By Leszek Erenfeicht

Henryk Strapoc (pronounced: “Strompoch”) of Czerwona Gora-Podlesie in the Kielce region of southern Poland, was a village blacksmith’s younger son and a talented mechanic designer in his own, with a flair for amateur gunsmithing. At the ripe age of 15, in 1937, he made his first, entirely hand-made semiautomatic pistol patterned after his uncle’s cheap Spanish .25. He proudly demonstrated it to his classmates in a ravine behind the village, but got caught red-handed in the process by the school headmaster. He very nearly ended up in jail for illegal gun manufacturing and possession, but his early age proved his defense As a juvenile and first-offender, he was only chastised and ordered to report at the local police station once every week for a year’s duration. Despite this early setback, and his solemn promises not to stray again from the straight and narrow, he made three more pistols and a revolver before the war started.

In 1939, Poland was invaded by Nazi Germany and then, a little over a fortnight later, was stabbed in the back by the Soviet Union. Fighting on both fronts, she was eventually defeated despite a gallant defense. Hopes for a military action on the West, spurred by Britain’s and France’s declaration of war against Germany on September 3, were forlorn. Other than declarations, no tactile help was provided. The occupied country was divided, with “Uncle Joe” Stalin taking up 54% of the pre-war territory – more than Hitler did!

Almost overnight, various factions started to organize military underground resistance structures. The political spectrum of the Polish underground was as colorful and varied as was the pre-war society. Every party and a faction had its own underground military branch, running the gamut from socialists on the left wing up to crypto-fascist nationalists on the far right one; only the Communists kept out of it, obeying their orders from Moscow. Strapoc joined the conservative Polskie Stronnictwo Ludowe (PSL, Polish Peasant Party) underground forces, called the “Peasant Battalions” (Bataliony Chlopskie – BCh, or phonetically misspelled: BH, hence the later name of his submachine gun). He was at long last going to do what he loved: gunsmithing for the local guerilla force.

After two years of re-vamping the small arms dug out from sites, when surrendering Polish Army units cached their weapons for further fight, by the fall of 1942, he commenced work on the submachine gun of his own design.

One class of arms that his and most other outfits most sorely missed were submachine guns. Pre-war Polish Army only experimented with submachine guns, which by then proved to be very useful guerilla weapons. At that stage, the SOE had not started their weapon air-dropping program yet, and the front, where first-line units abounded in SMGs was far, far away, out in the East, at the feet of Caucasus, where German offensive targeted their own “one bridge too far” at the city of Stalingrad. The only source of SMGs at that time were German police units, mostly armed with antique MP 18,I – sometimes even complete with their oblique snail-drums. Disarming German police units resulted in bloody punitive raids against suspected villages, and, besides, only one in ten policemen or MPs had the bloody thing. Having an SMG at your disposal was a great prestige between the guerillas, and his outfit was going to have one, come hell or high water. Several ambushes against German police units produced no demanded result: several rifles and pistols were captured, but no SMGs, and in reprisal several villages were burned. Then Strapoc proposed to better use the other alternative, and decided to design and built a SMG of his own. He set up a workshop in his brother Edward’s forge. The only tools he got there for the job were those he was able to find in a village smithy: a hacksaw, hand-cranked drill and lathe, set of screw-taps and die-nuts, a handful of files and a couple of drifters.

Submachine guns were novel firearms then, and starting his work in the deep hinterland, Mr. Strapoc only had a general idea on how the actual SMG worked. Despite this, by spring of 1943 the weapon was ready for testing and worked remarkably well from the first shot on. Jan Swat (nome-de-guerre “Orzel”), a draughtsman from the former Huta Ostrowiec (HO) metalworks in nearby Ostrowiec Swietokrzyski, now renamed the Hermann-Goering-Werke, prepared a set of drawings for all component parts of the gun. His other friends, sworn-in guerilla soldiers from the HO works, started to turn out parts for the weapon in secrecy. Strapoc was tasked with finishing, fitting and assembling the submachine guns. The misspelled name “BH” struck to their sides was a matter of available letter punches, and not a testimony to the incomplete education – his brother’s set of punches simply lacked the letter C.

Preparations for assembling the first batch took a full year to complete. Parts manufacture began by October 1943, with the first finished components delivered in late November. First complete “series-production” submachine guns were test-fired and handed over to the partisans in the first days of 1944. Of the 11 weapons finished before the Red Army arrived in July of 1944, only one has been preserved in Warsaw’s Polish Army Museum.

Main Characteristics

Most of the dozen BHs manufactured (one prototype and 11 of the first batch) were chambered for the 9×19 Luger, though the two or three last ones were chambered for the Soviet 7.62×25 Tokarev ammunition. As the barrels were recycled from old rifles, it was way much easier to find a ready .30 caliber barrel for the Soviet round than having to re-drill and re-rifle these to fit the German round.

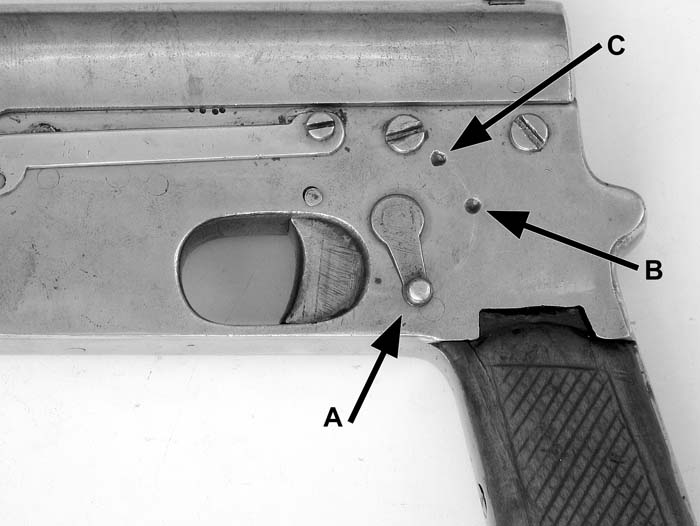

Though the BH was a blowback submachine gun, the design incorporated many novel and unusual features – more out of innocent ignorance, because Strapoc simply didn’t know that nobody used these in the real SMGs, than in the pursuit of the novel designing trends. The bolt is more of a slide, telescoping the barrel, the latter guiding the return spring in turn: just like in pocket semiautomatic pistols. The firing mechanism incorporates a hammer, and the weapon fires from the closed breech position. There is a three-setting safety/fire selector lever fitted on the left side of the receiver. In the fully automatic (FA) mode of fire, the automatic sear trips the sear for each shot, thus preventing the premature firing of the round. The trigger bar acts as a disconnector in semiautomatic (SA) firing mode. There is no hold-open device. The extractor claw is a spring-loaded rotary variation, also common for the European pocket automatics of the early 20th Century. Projection of the automatic sear serves as an ejector.

The weapon is fed from the 30/32-round staggered-row box magazine. The empty magazine weighs 0.31 kg (.68 lbs) and, loaded, weighs 0.7 kg (1.54 lbs). The sights are of open iron type, with a rigid, pistol-type V-notch and front blade, roughly set for 50 meters, with the sighting radius being 385 mm (15.15 in.). The bolt, incorporated into the slide reciprocating on top of the frame/receiver; again in a pocket-automatic fashion, can be retracted by hand or by pulling on the front portion of the sling attached to the underside of the slide’s front rounded portion. The weapon is 445 mm (17.52 in.) long overall. There is no stock of any type, nor a provision for one. The empty weapon weighs 2.43 kg (5.35 lbs.), and loaded 2.82 kg (6.21 lbs.).

Design Features

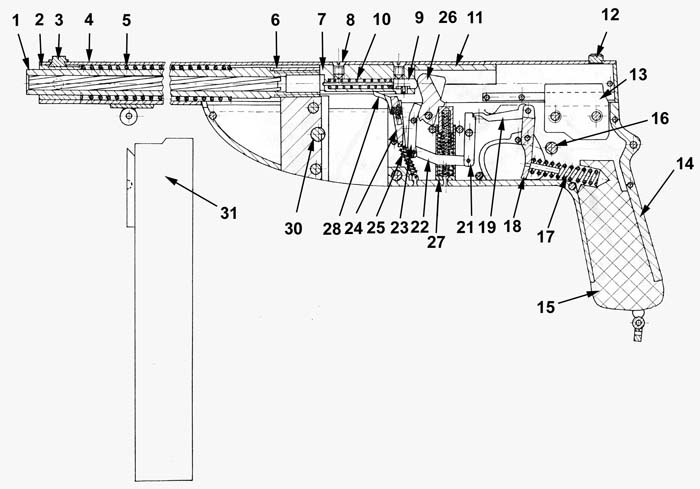

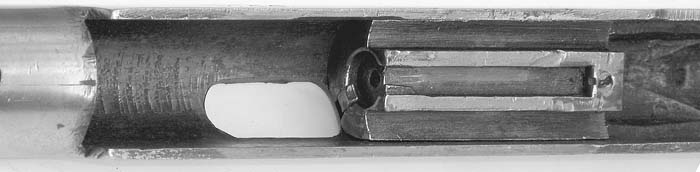

The BH submachine gun consists of six main groups and assemblies: a slide assembly, a frame assembly with rigidly installed (screwed-in) barrel, a trigger group, a hammer group, a magazine and a return spring.

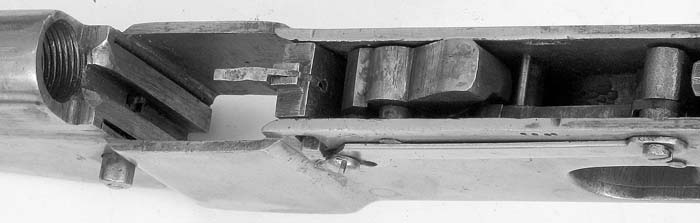

The slide assembly includes front spring cap/barrel bushing, slide, and the breechblock, complete with spring-loaded firing pin and extractor claw, secured inside the slide by means of two screws.

The spring cap is secured by two screws, one on either side of the muzzle. There is a large ejection opening on the upper right side of the slide. The front sling swivel is brass soldered to the lower part of the front, cylindrical portion of the slide. The complete bolt assembly weighs 0.685 kg (1.51 lbs.).

The frame assembly consists of the frame, barrel screwed into the frame projection, magazine catch assembly, two slide rails bolted to the rear part of the frame and a wooden pistol grip fitted with the rear sling swivel. The whole assembly weighs 1.39 kg (3.06 lbs.). The barrel is 240 mm (9.45 in.) long, with 6 grooves, right hand twist rifling, one turn in 224 mm (8.82 in.).

The trigger group incorporates an ingenious and intricate duplicated firing mechanism for the two firing modes, consisting of a single trigger blade with two trigger bars, sear with two linking levers, automatic sear for fully automatic fire and a fire selector-cum-safety lever. The automatic sear prevents the premature firing of the round and carries the ejector.

The hammer group consists of a hammer with its spindle and the hammer plunger containing concentric, doubled hammer spring.

The magazine is of a staggered row double-position type, and consists of a milled body with a catch lug soldered to the front, a follower, a bottom lid with a snap-catch, and an ingenious staggered-coil follower spring.

The return spring is of helical variety, 20 mm (.79 in.) in external diameter, and has 32 coils made of 1.2 mm (.047 in.) wire.

Field Stripping and Reassembly

- Unload and clear the weapon.

- Unscrew the front cap retaining screws and remove the cap and spring.

- Retract the slide, unscrew the barrel and withdraw it from the slide.

- Loosen four frame-rail retaining screws, thus enabling the slide to be slid up and off the frame. Further stripping is neither needed nor recommended. To reassemble, repeat in reverse order.

Action of the Mechanisms

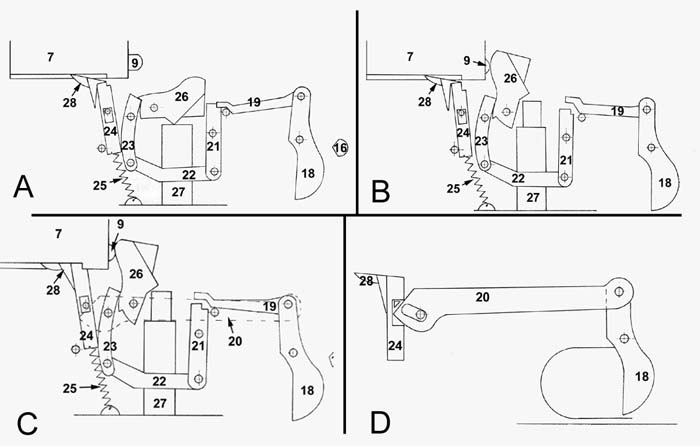

The weapon is ready to fire in a semiautomatic mode with the full magazine (31) in place, bolt (7) fully home, hammer (26) cocked, automatic sear (24) lowered, fire selector (16) set to the semiautomatic notch. Upon squeezing the trigger (18), the main trigger bar (19) rotates the upper sear link (21) and disconnects with it in its foremost position. The upper sear link pulls the lower sear link (22), which in turn rotates the sear (23), freeing the hammer (26) to fall. The hammer, propelled by the mainspring acting via plunger (27), strikes the inertia firing pin (9), which in turn strikes the primer of the chambered round, thus igniting the cartridge. The expanding gases blow the bolt backwards. The bolt extracts the spent case from the chamber by means of the extractor claw, while cocking the hammer. The case is then ejected through the opening in the slide upon hitting the ejector (28), forming part of the automatic sear (24). During the return stroke, the bolt strips the next round from the magazine’s (31) lips, feeds and then chambers it. The returning trigger makes the trigger bar (18) snap in place and contact the upper sear link. Upon pulling the trigger again, the cycle is repeated until all the rounds are fed from the magazine.

In the fully automatic mode the cycle is mostly the same. It starts with the same parts disposition, except for the fire selector being set to the full automatic notch. The trigger sets the hammer in motion by lieu of a semiautomatic trigger bar and both sear links, just like in the semiautomatic mode, but at the same time the secondary, external fully automatic trigger bar (20) raises the automatic sear (24). Upon the shot, the slide on finishing its return stroke rotates the automatic sear, which in turn pushes back the sear, thus triggering the next shot. The cycle repeats itself as long as rounds are fed and the trigger is held back.

The Technology Issue

To manufacture such a complicated device with the primitive tools at hand was a serious technological challenge; making the production difficult and time-consuming. It would take several months for one man to make the whole set of parts for one gun. This rate was unacceptable, and thus the manufacturing of the parts was delegated to the Huta Ostrowiec employees. They were responsible for production of the slides, bolts, frame groups, trigger and hammer mechanisms, magazines and barrels pre-fabrication. The latter were made out of rifle barrels from scrapped World War I worn-out rifles, found by accident in the far corner of the metal works scrap-heap. These were then supplied to Strapoc in 480 mm (18.9 in.) long sections, with external threads cut to either end. Strapoc was boring these out to about 9mm internal diameter, from the original 7.62mm (Mosin), 8mm (Mannlicher) or 7.92mm (Mauser), then rifled them with the use of ram-drifters. This was a very difficult operation because it called for accuracy, which was in a very short supply indeed with the tools at hand. Many barrel blanks were wasted in the process. Upon rifling the barrel blanks, chambers were drilled on either end of the barrel, and then the barrel was hack-sawed in half to make two submachine guns barrels.

The HO people manufactured the semi-finished slides out of 26 mm (1.02 in.) diameter steel tubing, cut down to 405 mm (15.94 in.) length. Then the tube was cut longitudinally for a half of a future slide, the sides were unfolded and hammer-straightened to become vertical sides of the slide. Strapoc then made the ejection openings and screw holes, soldered-in the end-parts of the slides, complete with the bolt attaching lugs, and riveted the slide rails in place. The frame group components were then brass-soldered or riveted together.

Design Analysis

The BH submachine gun is by all means an original weapon. It was – as far as it is known – probably the first submachine gun ever to fire from the closed breech with the swinging hammer-type trigger mechanism. Only the US Reising and Swiss Furrer MP 41 submachine guns were firing from a closed bolt before it, but both were striker-fired. The bolt is of the external slide variety, straddling the frame, much like in the automatic pistols, a design feature to be re-born in Mr. Wilniewczyc’s PM63 machine pistol of the late 1950s. At the same time, the hammer-fired submachine guns were also re-discovered, in the form of the German HK MP5 (then still known as the MP64) and the Czech Skorpion vz.61.

The setup of the weapon is readily inspired by the MP38/MP40 series with their separate pistol grips, folding stocks and vertical magazines. The vague knowledge of the actual principles on which a weapon like that operates caused Strapoc to built a very complicated hammer mechanism instead of some kind of KISS-principle (keep-it-simple-stupid) slam-fire one. Several parts bear some resemblance to various weapons, mostly the pocket automatics of the early 20th Century. The hammer plunger assembly is similar to that found in 6.35mm Walther Mod.8 or Belgian F. Delu 6.35mm pistols, while the disconnecting action is similar to that of the Hungarian 7.65mm M1901 Frommer pistol. The trigger mechanism as a whole, however, is a very unusual one for a submachine gun in those days, and it is very doubtful if a village blacksmith ever had an opportunity to see most of the designs listed above.

The positioning of the ejector (a projection on the automatic sear) is believed to be governed by the lack of space behind the magazine well – but no other gun has an ejector arrangement like that. The ability to cock the weapon by means of the sling is also an original idea, since then only once recalled, in the Austrian Steyr MPi 69, a quarter of a century later.

The hammer firing mechanism, then a rarity, nowadays is a standard for all high-tech submachine guns, such as the ubiquitous Heckler & Koch MP5, also designed a quarter of a century later. With such advanced design features, one can surely say that this out-back, middle-of-nowhere country blacksmith had preceded the professional submachine gun designers by at least that – a quarter of a century.

Polish BH Submachine Gun

| Weapon designation: | BH or Bechowiec (pronounced: Bekhoviets) |

| Country of origin: | Poland |

| Caliber: | 9mm/7.62mm |

| Cartridge: | 9×19 Luger/7.62×25 Tokarev |

| Type of operation: | Blowback |

| Type of fire: | Selective, full and semiautomatic |

| Cyclic rate of fire: | Estimated at 650-700 rpm (calculated for the 9×19 version, as it is unascertainable due to the deactivated condition of the only surviving weapon) |

| Length, over all: | 445 mm (17.51 in.) |

| Barrel length: | 240 mm (9.44 in.) |

| Weight, unloaded: | 2.43 kg (5.35 lbs.) |

| Weight, loaded: | 2.82 kg (6.21 lbs.) |

| Type of feed: | Magazine, staggering row, two-position-feed, soldered box, straight |

| Magazine capacity: | 32 rounds |

| Weight of loaded magazine: | 0.7 kg (1.54 lbs.) |

| Number of lands/grooves: | 6 |

| Rifling twist direction: | Right hand twist |

| Approx. muzzle velocity (calculated for 9×19): | 365 mps (1,200 fps) |

| Sight, front: | Blade |

| Sight, rear: | Open “U” notch, set for 50 m |

| This article first appeared in Small Arms Review V12N1 (October 2008) |