By Stephen Gearinger

Belt-fed machine guns have played an important role in nearly every major military battle since the “The War to End all Wars”, World War I. Across the open fields of France in “no man’s land” belt-fed machine guns commanded the flow of battle and were always the focal point of attacking forces within the defensive lines of their enemy. The utter devastation of sustained, full-power rifle caliber automatic fire against attacking infantry is well known and still every bit as lethal today even with all of our many technological advances in individual weapons and protective equipment.

World War II proved that the belt-fed machine gun had successfully progressed into the “light machine gun” role allowing the gun to be carried easily by one “shooter” during the assault. The use of air-cooled versus water-cooled sustainment methods, lighter yet stronger materials and designs, more streamlined weapons employing bipods, assault slings, belt boxes and drums made the belt-fed machine gun mobile without lessening its lethality.

The frightening target effects of the heavy machine guns of World War I, like the Vickers, Maxim and Browning guns had not changed. The weapons designers of the world had simply designed into the lighter, smaller weapons all of the capabilities of the heavy machine guns but with new enhancements to make them even more lethal than their more bulky predecessors.

The world learned very quickly to respect the German MG34 and MG42 machine guns for their high rates of fire and almost assured lethality of anyone seen through the gunners sights. The MG34 and MG42 are generally recognized as the earliest successful examples of a true “General Purpose Machine Gun” (GPMG). GPMG’s are commonly defined as guns that can be used effectively by a lone gunner in the light assault role from the shoulder, assault firing position or from the prone position using a light bipod. By placing these same weapons onto field tripods, fixed or vehicular mounts the GPMG serves well in the role of a medium machine gun serviced by a crew for defensive, sustained fire engagement.

During World War II the Germans favored high rates of fire in their machine guns for numerous reasons, not excluding the bone chilling psychological effects on the enemy. German designers believed, and it was well proven in actual combat, that a higher rate of fire would saturate the beaten zone produced by the weapon down range with more projectiles. On an enemy squad in the open for example, this would increase the probability that any personnel within this area would be hit before they could “go to ground” and seek cover after the initial engagement.

Anyone who has seen the recent film “Saving Private Ryan” can better appreciate the abilities of a machine gun like the MG42 in competent hands. Referred to as “Hitler’s chain saw”, the report of the MG42 with it’s 1,200 – 1,400 cyclic rate of fire was often described as sounding like the tearing of canvas. That sound, and the guns immense capability for suppressive fire both in the defensive role and during the assault, were feared in its day and are still revered in modern times by many who believe the MG42 to be one of the worlds best all-around belt-fed machine guns. In fact, the MG42 is still used by the German Bundeswehr today as the MG3 chambered for the 7.62X51mm NATO cartridge.

The attributes of all of today’s successful belt-fed GPMG’s are similar. Lightweight (generally under 26 pounds) man-portable and sustainable by a single operator with quick change barrels for sustained fire and a bipod and buttstock for assault firing. Beyond these common attributes, the designs, features, accessories, methods of operation, reliability and performance vary wildly.

Without question, one of the worlds best though severely underrated GPMG’s is the 7.62X51mm NATO caliber HK21E Machine Gun from Heckler & Koch. To many, the HK21E is without question the world’s most flexible weapon of its type, offering its users features and capabilities not available in competing designs. It is for this reason that the special units in the world that understand and appreciate the unique capabilities of the HK21E have selected it for use in both classic machine gun roles and for military and law enforcement special applications.

The HK21E (E for “Export”) is a true lightweight, general-purpose machine gun in caliber 7.62X51mm NATO. The HK21E can be fired from a tripod, bipod or from the shoulder. In the belt-fed configuration fitted with a 22-inch barrel the weapon weighs just over 20 pounds with the bipod, unloaded. With the 17.7 inch barrel installed the HK21E weighs in at 19.40 pounds and at 17.96 pounds without bipod. Detailed specifications for the HK21E and its many modular variations are included within the following pages.

Some may remember the less than stellar long-term performance of the first belt-fed HK machine gun, the HK21. Little more than an HK 7.62mm G3 assault rifle with a belt feed mechanism added to feed the weapon, early HK21s and later the improved HK21A1 models found favor with many Armies around the world. Some of the current users of the HK21E machine gun and its numerous variants include the armies of Thailand, Peru, Mexico, Finland, Ecuador and many others too numerous to mention here. Even special units like the U.S. Army’s elite Delta Force used the early model of the HK21 during the attempt to rescue the American hostages in Iran in 1980 during Operation Eagle Claw. Today various U.S. special operations units and federal law enforcement agencies as well as security elements within the Department of Energy use HK21Es.

However, early HK21s were not without their problems and in many ways could be described as immature in their design. The early prototype 5.56X45mm NATO HK23s, basically HK21s fitted with 5.56mm bolt, barrel and feed unit, submitted to the U.S. Army for testing as the XM262 candidate for the Army’s SAW trials performed poorly. At the end the Army’s testing the HK gun was surpassed by the performance of the FN MINIMI which was ultimately selected and fielded within the U.S. military as the M249.

Exposure of many to “converted” HK21’s built by American Class II manufacturers from semi-automatic HK91 assault rifles or the inferior HK21s built by HK licensed plants throughout the world did little to improve the collective admiration of the HK21 design.

Parts breakages, buffer problems and other weak points in the early HK21 and HK23 models resulted in almost continuous improvements in the design, throughout the life span of the HK21 and HK21A1 and finally into the current model today known as the HK21E. In the E model the length of the receiver was increased by a full inch to provide additional recoil length for the bolt group. Reinforcing bars were added to the receiver to provide additional strength and rigidity. The bolt head, extractor and locking roller holder were completely redesigned as were the bolt carrier and recoil spring assembly, belt feed unit, buffer, barrel and trigger group. Little remains unchanged in the design or performance of the HK21E from its earlier iterations.

During its 35+ years of life, many variants to the basic weapon have been produced, primarily due to the HK21’s unique modular design, typical of the HK family of weapons. A simple swap of the barrel, feed unit and bolt group allows the weapon to be converted in any one of three calibers to include 7.62X51mm NATO, 5.56X45mm NATO and even 7.62X39mm Russian in a model never produced called the HK22A1. This caliber conversion of the HK21 can easily be accomplished by the operator without tools, in a matter of seconds. Simple conversion from belt to box magazine or drum feed is also possible at operator level in the field. There were even plans at HK for a .50 BMG caliber HK25 machine gun, a gun that by all accounts never progressed beyond an advertisement that once appeared in an HK catalog.

HK21Es imported into the U.S. prior to 1995 would function with disintegrating M13 or DM6 link belts or the continuous German DM1 belts without adjustment. In 1995 HK redesigned the belt feed units and bolt heads of the HK21E to optimize the reliability of the weapon when using belts assembled with U.S. M13 links. As the pitch or distance between the M13/DM6 and DM1 links varies, HK21Es produced after 1995 are no longer designed to work reliably with continuous, non-disintegrating DM1 belts, though HK21Es can be special ordered for use with these belts. A true series production caliber and feed convertible general-purpose machine gun, the HK21E is unique in the history of the breed. Even today the truly modern HK21E machine gun can still be fitted with caliber and feed conversion kits that allow for flexibility unheard of in competing designs. The component parts that need to be exchanged to effect these conversions are listed in the specification table on page 50.

What is it that reputedly makes the HK21E so superior to other designs? As is often the case with successful products there is no single feature that reserves its place in the history books. With the HK21E its unmatched capabilities come from its combination of unparalleled flexibility, features and uncompromising performance.

The HK21’s closed bolt operation and free-floating barrel provide excellent accuracy like that of a sniper rifle. While many rightly contend that historically a machine gun has been an area fire, suppressive weapon, the HK21E with its cyclic rate of fire of 800 rounds per minute (13 rounds per second) can definitely suppress a target area. However, the superior accuracy, which its design brings to the user, allows it to be used in ways and in roles never before envisioned for a machine gun. For example, HK21E’s are used by the German Border Guard in a 7.62mm box magazine-fed version called the G8 Rifle. Employing a special 50-round drum magazine and telescopic sight the G8 is used in a paramilitary/law enforcement role as a light support weapon when highly accurate, surgical or suppressive fire is required against vehicular, aircraft or massed personnel threats.

The HK21E, or its box magazine-fed variants, is often used in conjunction with or in place of a sniper rifle for precision long-range engagements across the full target spectrum. Its capabilities allow it to be used to engage single personnel targets, to accurately mark targets for other weapons, to disable vehicles or equipment, or for any task where the capabilities of putting .30 caliber slugs onto or through a target with repeatable accuracy is required. The HK21E can easily accomplish this task and, unlike the fully automatic fire from a conventional machine gun, without creating the liability of rounds that miss the intended target and could cause unwanted collateral damage to surrounding personnel or materials.

Even firing belted military ball ammunition using iron sights HK21Es regularly will shoot sub-MOA groups at almost any range. Three-shot groups measuring .75 inches at 100 meters are well within this machine guns capabilities when fired from a bipod supported prone firing position. This level of accuracy opens the door for the users of the HK21E to engage pinpoint targets with accurate, effective semi-automatic fire precluding the need to waste precious ammunition in the sustained fire mode. If necessary, as the tactical situation demands, a simple flick of the safety/selector lever will allow that same shooter to “hose down” targets with sustainable automatic fire. This unique capability is not an HK “sales pitch” that is promoted and never used in the “real world”. This capability is available only in the HK21E and is one that is being used every day by military and law enforcement units around the world.

An ambidextrous 4-position trigger group with semi-automatic, 3-round burst and fully automatic modes of fire and “pictogram” markings (HK’s unique and universally understood colored bullet symbols) for the modes of fire are standard on the HK21E. Few machine guns offer other than the fully automatic mode of fire or safety/selector levers for left hand firing though these features are often used by the HK21E gunner during normal training and deployment.

Like the German MG42 and MG3 machine guns, the HK21E provides the user with a simple, quick-change barrel capability. The HK design takes the simplicity and ease of the barrel exchange to new heights of simplicity. To change the barrel of the HK21E the bolt is locked open, the barrel release lever depressed with the thumb and the barrel rotated 35 degrees and removed rearward from the weapon using only one hand. This procedure can be easily accomplished even after firing 1,000 rounds, as the well-insulated barrel handle precludes the need for an asbestos glove, as with many other machine gun designs. A special insulated spare barrel carrier is offered for the HK machine guns that allows a scalding hot barrel slung across the shoulder to be safely carried by a member of the gun crew. The layout of the HK21E allows the gunner the means to easily change the barrel with one hand, in the prone without the need to break out of the firing position or expose himself unnecessarily to unwelcome enemy observation or fire.

Unlike the American M60 and FN MAG58 (known in the U.S. as the M240) machine guns, only the barrel of the HK21E is removed during barrel changes. There is no bipod, gas system, carrying handle or front sight attached to the barrel. This well thought out and executed arrangement simplifies and speeds barrel changes from all firing positions and all but eliminates any change in zero of the weapon from barrel to barrel. This design also reduces the total weight of the machine gun crew’s load as spare barrels are carried free from attached bipods and gas systems that add to the weight of competing designs. Without a gas system and its required gas port, the structural integrity of the cold hammer forged HK21E barrel is not compromised.

Anyone who has attempted to change a hot barrel on an M60 from a prone position when firing off the bipod can attest to the complexity of this procedure. Lift and hold the gun off of the bipod to free the barrel, disengage the barrel latch, don your asbestos glove, remove the hot barrel (remember not to lay the hot barrel on the spare barrel bag or it will melt through the bag), insert the new barrel and align the gas piston, fully seat the barrel in the receiver and hold it in place while you engage the barrel latch. None of this is required with the HK21E.

The HK21E provides the operator with a forward assist for silent loading or to help chamber a round due to improper loading procedure, such as riding the cocking lever forward. The receiver of the HK21E has a guaranteed 60,000 round minimum service life. Barrels regularly withstand the firing of 40,000 rounds or more with no sign of accuracy degradation, even after being abused by long bursts of uninterrupted automatic fire.

A removable folding carrying handle on the receiver, used most often to lift the weapon from the ground as the gunner rushes forward, is positioned at the weapon’s balance point and folds out of the way when not being used. The HK21E provides a cook-off rate in excess of 1,000 rounds (cyclic), a fact proven by extensive testing, despite some claims that this is impossible from a closed-bolt design like the HK21E.

Removable belt boxes can be used to hold 100 rounds of 7.62X51mm NATO on the HK21E for firing from vehicles or during the assault. Special belt starter tabs allow the weapon to be loaded with the bolt open or closed and with the belt feed unit locked in the normal firing position. A quick drag of the belt through the unique ratchet drive wheel arrangement of the HK21Es belt feed unit using the belt starter tab places the belt in the position for loading. Retracting and releasing the cocking lever chambers the first round and prepares the weapon for firing.

It is possible with the HK21E to actuate the cocking lever and bolt of the weapon while the safety/selector lever remains in the safe position, a safety feature not available on many machine guns. “Run away” firing wherein the gun continues firing after the trigger is released (dangerous and not uncommon in the M60 due to it’s simple but unreliable sear/operating rod design), is unlikely in the HK21E due to the unique design of the gun’s trigger mechanism.

The weapon is of a closed-bolt design and is delayed blow-back operated using the classic HK roller-locked bolt to delay the opening of the breech. With the fluted chamber common in many HK weapons, the cartridge case actually pushes itself from the chamber, insuring positive extraction and ejection even under the most inhospitable environmental conditions. In most gas-operated machine guns the empty cartridge case is pulled from the chamber by the bolt as it is driven rearward by the gas system. Should the extractor or extractor spring of the gas-operated machine gun fail, the spent case may well remain in the weapon causing a stoppage. Unlike gas-operated machine guns (such as the FN MAG58) in the HK21E there is no need for a gas regulator to adjust the gas flow into the system to account for sluggish operation due to fouling in the weapon. In fact there is no gas system in the HK21E at all to be maintained. The cyclic rate of fire of the HK21E decreases in cadence to 700 rounds per minute when the weapon is converted to anyone of the box magazine-fed variants.

The HK21E is unique in its modular approach. Each of the assembly groups of the weapon can be removed in seconds by the operator without tools. This allows the configuration of the HK21E to be “tailored” to meet the specific operational needs of the operator. Maintenance is also simplified with the HK21E, as all of the modular assembly groups and individual parts of the weapon are 100 % interchangeable without the need for hand fitting. Damaged or unserviceable assembly groups can simply be exchanged by the operator with a new one and fixed by an armorer when the opportunity allows, without having to pull the complete weapon out of service. Like all HK weapons, the HK21E is simple and quick to field strip and reassemble and requires no tools to accomplish this. The removable assembly group construction and accessibility to the breech area in the HK21E receiver makes for quick and easy cleaning.

The iron sights of the HK21E are of the classic style found on most HK long guns. The front sight post is protected by circular hood that is in fact an integral component of sight alignment with the rear “peep” aperture. The rear sight offers external knobs for elevation and windage adjustment to ranges matching the 1,200 meter maximum effective range of the weapon. The rear sight provides a means to zero the weapon independent of the external adjustment knob settings using a simple Philips head screwdriver.

The HK Export model machine guns have a well thought out quick-detachable sight mounting system that provides 100 percent return-to-zero capability for all types of targeting devices including telescopic and reflex sights and visible or IR laser aimers. This system is used on HK sniper rifles and provides sub-minute of angle accuracy, even from the HK21E. It allows various types of targeting devices to be interchanged on the weapon with the assurance that the zero will remain unaffected even after repeated mounting and dismounting. This sight mounting system allows the standard iron sights and optional targeting devices to be mounted in tandem on the weapon. The special box magazine-fed light machine gun version of the HK21E used with a telescopic sight by the German Border Guard unit GSG-9 as a light support weapon provides excellent accuracy approaching or even exceeding that of many precision sniper rifles.

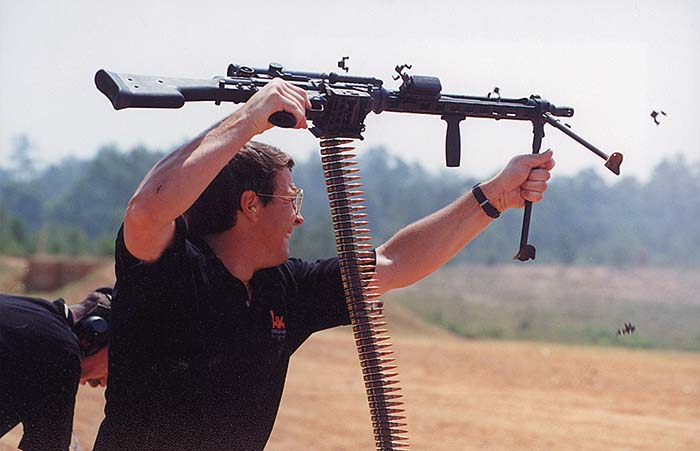

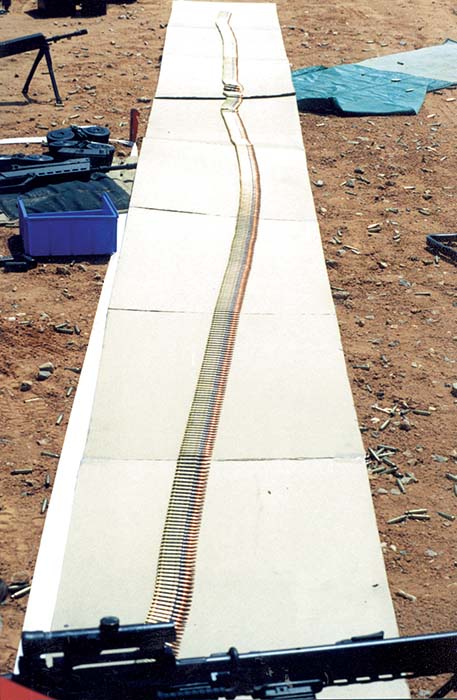

As an example of the weapon’s incredible performance, many public live-fire demonstrations have been conducted by HK, each year in fact at the annual Small Arms Division meeting of the American Defense Preparedness Association (ADPA, now NDIA). HK demonstrators prove the reliability of the HK21E by firing a single continuous 500 or even 1,000-round belt in the fully automatic mode of fire without interruption. During this firing the unique feed system of the HK21E drags the 32-foot long, 25 pound 500-round belt along the ground and up into the weapon without assistance from the gunner or assistant gunner. Immediately upon completion of firing the barrel is removed from the weapon and held by the shooter in his bare hand to illustrate the advantages of the HK21Es quick-change barrel system. The barrel, hot enough to easily light a cigarette on, is dunked in water to return it to the ambient temperature and reinstalled in the weapon. Afterwards the gun is placed in the semi-automatic mode of fire and then used to accurately and easily engage 3-inch targets at ranges up to and including 300 meters in rapid-fire cadence. This same barrel can and will be used time and time again in other similar demonstrations due to the quality of the materials and the cold hammer forging production process used during its manufacture.

The HK21E can also pull a free hanging belt longer than 7 feet in length into the weapon during firing without assistance, a mark of excellent belt pull and reliability, a characteristic especially appreciated in less than ideal environmental conditions.

Often times the demonstrator will convert the weapon from caliber to caliber and from box feed to belt feed and back in under a minute without tools as the crowd looks on, finishing each manipulation by firing a box, drum or belt of ammunition to demonstrate the weapon’s proper function. This kind of performance is typical of that which has made the HK21E appreciated by those who know machine guns.

The standard U.S. military published price for the HK21E complete with 22.0 or 17.7 inch barrel, detachable bipod with adjustable folding legs, assault grip, carrying handle, pistol grip cleaning kit, plastic muzzle cap, a combat carrying sling and operators manual is @ $4,600 U.S. This price is comparable to or less than many competing designs that offer far less in the way of performance and features than those offered as standard on the HK21E.

Accessories and mounts for the HK21E are endless and are listed within the enclosed specification table. New accessories being developed for the HK21E include adapters to allow for the use of ammunition packaged in cloth U.S. M60 100-round bandoleers, belt box carrying pouches, multiple MIL-STND-1913 (Picatinny) Rail sections for attachment to the weapon’s scope mount and receiver, a special helicopter firing platform, a cartridge case deflector with detachable collection bag, extended safety/selector levers and even screw-on sound suppressors for the weapon.

The preceding leads to the obvious question “If the HK21E is so good, so superior to other machine guns, then why is it not used by the American military in other then a few select special units?” This question is actually quite easy to address. A common phrase “The logistical tail wags the operational dog” applies in this case. Often times throughout history the infantry has asked for proven, superior weapons available off the shelf to carry the fight to the enemy yet were denied them due to the intervention of influential factors associated with the logistical support for the weapon. Through the last half of the 1800’s the single-shot U.S. Springfield Trapdoor rifle remained in service with American infantry even though the superiority of repeating weapons like the Henry, Spencer, Winchester and other rifles had been proven, demonstrated in battle and requested by unit commanders, and even approved by the U.S. President himself. Managers of the armories where the Trapdoor rifles were made, seemingly more concerned with their positions and jobs then the lives of the combat soldiers carrying the weapons into battle, used their political influence from within the logistical system to delay and even prevent the issue of superior weapons available in that day. This is only one example, there were many others.

In the United States the M60 was developed within our national armory system. American armory designers made use of existing design features from various weapons, many of them WWII German machine guns, and combined these features into what should have been a superior weapon. In the eyes of many however the M60 was and still is today disturbingly inferior in countless ways to the German guns that had come decades before the M60, and in the case of the HK21E decades after. Yet with all of its shortcomings the M60 and its E3 variant remain in service today within the U.S. Navy and Air Force. However, the U.S. Army, the Marine Corps and various special operations groups have seen the light and within the past five years have replaced almost all of their M60s with a ground model of the FN M240 machine gun (called the M240G in the Marine Corps, the M240B in the U.S. Army). While this gun is far superior to the M60 in the minds of many informed individuals, its selection to replace the tired old M60 was not made simply on its own merit.

For many years the Marine Corps was dissatisfied with the reliability of the M60. During the 1980’s it became aware that the Army had in its war stock a large surplus of new, unissued M240 machine guns that had been purchased for use on the M1A1 tank. These guns were made available to the Marines who, with the help of FNMI, quickly developed a ground modification kit to allow the weapons to be used as a GPMG in place of the M60E3s then fielded in the Corps. Though weighing nearly 26 pounds, some three or more pounds heavier than the new improved M60E4, test sample of the M240E4 proved to be far more reliable than those of the M60E4 in extensive firing tests and was thus selected for issue within the Marine Corps.

Based on the finding of the Marine Corps tests, the U.S. Army has since replaced all of the M60s within units like the 82nd Airborne Division, the Ranger Regiment and other conventional infantry and special operations units with the M240B. The Army’s version of the M240 differs slightly from the Corps version and weighs approximately 28 pounds. In the case of the Army’s decision to field the M240B to replace the M60, they did for a short time consider conducting a side-by-side comparative test that was also to include the lighter HK21E. This was the point where the logistical tail wagged the operational dog. The HK21E was never tested by the U.S. Army against the M60E4 and M240E4 because “it was not in or supported by the U.S. Government supply system”. Try explaining this to the grunt carrying the M240B or G model, an admittedly excellent 26 to 28 pound weapon but one designed in 1958 and without any of the many desirable features found on the HK21E. With all of the equipment that makes up the infantryman’s current minimum combat load which can often exceed 100 pounds or more, instead of issuing a new machine gun that was lighter than the 23 pound M60E3, we issued him one that was actually three to five pounds heavier. (This was done without considering the fact that there are lighter machine guns available off the shelf with a proven record of performance that would preclude the need to spend precious R&D dollars, like the 18 pound HK21E). Eight full pounds, the difference in weight between the M240G and the HK21E, nearly one tenth of his total 100-pound combat load, or 125 rounds of belted 7.62X51mm NATO ammunition. This is a significant difference one that could mean the difference between mission success and failure. For those special units who can afford to and are able to buy the best available weapons to get the job done, the HK21E is very often their first choice.

What is it like to shoot the HK21E? From the classic light machine gun, bipod supported position the weapon handles like a slightly bulky semi-automatic rifle on a bipod. The weapon is normally loaded in the “cleared” condition, safety on, bolt locked open. The belt is laid across the belt feed unit against the cartridge stop with the open side of the links facing up. Unlike the M60 where the bolt travels below the feed cover, the bolt of the HK21E rides over the belt feed unit and thus the open side of the links must face the bolt so that the cartridges can be stripped from it. The cover to the belt feed unit is then locked in place to secure the belt. The belt feed unit is then pivoted up and locked in place on the receiver. If belt starter tabs are available the belt can simply be pulled through the belt feed unit with it in the normal firing position. Of course, the HK21E fires standard 7.62X51mm NATO ammunition assembled with American M13 or German DM6 disintegrating links. The HK21E is also compatible with special purpose ammunition to include match, special ball, armor piercing, visible and IR tracer. From this point once the belt is inserted the cocking lever is then released with a practiced slap of the non-firing hand and a round is chambered.

The actuation of the firing controls of the HK21E, the use of the sights and firing are just like that of most other HK weapons, a distinct advantage from the training aspect of the operator. In the small arms currently in the U.S. inventory with the exception of the M16 rifle and M4 carbine there is no similarity between the operating controls of the weapons, each one is different. The HK weapons “system” reduces training time and increases the familiarity of the operator with all of the weapons in the inventory, whether it be a rifle, submachine gun, sniper rifle or machine gun.

A good firing position from the bipod can be improved by placing the feet of the bipod well into the ground or against support, such as the edge of a pavement, windowsill or fighting position. With the rubber buttstock of the weapon in his shoulder the gunner slides his body forward against the fixed bipod.

This creates a rock solid and stable firing position that is undisturbed by even prolonged bursts of automatic fire. Even inexperienced gunners find it easy to get two or even three hits on an E-type kneeling silhouette at 100 yards when firing in the three-round burst mode from this position. The gunner’s non-firing hand grasps the toe of the buttstock and holds it securely into his shoulder pocket. The design of the bipod allows for a limited amount of left to right traverse of the weapon without moving the placement of the bipod’s feet. The elevation adjustment required to get the sights on target requires only a slight shift forward or backward of the shooters body. The gunner makes firm contact with his or her cheek against the comb of the buttstock. This brings the rear and front sights into easy alignment. Centering the circle created by the front sight hood within the rear sight aperture, by intended design a skill almost naturally accomplished by the eye and brain, automatically aligns the sights. The front sight post is then simply placed on the target at the desired point-of-impact. A quick adjustment of the non-firing hand (always free to manipulate the controls of the weapon while in a firing position, an HK trademark) to the elevation adjustment knob corrects the sight setting for the estimated range to the target. The gunner’s now ready to “smoke” the target. Rotate the combined safety/selector lever into one of three available modes of fire. 7 to 11 pounds of constant rearward pressure applied to the trigger will release the hammer from the sear and fire the weapon. The design of the HK21E’s trigger group insures that the hammer will not release if the weapon is handled roughly or dropped from a height of up to 2 meters with safety/selector set in the safe or fire positions. Recoil of the HK21E is most often described as mild, less than from HK assault rifles of the same caliber, mainly due to the weight of the weapon in comparison to that of a rifle, its enhanced spring buffer and the solid bipod supported position described above.

In the 3-round burst mode, the three rounds are fired quickly enough that a clear vision of the sight picture as seen before the first round is fired is still visible to the shooter when the weapon stops firing. Unlike the 3-round burst mode of the M16A2 rifle, there is no memory in the HK burst device so the weapon will always respond with a full three rounds each time the trigger is pulled and held to the rear, regardless of how many rounds were fired during the previous burst.

It is in the fully automatic mode of fire, represented on the HK21E trigger group as seven little red bullets in a red box with an open-end meaning “infinite”, that you know you are firing a belt-fed weapon. Short six to nine round bursts are most effective from the bipod-supported position. As is the case in most machine guns fired from the ground, after the second or third shot the gunners view through the sights is obscured by the smoke and dust created from the muzzle blast of the weapon. This is where the eyes of the assistant gunner to help direct the gunner’s aim pays large dividends in hits on target.

There are the telltale signatures, sounds and sights common in all guns and unique to each specific model. Like the sound of the buffer recoiling through the buffer spring and housing in the buttstock of an M16/AR15, the HK21E is not without its own unique character. The high rate of fire is felt in the shoulder as a mild whack as the bolt group meets the waiting spring buffer in the buttstock. At 800 rounds per minute the visual signature of the weapon comes mainly from the brass colored “stream” of empty cartridge cases being ejected from the weapon to the right and forward of the firing position. Expended links form a tidy pile below and to the right of the belt feed unit. Violent is one word often used to describe the ejection pattern of the HK21E. Cases are thrown 25 feet or more from the weapon due to the blow-back operating principle unique to the HK weapon. The always-unpopular police call of empty brass on the range can be reduced or even eliminated by an experienced gunner by the careful selection of a firing point for the HK21E so that the empty cases land in an area not included in the clean up! A cartridge case deflector with detachable collection bag is available for the HK21E and is popular in roles where ejected cases pose a serious threat to the well being of the shooter, especially a shooter firing from a helicopter in flight. 7.62mm brass does not mix well with rotor and turbine blades common in today’s modern helicopters.

The gunner can make barrel changes while still in the prone position and without the burns often received from less user-friendly weapons. Barrel changes in the HK21E can only be made with the bolt locked rearward and thus the weapon in a “cleared” condition, an additional safety feature of the gun.

When firing in the assault mode from a standing or hip firing position, a few select accessories are desirable and in fact come with the weapon. The detachable assault grip can be fitted without tools in seconds to one of the many slots in the barrel casing. Right handed gunners usually prefer it positioned at about the 7 o’clock position midway along the barrel casing below the cocking lever’s “rest” position. The adjustable cotton web sling attaches to the sling mounting points on the left side of the weapon and is slung over the shooter’s head and under his firing arm. The gunner may then adjust the size of the loop so that the sling is pulled tight just as the elbow of the non-firing arm is locked out.

With the gunner assuming an aggressive “fighter’s” stance the control of this relatively lightweight 18 pound 7.62mm machine gun, even in long sustained fire bursts at 800 rounds per minute, is impressive, especially in the hands of an experienced HK21E gunner. For more accurate aimed fire the HK21E can be raised to and fired from the shoulder using the sights of the weapon as a rifle might be.

Firing the HK21E from one of the many available tripod or fixed mounts is generally just a matter of aligning the sights and pulling the trigger. The unique buffered mounts offered for HK machine guns removes most of the vibration and recoil from the weapon normally imparted to the shooter, improving hit probability. “Soft mounts” with integral recoil buffers are relatively new developments in U.S. military mounts more common within the past 5 to 10 years. HK mounts have always included this useful feature, like the WWI and WWII German mounts that came before them. The HK mounts designed for anti-aircraft use include the unique “free-aiming” feature wherein the weight of the gun is supported by the mount itself to ease aiming and firing at fast moving targets.

After firing the gun is “cleared” and the last link or two is removed from the belt feed unit and the hits on the target can be assessed. If everything was done correctly the target should be showing signs of the serious damage that only a belt-fed machine gun can inflict.

There is a great deal more to the HK21E machine gun then meets the eye. It is certainly a machine gun that, when compared to even more modern designs, has a lot going for it. Users who have experienced the HK21E know that it offers unmatched tactical flexibility in a lightweight, reliable design, with mission capability second to none.

| This article first appeared in Small Arms Review V2N3 (December 1998) |