By J.M. Ramos

In 1958 after World War II, Erfurte Werkzeug und Machinefabrik, better known as Erma Werke, one of the manufacturers of the renowned MP40, resumed submachine gun development and came up with a number developments. Beginning with the Panzer 58, or SMART submachine gun that fired from a closed bolt, hammer fired mechanism and had the capability to fire rifle grenades, through the MP58, MP60, MP61 and MP64 submachine guns, they sought acceptance from the German Bundeswehr and German Army. Unfortunately, by the time the MP64 was ready for testing, the military had adopted the Israeli UZI leading to the termination of the Erma SMG development program. Erma’s activity in the small arms field subsided between 1970-1980.

In the early part of the 1980s, Erma Werke sprung back to life; this time as a commercial arms producer. Between 1982 to the later part of the 1990s, Erma developed and produced some of the most versatile clones of famous rifles, pistol and revolvers. This include the Erma EG 76, EG 712 series (western type lever action rifles), the ESG 22, EGG 1, EM 1, EG M1 series (U.S. M1 .30 Carbine clones) and semiautomatic pistols that copied the Luger in cal. .22 (EP 22, KGP 69) and KGP 68A which were offered in .32 and .380 ACPs. This model was soon followed by EP 422, EP 752, EP 652, EP 552S (copy of Walther PP and PPK), and the EP 882 series (copy of the Walther P-38). In addition to its self loading weapon clones, Erma also produced excellent copies of the Smith & Wesson swing out revolvers namely the ER 777 (5-1/ 2 inch barrel) and ER 442 (snub nose type with 2-inch barrel). These handguns were also produced as gas pistols and were quite popular in Europe.

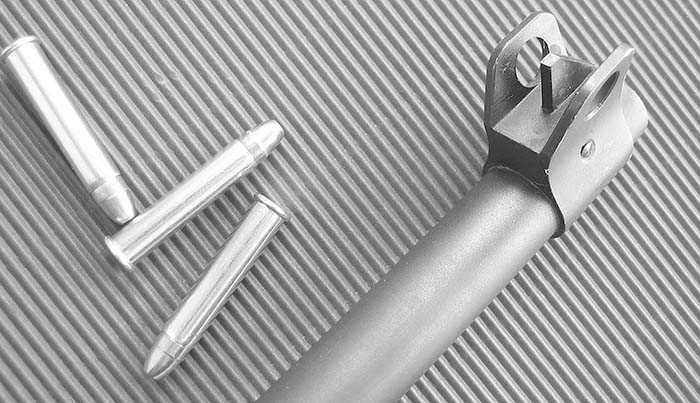

Among the extensive line up of Erma’s M1 Carbine lookalikes was the ESG 22, the US M1 .30 Carbine clone chambered for the potent .22 rim fire Magnum. This rifle was first imported into the United States by Excam, Inc. of Hialeah, Florida starting in 1982. As the boom of paramilitary type weaponry peaked sometime in the mid to late 1980s, Iver Johnson, an American company that produced the commercial M1 Carbine, began importing the M1 .22 clones from Germany to be marketed alongside their production .30 caliber counterpart. In that same era, another well known commercial carbine manufacturer, Universal, was also producing their own .22 Carbine look-alike called the Leatherneck. The Leatherneck carbine takes 10 and 30-round steel magazines made in Italy. Erma’s .22 Carbine clone was soon competing against with the world’s finest rim fire clones in the likes of the Bingham PPS-50, Jager M1622, AK22, Galil 22, Famas 22, Auto-Ordnance M27 A3 (Thompson SMG look alike) and the civilian version of the American 180 SMG the AM180 M1. Among the many import clones that were offered in the American market, only Jager and Erma offered their look-alikes in .22 Magnum chambering. However, Erma produced the only gas operated .22 Magnum with their ESG 22 truly simulating the action of the US M1 .30 Carbine.

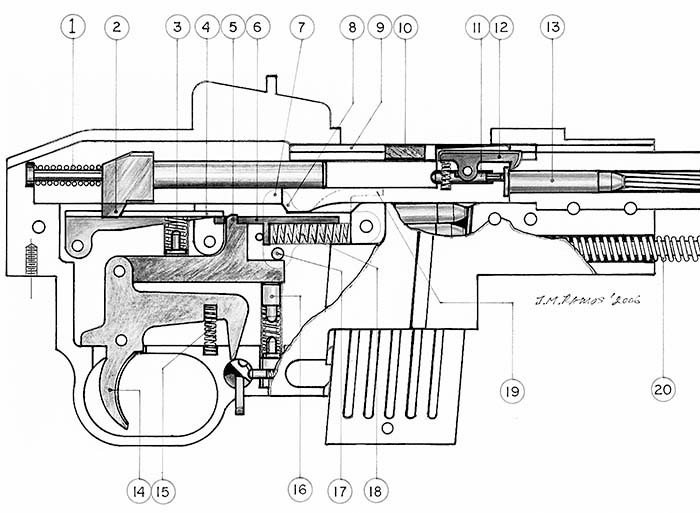

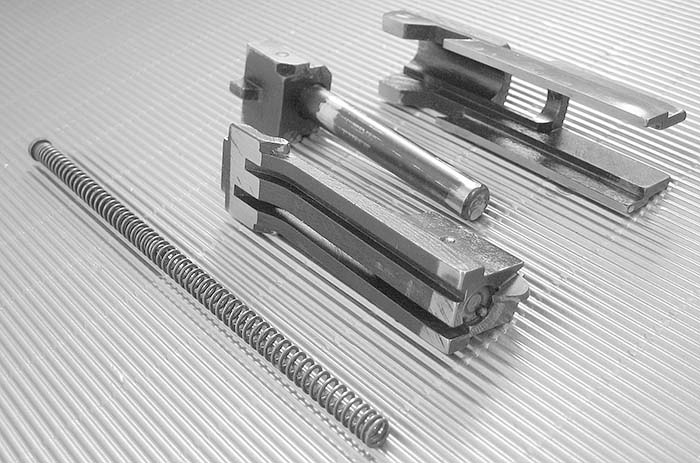

In order to understand how the ESG 22 works, a detailed cutaway illustration of the internal mechanism of the weapon showing how each mechanical component correlates to each other has been prepared. The trigger mechanism of the weapon is quite impressive and appears original in concept. The illustration shows the weapon is loaded and ready to fire. The striker is seen on the rear on “cocked” position. The manual safety is engaged and was blocking the movement of the trigger. Looking at the weapon externally, one can see an almost exact duplicate of the famous GI M1 .30 Carbine. Internally however, tells a different story. We can clearly see that the trigger mechanism is completely opposite from the original. The original US battle gun is hammer fired with a rotating bolt actuated by the direct action of the slide. The Erma .22 Magnum clone on the other hand, utilizes a separate firing pin activated by a massive striker fire mechanism. The bolt of the ESG 22 is square and enclosed by a wrap-around carrier similar to that of the Tokarev or FAL automatic rifle. The locking action also works in the same manner. The trigger housing is made of a light alloy material. A large steel insert (with built-in ejector) saddles on the top centermost portion of the housing to mate with the bolt during the locking and unlocking sequence. The steel insert is necessary since the soft alloy metal will not last when used as a support for a locking mechanism. When the bolt is in the full forward (closed) position, the rear section of the bolt will drop approximately .100 inch and wedges against the corresponding step of the steel insert. The bolt incorporates twin side lugs mounted on each side at the rear. The carrier has a matching horizontal slot on both sides to act as a cam for the bolt side lugs during the locking and unlocking operation. The slide is retained and cycles along the top right hand side of the trigger housing frame during operation by an assembly groove similar to that found in the M1 Carbine.

System of Operation

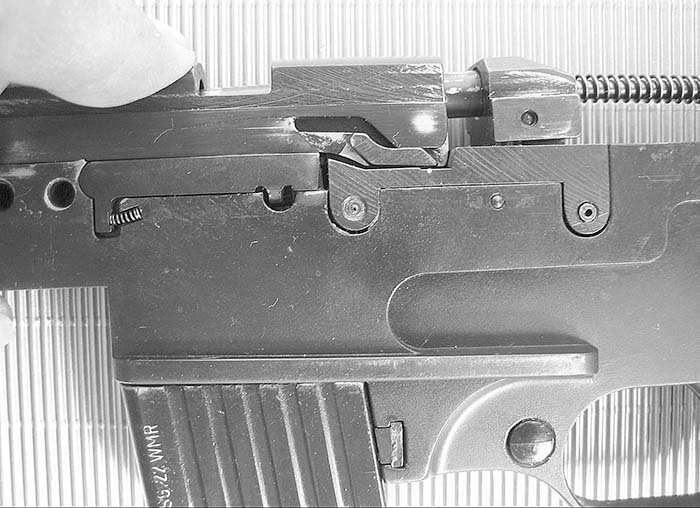

The operating procedure is virtually identical to the original M1 .30 Carbine. From the charging handle, magazine catch and the manual safety design, the ESG 22 (EM1 type) faithfully copied it all. The weight, feel and size are virtually the same. Externally, the Erma clone is nearly perfect. However, the weapon comes with a standard 5-shot box type magazine (and an optional 12-shot magazine was available) rather than the standard 15 and 30-round magazine of the original. To load the weapon, insert a loaded magazine and pull the charging handle. As stated earlier, the slide (10) is connected to the bolt carrier (9). As the charging handle is pulled, the front end section of the carrier horizontal slot cams the front end of the bolt side lugs and forces it upward to disengage the bottom rear of the bolt (8) from the locked position. The bolt and carrier will now move all the way to the rear together until the operator releases the charging handle to allow the bolt group to move forward under the power of the recoil spring (20). The recoil spring is positioned under the barrel and connected to the slide just like the M1 carbine. As the bolt and carrier move forward to accomplish the usual loading sequence, the striker will be intercepted by the sear (4). The sear is made of a simple sheet metal stamping and powered by a very light spring (3); just enough to push the part upward to engage and re-engage the striker under the lug (2) during operation. When the striker is cocked, the sear’s front end (4) will rest over the rear of the sear release plate (6). The sear release plate is powered by a large spring (18) mounted below the part’s front end and is pushing against a bent portion underneath providing the resistance for a fore-and-aft movement during trigger pull. The trigger bar top end (5) rests against the corresponding slot at the rear of the sear release plate. The upward tension for the trigger bar is provided by a spring loaded plunger (16) positioned underneath its front end. The disconnector connecting pin (17) rest over the top front section of the bar at all times. The trigger return spring (15) is positioned at the part’s most forward end allowing pivoting action of the trigger while being manipulated during firing. As the breech face hits the chamber mouth after loading a round (13), the rear incline of the bolt side lugs will be hit by the carrier cam forcing the lugs to move downward in order for the rear (8) of the bolt to drop into locked position. As the bolt side lugs level with the trigger housing steel insert platform, the carrier will continue to move forward by another 1/4 inch thereby allowing the rear underside portion of the carrier to ride over the bolt side lugs prior to battery. This completes the locking sequence.

To fire the weapon, the manual safety lever must be rotated horizontally towards the trigger. In this position, the large notch of the pin allows trigger movement. When the safety is moved horizontally, the solid portion of the pin blocks the trigger movement and will not fire the gun. The safety arrangement is the same as on the M1 carbine. Pulling the trigger (14) causes the trigger bar top end (5) to push the sear release plate (6) forward. As the sear release plate moves forward, the sear (4) automatically drops and releases its connection with the striker under lug (2). The striker will fly forward and will hit the separate firing pin (11) mounted on the bolt head firing the chambered round (13). The striker’s powerful spring (1) easily overcomes the resistance of the light sear spring (3). Note that both the striker under lug and the sear engagement shoulders are cut in the inclined position allowing the striker to slip freely as soon as the sear drops. This type of trigger let-off provides an incredible crisp and very light trigger pull. After firing, as the bullet passes the gas orifice, a volume of gas is bled off to the piston cylinder housing. As gas pressure builds up inside the housing, the piston is forced to act against the slide. The piston retracts approximately .438 inch after the bullet has left the barrel. At this distance, the slide (connected to the carrier) has completed the unlocking sequence after the bullet has left the muzzle. After the bolt/carrier accomplished the unlocking process, both parts will recoil rearward and the extractor (12) pulls the empty shell out of the chamber. As the two parts moved together, the rear of the bolt carrier will depress the disconnector hump (7) located on the right side of the trigger housing. As the disconnector is forced downward, the connecting pin (17) will in turn depress the trigger bar forcing the top end of the bar (5) to disengage its connection with the sear release plate (6). Note that after the striker was released by the sear (4) it will automatically bounce back to its normal position as soon as the striker passes the sear’s front end. Immediately after the trigger bar top end (5) disconnects from the sear release lever (6), the sear release lever spring (18) will force the release lever to move rearward to its normal position with its rear end resting underneath the front end of the sear (4). With the trigger pull still being maintained, the top end of the trigger bar (5) will now rest underneath the sear release lever just forward of the small notch. The small notch is where the bar top end (5) would normally pop out to re-engage the sear release lever after the trigger pull is released. As the bolt and its carrier continue to move rearward, the empty shell is ejected just before the rearward recoil of the bolt group is accomplished. On its return to battery, the striker cocking lug (2) will be intercepted by the sear (4). Fresh ammunition will be stripped from the top of the magazine and pushed towards the chamber. As the breech face closes against the chamber mouth sealing the live round for battery, the rear end (8) of the bolt will drop to its matching seat on top of the trigger housing. The carrier will continue its forward movement by another 1/4 inch riding over the side lugs of the bolt assuring positive lock up of the bolt before the next round can be fired. To fire the next shot, the trigger pull must be released. Once the pull is released, the trigger (14) will pivot backward by the action of its spring (15). This will also pull the trigger bar rearward to its normal position. As soon as the bar stops its rearward motion, its top end (5) will automatically line up with the sear release lever notch. The spring loaded plunger (16) underneath the bar forces the part upward and its top end (5) loops with the release lever corresponding notch. Simultaneously, at this point, the disconnector connecting pin is also carried upward by the action of the trigger bar permitting the disconnector hump (7) to bounce back to its normal upward position. The weapon is ready for the next shot. This sequence of operation is repeated automatically as fast as the operator can manipulate the trigger or until the magazine is empty. The gun incorporates a magazine follower hold open device allowing the bolt group to be held open after the last round is fired.

Everything Looks Good but Not So Perfect

Upon acquiring the ESG 22, the first impression when handling it is impressive. Originally purchased in the mid 1980s, no more than 1,000 rounds were fired through it. It performed excellently and became a collector’s keeper after that. It was sold in 1990 and the new owner fired about 2,000 rounds and came back later complaining about jamming and erratic functioning, mentioning that after about 1,200 rounds the gun became problematic and almost non functional.

The gun was completely stripped to thoroughly clean and examine it to determine what was causing the problem. Nothing unusual was seen except for the usual carbon and minor dirt build-up. All parts were sprayed with oil and let soaked for one hour before being brushed and wiped clean. As the dirt build-up was wiped off the carrier, a fine line on the upper forward corner section of the cam slot was noticed. Thinking it was just a scratch caused by cycling action, upon closer inspection the fine line was actually a long fracture on both sides at the exact locations. The crack starts from the top front corner edge of the cam and ends just about to the front end of the part. It appears that the triangular edge of the cam is being forced open by the side lug of the bolt each time the two parts (bolt and carrier) interlock and move together during the locking and unlocking process. One must wonder how a foremost arms manufacturer like Erma overlooked this. It would be expected of them to have fired a pre-production prototype for at least 10,000 rounds without any breakage; especially on a vital part like the carrier. Was a product recall missed? So far, there doesn’t seem to be one and, what’s worse, Erma seems to have disappeared again from the gun scene.

Why did such a marvelous looking gun turn out to be a complete disaster? The trigger lock work, the gas operated mechanism and the quality of workmanship were all great. But the most vital ingredient of a great design was certainly overlooked in this one – safety! There is only a small fraction at the front end of the carrier that is holding the part together. If a few more shots had been fired, the bolt group would have certainly disintegrated and caused serious injury. It is a good thing this was caught in time. The bolt itself is well made including the striker with the separate firing pin arrangement. This arrangement minimizes the tendency for firing pin breakage that is normally encountered if the pin is an integral part of the striker. It is also easier and cheaper to replace it if needed. So what is wrong with the carrier design? The method of locking and unlocking of the gun appears sound, solid and workable with the .22 Magnum round. As noted earlier, the overall design is similar to that of the Tokarev and FAL rifles. The big-bore rifles incorporated an internal cam for the bolt side lugs totally enclosing the bolt on both sides and the top. This is a solid construction and eliminates any starting point for a fracture or breakage especially with a less powerful .22 Magnum round. In the Erma design, the carrier cam is a simple open inclined slot cut on both sides. To make things worse, the front top corner of the slot is a prominent V-notch instead of rounded pattern. This particular area absorbed most of the stress impacted by the bolt side lugs during the locking and unlocking process. This is no doubt the major design flaw of the carrier that could have been easily corrected if the manufacturer had paid more attention assuming they had extensively tested the gun prior to mass production. The wall thickness of the carrier is only .075 inch; not sturdy enough to take the impact of bolt unlocking during operation. To completely solve this major flaw of the design, the carrier should have been made exactly as the Tokarev or FAL carriers incorporating an internal cam and not an open slot as was done on the Erma. This arrangement has proven itself to be very strong and efficient enough to handle a full power battle round even in full auto. It would have easily handled the .22 Magnum.

The ESG 22 is a very pleasant gun to shoot prior to the carrier problem showing up. The light bolt and gas operated locking mechanism contribute much to the weapon’s very negligible recoil impulse. The gun proved quite accurate averaging two-inch groups at 25 meters and under three inches at 50 meters. The rear sight is almost an identical copy of the M1 Carbine and has four elevation settings ranging from 25, 50, 75 and 100 meters. It is also windage adjustable via the large knurled drum on the right side of the protective wing. Unfortunately, the impressive looking .22 Magnum clone simply did not fare well. Erma clearly did not do their homework properly with this one and, one thing for sure, they made an excellent wall hanger.

| This article first appeared in Small Arms Review V11N3 (December 2007) |