American engineer and inventor Hiram Maxim, living in London, developed an automatic gun that was presented in Great Britain and in several European countries. On October 20, 1886, a ministerial dispatch advised the Versailles Commission of Experiments that Mr. Maxim was authorized to present a semiautomatic rifle of his invention. On November 4th of the same year, another dispatch informed the commission that Mr. Bariquant, representing the inventor in France, would also present an automatic machine gun. According to the official test report, this weapon shot Gatling cartridges, while the files of Maxim-Nordenfelt spoke about a machine gun No. 129, shooting the .450 Martini-Henry.

11mm Machine Guns

During the first tests, the Maxim machine gun appeared remarkable and the Commission wanted to conduct further tests firing the ammunition of the Gras M1874 rifle. Four machine guns arrived on August 6, 1887 and after some tests, three of them were modified by the inventor and were turned over on August 12th. These weapons carried No. 53, 54, 55 and 63.

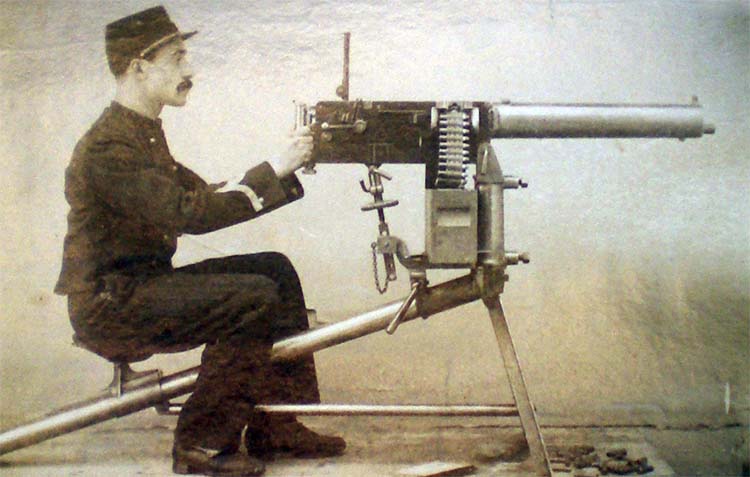

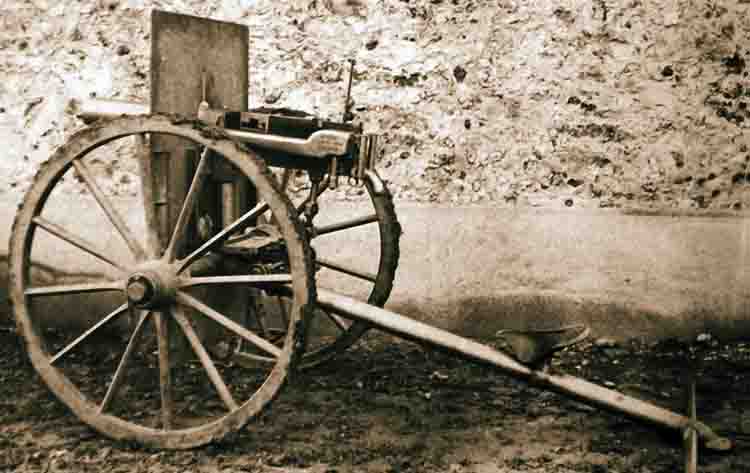

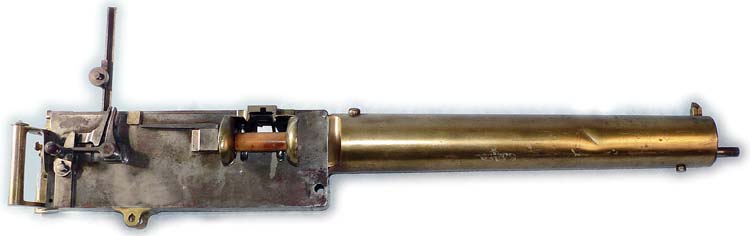

Each one of these weapons had a single barrel that moved back at the time of firing and ensured the unlocking of a mobile bolt knuckle. It returned to battery by action of a laterally installed spring. The cartridges are installed in a flexible fabric belt with brass eyelets. Its advance and feeding is the result of a distributor associated with displacement of the bolt. Weapons No. 54 and 63 had a rate of fire from 620 to 650 rounds per minute and were fitted with a water jacket ensuring the cooling of the gun. Machine gun No. 55 was fitted with a regulator that appeared as a glycerine-brake that made it possible to vary the rate from 5 to 500 rpm. It is fitted with the same water jacket. The model No. 53 had a cyclic rate from 620 to 650 rpm. Its water tank, under pressure, is installed in the tripod and is connected by a flexible tube, with a small baffle sleeve that surrounds the barrel. Machine guns No. 53, 54 and 63 could be mounted on the following supports: folding tripod made of steel, wheeled mount with armor-plated shield and crinoline mount made of steel. Weapon No. 55 could be installed on: folding tripod with tubular bronze leg forming the water tank and a conical mount made of bronze arranged as a water tank. The weight of the weapons varied from 24 to 35 kg and that of the mounts from 33 to 98 kg. Machine gun No. 55’s weight climbed with the wheeled mount, three cases of loaded cartridges and armor-plate to 190.8 kg.

During the tests, accuracy was considered to be very poor as the sight graduations did not correspond to the ranges and the mounts were unstable:

* H + L = 0.74 m x 0.69 m at 200 m,

* H + L = 1.95 m x 1.20 m at 400 m.

Between 600 m and 1,000 m, the results were even worse and as the rate of fire increased, accuracy decreased. Though this is not surprising today, at the time when automatic weapons were an innovation, they seemed surprising.

The operational tests were satisfactory and failures to fire incidents were scarce in spite of a significant heating of the barrel. Also noticed was a significant depositing of lead in the bore of the barrel; but this fault was charged to the use of lead bullet ammunition without a jacket. After shooting three 334-round belts (more than one thousand cartridges) in less than three minutes, it was also noticed that the chamber was fouling, though not surprising, with cartridges loaded with black powder.

The tests of model No. 53, fitted with a condenser tank, showed that the cooling of the barrel was not carried out in a reasonable way and involved a deformation of the barrel that was detrimental for accuracy. As for the model No. 55, fitted with a regulator, it was noted that its operation was too sensitive to room temperature and that its system was too intricate compared to the possible advantages which it could offer.

In conclusion, the Commission while recognizing the ingeniousness of the mechanisms present on the weapons tested, wanted improvements to the cooling system, the feed mechanism, safety, the belts carrying the cartridges and more stable mounts. In its final report of September 26, 1887, they encouraged the development of the model with regulator and single tank.

Following that, the inventor presented on June 20, 1888, two new machine guns No. 88 and 89 that comprised the majority of the desired modifications. But the first tests proved to be less than satisfactory and the weapons were returned for repair and then returned for testing on July 20th. Their operation was similar to that of the models presented previously. The barrel is cooled better as it sits entirely in the water of the jacket whose capacity was increased to 2.5 litres. The distributor was simplified, which made it possible to cure the problems of incidents of supply met previously. The regulator appeared to operate randomly. The mounts (model with wheels and tripod) were unchanged, but the attachment device of the weapons was improved.

The majority of the defects in firing were attributed to the feeding attachment and a failing of synchronization between the movement of the bolt and the advance of the belt. In spite of the noted defects, it was recognized that the accuracy of the machine guns were much higher than the various distances with that obtained with a collective shooting with rifle. Finally the French officers, conscious of the advantages had by the machine guns, but also of the stresses driven by their use (consumption of ammunition, training of specialized personnel) wanted the inventor to propose to them a new weapon fitted to fire the 8mm Lebel cartridge.

8mm Machine Guns

May 8, 1889, the Versailles Experiments Commission took delivery of two 8mm Lebel Maxim machine guns, carrying numbers 169 and 173. These weapons were fitted with an easily dismountable barrel enclosed in a bronze water jacket of 2.7 litres capacity. The system of waterproofing around the jacket was simplified. The actuating lever was improved, the bolt was lightened and the feeding system modified. These machine guns were then installed on a lighter mount with wheels.

The weapons worked well at the beginning of the tests, but thereafter there were many failure to fire incidents and the breaking of several parts were noted. The rates of fire lay between 550 and 600 rounds per minute. The endurance tests were concluded up to 1,300 rounds. Accuracy was lower than that of a Lebel rifle, with:

* a H + L of 66 x 48 cm at 200 m,

* a H + L of 90 x 70 cm at 200 m,

* a H + L of 100 x 120 cm at 400 m.

After that, the Commission asked that many modifications be carried out.

Following that, Misters Bariquant and Marre, representing the inventor, asked the Commission to test four other 8mm machine guns: No. 174, 612, 613 and 614. These weapons were subjected to tests similar to those carried out previously. The results obtained were compared with those obtained with other machine guns also put to the test at the same time:

* Hotchkiss machine gun,

* Colt-Browning machine gun,

* APX 1895 machine gun, gun made at the Puteaux Arsenal near Paris, it was a Gatling type gun with mechanical repeater system.

The final conclusions were rather severe. While they recognized the ingeniousness of the mechanism, which was judged complex, the many-times improved mechanisms had suffered much from the tests and did not support any more the comparison with a new weapon. And it was recommended that the water cooling system be abandoned in favour of air cooling. This report, dated February 27, 1899, finally rejected the Maxim machine gun that was specifically conceived for the French Army. However, an ultimate model in 8mm Lebel (No. 9646) was presented in 1909, but by then it was too late.

| This article first appeared in Small Arms Review V14N4 (January 2011) |