By Christopher R. Bartocci

World War II brought the submachine gun into prominence with many armies. First being used successfully on a large scale by Germany during the war, Russia, England and eventfully the United States developed their own. It was just as quickly seen the ineffectiveness of the pistol cartridge on the battle field, especially compared to the new intermediate cartridges. Soon after the war, the SMG would be decommissioned throughout the world in favor of intermediate caliber assault rifles.

The SMG did not entirely disappear; they filled a role in law enforcement and in military special operations units. As a military weapon, it was effective under controlled conditions such as close quarter battle as well as when suppressed fire was needed. However, the biggest customer for the SMG was to become law enforcement. The SMG fit their area of operations perfectly. First, it dealt with the issues of over-penetration in the nation’s cities and kept compatibility with the ammunition police officers used in their sidearms. Police were not restricted as the military was in what type of ammunition they could use. By using modern high performance jacketed hollow point ammunition the 9mm NATO cartridge was quite effective and did not suffer from the over penetration and lack of stopping power as the military ball round. The SMG offered SWAT teams a significant amount of firepower in a small package. The first truly successful SMG to be used world-wide came out of Israel: the Uzi SMG – an open bolt selective fire SMG. The next, and the most successful SMG of all time, was the Heckler & Koch MP5. The MP5 would be the standard SMG in use by both military and law enforcement throughout the world. The MP5 was basically a scaled down version of the 7.62x51mm G3 assault rifle. Although the MP5 was a great success, the 7.62x51mm and 5.56x45mm H&K rifles never achieved popularity with U.S. law enforcement. The rifle and carbines of choice were the Colt M16/AR-15 series.

Colt decided that they were losing out on an entire market in the early 1980s. They realized they controlled the rifle and carbine markets in the U.S. but they offered nothing to fill the need for police who needed the lower powered pistol cartridges that were best used in urban environments. Consequently, they set out to design their own SMG and the project for the Colt SMG was given to their Senior Engineer, Henry “Hank” Tatro. With the knowledge that the M16/AR-15 is considered by many to be the finest human engineered small arm in the world (i.e. most ergonomic: controls all within reach of the shooter’s hand without the hand ever leaving the pistol grip and speed of reloading), it only made sense to base it off of the M16. Another viable reason for this is that law enforcement personnel are often made up of armed forces veterans who had already trained, and were familiar with, the weapon system. Additionally, since most of the departments used M16/AR-15 rifles and carbines, there would be little, if any, transitional training. The controls and procedures for loading, unloading, firing, disassembly and cleaning would be identical for the rifles, carbines and well as the SMG.

•B) Pre-Sporter Colt 9mm carbine Model R6540. Notice the addition of the gas deflector as well as the lower receiver is manufactured from an A2 lower receiver forging. These utilize the original two-piece magazine well adapter.

•C) Colt Sporter Lightweight 9mm Carbine (R6430). When Colt introduced their Sporter Series of rifles, Colt omitted the sliding stock and the bayonet lug. Additionally, Colt made the addition of the insertion of the steel automatic sear block and use of the larger .170 inch diameter hammer and trigger pins. These model rifles are normally found with the first generation two-piece magazine well adapter. (Courtesy of Colt Defense LLC)

•D) Colt Match Target Lightweight 9mm Carbine (MT6430). After the enactment of the Federal Assault Weapon Ban in September of 1994, Colt had to make additional changes to be able to sell the carbine by eliminating the flash suppressor. These are to be found with both first and third generation magazine well adapters. (Courtesy of Colt Defense LLC)

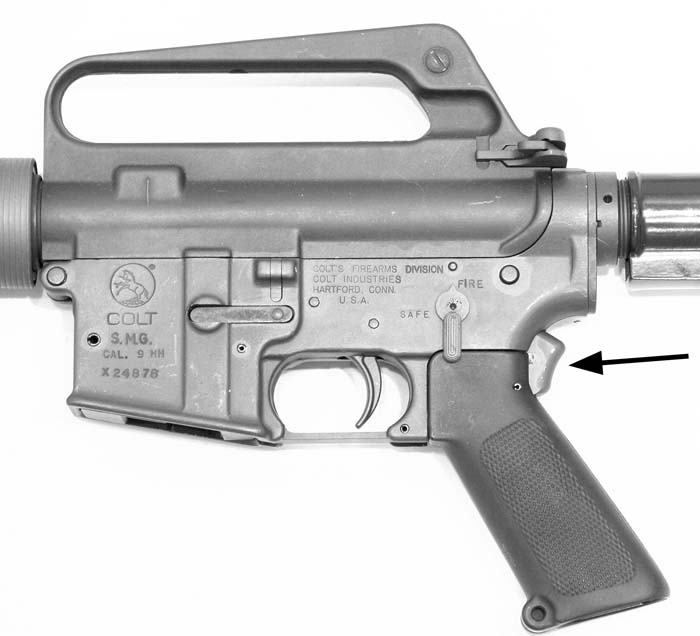

Since the SMG was to be chambered for the 9mm NATO caliber pistol cartridge, it was initially thought there was no need for a locking system and the weapon would utilize a blow back operation. Initial prototype SMGs would be open bolt. During testing by Tatro, it was discovered that the open bolt mechanism was not as desirable as a closed bolt for two main reasons. First was the concern for safety. If the SMG was to be dropped or jarred sharply on its butt, there was a better than average chance the bolt would travel rearward just far enough to pick up a cartridge from the magazine and chamber and fire it, resulting in an accidental discharge. According to designer Henry Tatro, clearing malfunctions could be dangerous as well. Additionally, ammunition/primer sensitivity could cause safety issues. Lastly, accuracy was decreased. Early prototype Colt SMGs utilized an M1911-style grip safety on the back of the pistol grip. Once the open bolt system was dropped, the grip safety went along with it.

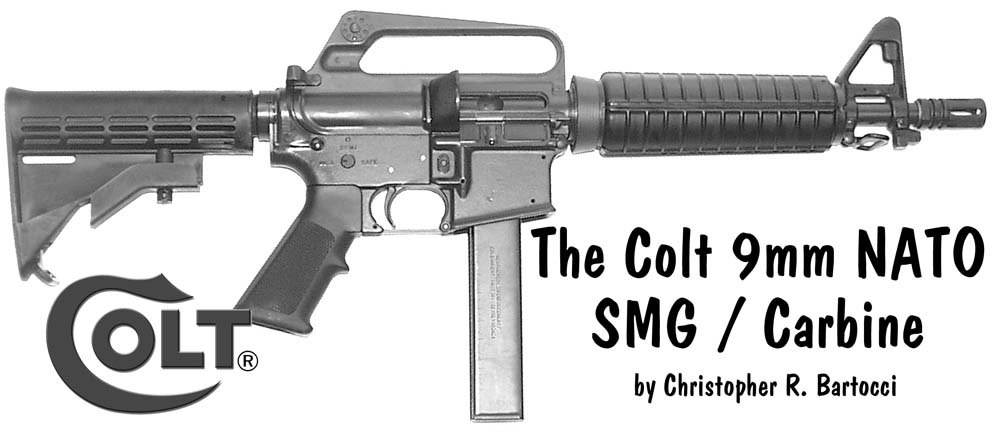

The finalized SMG would be released in 1985 and would be based off the Colt “Commando” carbine utilizing a standard M16 upper receiver without the forward assist. The cam pin slot as well as the gas tube hole in the face of the receiver was omitted. Standard field sights were used with a special designed rear sight aperture. One aperture was for 0-50meters and the other was for 50 meters and farther out. Standard carbine handguards were used with a single heat shield in each.

The barrels were 10.5 inches long and utilized the standard birdcage flash suppressor. The barrels were chrome plated and designed specifically for the 9mm NATO cartridge (FMJ RN, high power). Each barrel was proof tested with a high pressure cartridge and then magnetic particle inspected like their 5.56mm counterparts. The barrel would employ the standard front sight assembly of the carbine.

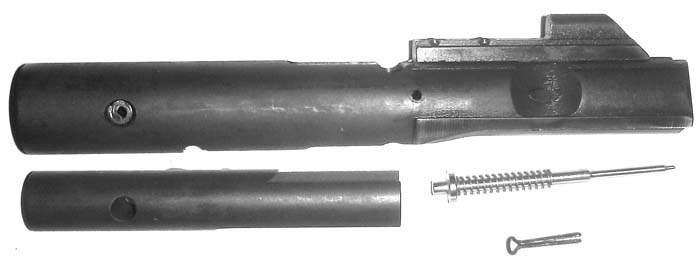

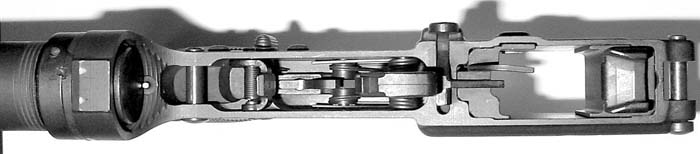

Since the new SMG was not gas operated, the bolt had to be completely redesigned. The bolt/carrier would be manufactured from a single piece of steel with the breech face machined into the face of the carrier. Original prototypes used a standard 5.56mm extractor but when they went into production a specific 9mm extractor was made. Due to these firing from the blow back method of operation, weight had to be added to the bolt to give higher mass to delay the bolt from opening before the bullet left the barrel. This weight was pinned into the rear of the bolt. Another significant change was the firing pin. The firing pin only had one head and utilized a firing pin spring decreasing weight and mass of the firing pin. Due to the much softer primers used in pistol ammunition, the lighter weight and firing spring were used to prevent accidental discharges from the inertia of the firing pin striking the primer when the bolt closed on a loaded chamber.

The lower receiver would actually be a standard M16/AR-15 lower receiver with a telescopic stock. The main changes would be to the buffer and magazine well. The buffer had to be changed to slow down the cyclic rate of fire. If a standard carbine buffer was used, the cyclic rate would be well over 1,250 rounds per minute. This rate of fire is excessive to control as well as being destructive to the weapon. By developing a heavier buffer (2-piece steel), the cyclic rate was decreased to under 1,000 rounds per minute. Ammunition is a significant factor in cyclic rate as well. Additionally, if a lower cyclic rate was desired, Colt offered a hydraulic buffer which would decrease the rate even further to around 650 to 850 rounds per minute. These models were denoted by a HB suffix on the end of the model number. Another modification to the lower receiver was the redesign of the hammer/trigger pins; making them out of stainless steel to increase their strength due to the pounding of the heavy cyclic rate of the SMG. The hammer pin in particular would break with heavy full-auto fire. This change (hammer/trigger pin is nickel plated for identification purposes) significantly enhanced the durability of this pin for use in the 9mm SMG.

The magazine well had to be modified to accept the significantly shorter 9mm magazine. To keep with parts commonality the standard magazine well was used. Early prototype SMGs utilized a one-piece magazine well adapter. This early design had problems with tolerancing and was not consistent in fit. Production weapons utilized a magazine well with two inserts with the rear insert containing the ejector. An extended bolt catch was used so the rear of the magazine follower would trip the catch to hold the bolt open on the last shot. This insert was pinned in place using a roll pin. The forward insert contained the feed ramp that would guide the cartridge from the magazine into the chamber. This was also pinned in place. This was a good way to do this because it allowed the lower receiver to easily be converted back to 5.56mm by simply removing the three roll pins and replacing the bolt catch. In 2001, Colt changed back to a one-piece insert designed and patented by Colt Model Product Development Engineer Art Daigle (U. S. Patent No. 6,072,352). Mr. Daigle designed this adapter for his own rifle prior to his employment at Colt. He had a receiver that he modified with the two-piece magazine well conversion. He would use this receiver to fire both 9mm and 5.56mm, so the two inserts were removed when he wanted to fire 5.56mm. As he kept re-installing the inserts, the holes in the receiver would “woller” and become oversized. He felt there had to be a better way so that his receiver would not be further damaged. He designed the one-piece adapter and Colt adopted his design in 2001. The first generation was held in place by a lock inside the adapter. A hex screw was tightened and two pins would move outward on the front of the adapter locking the adapter into place. This worked very well for occasional use but there was one problem with the design: when the end user would get hold of it, they would tighten the screw down so tight that the inside of the magazine well would bend or crack. The current production model is pinned in place. The present design is identical to the first one designed by Mr. Daigle, but the lock mechanism was removed and the adapter would be held in by roll pins. This adapter could as well be removed and the carbine turned back into the 5.56mm caliber. This design also eliminated Colt from needing an additional bolt catch specific for the 9mm SMG and carbines. The one-piece adapter has a lever installed that is lifted upward by the standard bolt catch.

The magazine is based on the Uzi magazine. In fact, Uzi magazines may be converted for use in the Colt SMG by cutting out the mag catch notch in the left side. Colt designed their own magazine for the production guns. This included a 20 and a 32-round magazine with witness holes in the side. This double column/double feed magazine was always considered the weapon’s weak link as it was for the Uzi. Due to the design, if the mag was to be dropped on its base, some or all of the cartridges could pop out of the magazine. This fault was cured in other SMGs by changing the way the magazine feeds. Instead of the bolt picking one round off each side of the magazine (double feed), it would pick it up from a central single location (single feed) similar to that of semi-auto pistol magazines (Beretta M9 and SIG Sauer P226, for example). Colt is currently looking at updating their magazine to incorporate this double column and single feed design.

The final design would be the R0635. This was the standard LE version that would fire semiautomatic and in full automatic mode. The R0639 was the same weapon but with a 3-round burst instead of automatic. Additionally, Colt manufactured a 7-inch barrel version of the SMG (R0633) known as the “Briefcase” SMG. This model has been discontinued. As the guns went into circulation one more improvement was made. A gas block was added to the ejection port cover. This was not a cartridge case deflector. Rather, this block prevented gas and unburnt powder from striking the shooter in the face. It was made of a polymer deflector that slid on the ejection port dust cover rod. A modified/cut down ejection port cover was placed next to that. This could be installed on any 9mm gun.

The Commercial 9mm Carbines

As with all the previous rifles and carbines, the 9mm was offered for commercial sale. The first was the R6540; the AR-15 9mm carbine. This was a standard AR-15 carbine with a 16-inch barrel. The carbine used the larger diameter semiautomatic only upper and lower receiver with a standard semiautomatic only trigger group with a newly designed semiautomatic only hammer. This new hammer was designed by Henry Tatro and on April 21, 1987, his “Safety Device Preventing Conversion To Full Automatic Firing” was patented (U. S. Patent No. 4,658,702). This hammer was to prevent slam fire if the disconnector was to fail whether by malfunction or intentional attempt to convert the weapon to automatic fire. The forward ramp on the hammer would catch on the underside of the bolt carrier, catching the carrier and preventing it from chambering a cartridge.

The next evolution of the 9mm carbine was the Colt Sporter Lightweight model R6430 incorporating several changes. Colt omitted the telescopic stock in favor of a fixed stock, the bayonet lug was removed, the fire control group was changed to the larger .170 inch diameter hammer/trigger pins to prevent fully-automatic fire control parts from being installed, and the addition of the pinned-in automatic sear block.

With the passage of the 1994 Assault Weapon Ban, Colt, by law, had to make an additional change to stay in production of commercial rifles; they had to omit the flash suppressor. The Colt Match Lightweight Model MT6430 was introduced.

Current production is the AR6450 of Colt’s Law Enforcement Only line of weapons. This version uses standard mil-spec small pin upper and lower receivers. There is no automatic sear block but additional aluminum has been left inside the receiver. That, along with the use of the large diameter (.170 inch) hammer and trigger pins, prevent conversion to full automatic. The carbine has a 16-inch barrel with flash suppressor and bayonet lug. Marked on the right side of the magazine well is “Restricted Law Enforcement/Government Use Only.”

Conclusions

The Colt 9mm SMG has served many law enforcement agencies well including the U.S. Drug Enforcement Administration, U.S. Department of Energy as well as the U.S. Marine Corps. The SMG never achieved great success nor its potential. Those who use it like it, especially departments that also utilize M16 rifles or M4 carbines. They can switch to the 9mm SMG with no transitional training and not have to learn a new weapon such as agencies utilizing the M4 carbine and MP5 SMG. These have completely different operational differences and the muscle memory from training is compromised with the use of different weapon systems.

| This article first appeared in Small Arms Review V11N11 (August 2008) |