By Will Dabbs, MD

Caseless firearms represent the golden ring for gun designers. The advantages are obvious. Ammunition weighs but a fraction of its cased counterpart. Strategic materials are conserved. Reciprocating weapons are by definition mechanically more reliable as there is no case to extract and eject. At the end of the day the range is tidier. Like most things, however, the devil is in the details.

The Germans chased this goal vigorously in World War II. As the demands of Total War began to take their toll Nazi planners saw the appeal of caseless technology and invested heavily in its development. At the end of the day the state-of-the-art in materials science simply did not support the production of caseless ammunition that was sufficiently robust for combat use. What did spring forth from this undertaking was the use of steel in the manufacture of conventional ammunition cartridge cases. Anyone who has ever run a contemporary box of steel-cased Wolf or Tulammo through their weapons has benefitted from that research directly.

The argument could be made that H&K and Dynamit Nobel actually got there with the G-11. Designed in the waning days of the Cold War, the G-11 was revolutionary in every sense of the word. The G-11 incorporated a vertically mounted box magazine that was at least generationally similar to that of the contemporary FN P-90 though the geometry was totally different. The G-11 operated with an ingenious rotating bolt system wherein the bolt itself incorporated an integral chamber and rotated through 90 degrees to align with the barrel for firing. The modes of fire included semiautomatic as well as a conventional fully automatic rate of fire of around 600 rounds per minute. On three round burst, however, the weapon cycled at around 2,000 rounds per minute and was purported to have all three projectiles out of the bore before the recoil impulse transferred to the firer. Heady stuff that.

The ammunition for this system really broke new ground as well. Rounds sported 4.7mm bullets and were 21mm long. Projectiles weighed a mere 52.5 grains. The propellant grain itself was molded in a square cross section and the primer was consumable such that there was no residue remaining after firing. The rounds were said to be so robust that one Nobel engineer carried one around in his pocket for a year along with his keys before chambering and firing it successfully.

The combustion was said to be so clean that the weapon was not intended to be field stripped for cleaning. That particular claim seems to hearken back to a certain Colt rifle that was itself a technological breakthrough for its time. The assertion back in the sixties that cleaning was optional did not bear out well in the rice paddies of Vietnam. Alas, we never had the opportunity to put the claims of the G-11 to the test. The G-11 was ready to come online at about the same time the Iron Curtain fell so the entire project was shelved. Eventually after the reunification of Germany, H&K engineers produced the more conventional G-36 that has gone on to serve around the globe with a variety of militaries. The basic operating system was also adapted to drive the H&K 416 as well as the upgraded British SA-80. In the interim between these two major firearms milestones an American company known for its BB guns briefly produced a caseless rifle that would be ground shaking even if it was released today.

Classic Americana

Daisy BB guns are as American as Ford, Chevrolet, McDonald’s, and NFL football. Interestingly, these guns were originally conceived as promotional perks to be given to farmers when they purchased a Daisy brand of windmill pump for their livestock. It was found that the BB guns generated more enthusiasm than the windmills and the Daisy BB gun company was born. As windmills look at least esoterically like daisies now you know where the name came from.

It is the rare American who is not familiar with the story of Ralphie shooting himself in the eye with a “Daisy Red Rider spring action repeating air rifle with a compass in the stock and a sling that tells time” from the classic movie A Christmas Story. While Daisy is rightfully renowned for their timeless line of air rifles, in the late sixties they ventured into something fairly radical.

In 1962 Daisy purchased the rights to a revolutionary new gun. Titled the V/L after the initials of the designer, this caseless rifle was only produced for two years. From 1968 to 1969 Daisy produced roughly 25,000 of these guns in three configurations. Their solution to the frustrating challenges of caseless ammunition was novel.

A Surprisingly Simple Solution

One of the significant hurdles to producing caseless ammunition for civilian use is the concept of a consumable primer. Ignition must be residue-free if a system is to take full advantage of the caseless concept. In the case of the V/L rifle, the solution rested in air rifle technology.

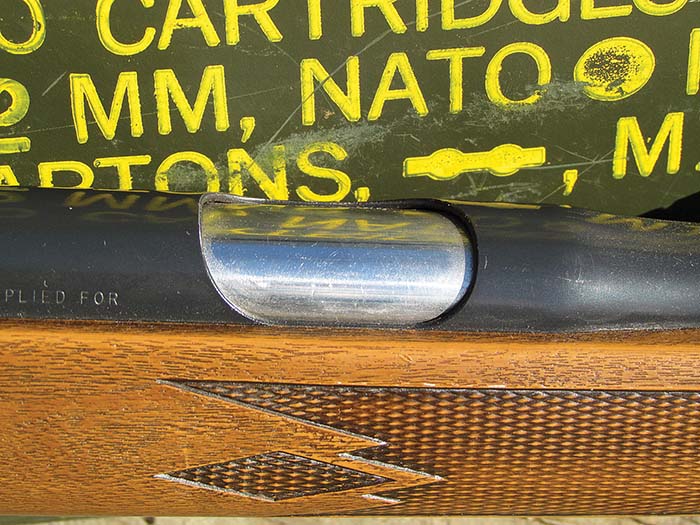

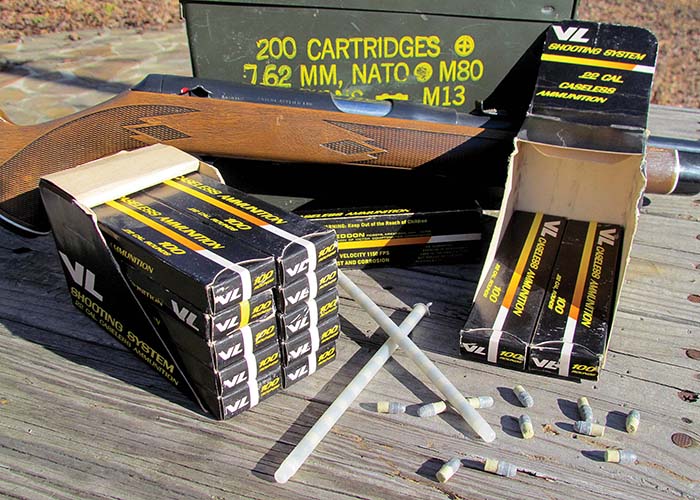

Ammunition for the V/L system consists of a simple lead 40 grain bullet mounted atop a pellet of yellow cake propellant. The rifle itself has an under lever spring piston that compresses a volume of air with activation. The round is set into the chamber and the action closed. Upon firing, the trigger releases a jet of pressurized air into the base of the propellant grain. The resulting adiabatic heating raises the temperature of the propellant to the point of ignition. The gun is single shot only and there remains no residual detritus to extract or eject. The engineering behind the concept is brilliant.

Ammunition was packaged ten rounds to a round plastic tube not unlike a drinking straw. One end of the tube was heat sealed and the other sealed with a small plastic plug. These tubes were sold ten to a box and ten boxes to a case. Each case of 1,000 rounds occupies little more much space than a brick of five hundred rounds of .22 LR. Cases were designed so that the end could be folded back and the entire affair set on a dealer’s counter for consumers to purchase boxes one at a time. While the rifle was manufactured in Rogers, Arkansas the ammunition was produced in Canada. I have no idea what the ammunition cost new.

With each activation of the spring piston the safety resets. Parts are typically pressed steel coated with enamel paint consistent with the standard of manufacturing of air rifles of the day. Sights are a fixed front blade and a simple sliding rear sight adjustable for elevation.

The guns themselves came in different grades. The service grade version as I have in my collection sports a fairly flimsy hollow plastic stock that hefts like an inexpensive BB gun. Fancier versions had wooden stocks and presentation cases. In the case of my rifle it has an interesting story itself. My grandfather was a railroad man of modest means but he had a gift for machines. I spent countless hours with him in my youth in his workshop building toys, furniture, tools, or whatever else we might need or want. Though he was a survivor of the Great Depression and died decades ago I still use a wood lathe in my own shop that he built from scratch out of a surplus set of wheel bearings and a washing machine motor. Always on the lookout for the mechanically cool and unusual, my grandfather bought this particular V/L rifle new from a hardware store in Hattiesburg, Mississippi in 1969. Though it has little innate value it is priceless to me given its genesis. I still remember shooting it off of bridges at stumps and logs with him when I was very small.

Range Time

I was fortunate to happen upon several thousand rounds of ammunition for sale through a catalog back when the Internet was just a gleam in Al Gore’s eye. As I have stored it sealed in a steel ammunition box ever since then, it is still surprisingly reliable. Failures to fire are uncommon but I cannot attest to what sort of performance the gun might produce were it new with fresh fodder. As it is, typical muzzle velocities ranged from 1,100-1,600 feet per second and the rifle disperses vertically based on inconsistent velocities. Considering that the propellant is hydrophilic and deteriorates over time and that the spring piston has been cycled several thousand times over the past 43 years, performance was likely better a few decades ago. In the case of my rifle and ammunition, the propellant cakes are starting to crumble a bit and that no doubt accounts for the wide variation in velocities.

To fire the rifle you cock the action lever underneath the forearm and leave it open. This action compresses the air cylinder, opens the bolt assembly, and resets the safety. Place a single round of ammunition in the chamber and replace the cocking lever. This action closes and seats the bolt as well. Now take the safety off and the rifle will fire in the conventional manner. Report is mild but the bullets still produce a noticeable sonic crack.

I do recall that this very rifle accounted for a veritable battalion of squirrels that threatened my grandfather’s garden. Interestingly, the report of the gun during firing is only slightly louder than my suppressed .22 pistols. My grandfather shot squirrels out of the trees with this rifle in his backyard with impunity back in the day despite the fact that he lived in the middle of town.

The Rest of the Story

Daisy clearly hoped that the V/L rifle would fall solidly into the category of air rifle and not be subject to the gleaming new restrictions of the 1968 Gun Control Act. The gun will actually launch conventional .22 caliber air gun pellets at around 300 feet per second but as the nominal diameter of an air gun pellet is 0.218 as compared to 0.222 for a rimfire bullet, accuracy and consistency are atrocious. Alas, ATF had other ideas and classified the gun as a firearm. As Daisy was not legally configured to produce conventional firearms given the new record-keeping requirements, they dropped the V/L like a hot rock.

The V/L rifle never was really tack-driving accurate due to inevitable inconsistencies with propellant burn and quality control of the revolutionary new ammunition. Combine this with the ATF involvement and the equally inevitable challenges of reliably supplying gun owners with an entirely new class of ammunition and the V/L died a natural death. Given its truly revolutionary position in the development of firearms it is a surprisingly easy addition to the collection of most serious gun collectors. $250-300 will typically score a V/L rifle in decent shape with a little ammunition to boot. Large quantities of ammunition are no longer available and subsequently command collector’s prices when it can be found. I cannot fathom anyone wanting to really shoot this gun a lot anyway. Conventional .22 LR is still cheap and platforms to launch it cheap as well. The V/L is intriguing simply for its novelty.

The Grail-like search for military-grade caseless systems continues apace to this day and the incorporation of polymer cases and semi-cased designs represent intermediate steps. It is interesting to ponder, however, that more than forty years ago an iconic American BB gun company produced briefly a fascinating caseless rifle system that, were it not for Uncle Sam’s regulatory involvement, might have established an entirely new genre of firearms in America. That is an interesting thing to consider.

| This article first appeared in Small Arms Review V17N3 (September 2013) |