A vintage M1 carbine is displayed with an Automag III pistols and a box of 1944 dated Winchester carbine ammo. The loose rounds in the photo are modern soft-points.

By Frank Iannamico

Probably the best promotional advertising for any firearm is to be featured in a Hollywood film. An example was when the Smith & Wesson Model 29 appeared in several of the Dirty Harry movies beginning in 1971. The demand, and asking price, for S&Ws .44 Magnum revolvers skyrocketed and they soon became very difficult to find.

The term Auto Mag became part of the American lexicon in a 1983 sequel to the Dirty Harry film, Sudden Impact. In that film Clint Eastwood’s character inspector Harry Callahan, uses his .44 Auto Mag pistol to take down the bad guys. In the 1987 film Beverly Hills Cop II a .44 Auto Mag is used by the bad guys. However, due in part to a lack of availability, sales of the Auto Mag pistol never approached that of Dirty Harry’s Model 29.

The Auto Mag Pistol

The original Auto Mag pistol was conceived and designed by Harry Sanford and Max Gera during the late 1960s. Mr. Sanford established the Auto Mag Corporation during 1969 in California. The .44 AMP (Auto Mag Pistol) cartridge was also conceived by Harry Sanford. The original cartridge cases were formed from .308 rifle brass shortened to a length of 1.298 inches. The bullet was .429-caliber 240-grain with a powder charge of 26 grains. The average velocity was 1450 feet per second with 1120-ft/lbs of energy.

Production of the Auto Mag pistol began at a factory located in Pasadena, California during 1970. The first gun was shipped to a dealer in August 1971. After producing only a few thousand pistols, the Auto Mag Corporation declared bankruptcy on May 3, 1972. The Trust Deeds Estates Corporation (TDE) of El Monte, California purchased the machinery, unfinished guns and parts. They also hired Sanford to produce the guns from the parts. In 1974 after new financing was acquired, TDE made minor engineering changes and re-tooled for complete production. In September of that year Lee Jurras signed an exclusive world-wide sales and distribution agreement for all Auto Mag pistols. Mr. Jurras not only took over distribution but also handled warranty and parts supply. By 1982 the Auto Mag was once again facing financial difficulties, the assets changing hands and logos several times before the Auto Mag pistol passed into history. In the end there were Auto Mag pistols produced with Pasadena, North Hollywood and El Monte, California addresses.

The Automag II

Automag Pistols

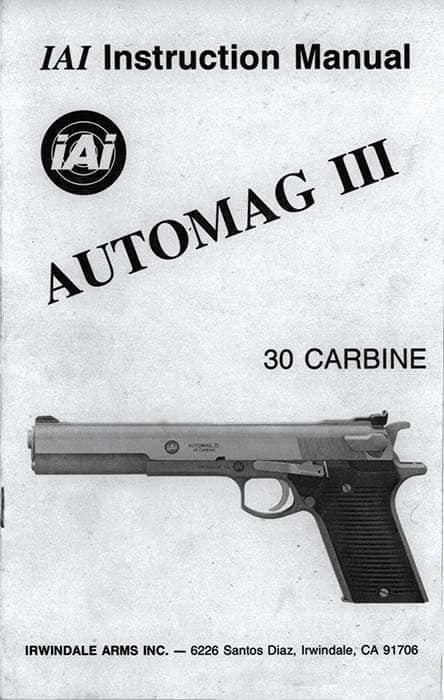

During 1987, the .22 magnum Automag II pistol was introduced, the Automag name now appearing as one word. The new pistol was designed by Harry Grossman and manufactured by Arcadia Machine and Tool Inc. / AMT of Covina, California; a company owned by the same Harry Sanford of the original Auto Mag Corporation. After the original AMT encountered financial problems a new company was formed in 1989 called Irwindale Arms Inc or IAI, relocated to Irwindale, California. At the 1989 SHOT show it was announced that IAI would be producing the Automag II and III.

Automag III

The focus of this article is on the Irwindale Arms Inc. /Arcadia Machine and Tool Automag III pistol, chambered for the .30 caliber M1 carbine cartridge.

The first semi-automatic pistol chambered for the .30 carbine cartridge was the Kimball, first advertised in 1955 by the J. Kimball Arms Company of Detroit, Michigan. The Kimball was billed as “The World’s Most Powerful Automatic Pistol”. The Kimball went into series production in 1958. However, the delayed blow-back Kimball quickly developed a reputation for self-destructing; the carbine cartridge proved too powerful for the pistol’s design. Only a few hundred .30 Kimball pistols were produced before the company went out of business.

The first known public advertisement for the .30 caliber Automag III pistol appeared in the February 1989 issue of Guns & Ammo magazine. The first known gun writer’s test was conducted in July of 1989, and was featured in the October 1989 issue of Petersen’s Handguns. Also featured in the article was the Irwindale Arms Inc. Javelina in 10mm, which was similar in appearance. Both pistols were marked with the IAI logo and Irwindale address. During 1990 the Automag III was placed in series production.

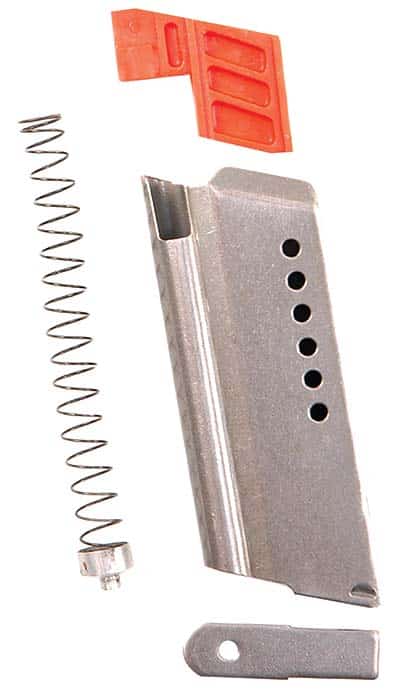

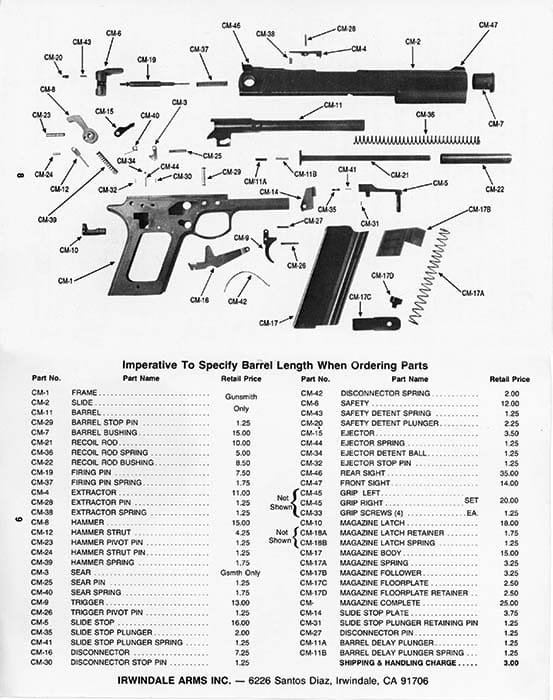

The Automag III is a single action, recoil-operated semi-automatic pistol whose action is based on John Browning’s tilting barrel locking system, unlocking is controlled by cam-shaped slot in the lug below the chamber of the barrel, which interacts with the slide stop axis pin. The pistol is made of a 17-4 stainless steel, with the exception of the barrel, which is 416 stainless, and the A-2 tool steel sear. The major components including the slide and frame are investment castings. The stainless steel has a bead-blasted matte appearance with the exception of the sides of the slide, which are polished. The grips are made of a black composite material. The slide mounted safety is a simple rotating cylinder that blocks the hammer from contacting the firing pin. The pistol can be placed on safe even if the hammer is not cocked, the safety does not lock the sear or trigger. A cocked hammer will fall by pulling the trigger when the safety is applied, but the safety will block the hammer from striking the firing pin. The slide stop is on the left side of the frame, it locks the slide back after the last shot has been fired from the magazine. The magazine release button is located on the left side of the frame just aft of the trigger. The single-stack, single-feed magazine holds 8 rounds. The rear sight is a Millet adjustable; the front sight is a fixed ramp. The trigger pull measured 4.5 pounds. The Automag III is similar in appearance to the classic 1911 pistol, albeit larger in size. The grip is somewhat wide, measuring 2.25-inches by 1.25-inches, necessitated by the length of the .30 carbine round. The unloaded weight of the Automag III is 45 ounces, overall length is 10.5-inches, barrel length is 6.5-inches. Field stripping procedures are very similar to the 1911 pistol.

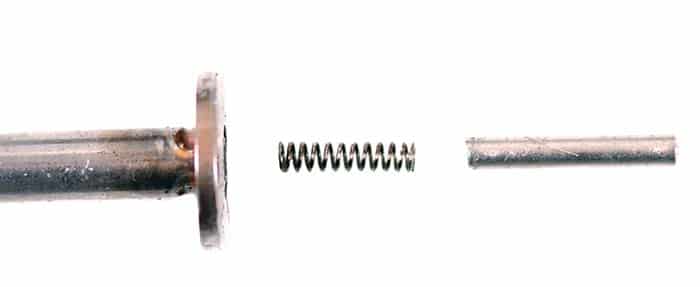

An interesting design feature is the spring-loaded pin assembly that protrudes out of the rear of the recoil spring guide rod. The purpose of the pin is to delay the barrel in order to prevent it from jamming on the slide as it moves forward. It should be mentioned that when field stripping the pistol, special attention should be paid to the, easily lost, spring and pin.

There are different configurations of the Automag III pistol, which was manufactured under different company logos. Due to the small number of examples available to examine it is not possible to pin point exactly when certain features appeared or were deleted.

The earliest Automag III pistols in .30 caliber carbine were marked with the IAI logo of Irwindale Arms Incorporated on the slide and frame. Known examples have a locking lug on the barrel and corresponding locking groove in the slide.

Later Automag pistols were marked with the AMT logo of Arcadia Machine and Tool on the slide and frame.

The right side of the slide now included the warning “CAUTION capable of firing with the magazine removed, read instruction manual before handling this firearm”. Known examples of this variation had a small or no locking lug on the barrel, the barrel hood locked into the slide. Reportedly this variation will function without the barrel delay spring and plunger assembly in the guide rod. Two other features on the AMT pistols are a three dot rear sight and the magazine release button has a slightly different checkering pattern. The AMT marked models are more common than the earlier production IAI marked pistols.

There was also an Automag III model available in 9mm Winchester Magnum. However, many of the components differed in dimensions from the .30 carbine caliber model and swapping calibers between the two guns is not practical.

After squeezing the trigger of the .30 carbine caliber Automag III two things become immediately apparent, a huge muzzle flash and a loud report. Despite the flash and bang, recoil is relatively mild. The average muzzle velocity is 1650 to 1775 feet per second firing GI surplus ammunition. After one grows accustomed to the noise and flash, the pistol is capable of decent accuracy, shooting groups of 2.5 to 3-inches at a distance of 25 yards.

Pistols produced under the Automag name by IAI/AMT included: the Automag II in .22 WMR, Automag III in .30 Carbine and 9mm Winchester Magnum, Automag IV in .45 Winchester Magnum, Automag V in .50 Action Express and the Baby Automag in .22 LR.

After AMT went out of business in the late 1990s the company’s assets and trademarks were sold to the Galena Industries of Sturgis, South Dakota, who continued the AMT line of pistols. Galena’s assets that included tools and tooling, sixty pistols and thousands of parts were offered at auction in July of 2002.

In 2004, the re-established High Standard Corporation announced that they would make Automag pistols and now offers several models under the AMT banner. To date the company does not offer a .30 caliber Automag III.

Field stripping the Automag III is similar to the 1911 pistol.

- Remove the magazine and visibly check the chamber to ensure it is not loaded.

- Retract the slide far enough to push out the slide stop, and pull it out of the frame.

- Pull the slide/barrel assembly forward and off of the frame.

- To remove the barrel from the slide, depress the recoil rod bushing and rotate the barrel bushing until it clears the rod bushing. CAUTION the recoil rod bushing is under spring pressure.

- Remove the recoil rod, being careful to keep the barrel delay spring and pin from becoming lost.

- Remove the barrel through the front of the slide.

- No further disassembly is needed or recommended.

Despite being a proprietary cartridge for a military weapon, those who carried the M1 carbine became fond of the handy weapon. Interest was renewed during the 1960s when surplus carbines were offered through the NRA for $17.00. When the original supply of military issue carbines dried up, there were several commercial companies that introduced aftermarket copies. Before long several hand guns were produced, further increasing interest in the little .30 caliber round.

During World War II there were four experimental Smith and Wesson revolvers made for the round, the cartridges were loaded on half-moon clips. More modern handguns include the Ruger Blackhawk revolver introduced in 1968, was revised in 1973 as the New Model Blackhawk, and the Dakota single action army revolver in .30 carbine made in Italy. Also available in .30 carbine caliber was the Thompson/Center single-shot pistol, which is no longer offered by the manufacturer. Marlin briefly offered their .30 carbine caliber Model 62 Levermatic rifle from 1966 to 1969. All of the aforementioned firearms helped sustain interest in the cartridge.

Origins of the .30 Caliber Carbine Cartridge

The lightweight U.S. caliber .30 carbine emerged during World War II from the need to better arm soldiers who were rear echelon support troops. The carbine was conceived to provide an offensive as well as a defensive weapon that would have far more range than a pistol. The semi-automatic carbine offered a 300 yard range and a 15 round magazine.

Cartridge, Carbine, Caliber .30

Winchester developed a new mid-range cartridge to be used in the new “light rifle”. The cartridge was designated as, Cartridge, Carbine, Caliber .30 M1. The early characteristics of the new cartridge were;

a. Bullet weight: 110 grains.

b. Charge weight: 14.5 grains

of IMR 4227

c. Primer: Winchester No. 116

d. Pressure: 31,000 PSI

e. Muzzle velocity 1,860 feet per second.

The cartridge was approved as Standard on 30 September 1941. The Ordnance Department awarded contracts to the Western Cartridge Company, Winchester Repeating Arms, Remington Arms Company, Lake City Ordnance Plant and the Kings Mills Ordnance Plant. While corrosive primers were used in WWII 30’06 and .45 ACP caliber U.S. service cartridges, the .30 caliber carbine rounds all utilized non-corrosive primers.

The original configuration of the .30 caliber carbine cartridge was changed early in 1942. The original .30 caliber 110-grain projectile had a cup style base, which tests had shown was unstable during firing, and would often leave a ring of gilding metal in the forward end of the chamber. A new flat base 110-grain projectile was designed to eliminate the problem. The type of powder used in carbine cartridge was also changed. The original DuPont powder proved to be too bulky for the small case. To achieve a higher projectile velocity a new DuPont powder was introduced. The new powder increased the carbine’s muzzle velocity to 1,970 feet per second and raised the chamber pressure to 40,000 PSI.

The new specifications for the improved carbine cartridge were;

a. Bullet weight; 110 grains

b. Charge: DuPont 4809 or Hercules 3950.8B (alternate)

c. Primer: commercial non-corrosive

d. Pressure: 40,000 PSI

e. Muzzle velocity 1,970 feet per second

In September of 1944, the nomenclature of the .30 carbine round was changed to Cartridge, Ball, Carbine, Caliber .30 M1. The change, adding the word “ball”, was to avoid confusion with the newly adopted tracer and grenade launching cartridges developed for the carbine.

| This article first appeared in Small Arms Review V20N2 (March 2016) |