By Thomas Hoel

Ranking right up there with cleaning weapons after firing them, linking ammunition prior to going out shooting a belt fed machine gun has got to be one of the least desirable aspects of the hobby for the Civilian MG shooter/owner. Historically the only away around the tedious task of hand linking ammo (..when you could) was to obtain a Military surplus belting machine or linker. Even these were not always an easy or fast method to link up large quantities of ammo, despite their design origins, and they were never inexpensive, when they were obtainable at all.

Fortunately for all of us with this problem, Doug Melton, of the D. H. Melton Co. (1221 East Del Rio Drive, Tempe, Arizona 85282 (602)967-6218), grabbed the Brass Ring and ran with it. His new creation, The Link-Master(reg. tm), is THE simple, well-engineered, and well-manufactured answer we have been anxiously waiting for!! With his latest creation the job of loading large quantities of ammunition into either disintegrating or non-disintegrating metallic link belts prior to going to the Range has been reduced to a simple and efficient task, while the built in alignment feature guarantees that each linked round has been properly located at the correct shoulder depth position for each type of link or belt being used.

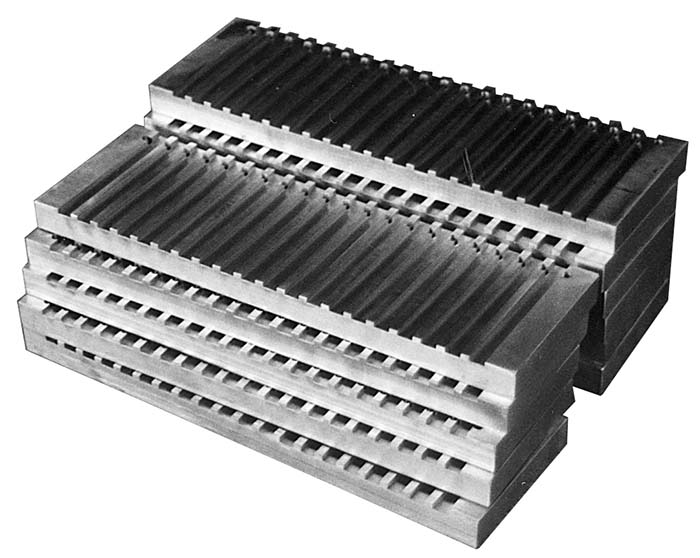

Knowing that crank type, hopper or strip feed, loading machines are sometimes temperamental to get to operate reliably, Doug opted to go with the more conventional throw-lever design as typified by the USGI M7 linker issued as standard equipment for the manual linking/de-linking of .50 caliber ammo in the field. In fact, Doug realized that the basic design of the M7 linker was so good that it only had one failing; it was designed to load only one caliber, .50 BMG. Rather than try and make a down sized M7 linker like others were offering (usually modeled after the old GI issue .30-’06 linker made for the 1919 series of MG’s) that could only load one caliber on one type of link, Doug opted to use the issue M7 as a universal base unit by slightly modifying it and then designed a series of 20 rd capacity “die-plates” that could be mounted to the M7. This allowed a virtually unlimited number of combinations of ammo calibers and link/belt types that could be loaded/un-loaded, all while still allowing the base M7 to still be able to load/un-load .50 BMG caliber ammo. Changing calibers or link/belt types only requires that the die-plate for the desired caliber/link combination be mounted to the slightly modified base M7 and loading may commence. Changing die-plates takes less than 1 minute. Each die-plate is engineered and manufactured to function flawlessly in the selected caliber/link type specified.

The standard issue M7 is only altered by having three mounting holes placed in the original throw lever to accommodate the new pusher bar used with the smaller caliber ammunition die-plates to adapt it to the new set up. The individual die-plates are made from forged and machined, heat treated, alloy aluminum bases and have hardened steel pin posts to hold the links in position. The new throw bar is also made from the same aluminum alloy, and is universal for all calibers other than .50 BMG. Doug currently offers ready-to-go die plates for .308 caliber ammo in disintegrating link styles for Israeli .308 BMG links and USGI/NATO M13 (“M60”) links, in .30-’06 and 8mm calibers for USGI BMG links, in .223 Rem. caliber for NATO M27 SAW links(25rd capacity), and for non-disintegrating belts in caliber .308 using German MG34/42 or HK21 belts (the pitch of these type belts is close enough to not cause any problems during linking). He will be offering many more styles of die-plates as time goes on, he can also make any custom order die-plate if he is provided with a handful of the required links to work from. He will also shortly be making available special die-plates to load USGI (.30-’06 caliber), or Israeli (caliber .308) fabric belts for the Browning 1919 series of machine guns.

We tested the Link-Master(tm) in .308 caliber with both IMI .308 BMG links and US M13 “M60” links. Both die-plates ran flawlessly through over 800 rounds of linking, and once the procedure for quick changing the die-plates was learned we could switch link styles as fast as the hands could move. There was some small surface roughness from the final machining operations but after a few dozen rounds these were all burnished away and cartridges could be linked as fast as our helper could drop 20 new links and cartridges into their slots and then throw the lever bar. (To help in the smooth sliding of the cartridges, we lubricated the top surface of the individual die-plates with MIL-COMM TW25B synthetic flouropolymer spay lubricant which impregnates the metal pores with a TEFLON(tm) coating.) Timing the operation we could easily load 5 20rd sections into complete 100rd belts in less than 4 minutes, which is fast by any standard!

The Link-Master(tm) is currently available two ways. Doug has obtained a quantity of new, never issued USGI M7 linkers which he is offering already modified and set up to go with the die-plate of your choice included, with optional die-plates available at extra cost, or he will accept your M7 linker and perform the necessary work to adapt it and then return it with the desired die-plate included (again, optional die-plate sets available). Remember, your original M7 linker will still function normally with .50 caliber BMG ammo, so if you do not need to have two linkers to still load .50 BMG ammo, just have your M7 linker modified and then order all the other caliber die-plates you need! The price of the Link-Master(reg. tm) and several optional die-plates is still often less than a Military surplus single caliber/link type crank loader. For the shooter with multiple guns in different caliber/link types this is the ONLY way to go!

The pricing structure is as follows:

Complete Link-Master

w/1 die-plate $185.00

Extra caliber/link

style die plates $95.00

Deduct $20.00 for supplying

your own M7 linker to be modified.

Shipping and Handling

charges are variable $8.00-13.00.

D.H. Melton Co., Inc.

1221 E. Del Rio Drive

Tempe, AZ 85282

| This article first appeared in Small Arms Review V1N10 (July 1998) |