By Michael Heidler

Some people may find it a nuisance to reload a single-shot shotgun after every shot. This was also the case for Herman Alofs, who in the early 1920s thought about how to make a repeating shotgun out of it.

Herman Gerrit Alofs was a descendant of the Dutch emigrants Gerrit and Anna Alofs (née Balder) and was born on May 17, 1903, in a small settlement called East Saugatuck in Michigan. Not much has been found out about his life and education so far. In any case, he was probably a keen tinkerer, handyman, and marksman. And, so, at some point he had the idea of converting single-shot shotguns into repeaters.

The U.S. patent 1,507,881 granted to him on 9 September 1924 with the uninspiring title ‘Firearm’ is the first sign of his inventive activity. In the meantime, he also moved a few miles north to the city of Holland. In order to manufacture and market his patented invention “Alofs Reloading Magazine”, another change of location was necessary. This time to Grand Rapids, the second largest city in the state of Michigan. There he founded the Alofs Manufacturing Company. So far, however, the only known product of this company is the multi-loading magazine. Where the start-up capital came from and whether Alofs had any other occupation lies in the darkness of history.

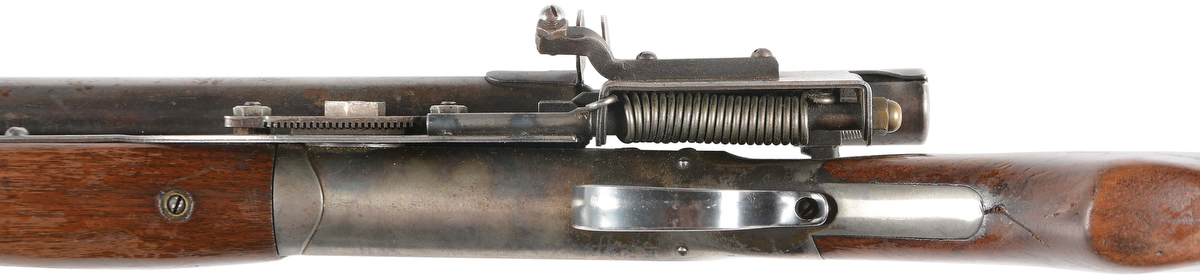

The mechanics of the device were simple and robust. It could be attached to a break action shotgun by anyone who did not have two left hands. Although the weapon was not a semi-automatic, the reloading process was extremely fast and allowed for an astonishingly quick firing sequence.

Alofs summarized the basic idea of his design in the introduction to his patent, “My invention relates to improvements in fire arms, and more especially in shot guns, and its objects are: first, to provide a means whereby an ordinary shot gun may be readily converted into a ‘magazine’ gun; second to provide a means whereby a new cartridge will be transferred to the gun barrel when the stock is broken down, and, third, to provide a means whereby the expulsion of a discharged cartridge from the gun barrel will trip a catch and allow the transfer magazine of my appliance to transfer a cartridge to, and into the gun barrel.”

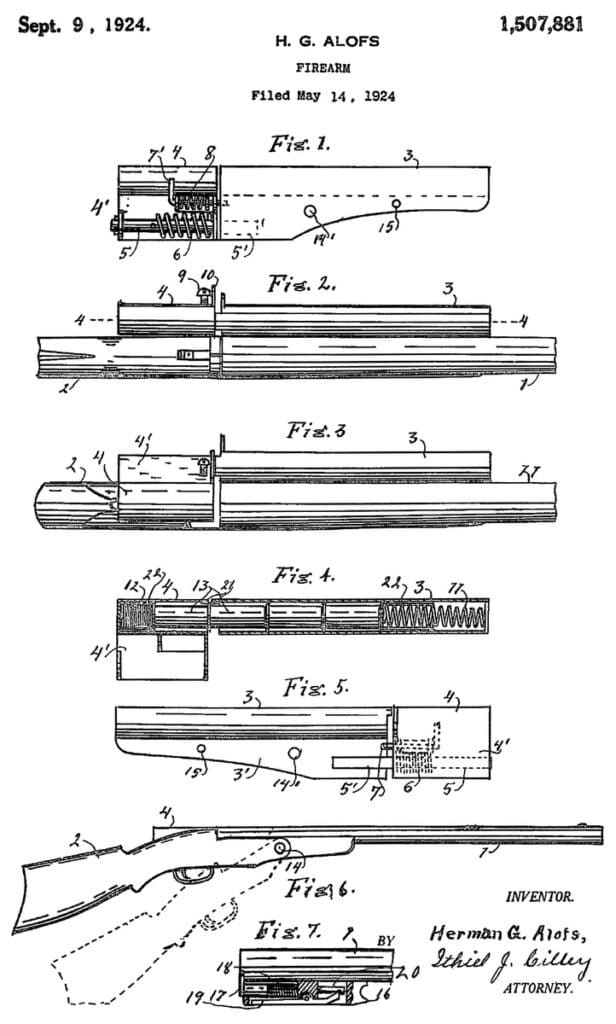

The function is well explained by the drawing in Alofs’s patent… The device was attached to the weapon with a bolt that replaced the standard hinge pin (14) and a screw that was screwed into the wooden fore-end (15). Slotted holes for the screws allowed the device to be adjusted exactly to the respective weapon. The tubular magazine consists of a stationary part (3) and a movable part (4) that can rotate around an axis (5) under the action of a spring (6). The lock (7) prevents the movable part from rotating. The stationary part of the magazine has room for three shells which, when inserted, gradually compress the strong spring (11). A fourth shell can be stowed in the movable part of the magazine, against the pressure of a slightly weaker spring (12). With an additional shell inserted into the gun, the shooter has a total of 5 shells at his disposal.

After firing, the shooter opens his break action shotgun as usual, and the extractor ejects the empty case. It hits the hook of the catch (7) with momentum and releases it. This causes the movable magazine part to swing to the right behind the chamber under the action of the spring (6) and the next shell is pushed into the chamber by the spring (12). A plate on the left of the movable magazine section covers the opening of the stationary section so that no shells fall out. When the gun is closed, the movable magazine part turns back to the left into its original position. Then the spring (11) pushes the next shell from the stationary to the movable part of the magazine and compresses the spring (12).

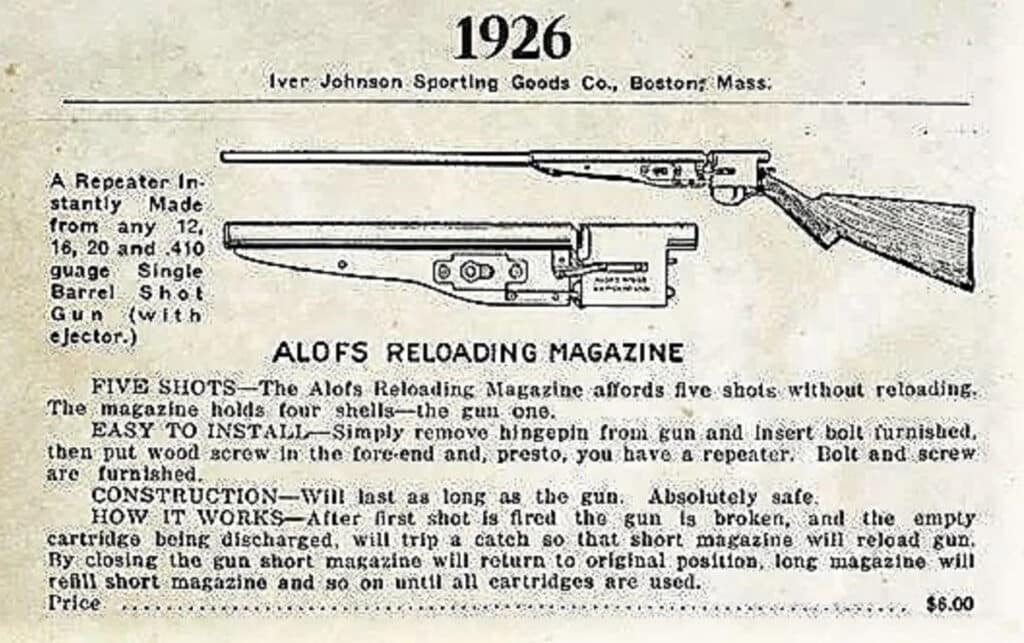

The Reloading Magazine was sold by Alofs for single-shot break action shotguns in .410, 20-, 16- and 12-gauge. A mandatory prerequisite for successful use was the presence of an ejector, as his magazine could not offer this function. For optimal adjustment, several different spring types were available for the two magazine sections, depending on the weapon and type of ammunition. A complete conversion kit with magazine, mount, fixing material and an instruction manual cost an even $6 in the 1926 catalogue of Iver Johnson Sporting Firearms.

Before World War II, the Alofs Manufacturing Company produced various metal products, such as clothes hangers. During the war, defense products were increasingly on the agenda. Among other things, the company produced devices for demagnetizing aircraft so that their magnetic compasses would function properly. In 1946, the company was converted into a joint-stock company. In the early 1960s, the company began manufacturing safety belts for motor vehicles. Although seat belts were not made compulsory until 1966, many manufacturers had already started to offer this extra safety for passengers as an optional extra. Alofs’s business was good, his belts under the brand name LYFE-LOK were used by almost all well-known vehicle manufacturers at home and abroad. With the introduction of compulsory seat belts, the brand name was changed to LYFE-BELT. Together with Andrew G. Carter of the Carter Engineering Company in Grand Rapids, Herman Alofs developed further belts and locking mechanisms until 1969, some of whose advantages he patented.

Herman Gerrit Alofs died on March 10, 1983, at the age of 79. His Alofs Manufacturing Company is listed in the commercial databases as dissolved, without further details. Due to the lack of surviving documents, nothing is known about the sales figures of his Reloading Magazine. Only very rarely does one appear on the collectors’ market. And although technically exceptionally interesting, the hammer usually falls surprisingly early at 500 to 1,000 dollars. And that includes the shotgun.

Thanks for the photos and information to Morphy Auctions and Springfield Armory NHS.