By Jonathan Ferguson, Armament Research Services (ARES)

Above: The Thorpe E.M.1 automatic rifle in profile (left-hand side). (N.R. JENZEN-JONES/ARES)

Introduction

When the Second World War broke out in 1939, the standard British service rifle was still the rifle, Short, Magazine, Lee-Enfield (SMLE), by that time known simply as “Rifle, No.1.” A successor had already been adopted and put into mass-production but this, the No.4 rifle, was simply a re-engineered SMLE; still chambered for the outdated rimmed .303 cartridge and still a manually operated firearm. Surprisingly, self-loading rifles had been trialled soon after the turn of the century, culminating in the adoption (but not the issue) of the Rifle, Self-Loading, Pattern 1918. This weapon was intended for use by aircrew; a relic of the early war in the air. However, in 1940, a new future rifle specification was issued by the British War Office, specifying a weapon of SMLE (i.e., relatively short for the period) with overall length, a 22- to 24-inch barrel, a maximum weight of 10 pounds, semi-automatic-only operation by means of either gas or recoil, a bayonet similar to the No.4 pattern and—perhaps most interestingly—a calibre of 7.92mm.

By contrast, post-war Britain was determined to replace its full-power service rifle, submachine gun and light machine gun with one universal weapon or family of weapons in an intermediate calibre and capable of automatic fire. This was partially realised with the introduction of the Enfield Weapon System/SA80 in 1985. However, the ambition originated with the Small Arms Calibre Panel of 1945, which decided upon a new “ideal calibre” cartridge of the following specifications:

Calibre—.27 in

Bullet weight—130 grains

Bullet length—1.03 inches

Charge weight—19.1 grains

“Round length”—1.5 to 1.8 ratio

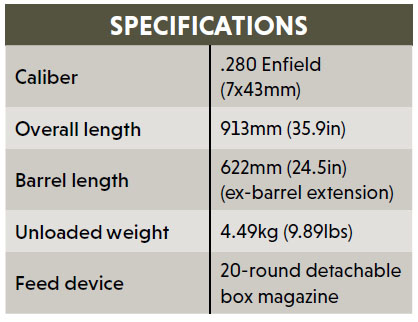

This new round would become the .280 Enfield, which was eventually (albeit briefly) adopted as the “7mm Mk.1Z.” The next step, logically enough, was to agree to a new War Office specification (which became WOPS No.9, issued in September 1947) for a new universal “Infantry Personal Weapon,” intended for use out to 600m, as opposed to the 1000m of prior doctrine. At this time, three new weapons were already under development, all of which were developed further, to a greater or lesser extent, as a result of the new specification. The real intention here seems to have been to combine the best features of existing cutting-edge designs into one new weapon. The two most promising were Korsak’s 7.92x57mm light machine gun and an automatic rifle developed by a team led by Stanley Thorpe, at that time chambered for the intermediate 7.92x33mm cartridge. The new requirement specified a light weight of between 7 and 8 pounds, a short overall length and rifle-grade accuracy with a closed, front-locking bolt and long barrel and automatic fire capability. This was further refined, following an ADE meeting of May 27, 1947, to require a bullpup configuration and gas operation.

As per this latest thinking, Thorpe’s E.M.1 was given a drastic redesign into a bullpup weapon chambered for .280 calibre; although no details or images of the original, conventionally configured prototype survive. This redesign might explain the incredibly complicated trigger mechanism—of which, more later. One early prototype included an FG 42-style integral bipod that was soon dropped in favour of a detachable version. Only one prototype survives, which resides in the Royal Armouries collection. Its trigger group is missing, but aside from a straight magazine released using a long magazine release lever, it is very close to the final design.

Nomenclature

Confusingly, both the Korsac and Thorpe designs received the designation “E.M.1” (for “Experimental Model 1”). This might have made sense given their differing roles; there would be a British E.M.1 rifle and E.M.1 light machine gun, just as there was an M1 Rifle and an M1 Carbine in U.S. service. However, this does not seem to have been how the system of nomenclature worked in practice, since there were in fact two weapons designated “E.M.2”, as well as two designated “E.M.3” and one designated “E.M.4!” Rather, it seems that E.M. designations were “rebooted” in 1948, superseding existing ones and creating the following two series, which we have numbered for clarity:

Series 1 (to May 1947)

- Korsak E.M.1 (gas-operated, rotating bolt, 7.92x57mm)

- Jezioranski E.M.2 (blowback, inertia-locked, 7.92x33mm)

- Metcalf E.M.3 (gas-operated, roller-locked, 7.92x33mm)*

- *NB the Series 1 E.M.3 became the Thorpe E.M.1 in Series 2.

Series 2 (1948 onwards)

- Thorpe E.M.1 (gas-operated, roller-locked, .280 Enfield)

- Janson E.M.2 (gas-operated, flapper-locked, .280 Enfield)

- Hall E.M.3 (gas-operated, dropping block, .303 Rimless)*

*This appears to be an error of some sort, as the Hall self-loading (semi-automatic-only) rifle had never progressed beyond the mock-up stage and had, in fact, been discontinued in 1947. This second E.M.3 can thus be ignored for practical purposes.

Regardless, the key thing to remember is that Korsak’s series 1 E.M.1 LMG shares a design lineage with Janson’s later series 2 E.M.2 rifle, whereas the Thorpe E.M.1 rifle was of a totally different design. The Thorpe shares a design lineage with the earlier Metcalf E.M.3, as noted above.

Both the Thorpe E.M.2 and Korsak E.M.1 (and later Janson E.M.2) did share German inspiration, however. Korsak’s LMG had been closely based upon the FG 42 automatic rifle, and Thorpe’s rifle also took cues from the FG 42’s pinned trigger group and the pistol grip shape of the second model. The gas system and working parts were based upon the German Second World War Gerät 06, however. One variant, the roller-delayed blowback Gerät 06H (H for “half-locked”), is often touted as a putative “StG 45” that would have replaced the long-stroke, gas-operated StG 44. This elegant and lightweight design evolved into the extremely successful CETME, G3 and MP5 family of small arms. However, with delayed blowback as-yet unproven in a full-power long arm, Thorpe chose to revert to a mechanism wherein the rollers positively locked the bolt closed—just as a tilting or rotating bolt would—relying upon a gas piston to unlock the bolt. Instead of the short-stroke gas piston of the Gerät 06H, however, he opted for a long-stroke gas piston.

Description

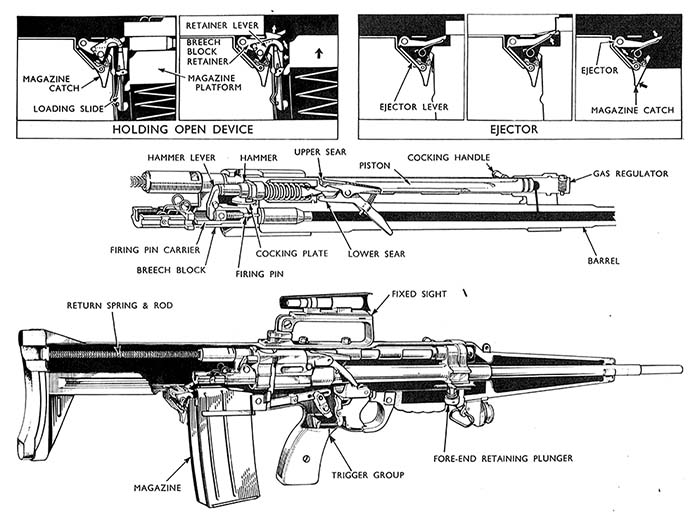

Sources disagree on when the first Thorpe prototypes were completed and proofed; either June 1948 (Edwards, 2014) or December 1949 (Dugelby, 1980, 41). Nomenclature was further complicated by the use of a codename: “COBRA.” Unlike the rival E.M.2, the Thorpe E.M.1 made use of the latest manufacturing techniques to produce square-section pressed and welded steel body with reinforcing ribs. Its receiver should therefore have been cheaper and quicker to produce had it reached the mass production stage. Unfortunately, other assemblies were not so well designed for modern industry.

Interestingly, specific mention was made in its provisional manual of its in-line design, intended to manage recoil. This was of course one of the much-touted features of the later Stoner/ArmaLite AR-10 and AR-15 series of rifles. The weapon also included an StG 44-inspired sprung “ejection opening cover” (dust cover) which, together with a well-sealed architecture, would have limited internal contamination in the field. Less prescient was the incorporation of a mechanism to automatically drop the bolt and chamber a round upon the insertion of a loaded magazine. As on the E.M.2, the magazine catch doubles as a bolt release catch. Pushing it forward releases the magazine as one would expect, but pushing it to the rear activates the bolt hold-open catch and releases the bolt. Unlike modern hold-open devices, the E.M.1 locks open when empty whether or not a magazine is fitted. This means that the user must manually close the bolt as well as “ease springs” (i.e., dry fire) whenever the weapon is cleared. Also shared with E.M.2 is the built-in charger guide in the rear of the magazine body. This slides upward to receive a charger clip of cartridges for rapid loading.

There is a combined safety catch and “change lever” (selector switch) conveniently positioned for use by the right thumb. Much of the rear portion of the body and grip frame assembly are, in British fashion, clad with a walnut veneer. Sling loops are provided on the bipod lug and on the bottom of the butt-plate assembly. Notably, provision is also made for an optional bipod, although this is hardly of quick-detach design, requiring the removal of the front handguard/heat-shield assembly to access the circular bipod lug. The cyclic rate of fire is a controllable 600rpm, although this was probably a beneficial feature given the .280 Enfield cartridge produces somewhat more felt recoil than smaller intermediate cartridges such as 5.56x45mm.

Along with the E.M.2, this weapon was one of the first to offer an optical sight as standard, specifically the Universal Optical Sight or “UOS” with a simple sheet steel protective cover. The UOS was adjustable for elevation and windage and featured an inverted pointer with graduations for 300-900 yards—despite the original requirement for 600 yards maximum. Finally, as befits a 1950s military rifle, the Thorpe rifle was fitted for both bayonet and an optional rifle grenade projector, attached by means of the same twin lugs on the barrel near the muzzle. The socket bayonet was of a combat/utility knife pattern sensibly shared with the E.M.2. The grenade launcher attachment had a built-in flip-up leaf sight graduated to the terrifyingly short ranges of 50, 75 and 100 yards. Official reports were positive, praising the ability to perform all functions without removing the weapon from the shoulder as well as the weapon’s accuracy, balance and low recoil. The trigger, whilst unconventional in form, is of typical military style, with a single stage, some take-up and a pull just shy of 7 pounds. Due to the unusual trigger mechanism, it is free of the typical bullpup linkage rod foibles.

With the benefit of hindsight, however, there are some obvious flaws. The UOS sight has a tiny field of view, is non-magnifying and is not adjustable without a tool. Worse, there are no integral iron sights or indeed any emergency backup sights on the weapon. This is a heavy weapon and feels every ounce of its more than 10 pounds (when fitted with an empty magazine), although the rebalancing effect of the bullpup design compensates somewhat for this. The 8-pound E.M.2 clearly had the advantage in this respect. It is also extremely difficult to cock due to the need to overcome the resistance caused by the interface of piston, cocking plate and upper sear. Once the upper sear is out of its corresponding bent on the piston, the working parts move with ease. The weapon might have benefitted from a lever-type cocking handle offering some mechanical advantage as on the CETME/G3 series.

Operating System

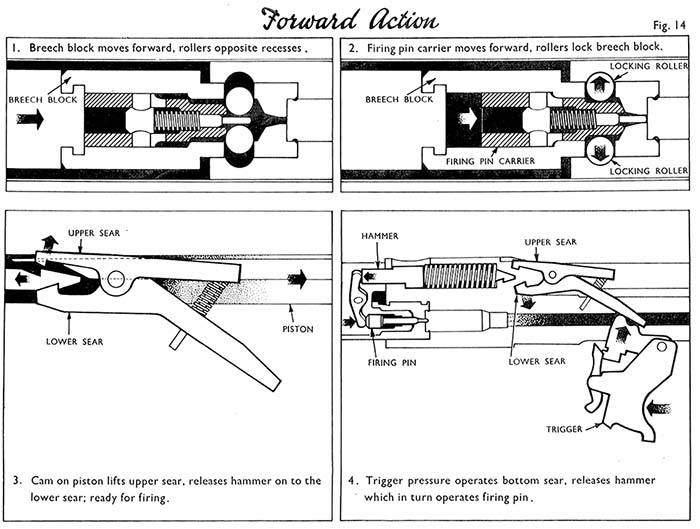

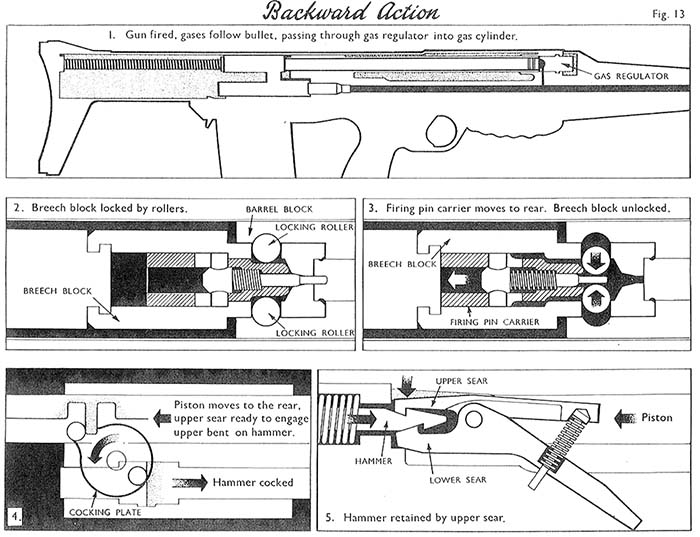

Where the gun really falls down, however, is in its mechanical complexity. The bolt carrier group is unnecessarily complicated, with an additional assembly known as the “piston extension.” In most firearms, the striker or hammer is cocked by the bolt carrier as it travels to the rear. Because of the extremely compact in-line design of the EM-1, the bolt carrier group equivalent is located adjacent to the gas piston rather than directly below or above it as in most gas-operated designs. This means that the piston extension is also offset to one side, requiring a unique circular “cocking plate” with its own captive spring to translate the backward movement of the piston into a rotary cocking motion for the so-called “hammer” plunger (see below). This plate is actuated by a machined surface on the gas piston. If this seems confusing, that is because it is! However, the provisional manual for the type helps a great deal.

Trigger Mechanism

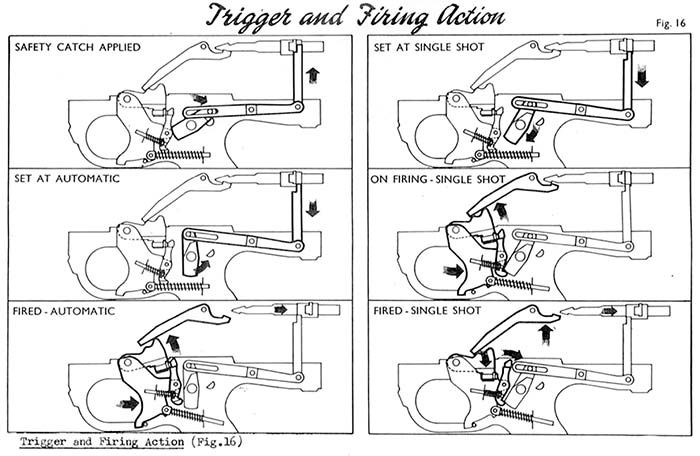

The trigger mechanism within the grip frame consists of a hinged (not sliding as its appearance might suggest) trigger assembly containing a sheet metal primary trigger, solid “upper trigger” and a disconnector pawl. This is acted upon by the rotating selector, which also activates an elaborate out-of-battery safety housed at the rear of the trigger group. There are no sears contained with the trigger group; instead, it engages with an extremely convoluted internal fire control group housed in the body of the rifle. This group houses the two safety/auto and primary (known as “upper” and “lower”) sears as well as a plunger (confusingly called the “hammer”) into which corresponding bents are cut. This plunger reciprocates in the housing under tension from its own spring, in effect operating like a backward-acting striker. Instead of directly impacting the primer—it is afterall travelling in the opposite direction!—it strikes the top of a lever in yet another assembly, which in turn pivots to thrust the firing pin forwards.

This Heath Robinson-esque arrangement was designed simply to connect the bullpup trigger to the working parts some distance behind it. Korsak’s LMG had used a long “slide” to allow its more conventional sears to interface with the working parts. Modern bullpups invariably make use of a long linkage bar, resulting in an inferior trigger pull. It is not clear whether Thorpe had anticipated the trigger bar solution and was actively seeking to avoid it, or whether the design team had simply not realised the potential of the simpler bar idea.

Fire selection is more conventional. On automatic, the trigger pawl provides support for the “upper trigger,” which in turn presses upward on the lower sear, allowing the working parts to continue cycling until the trigger is released or ammunition is expended. With the selector set to semi-automatic, its lower portion (inside the housing) pushes against the lower part of the trigger pawl as the trigger pushes the latter to the rear. This rotates the upper part out from under the upper trigger. This disconnects the trigger and requires the shooter to manually reset it for the next shot. The third selector position is a traditional applied safety that rotates the same lower portion of the selector forward to physically bar the trigger from moving to the rear. The mechanism incorporates two additional mechanical safeties. To prevent malfunction and out-of-battery discharge, the safety sear is lifted by another machined surface on the piston to release the “hammer” plunger onto the lower sear only when the bolt is fully forward. Finally, a pair of vertically acting appendages or “safety levers” are (on “safe”) cammed up into the underside of the fire control unit, blocking both the hammer and the piston itself. On semi-automatic or automatic, they are withdrawn from engagement. They are not connected to the trigger itself and do not impinge upon its action.

End of the Road

As NATO trials approached in the early 1950s, the decision was taken to withdraw the Thorpe E.M.1 on the basis that Janson’s E.M.2 rifle was in a more advanced state of development. A comparison by the author suggests that the Thorpe was simply the more flawed of the two. Both designs featured a substantial number of complex machined components, but the trigger mechanism of the E.M.1 added an additional level of difficulty in terms of manufacture and maintenance. Likewise, the more advanced pressed steel construction, whilst it might pay dividends in ultimate manufacturing cost, was an unknown quantity in 1950 and required new tooling and expertise to perfect for mass production. Russia was at this time struggling with the “Type 1” stamped metal AK; Enfield faced similar challenges with its SA80 project as late as the 1980s. The E.M.1 was also 2 pounds heavier than the lighter and generally more svelte E.M.2. Finally, aside from the obvious extravagance of wood veneer, the weapon featured two separate handguards. The front handguard, together with its own metal armature, could have been left off the rifle entirely were it not for the recommended grenade launching and bayonet fighting stances illustrated in the manual. The sheer quantity of wood on the weapon (the front handguard was even named the “fore-end”) seems designed to fend off inevitable criticism from those used to the walnut and steel of traditional infantry rifles of more conventional designs. Whatever the specific relative merits of the two rifles, the Thorpe E.M.1 was discontinued in early 1950, shortly after the provisional manual was printed. This allowed all efforts to be focused upon the more promising Janson E.M.2.

•••

(This article is adapted from a chapter in Mr. Ferguson’s forthcoming book on British bullpup rifles, which will be published by Headstamp Publishing in 2019. HeadstampPublishing.com)

Special thanks to the National Firearms Centre at the Royal Armouries, who graciously allowed ARES access to their world-class collection for research and photography.

This is Part 2 in a series of posts examining the developmental history of the United Kingdom’s E.M.1 and E.M.2 designated firearms. Part 1, “British Korsak E.M.1 Light Machine Gun,” appeared in Small Arms Review, Vol. 22, No. 9.

See armamentresearch.com for further original content.

| This article first appeared in Small Arms Review V23N1 (January 2019) |