By Christopher R. Bartocci

Colt Defense’s introduction of piston operated M16/M4 type rifles over the past 3 years has been customer driven and expands the M16/M4 family of weapons. Prior to that, they had experimented with a piston driven mechanism in the late 1960s known as the Colt model 703. This piston system was looked at by the U.S. Army and they came to the conclusion that there was no benefit of the piston system over the direct gas system and the program was dropped.

In the last three years, Colt Defense has been involved in two military programs and one law enforcement program dealing with piston operated firearms. The first was the Special Operation SCAR (Special operations forces Combat Assault Rifle) and they submitted three rifles. The Type A utilized their proprietary one-piece upper receiver and a direct gas operating system. The Type B was a standard M4 upper receiver with an A.R.M., Inc. SIR (Selective Integrated Rail) system with a direct gas operating system. The Type C SCAR entry was Colt’s piston operated carbine utilizing their proprietary onepiece upper receiver. The Type C SCAR, as of this writing, is the only M16/M4 based weapon to ever compete and finish an official U.S. government test and evaluation program. The Type C would later be updated and improved, which leads to Colt’s current LE1020 weapon system. The second military program Colt’s piston system would be used in was the OICW (Offensive Individual Combat Weapon). However, the program was cancelled before Colt could complete the design of that family of weapons.

While Colt intends to offer only one piston operated weapon in its catalog, they are currently integrating the best of both designs into their final offering. The first is known as the LE1020 and the other is what Colt calls their M5. In this article we will get a first-hand look at the M5 carbine. This carbine has been shown at some industry trade shows but never before in its entirety. Small Arms Review gets the exclusive first look at Colt’s other piston carbine: the M5.

The M5 Carbine

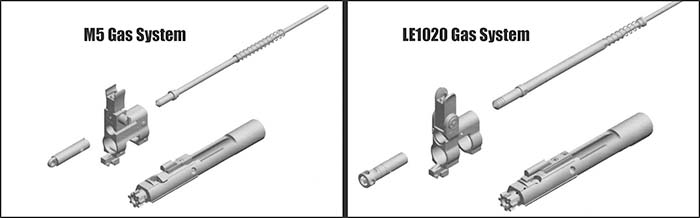

The M5 uses a conventional short-stroke tappet piston where a two piece piston/ operating rod strikes the face of the bolt carrier group driving it rearward and the piston rod returns to its forward position by a spring. However, unlike the Colt LE1020, the M5 uses a conventional M4 flat top upper receiver cut with extended feed ramps instead of Colt’s proprietary one-piece upper receiver. The piston itself rotates and locks onto the end of the operating rod. There is a spring and a stop on the rear of the operating rod. The operating rod/piston is inserted from the front of the receiver, pushed inward and guided into the front sight base. In Colt engineering testing, the M5 has fired 18,000 rounds without cleaning (other than the bore of the rifle) and without malfunction.

There are two current front sight base designs for the M5. The first is the one we just spoke of and is primarily for use with the standard upper receiver. The second more so resembles that of the LE1020 where the piston assembly is inserted from the front of the front sight base, slid back into position and held in place by a detent pin. This is designed for use with the one-piece upper receiver.

The front base is also very different from the LE1020 with a change to the front sight itself. The LE1020 uses a front sight assembly that is identical to the standard M16/M4. The M5 front sight is more similar to an AKM. The same front sight post as the M4 is used but the wings that protect the front sight post are round in profile giving greater field of view in-between the front sight base’s sides and the front sight post. This was based on the project leader speaking with many different operators and getting their opinion on what they thought would improve the sight picture of the rifle.

The barrel itself has had some redesign work on it as well though still utilizing the standard M4 feed ramps on the barrel extension. There are modifications of the chamber area of the barrel and the changes further ventilate gas and helps with air circulation by drawing heat out of the receiver and out the handguards. The cycling of the weapon acts as an air pump. Colt engineers have made the M5 in 10.5- and 14.5- inch barrel lengths.

The current prototype M5 utilizes a standard double heat shielded M4 handguard on the bottom and a modified one on the top. However, Colt is currently working on a universal handguard that will include quad Mil-Std-1913 rails. Prototype hand guards have been manufactured using a steel handguard with aluminum heat shields. Final handguard material is still under evaluation.

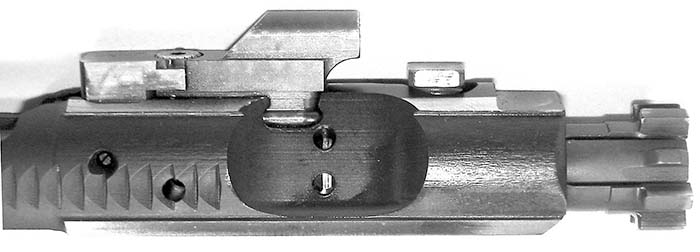

The bolt carrier is very unique and is quite different from the LE1020 in the way that the carrier key is held in place to cope with being struck by the piston rod. The carrier key is locked in place in the bolt carrier by a T-slot. The male connector is on the carrier key and the female connector is the bolt carrier. Then a screw is torqued to specification and crimped into place. The head of the screw has heavy serrations and, when crimped, is held firmly in place. The inside of the top of the bolt carrier has to be machined out so the two-piece carrier key assembly can be put in place. Due to this being a piston operated system; the gas rings on the bolt are not needed. The bolt is the standard M4 bolt with the heavy extractor spring and black stiffer buffer.

The lower receiver is the standard M4 lower receiver. Part of the design of the M5 upper receiver was so that it could be placed on an existing M4 lower receiver using the standard H buffer. Colt has made a very conscious effort to keep interchangeability of the lower receiver in the event the U.S. military decides they want a piston-operated rifle. Colt would be able to offer a simple retrofit upper receiver group that will meet this potential requirement.

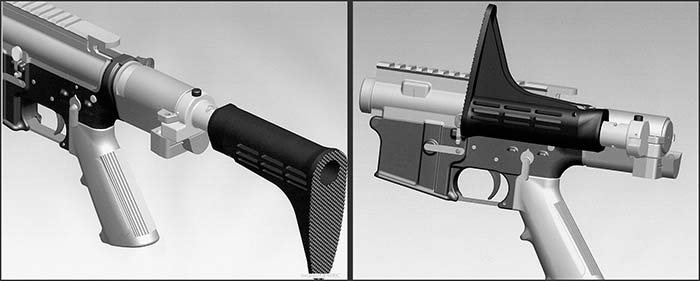

Side Folding Stock Assembly

Another project in development with Colt Defense is the design of a new sidefolding stock. This is accomplished by modifying the bolt carrier and the buffer extension is made significantly shorter. The bolt carrier has been heavily modified and does the job as the bolt carrier and the buffer. The rear of the bolt carrier has been modified so the recoil spring attaches to it. A bumper is placed on the rear of the bolt carrier. In order to assemble the modified lower receiver, the lower receiver is slid into position from the front and the takedown and pivot pins are engaged. To disassemble, both pins must be disengaged and the upper receiver slid out the front of the lower receiver. The stock pivots to the left side and the stock can be moved upward. When folded, the controls (i.e., selector, bolt catch) are easily accessible by the shooter. The stock is telescopic like the M4 and has four positions. The stock resembles that of the M4 as well but strengthened for the configuration it is in. The computer images provided by the Colt Defense engineering department show what they are working on. Models have been made and are currently going through testing.

Conclusions

The best features from both the LE1020 and the M5 will be combined into one. Colt has taken an incremental approach to their final release. Their piston designs have been proven in both the SOCOM trials as well as independent military testing in some foreign countries and it will be very interesting to see the final design. Nevertheless, the question remains as to whether the piston system will be the future of the M16/M4 weapon system, or will it be a passing fad. The debate continues and only time will tell.

| This article first appeared in Small Arms Review V11N3 (December 2007) |