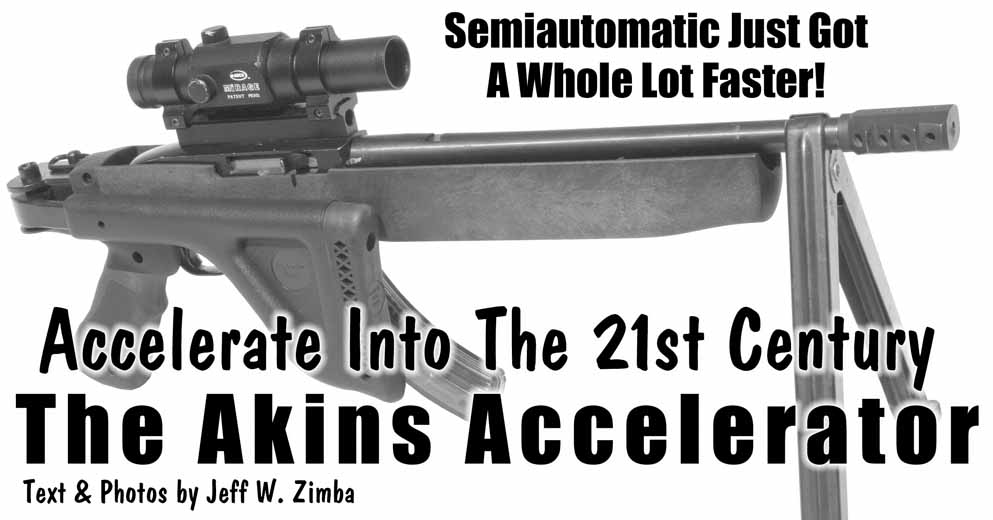

How far back in time would you have to travel to find a Ruger 10/22 that fires at 800 rounds per minute, accurately and controllably, that retails under $1,300? Thanks to the Akins Group, Inc., that time is now.

One of the newest innovations in the recreational firearms industry is now a reality. Under development for several years, the Akins Group, Inc. is releasing their latest product, the Akins Accelerator. The Akins Accelerator is a rifle stock designed to be used with a Ruger 10/22. It contains a linear motion device that in simple terms allows the rifle to recoil inside the stock. This slight rearward travel allows the trigger to be reset upon firing. Upon resetting the trigger, the return-forward motion of the firearm brings the trigger back into contact with the trigger finger of the shooter starting the process over again. It will continue until the magazine has emptied or until the shooter takes his finger off the trigger.

When first contacted by the principals of the Akins Group, Inc. regarding this project a few years ago, while the mechanism description made perfect sense, it definitely sounded a little “too good to be true.” Over the last few decades we have seen several gimmicks and gadgets that were “guaranteed” to create a legal and inexpensive alternative to transferable machine guns and very few have delivered as promised.

About a year ago this writer was asked to participate in a group of BETA testers who would utilize and push the mechanical limits of this new Akins Accelerator learning whatever we could about it and its abilities. This testing would take place while mass quantities were being produced for a future, public release. The testers were given specific instructions not to publicly display the device but were given the option of sharing its existence with close members of their individual firearms community. There have been over 100 BETA test units in all corners of the United States for over a year. The collective test results have been shared within this group, and this knowledge has been utilized to create an even more reliable design. Such a wide test, in regard to environment, ammo, and accessories has helped the Akins Group to fine tune the Accelerator far before making a public release. Much to the pleasure of everyone who has been privy to this testing, the release time is now and units are already being delivered.

Unlike almost all other devices designed to give the shooter a simulated full automatic fire effect, the Akins Accelerator is held and utilized in exactly the same fashion as a traditional rifle or stock. During fire, the stock remains solidly in the grasp of the shooter with a tight cheek weld, and solid grip on the pistol grip and forend. This allows for unprecedented accuracy and control. The only movement is happening inside the stock and it is so smooth and fluid-like, the shooter is almost unaware of it happening at all.

Something else that makes the Akins Accelerator unique is the ability to fire a single shot when desired just by squeezing the trigger in a conventional manner. During our testing it was easy to shoot a single burst of 10-15 rounds, engage a different target and shoot a few rounds in semi, and then empty the remainder of the magazine in a single burst.

How exactly does it work?

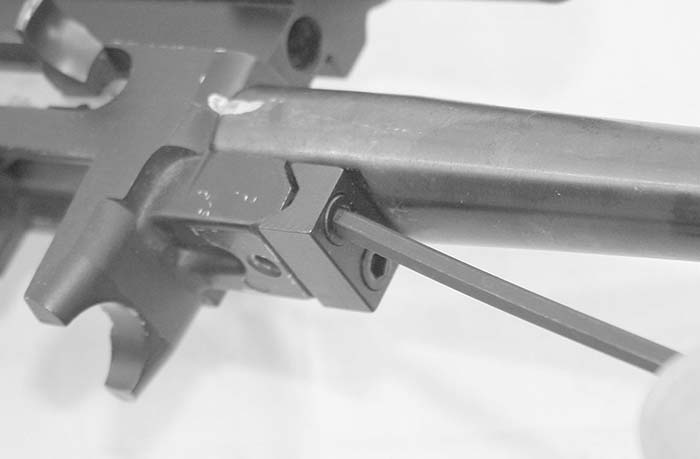

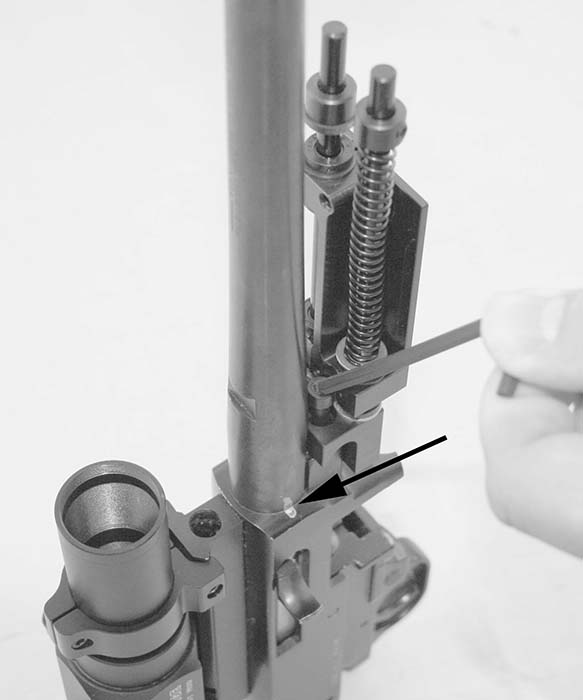

As already briefly explained, the rifle actually recoils inside the stock. It is attached to a device called a Linear Motion Assembly. This device takes the place of the standard V-block barrel retainer supplied with the 10/22 and is firmly attached to the receiver, solidly holding the barrel in place like the factory V-block. The Linear Motion Assembly is then secured into the stock. Once fastened into the stock, the top of the device along with the rifle and barrel are allowed to move rearward and return forward again while the bottom of the Linear Motion Assembly is fastened tightly to the stock.

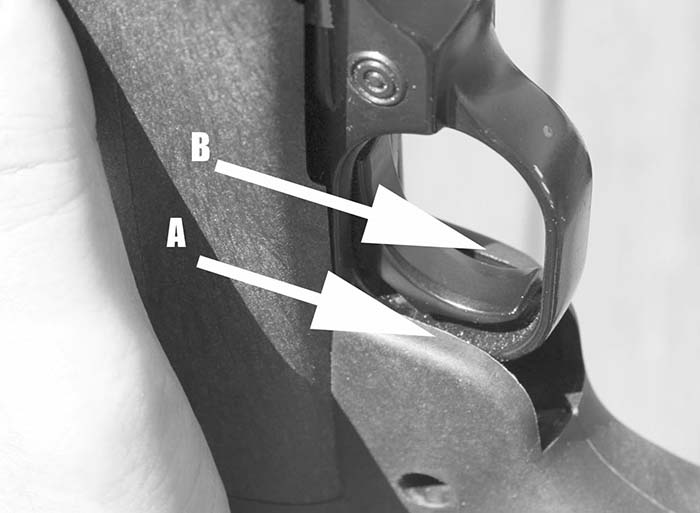

When correctly adjusted and assembled, the firing sequence works in the following manner. The firearm is loaded and charged in a typical fashion and the safety still works in the normal manner as well. When the shooter wishes to fire several rounds in a single burst, the trigger finger of the shooter is “bridged” over the trigger, touching both sides of the stock. As the trigger is depressed, the finger remains static. The recoil of the rifle causes the whole barreled action to move slightly rearward with the assistance of the Linear Motion Assembly. There is a return spring in the Linear Motion Assembly that brings the barreled action to its forward position after the recoil stroke is completed. As the rifle returns to its beginning position, the trigger finger of the shooter now acting as a “bridge” across the trigger area of the stock, comes back into contact with the trigger, starting the process over again. A properly assembled and well-fed 10/22 will continue to function in this way until the magazine is empty. If the shooter wishes to stop shooting the finger is simply removed like any traditional firearm. If the shooter wishes to fire single shots instead of bursts, regular pressure is applied to the trigger instead of using the “bridge” type hold described above. The gun may be used with either the left or right hand.

Why is this NOT considered a machine gun?

Simply enough, it does not meet the definition of a machine gun as defined in the National Firearm Act (NFA), 26 U.S.C. Chapter 53. Machine gun: “The term “machine gun” means any weapon designed to shoot, or can be readily restored to shoot, automatically more than one shot, without manual reloading, by a single function of the trigger. The term shall also include the frame or receiver of any such weapon, any part designed and intended solely and exclusively, or combination of parts designed and intended, for use in converting a weapon into a machine gun and any combination of parts from which a machine gun can be assembled if such parts are in the possession or under the control of a person.”

During the exchange of letters between the Firearms Technology Branch of ATF and the Akins Group, Inc., ATF said, “…As noted previously, the proposed theory of operation of this stock involves the application of the movement of the counter recoiling device to initiate a rapid succession of semiautomatic fire. Our examination and subsequent classification revealed that the stock did not constitute a “machine gun” as that term is defined in the National Firearms Act (NFA), 26 U.S.C. Chapter 53…”

Not only are the Akins Accelerator stock and assembly not considered a machine gun, they are not even classified as a firearm. This is only an accessory, needing a legal, semiautomatic host firearm to even function. The semiautomatic firearm (in this case the 10/22) added to the stock assembly still only has the ability to discharge one shot per function of the trigger as required by law. The rapid succession in which these shots are fired has no bearing on the legality of the system as noted in the above letter from the Firearms Technology. This is the same logic used in rulings for decades on the numerous hand cranks and similar rapid-fire devices offered on the market today and in the past.

Assembling your Akins Accelerator

When you receive your new stock assembly it will come with an owner’s manual, a few pins and clips, and a special Bondhus Ball End Wrench for removal of and replacement of the barrel retaining screws. Read the manual from front to rear and everything will immediately become crystal clear. It is a simple task to mount correctly but it must be done exactly as directed to function as well as it has the ability to do.

The factory trigger and magazine catch pins must be replaced with new provided pins before firing. The factory pins have a tendency to “walk-out” and these new retaining spring pins will stay firm.

The factory barrel retaining V-block must be removed and replaced with the new Linear Motion Device. Before removing or loosening this V-block it is wise to use a felt pen to mark the position of the barrel in relation to the receiver. This way during reassembly it will be in exactly the same position and the chance of malfunction from contact with the ejector will be drastically reduced.

After the V-block has been completely removed, the Linear Motion assembly will be installed in its place using the factory screws. This is most easily accomplished with the assistance of the ball end of the provided wrench. Making sure the barrel is lined up with the receiver with your previous markings, the Linear Motion Assembly can be tightened up. When doing this, only tighten each screw a little then alternate to the other one for a few turns. The necessity to line up the operating rods so they are completely parallel with the barrel is of extreme importance. Over-tightening one side may cause the rods to lean to one side. By slowly tightening them in an alternating manner getting them parallel with the barrel should be no problem.

After the device is tightened to the barrel block it is time to install the assembly to the stock. Care must be made when positioning the system into the stock so that the trigger mechanism is not too far forward. Upon firing, it has to break clean and allow the receiver to move rearward of the placement of the shooters finger. It should be positioned very close to the rearward most area. A little adjusting of this placement may be all the “fine tuning” necessary once everything is assembled and it is time to hit the range.

The whole trick to this running dependably is realizing that there is very little residual energy left from the recoil stage in this little Rimfire and anything allowed to rub anywhere will further rob that much needed power. This includes a good cleaning of the entire rifle mechanism not withstanding the trigger group and chamber area. If the rifle is dragging on the stock in any area it must be adjusted so it can float freely to ensure the fullest potential available.

Range Test Time

Range test time has been the greater portion of a year. This is a long time to work with something compared to most gun testing. We were fortunate in assembling a gun that ran well from the very beginning. It has been noticed that a small “break-in” period may be necessary to loosen up tight tolerances caused by factory finishing when using new firearms. A well-used rifle was chosen, being completely disassembled and given a thorough cleaning and lube prior to being assembled in the new unit. The guide rods of the Linear Motion Assembly were lined up correctly and it fit well in the stock. The factory 10-round magazines just whistled through it so immediately went on to 30-rounders and even a 50-round teardrop drum. All worked flawless.

An early concern was the number of accessories that could be added to the system and still work reliably. We ended up using a 12-inch barrel with an AWC MKII Silencer for the majority of the testing and the rifle was topped with a PRO-MAG scope mount and ADCO Mirage electronic sight. Nothing caused any type of regular malfunction and every combination of ammo, magazine and accessory worked just fine. Our test model ate everything it was fed.

The correct function testing procedure recommends factory 10-round magazines with CCI Mini-Mag solid point ammo to lessen the variables. After running reliably with that combination it is recommended to upgrade or change only one thing at a time to keep a firm grip on potential problems. In dealing with Rimfire guns, some guns are finicky with specific types of ammo while others only like specific magazines and this configuration will not be any different.

During our numerous trips to the range it was easy to complete 30-round and 50-round magazine dumps regularly. Keeping the gun clean was the key. Other than the excellent functionality of this system, the controllability was really what set it apart from other systems we have tried in the past. It is very easy to keep an entire magazine of ammo on a small target from 50 feet away due to the lack of felt recoil and muzzle rise.

We used a mixed bag of almost every type of .22LR ammo readily available with most functioning fine. We extensively fired the 550-round Federal bulk pack ammo and the Remington Golden Bullet bonus pack ammo, both retailing under $9. We also used lots of CCI Blazer. Testing has shown that the use of CCI Mini-Mag Solid Point ammo is one of the most dependable. We recorded rates of fire from the 650rpm range to almost 900rpm depending on ammunition used.

This device has brought smiles to the Class III enthusiasts I have allowed to view and handle it. It is not the amazing firepower or the availability of reliable and inexpensive ammunition. It isn’t even the number of available accessories like high capacity magazines and sound suppressors it seems to work fine with. The real allure seems to be the technological aspect that just keeps people grinning from ear to ear.

People quickly grasp the concept and then balk when they inquire about the price. A demonstration is necessary to really grasp how well this system works. A 30-round or 50-round mag dump is usually sufficient to solicit a, “Hey, let me look at that. That’s really just a semi? I gotta get me one of these!” Words alone, even sprinkled with a few photos just don’t convey how well this actually runs. For that purpose, Akins Group, Inc. has set up a little space in the web to share thoughts, ideas, photos and videos and you are welcome to participate. You can find them at www.firefaster.com. You will be very impressed with what you see and hear there.

The Akins Accelerator is currently offered in three configurations. The Full Stock retails for $975, the Folding Stock retails for $1,125 and the Pocket Folding Stock retailing for $1,185.

Akins Group, Inc Dept. SAR P.O. Box 430 Cornelius, OR 97113 (503)359-1359 www.firefaster.com

| This article first appeared in Small Arms Review V10N2 (November 2006) |