Three Fog Signal boxes, each packed with four Fog Signals, two paper envelopes of Cordtex Joint and a roll of Cordtex upon a linen mail post sack.

By Anders Thygesen

Sabotage – The Fog Signal serves as a brilliant example to illustrate how an organization in dire need was able to devise a useful and practical solution to an immediate problem without reinventing the wheel. As the S.O.E. (Special Operations Executive) took root in the occupied countries during World War II, the need for efficient sabotage equipment increased. An efficient and fairly easy place for the resistance groups to attack was the railway system. In Denmark alone 1,525 rails and trains were destroyed during the years of 1943 – 1945.

Often it was not only the trains that were blown up. The best and most cost efficient method of sabotage to hamper the German war machine was gained by derailing the train and its cargo of war materials, causing ruin or comprehensive delays. To this end, a trigger device was needed for demolishing the rail directly ahead of the oncoming locomotives eliminating the possibility of bringing the train to a halt before derailment was accomplished. The solution was obvious and had been used ever since the late 1800s.

Development

As early as March 1893, an article in a Danish local newspaper reported how a new signal device had been introduced that was able to notify a locomotive engineer when, for example, the Stop-signal was obscured by fog. The Danish Railway Guide Book of 1944 instructs a railway worker to place three Fog Signals in a row on both tracks in such a way that a locomotive crossing them would produce a series of loud “gunshots” notifying the engineer and warning him to reduce speed.

Description

The civilian version produced by Kynoch measures 2.055 inches (5.2cm) in diameter and 0.4 inch (10mm) high. It is made from a concentric metal bowl and soldered on the inside to a pressure plate. The bowl is crimped onto a circular sheet metal plate soldered to three, and in some cases up to seven, anvils on which percussion caps are placed. This plate serves as the base of the Fog Signal. The Fog Signal houses 125 grains (8 grams) of black powder adjacent to the percussion caps. A mount holding a pair of wire legs is soldered to the bottom plate. The legs are flexible allowing them to be squeezed over the track, thus fixing the Fog Signal to the track.

When the locomotive runs over the bowl with the pressure plate, it is squeezed against the percussion caps setting them off and igniting the black powder. Because the black powder is confined in such a small place the rapidly expanding gasses of the explosion cause the sealed bowl to burst generating a loud bang.

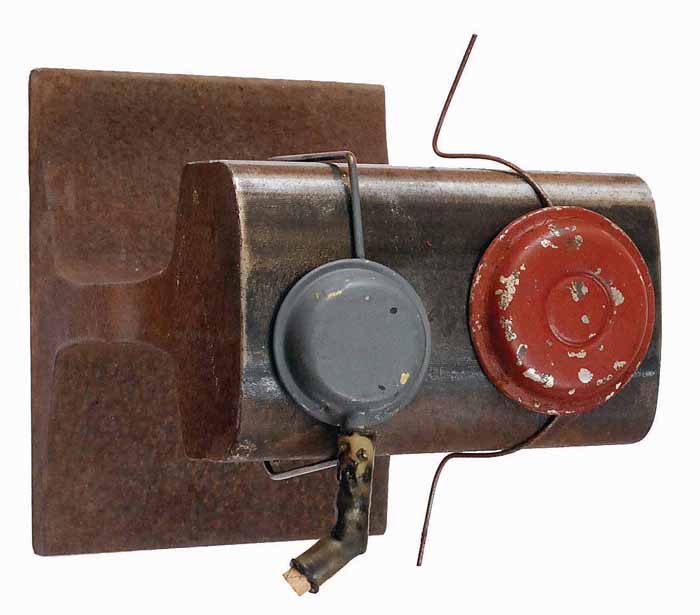

The modified S.O.E. version is grey and measures only 1.57 inches (4cm) in diameter and 0.6 inches (1.5cm) high. Mechanically it is built using identical principles as the civilian version. However, the bowl and the wire mount are made from brass. Only the bottom plate is sheet metal. Three percussion caps are to be found inside and there is a 2 inch (5cm) long quick match fuse wrapped around the caps adjacent to the black powder.

The most significant difference from the civilian Fog Signal is the 1.26 inch (3.2cm) spring snout protruding from the side of the bowl. It is identical to the spring snout found on the “Timepencil” Switch No.10 and serves exactly the same purpose of holding a detonator or a Bickford fuse. The snout itself serves as a funnel for leading hot gasses from the inside of the bowl through the snout and into the detonator assuring reliable ignition.

Function

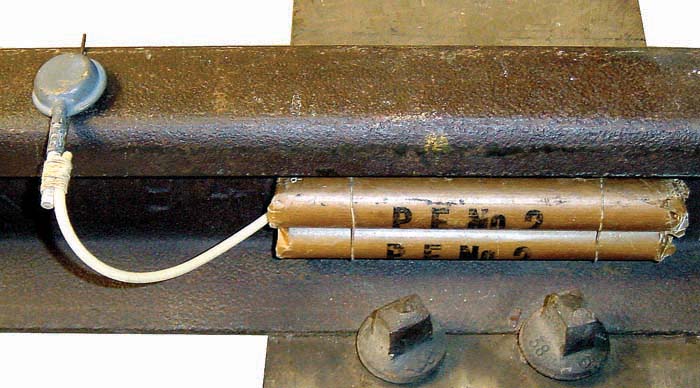

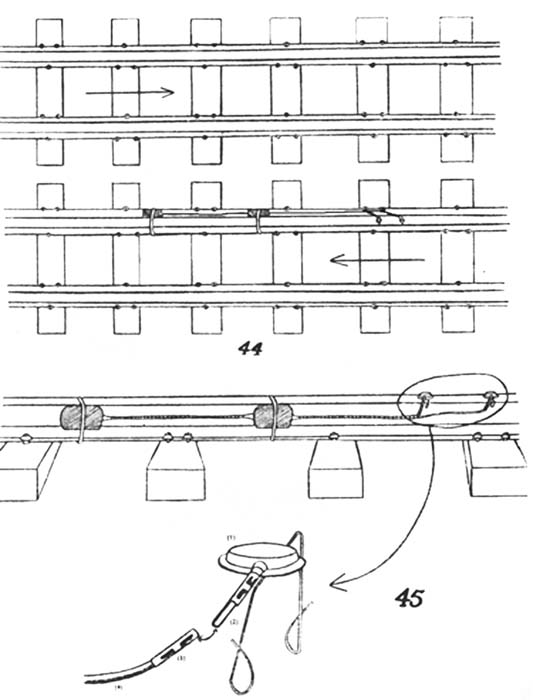

In order to guarantee successful operation it was essential that the Fog Signal be placed correctly on the track. As the illustration from the Enemy Sabotage Equipment, the War Office, May 1945, shows, it is clearly seen that the bowl is not centrally mounted on the wire pegs. This is so that the spring snout will protrude as far as possible from the surface of the track. It was therefore extremely important that the saboteur attached the Fog Signal so that the spring snout holding the detonator was facing towards the outside of the track, otherwise the snout with the detonator would be cut clean off by the flange on the locomotive’s wheels before ignition.

The distance between the Fog Signal (ignition point) to the main charge placed in front of the locomotive is set by the length of Cordtex (detonating cord). The Cordtex is attached to the detonator by tape or a Cordtex Joint wire and connected to one or more charges. The burning rate for the Cordtex is approximately 23,000 fps. (7,000m/s). This means that the ignition device and demolition charge fire simultaneously regardless of the length of Cordtex and number of charges used.

Different Models

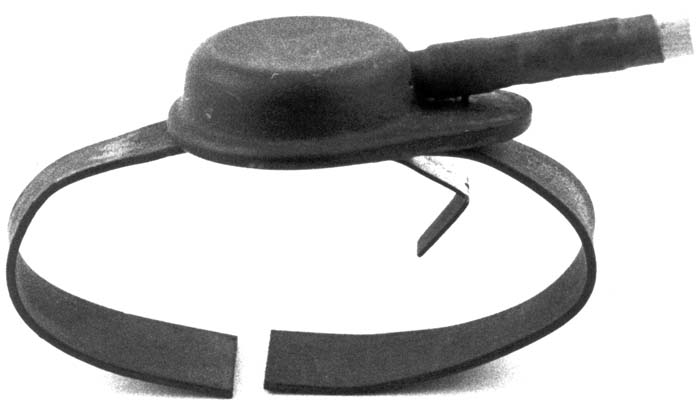

Two commonly known variations were available to the resistance. The British S.O.E. version Mk.I A as previously described and one produced by the U.S. O.S.S. (Office of Strategic Services) designated as Firing Device, R. R. Torpedo A3. It was an improved version developed in October 1943. Apparently the Germans, in an effort to avoid the Fog Signals, attached wire brushes to the front of the locomotive thus sweeping the tracks. The R. R. Torpedo A3 was more firmly attached to the tracks due to the lead straps making it more resistant to the wire brushes. It differs somewhat from the British version in appearance as the bottom plate is oval and the wire clams have been replaced with lead straps. The internal construction is exactly the same. The O.S.S. Fog Signal was produced by Western Cartridge Company of East Alton, Illinois.

Special thanks to Norman Bonney and Dave Sampson of the UK and Dr. John Brunner of the USA for assisting in the preparation of this article.

| This article first appeared in Small Arms Review V11N6 (March 2008) |