By Frank Iannamico

Milspec Primers for Reloaders

A topic that always concerns knowledgeable shooters of both full auto and semi auto firearms is the ever-present possibility of a slamfire. A slam fire can have a devastating effect on the shooter and firearm as well. Everyone has probably seen the pictures and heard the stories of the M16 that was destroyed by what apparently was an accidental slam fire, or worse, the shooter that was seriously injured.

What exactly is a slam fire? Generally, it is the premature firing of a partially chambered cartridge. This condition is a disaster because the bolt is not fully locked in the normal firing position. (This is different from a case detonation) A slam fire is much like the principle of an open bolt pistol caliber subgun, but with powerful rifle caliber ammo the unintentional result is much different. Full power and midrange rifle caliber firearms usually require a bolt that locks to the barrel to contain the force of a firing cartridge. Subguns using pistol caliber ammunition simply use a heavy non-locking bolt to retard the rearward force of a firing cartridge.

What causes a slam fire? There can be one or a combination of causes. In many cases the hammer is following the closing bolt causing an immediate discharge of a cartridge it contacts. Other causes could be; improper headspace, firing pin dimensions or protrusion, a foreign object or carbon in the firing pin cavity of the bolt, inertia of the firing pin and improper primer seating are just some of things that can cause a slam fire. If you have ever had a semiauto suddenly go full auto on you, or you have had a round fire upon closing the bolt you may have experienced a very dangerous slam fire condition.

There are several weapons that seem to be more susceptible to slam fires than others. Those weapons are; The AR15/M16, the AK series and the SKS. All of these firearms have floating firing pin designs (some manufacturers of the later imported Chinese AK’s incorporate a spring-loaded firing pin). Although weapons like the U.S. M-14, M1 Garand, and M1/M2 Carbine also use a floating firing pin, they are designed differently and slam fires, though certainly possible, are not as common.

Many publications and manufacturers have forewarned against using reloads in any of the aforementioned weapons. This would be very bad news for many reloaders/shooters- myself included. Surplus or milspec ammo with hard primers is often recommended in these and other similar weapons. Personally I have fired thousands of reloaded rounds in M16s and AK 47s over the years with no problems, but that’s not to suggest it couldn’t happen on the next round I fire. Try this simple test. Chamber a reload in your AK or M16, and with the muzzle pointed in a safe direction let the bolt close under full spring pressure. Now extract the round and inspect the primer. What you will probably see is an indentation from the firing pin on the primer. This indentation was probably caused by firing pin inertia. Scary? You bet!

What can you do to reduce the possibility of a slam fire? Always inspect your weapons for damaged or worn parts, check the chamber with a headspace gauge, keep your guns and ammo in top condition and thoroughly clean your weapons after each day’s shooting. Shoot only new factory loaded milspec ammunition.

If you are like me that last sentence “Shoot only new factory loaded milspec ammunition” isn’t very practical mainly due to cost. So the question now focuses on “What can I do to be sure my reloads are safe?” There are several things you can do. Obtain a cartridge headspace gauge, and be sure your resized cases properly fit into the gauge as per the instructions that accompany the gauges. Inspect your loaded cartridges to be sure the primers are properly seated in the primer pocket. Use only milspec primers.

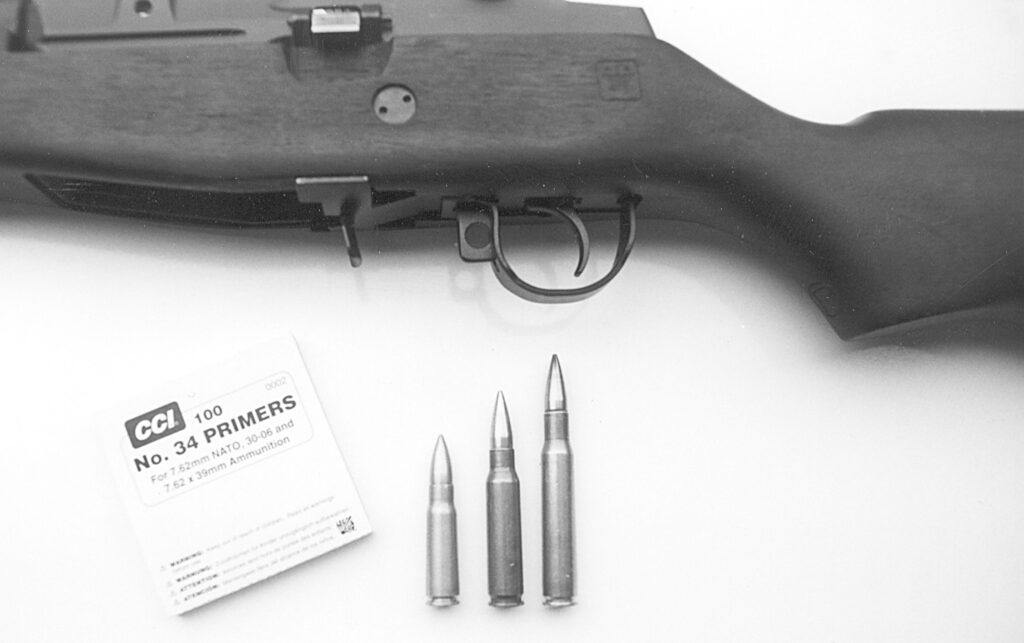

What are milspec primers? CCI came out with a primer a few years ago especially for use in military type firearms. They produce them in both large CCI No. #34 and small CCI #41 rifle sizes. They are often described as “hard” primers, but that description is not entirely accurate. The design of the anvil is different, not the thickness of the primer cup. The military anvil is shorter, and has a different dome radius than a normal commercial primer anvil. This design reduces the sensitivity of the primer making it slightly harder to ignite. (See chart for dimensions)

CCI primers are tested for sensitivity by dropping a steel ball of a specified weight onto a firing pin breached above a primed case. This test is repeated at different heights to establish the H-bar height. This H-bar height is the ball drop distance at which exactly half the primers in the sample fire. From this and the fire/misfire rates at other distances, the “all fire” and “no fire” heights are calculated.

The “no fire” height for commercial primers is specified as 2 inches. For military primers it is set at 3 inches. This means that a milspec primer needs slightly more energy to activate it. CCI No.34 and No. 41 primers achieve this specified sensitivity level not by the thickness of the primer cup, but rather by the anvil design.

Almost all military surplus ammo and today’s new manufacture milspec ammunition use a primer that requires more force to ignite than their commercial counter parts. This is necessary due to the design of modern military weapons and the combat field conditions they are likely to be subjected to.

My reloads these days are all capped with the CCI milspec primers. The margin of safety they provide for me and my firearms are well worth it. An ounce of prevention… Be Safe!

If your dealer doesn’t stock the CCI military primers call Blounts product support line for product availability. 1-800-627-3640.

| This article first appeared in Small Arms Review V2N8 (May 1999) |