By Christopher R. Bartocci

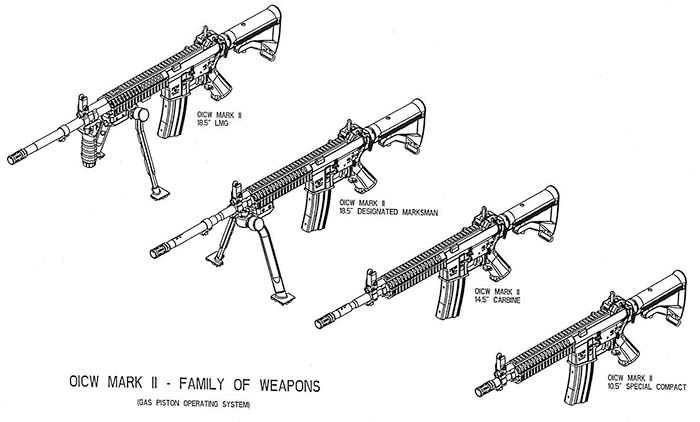

The OICW Increment 1 program commenced in 2005 to replace the current fleet of M16/M4 carbines in the U.S. government inventory: something that has been attempted many times without materializing over the last 40 years. This program had a requirement for a family of weapons and was broken down into three increments. Increment 1 was comprised of the family of weapons. This required a special compact model, a carbine, a designated marksman rifle and a light machine gun. Increment 2 was to be the development of the 25mm grenade launcher. Increment 3 was to be the combining of the two for the creation of the OICW (Offensive Individual Combat Weapon).

Several requirements were made in the solicitation. Most importantly, there needed to be 75% parts interchangeability in the special compact, carbine and designated marksman rifle and 50% parts interchangeability with the LMG (light machine gun).

Colt design engineers had a well-established starting point for their family of weapons. Just being post-SCAR development (Special forces Combat Assault Rifle); Colt already had a proven gas piston operated firearm and, additionally, already had a proprietary 1-piece upper receiver that would work well in all four weapons. The only major undertaking would be adapting the 1-piece upper receiver to the LMG variation.

The upper receiver for all four weapons would be based on the current LE1020 upper receiver, which is the product-improved version of Colt SCAR entry. The major change to the upper receiver would be the way the piston assembly is removed. On the SCAR rifle, there was a pin that held the piston assembly into the receiver that required a drift punch and a hammer to remove. Based on the criticism of difficulty in disassembly from SOCOM, Colt redesigned this with a sliding detent pin similar to the rear takedown and front pivot pin of the lower receiver. There was also a major redesign of the gas piston sleeve. The SCAR gas piston sleeve had no provision for easy alignment for assembly or griping method for removing an extremely fouled or corroded gas piston sleeve. The improved gas piston sleeve provided a guide for assembly to align the gas piston sleeve with the detent pin as well as a gripping surface for removal of a fouled or corroded gas piston sleeve.

The lower receiver of the OICW would be entirely interchangeable for all four models and is identical to that of the M4 carbine. The thought on this was twofold. First, the Colt OICW could be implemented as a ret-rofit of existing weapons by only replacing the upper receiver and, second, was the compliance with the parts commonality.

The LMG Variation

The LMG variation had some additional requirements to set it apart from the other three weapons that included the ability to have a heavy quick detachable barrel that did not need to have an ability to mount a grenade launcher. However, the LMG did need to have an ability to mount a bayonet. Also, the LMG was required to have a folding bipod.

The lower receiver of the LMG was the standard M4A1 lower receiver. Due to it being a light machine gun, Colt engineers took several trigger designs into consideration. They looked at an open bolt trigger mechanism; a closed bolt semi-auto/open bolt auto trigger mechanism, as well as the standard closed bolt trigger mechanism. The final decision was made to go with the standard closed bolt trigger mechanism; made primarily to keep with parts commonality. The only other departure from the norm was the replacement of the H buffer with the H2 buffer. The H buffer contains two steel and one tungsten weight and the H2 buffer contains one steel and two tungsten weights. The tungsten weight has the mass of two steel weights. This was changed to prevent bolt carrier bounce/light strikes when firing fully automatic.

As stated above, the upper receiver would be based on the 1-piece upper receiver. This receiver allowed the barrel to free-float, which in turn allowed more rapid cooling. Additionally, the upper receiver does not have a forward assist assembly. This has always been a controversial issue. Many believe, including Gene Stoner, that the forward assist was not necessary on the firearm and in fact detrimental. If your bolt is not fully closed, the rifle is trying to tell the user there is a problem! That means to get that round out of the chamber and load another. Forcing the bolt closed massively increases the potential of causing further problems. Others believe this is necessary to have the ability to force the bolt closed if need be. The forward assist has been retained due to it being required by the U.S. military Technical Data Package (TDP). However, Colt decided to remove it on this LMG.

The upper receiver is very similar to the standard 1-piece upper but with two major changes. Due to the requirement for the removable barrel, a locking mechanism had to be designed. The main changes would be made to the bottom of the handguard. The upper receiver and barrel extension are cut with the M4 extended feed ramps.

The 18.5 inch long heavy barrel has a diameter in-between that of the M4A1 heavy SOCOM barrel and the standard Colt open bolt LMG. The chamber area of the barrel has significantly more material making it much thicker and therefore increasing the LMG’s cook-off thermal threshold. The prototype LMG is set up for the 700 to 950 round per minute cyclic rate that is the same as the standard M4 carbine. The rear of the barrel would have two sets of index grooves. The first is at the rear of the barrel, which aligns into the upper receiver and acts as the barrel extension. The second is forward where the barrel is locked in place by the lever on the bottom of the receiver. To release the barrel, a lever on the bottom of the handguard is pulled out of engagement and the barrel is pulled out. This led to another problem: how the hot barrel would be removed, as asbestos gloves are no longer used or allowed. Colt was in the process of making a carrying handle to push the barrel out of the receiver right when the program was cancelled.

The gas system would also have to be modified from its original configuration. The piston/operating rod would be split into two separate pieces. The operating rod, spring and stop would be held captive in the upper receiver along with a new heat shield. This would be removed by an additional lever on the bottom of the lower handguard. The piston would be pinned into the gas piston sleeve and remain part of the barrel assembly. The gas piston sleeve is held into the front sight base in the same manner as the rest of the Colt OICW family of weapons by the detent pin on the front sight base. The piston pin is held in pace by an extended front sight base guide. To disassemble the piston assembly, the detent pin is pulled from the right, and the piston sleeve is removed from the front of the front sight base. The piston retaining pin is pushed out one of the two sides and the piston is removed from the sleeve.

The assembly of the LMG is as follows. Insert the heat shield, operating rod, spring and stop assembly into the upper receiver from the front of the receiver. Push it inward until it snaps into place and is held by the lever. Insert the piston into the piston sleeve and align the hole in the side of the piston with the channel groove in the gas piston sleeve and insert the retaining pin. Now slide the gas piston sleeve assembly into the front sight base and align the locating pin with the groove on the right side of the front sight base and push the detent pin in until it locks in place. Slide the barrel into the upper receiver (with the bolt carrier group locked to the rear) until it stops. Flip the locking lever back so it is flush with the receiver. Give the barrel a tug to be sure it is locked in place. The LMG is now assembled and ready to fire.

The bolt carrier group is identical to that of the LE1020 and the other three OICW weapons. It is a modified fully automatic bolt carrier with two major changes. The first is the addition of the “skis” on the bottom rear of the bolt carrier sear trip area. This is to keep the bolt carrier in alignment with the buffer extension when it moves rearward. This is necessary due to when the piston rod strikes the bolt carrier key as the rear of the bolt carrier has a tendency to tip down at a slight angle. The other change is the modified carrier key. The carrier key is solid steel and pinned in place to take the force of being struck by the operating rod. No gas rings are necessary. The bolt is the standard M4 bolt with the heavy extractor spring and stronger (black) extractor spring buffer.

The LMG was equipped with the standard Colt folding front sight base used on the SCAR Type C and the LE1020, and the Matech back-up iron sight; though any backup sight could be used. With the Mil-Std- 1913 rail any of the wide array of combat optics could be mounted. Due to having quad Mil-Std-1913 rails, the LMG could be equipped with a variety of accessories to include a flashlight, laser, vertical pistol grip or anything else that was wanted or needed. The LMG standard feeding device was to be the standard M16/M4 magazine, but it could also accept the Beta C-mag or any other high capacity magazine.

The program was cancelled in November of 2005. The prototype shown in this article is the only one in existence and was never finished. The bayonet lug and the barrel removal handle were never implemented.

| This article first appeared in Small Arms Review V11N4 (January 2008) |