By Al Paulson

In the previous issue, we discussed the silenced P9S pistol developed for the U.S. Navy which featured an innovative stainless steel silencer developed at Qual-A-Tec and manufactured by Heckler & Koch GmbH. The Small Suppressor was designed to work with the MP5-N and MP5K-N submachine guns as well as the P9S pistol. The P9S pistol and Small Suppressor system became standard issue in the 1986, replacing the MK 3 suppressor and MK 3 MOD 0 pistol. The previous discussion detailed the design and manufacturing of the Small Suppressor and alluded to the Large Suppressor, which was developed when the Navy discovered that the otherwise outstanding aluminum silencer built in Germany for the MP5SD integrally silenced submachine gun was subject to severe saltwater corrosion. In this issue, we’ll wrap up the discussion of H&K’s Small Suppressor and conclude with a look at the Large Suppressor designed for the MP5SD-N integrally silenced submachine gun.

Both the Small Suppressors and Large Suppressors of Qual-A-Tec design were manufactured by H&K in house at Chantilly, Virginia, and subsequently at Sterling, VA. It is interesting that a German technician would always supervise a production run of suppressors to ensure quality control. The welding required for this design was particularly demanding, and the in-house reject rate (before reworking the bullet passage by line-boring a second time) was perhaps 20 percent until H&K built a special TIG (Tungsten Inert Gas) welder for fabricating the Qual-A-Tec designs. The reject rate immediately dropped to 1-3 percent (before reworking the bullet passage by line boring a second time).

While not required by the end-user, H&K always test fired each and every Small Suppressor on an MP5 with optical sight to ensure that the can delivered outstanding accuracy at 100 meters. One man would shoot one gun while another exchanged suppressors on a second gun, enabling them to test a lot of cans throughout the course of a night at the in-house range. Using almost any ammunition of the day, the MP5 with Small Suppressor would deliver 6-8 inch (15-20 cm) five-shot groups when fired in semiautomatic mode. Using Winchester 115-grain JHP ammunition, the Small Suppressor on an MP5 usually delivered 2-4 inch (5-10 cm) five-round group. A given gun would be more accurate with a suppressor than without, presumably because the weight of the suppressor dampened barrel harmonics. If the suppressor failed the accuracy test, redressing the bullet passage through the suppressor to remove any burrs usually corrected any accuracy problems. If that failed, it was destroyed. H&K delivered somewhere between 1,000 and 1,500 Small Suppressors to the U.S. Navy between 1986 and 1989.

The Small Suppressor we examined with a P9S pistol featuring standard fixed sights has the following markings: CAL. 9MM HK INC CHANTILLY VA SN 91 1156-1.

This particular weapon and suppressor were used for the testing of terminal ballistics during the Navy’s quest for an improved 9x19mm round for CT (counter-terrorist) missions. The mid- to late 1980s were an important time in the history of handgun ammunition. U.S. ammunition manufacturers competed in the development of improved handgun projectiles for law-enforcement applications. Simultaneously, U.S. military units with responsibility for in extremis missions (such as hostage rescue) sought projectiles that increased the likelihood of incapacitating the target, while reducing over-penetration which could place both hostages and rescue personnel at risk. Thus, the Small Suppressor was at the right place at the right time to provide the Navy with both a superior tactical tool as well as a handy research tool for the development of new ammunition.

H&K’s Large Suppressor

H&K began the development of an integrally suppressed version of the MP5 in the late 1960s. Herr Kästner developed this first variant of the MP5SD, which featured aggressive slot-shaped barrel ports designed to rapidly vent combustion gases into metal mesh, which was combined with a series of five baffles in front of the barrel. But the mesh fouled so quickly that it had to be replaced every 70 rounds and the slots significantly reduced barrel strength, so H&K began the quest for a more durable suppressor soon after this first variant of the MP5SD was produced in 1968.

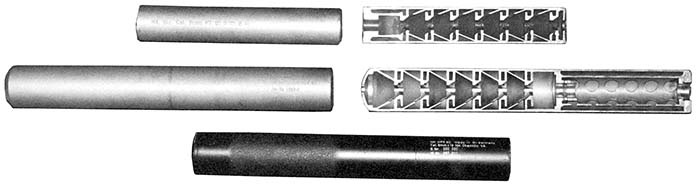

Working from 1970 to June 1972, Walter Wolf subsequently developed a silencer featuring a coaxial design that employed aluminum square tubing for the inner coaxial structure and round aluminum tubing for the outer casing. The square tubing begins life as an aluminum extrusion, which is then machined so opposing sections on all four sides of the tubing, can be bent inward and welded to form four pairs of baffles. The machined cuts are designed so that one cut section is shorter than the section facing it, forming V-shaped baffles that point at the chamber. Since the facing legs of the V have different lengths, the bent sections of extruded tubing form asymmetrical surfaces for increasing the turbulence of combustion gases within the suppressor. Machined adapters are then welded in place at each end of the square module to center the module inside the outer tube. The net result is a coaxial design, with the inner coaxial chamber being square in cross section rather than circular. One adapter nestles in a channel cut in the dome’s front end cap, while the other is threaded to mate with the separate tube that surrounds the ported barrel. Once the adapters are welded in place, the square module assembly is bored for a bullet passage. The domed front end cap and rear end cap of the Wolf silencer are glued into place, so the suppressor must be submerged in a solvent such as Varsol for several days for periodic cleaning. Simply drain and blow out with compressed air.

The system is ingenious, well suited for mass production, and quiet. The patented Wolf silencer is 11.88 inches (30.2 cm) long and 1.58 inches (4.0 cm) in diameter. The aluminum silencer weighs 1.0 pounds (0.45 kg). When fitted with the aluminum silencer and retractable stock extended, the MP5SD3 is 30.4 inches (77.2 cm) long and it weighs 7.5 pounds (3.4 kg) empty and 8.7 pounds (3.9 kg) with a loaded 30-round magazine.

The Navy discovered that the aluminum components of the MP5SD suppressor were subject to saltwater corrosion. This stimulated Qual-A-Tec to develop a suppressor for the MP5SD that was fabricated entirely out of stainless steel. While heavier than the original factory silencer, Q’s stainless suppressor not only mitigated saltwater corrosion problems, it was also quieter than the Wolf design. Qual-A-Tec produced only a small number of these replacement suppressors before licensing the technology to Heckler & Koch. This design became the so-called Large Suppressor which H&K subsequently delivered to the Navy. Like its smaller sibling, the Large Suppressor also used Q’s Type 3 baffle.

The Large Suppressor is 12.40 inches (31.5 cm) long and 1.63 inches (4.14 cm) in diameter. The stainless steel silencer weighs 2.24 pounds (1.02 kg). Because the Large Suppressor had a greater diameter than the German can (due to using tubing of Imperial rather than metric measurements), H&K had to mill down the cocking lever supports on the MP5SD-N to provide clearance for the stainless suppressor when locking the cocking lever back in the detent.

The baffle stack of the Large Suppressor is about as long as the Small Suppressor, but the stainless steel replacement can for the MP5SD only incorporates six Type 3 baffles. This silencer features a domed front-end cap and a long primary expansion chamber. Designed to envelop the MP5SD’s ported barrel, the primary expansion chamber adds considerable length to the rear of the suppressor. This rear portion of the silencer is 4.75 inches (12.1 cm) long. The primary expansion chamber vents into a cylindrical coaxial expansion chamber via three rows of six large (0.50 inch, 1.3 cm) holes. A muzzle support separates the rear-most chambers from a secondary expansion chamber formed by a cylindrical spacer that fits tightly against the outer suppressor tube. Ports in the muzzle support enable gases from the chambers surrounding the barrel to continue forward through the suppressor, which prevents the buildup of back pressure from limiting the effectiveness of the primary expansion chamber and the coaxial chamber surrounding it. A cylindrical spacer separates the rearmost baffle from the muzzle support. Otherwise the design and function of the conical spacers is comparable to the Small Suppressor. The baffles have a larger diameter and, therefore, larger coaxial and annular expansion chambers to enhance the performance of the suppressor.

The Type 3 baffle used in the Large Suppressor is 1.19 inches (30.3 mm) long and has a diameter of 1.49 inches (37.7 mm). The cut-off chord is 0.78 inches (19.9 mm) long and has a maximum depth of 0.17-inch (4.4 mm) from the circumference of the rear baffle face. The rear face of the baffle has a diameter of 1.40 inches (35.6 mm) and the lip on the front of the conical spacer is 0.20 inch high with a wall thickness of 0.037-inch (0.94 mm). The LOA of the conical spacer and lip is 0.90 inch (22.9 mm). The bullet passage has a diameter of 0.39 inches (9.8 mm). The annular expansion chamber has a depth of 0.35 inch (8.9 mm) as measured from the diameter of the baffle’s front face, and the annular chamber has a length of 0.15 inch (3.8 mm). The three outlets venting from the annular expansion chamber into the slanted sidewall bullet passage have a diameter of 1/8-inch (3.2 mm). The slots in the rear face of the baffle are 1.0-inch (25.4-mm) long and 1/8 inch (3.2 mm) in width. An individual stainless steel baffle made for the Large Suppressor weighs 1.7 ounces (49 grams).

When fitted with the stainless steel Large Suppressor and folding stock extended, the MP5SD-N is 31.0 inches (78.7 cm) long, and it weighs 8.7 pounds (4.0 kg) empty and 9.9 pounds (4.5 kg) with a loaded 30-round magazine. Heckler & Koch made perhaps 750 Large Suppressors in Virginia, most of which went to the Navy between 1986 and 1989.

An interesting footnote to this story is that H&K still uses the extruded aluminum, square tubing silencer developed by Walter Wolf in the early 1970s as the standard issue sound suppressor on the MP5SD. A recently introduced, very simple modification to that design provides an impressive 3-decibel gain in sound reduction.

Conclusions

While the suppressed H&K P9S pistol was outstanding technology, the Teams seemed to prefer using a silenced submachine gun over a silenced 9mm pistol in the decade following the introduction of the Small Suppressor. Therefore, this silencer was normally fielded on an MP5-N or MP5K-N submachine gun. Despite the fact that the Navy adopted the .45 caliber Mark 23 Mod. 0 pistol from Heckler and Koch and the Model OHG suppressor from Knight’s Armament in 1996, the suppressed P9S pistol can still be found in the arms rooms of the Teams and are still available for missions. It is safe to say that the H&K P9S pistol with H&K’s Small Suppressor remains one of the best silenced 9x19mm pistols ever fielded by a military unit.

The stainless steel Large Suppressor designed for the MP5SD-N was about 19 ounces (0.55 kg) heavier than the aluminum factory silencer used in the MP5SD, but it provided the corrosion resistance necessary for amphibious operations in the marine environment. The Large Suppressor also provided superior sound reduction to the excellent German-made aluminum suppressor. While both the Large and Small Suppressors designed by Qual-A-Tec are now out of production, they represented a major improvement in the evolution of silencer technology when Heckler & Koch began producing them in 1986. Robust, accurate and quiet—these stainless steel sound suppressors fundamentally changed the subsequent direction of silencer design around the world. Heckler & Koch and Qual-A-Tec wrote a very important chapter of silencer history with their collaboration on the Large and Small Suppressors, and these outstanding sound suppressors remain in service to this day.

Author’s note: I would like to thank Frank W. James, Doug Olson, N.R. Parker, Hays Parks, and Jim Schatz for their considerable help with my research into this story.

| This article first appeared in Small Arms Review V2N5 (February 1999) |