzle velocity. When fired from the AKS-74U, the heavy bullet from the downloaded 5.45 cartridge would exit the muzzle before reaching the speed of sound. The PBS-3 weighs 2 pounds (.91kg) with an overall length of 8.86 inches (225mm).

The PBS-4

The PBS-4 was also designed for the short-barrel AKS-74U and is basically the same as the PBS-3, but the PBS-4 has a slightly different internal design that does not use a rubber wipe. This allows full-auto fire and the use of standard velocity ammunition to be fired through it without seriously affecting its performance. Although the use of supersonic ammunition makes considerable noise when fired through a sound suppressor, it does make it difficult for an enemy to pinpoint the location of the shooter. The PBS-4 had better flash suppression than the PBS-3 and is lighter at 1.34 pounds (.61kg). The overall length is also slightly shorter at 8.66 inches (220mm). The PBS- 4 was often used with the BS-1 silent grenade launcher.

A Modern Solution

Sound suppressors have become quite mainstream in the last few years. Many firearms manufacturers now offer factory-threaded barrels on their products, solely for the mounting of a suppressor.

There are many reasons for wanting a suppressor: it allows the discharging of a firearm in an area where the noise could disturb neighbors or animals; it protects the shooter from hearing damage; and last of all suppressors are just cool. Many states now permit suppressors for hunting. The military is issuing an increasing number of suppressors to protect their troops’ hearing and avoid service-related claims of hearing loss.

Today, there are a substantial number of suppressor manufacturers, and their numbers are growing. There are suppressors available for just about any budget and application from .22 rimfire to .50 caliber BMG. However, suppressors for one group of an extremely popular weapon are conspicuously absent. The options of suppressing an AK-pattern rifle are quite limited; however, the suppressing options for the AK’s nemesis, the AR-15/M16 rifles, seem limitless. So why has the AK been ignored?

The concept of a suppressed AK has always been appealing to enthusiasts. However, though most AK-pattern rifles have a factory-threaded barrel, bore to muzzle thread concentricity is a major concern with most AK rifles. While less of a concern when a short, thread protector or a slant brake is attached, adding several inches of sound suppressor to the muzzle, concentricity becomes a problem and will result in baffle strikes or worse. There are several additional issues with the weapon’s design to consider. Much of the legendary reliability of the Kalashnikov rifle is due to the sheer volume of gas the system puts out. Restricting this substantial gas flow with a suppressor causes several issues. Felt recoil is increased, and gas and noise are emitted from the ejection port in close proximity to the shooter’s ear.

Dead Air Armament Wolverine PBS-1

The Dead Air Armament of Georgia is well-known in the NFA community for manufacturing high-quality suppressors from the best materials available. They currently offer a long line of suppressors for rifle, centerfire and rimfire pistol applications.

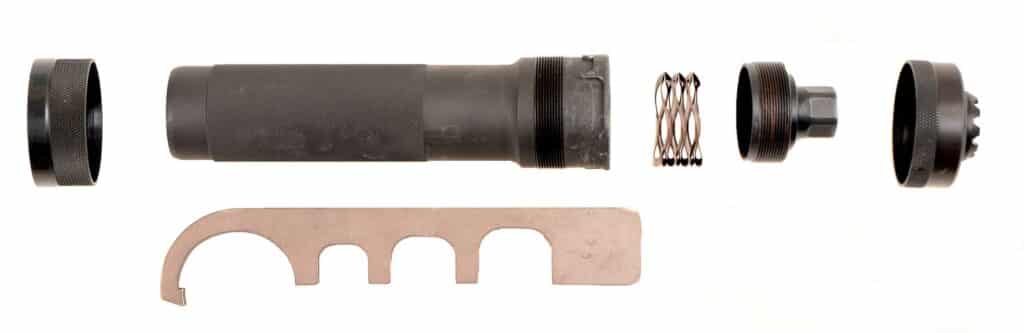

One product that the company wanted to offer was a suppressor for the Kalashnikov rifle. After much trial and error research and development, the company introduced the Wolverine PBS-1 AK suppressor. The Wolverine was specifically engineered to address all of the issues involved with suppressing an AK rifle. Instead of trying to tailor the AK to the silencer, they decided to tailor the silencer to the AK. In other words, there is no modifying the rifle or rethreading of the muzzle threads necessary.

The adaptation of a suppressor to the idiosyncrasies of the AK design, due in part to the tolerances of foreign thread patterns, was made possible by a specifically engineered bore taper that allows the Wolverine to be used on all but the poorest examples of non-concentric threads. Dead Air Armament considers it to be the optimal bore diameter and taper to prevent baffle strikes on the majority of rifles without major sacrifices in sound reduction performance.

The Wolverine was designed to look like an original Soviet 7.62mm PBS-1 AK suppressor. However, that is where the similarities end. The Wolverine PBS-1 features modern, state-of-the-art baffle designs and materials, while the Soviet PBS-1 was a rudimentary design based on 1950s technology, resulting in minimum sound reduction.

The Wolverine PBS-1 is a direct-thread silencer. The mounting system consists of a thread adapter and a locking collar. The adapter and locking collar are counter-threaded to each other to prevent unintentional removal. To mount the Wolverine, it is simply threaded onto the barrel, and the locking collar is tightened down. There are relief cuts in the locking collar to engage the spring-loaded pins on AK front sight bases to keep the suppressor from loosening during firing. The Wolverine comes with the standard 7.62mm 14L AK thread adapter. Adapters are available for other common AK-pattern threads, including 24mm RH for the 5.45mm caliber AK-74, and a 26mm LH for the Yugo M92. Adapters for popular American thread patterns include 1/2×28 and 5/8×24.

Built Like an AK

The Dead Air Wolverine features a stainless-steel exterior with a Cerakote® high-temperature finish. The interior baffles are made of Stellite®, which is exceptionally resistant to heat erosion, making it ideal for rifle baffles. The Wolverine is full-auto and multicaliber-rated up to the Russian 7.62x54R. There are no minimum barrel length restrictions. The Dead Air Wolverine’s overall length is 7.2 inches, with an outside body diameter of 1.5 inches and base diameter of 1.9 inches. Its weight is 20.8 ounces. It comes with a lifetime factory warranty. Manufacturer’s published decibel readings from a 7.62×39 AKM, with a 16-inch barrel are 137dB at the muzzle; 142dB at the shooter’s ear.

• • •

Portions of this article were excerpted from the book AK-47: The Grim Reaper II.

| This article first appeared in Small Arms Review V23N10 (Dec 2019) |