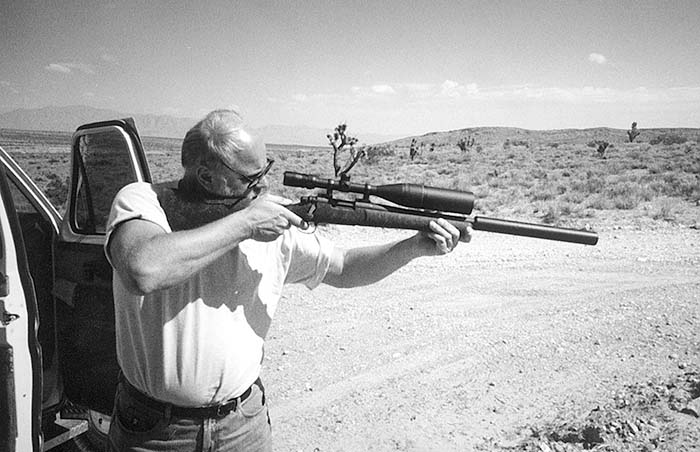

Mark White seen here shooting a Remington Model 700, 22-250 with a Dark Star suppressor.

By Matt Smith

SAR’s Precision Shooting Editor is the owner of Sound Technology Inc, which specializes in accurized suppressed shooting systems. Roving reporter Matt Smith took a few minutes to interview Mark, hoping to bring some better information to light about this interesting Class 2 manufacturer.

SAR: Mark, tell us about your background? Where did you come from?

Mark: I came from a big family and grew up in a little farming community in Upper New York State. From a very early age I was interested in mechanical things. I was building functional boats and crossbows by age seven. When I got out of high school I went right into local industry, which in my case turned out to be the motor division of GM, near Buffalo, NY. I worked there a year or so and then moved to a nearby metal fabricating plant, where we built heavy industrial equipment. I worked there as a machinist on big, sixty foot lathes, huge metal planers and vertical boring mills. Everything was loaded with 40-ton gantry cranes, which moved on three miles of rails inside the facility.

SAR: How long did that last?

Mark: About seven years. After which I got a lecture from one of my uncles about going to college and getting a degree. They say timing is everything. I must have been ready. I took his advice, worked very hard, and got a B.S. and an M.S. in industrial technology in a little over three years.

SAR: When did you start writing?

Mark: Before I got out of high school. Most of what I did was non-fiction, related to building things that I was interested in. My first article dealt with building a muzzle-loading rifle. It was published in a magazine similar to Popular Mechanics, in the late ’50s. I’ve since written hundreds of articles, and three books. I have a driving need to write, to produce.

After college I got a two-year job offer teaching in a state-run vocational school for Natives on Kodiak Island, 100 miles off the coast of Alaska. I went and filled the contract, teaching construction and welding by day, and raising and running a team of Siberian Huskies behind a sled at night. When the teaching contract ended I landed a job in one of our secret satellite facilities, which was primarily involved with monitoring offensive military activities in Soviet Russia. That was the most interesting activity I’ve been involved in. Secret clearance. Important missions. High tech. Crypto. Fascinating, bright people to work with. Remote, secured location. Great food. Very stimulating. I loved it. I’d go back in a minute.

SAR: What then?

Mark: After a time the government contractor who hired me was underbid, and about 300 of us lost our employment. I picked up a job as a welder/fitter/rigger in a ship repair yard. The yard had a 500-ton screw lift, and a set of rails that were used to move vessels around once they were pulled out of the ocean. My favorite job there was running the winch that pulled vessels along the track with a length of 1-1/4-inch cable. Most of the workers were afraid to run the winch, because the cable would frequently jump and make a fearsome noise when it snapped over one of the coils on the drum, and the operator had to stand pretty close, with one hand on the clutch lever. The chances were fair that the operator would get hit and cut in two if the load caught and the cable snapped. I had spent quite a bit of time as a rigger with one of the 40-ton cranes when I worked in the machine shop, so the noise of the cable thrumming and the creaking of the carriages didn’t bother me. I personally inspected the cable and always shackled the carriage myself, so I had faith that the gear wouldn’t fail.

I started teaching writing part-time, at night, for the University of Alaska. They knew I could build and weld, and asked me if I would set up a construction program, and then later a welding program, for their college on Kodiak. I did, and worked in those programs as a college professor for almost twenty years. In the summers I would either fish commercially on my little 45-foot longliner, work in heavy construction, or build rental houses for myself. I ended up with twelve houses in Alaska, and eventually retired from the University in the early ’90s.

SAR: What got you into suppressors?

Mark: I had been interested in the mechanical challenges of sound reduction for some time, and was looking for something to do after retirement. A mutual friend suggested I buy a plane ticket and fly to Fairbanks to spend a couple of days with silencer guru, Al Paulson, who I had met briefly when he worked in Kodiak as a research biologist for the state. I flew up in January, and we spent a couple of days in crisp thirty-degree-below-zero weather firing various silenced machineguns in an abandoned gold mining pit. It’s amazing how few guns actually function effectively in cold weather. The Sterling was the only one that was dependable. It’s also amazing how much energy it takes to stay warm in the interior of Alaska. I spent most of my time on the coast, which is tempered a bit by the ocean, when it isn’t frozen. The interior has a different kind of cold. Al encouraged me to apply for a Class II license, which I did.

SAR: And the rest was easy?

Mark: Not really. I hadn’t run a lathe in almost 30 years. I bought a 1941 South Bend with a locked-up headstock at a military auction and rebuilt it. I was experimenting and manufacturing in my unheated warehouse in the middle of winter in Alaska, going from a macro scale to a micro scale, learning to machine metal all over again, by trial and error. The only benefit from working at ten degrees was that tool bits didn’t often overheat. Forty years ago we ground most of our tool bits by hand. Now we simply change the point on a carbide insert, but one has to know what insert system to base an operation on, and that was an expensive learning process. Shipping, handling and phones to an offshore island in Alaska are very costly. Experimentation and development took up a lot of time. I made a lot of cans that I wasn’t very proud of before I began to understand gas flow and heat dissipation.

Curiously, the same people we’d been spying on 20 years earlier [the Russians] began making regular trips to Kodiak on research and training vessels from Siberia. I made it a point to spend some time with a few of them when they came into town. The Japanese also came, but our cultures were so different that I had a difficult time relating with crews from Japan. The people I got along with best were Russian news crews and former KGB agents. Sometimes I would have dinner with the crew on a Russian vessel. I enjoy cooking for large groups, and I would occasionally organize a dinner party and invite a few of them over to my house. Kodiak is blessed with a great number of people from foreign nations, and I would try to get an interesting mix of people from, say Switzerland, West Germany, Iceland and Israel to combine and have dialogue with the people from the USSR. Most of the Russians could speak fair English, and we often had some very insightful and interesting discussions. I think we changed the way some Soviets think about the United States. It was interesting to walk into an American grocery store with a group of Russians fresh off a boat from Siberia. They couldn’t believe the abundance and variety of goods we had lining the shelves. Yes, the prices were high, but Americans seemed to have plenty of money. They would watch with their mouths open when an American fishing crew came down an aisle with five carts tied together, raking goods off the shelves for a month’s trip, spending $4,000 in an hour.

One of the former agents talked about some S-baffle silencer technology. I took a few simple concepts from what had been orally described to me, and began playing with them, modifying rotation and spacing for various applications. About this same time Ralph Seifert from RASE began calling from Florida, and we began a productive dialogue in experimentation and technology. Ralph is able to take global concepts from many different areas and apply them in novel and interesting ways.

SAR: When and why did you move Sound Technology from Alaska to Alabama?

Mark: I got married a second time, and family pressures (a CFD, or complicated family deal) eventually caused me to move for part of each year. I started to build a shop south of Birmingham in the early ’90s. It took about three more years to scrape up the tooling to duplicate that which I had left in Alaska. I bought new stuff, and developed a manufacturing system that I could be happy with.

SAR: What do you mean by system?

Mark: Whenever anyone assembles a product, there’s a way of cutting out or stamping the pieces, and a method of assembling them. There’s a design philosophy about the product itself. Some manufacture suppressors that are extremely light in weight, are designed to be used a few times on a mission, and then thrown away or destroyed. Some systems work fairly well at first, but then choke up with filth and corruption and won’t ever work effectively again. It’s not hard to design a can that does a good job on a temporary basis, if you don’t care about the longevity of blind alleys and dead ends that won’t clean out unless the unit is disassembled. Many integral systems are built in such a way that all the voids fill up with crud, and the barrel corrodes and seizes to the inside so it can’t ever be taken apart without a hacksaw. While lightweight and small in diameter doesn’t necessarily have to mean fragile and short-lived, that’s often the way it shells out. My life training and work experience in industry and in Alaska has taught me to strive to design ruggedly strong, simple products that can be quickly fabricated and sold for a fair price.

We know that Boeing can make a light, strong, long-lived 737, but a lot of money, material and design expertise will go into a can with those qualities. Imagine what a suppressor a team from Boeing could make if they got funding and set their minds to it.

Most of the aluminum cans that I see are thin and fragile. They don’t have steel inserts where the threads or locking systems wear. The QD systems work fairly well when they are new and freshly greased, but bind up and choke after they are used awhile. I build my stuff to last a long time. Simplicity, strength and longevity are very important to me. If what Sound Tech builds turns out too rugged, too strong, too heavy for you, buy someone else’s can.

SAR: Do you use aluminum?

Mark: While I like aluminum, it has to be used selectively and in a thicker section to handle stress. One can’t normally use thin aluminum for all of the components without having problems with strength and longevity. As a metallurgist, I know that aluminum reaches its maximum strength at a temperature about 200 degrees below zero, F. Aluminum makes a great aircraft structure in the colder temperatures found at forty thousand feet. Steel achieves its maximum strength at about 200+ degrees F, quite near the boiling point of water, and coincidentally the temperature that our .223 M-Cans operate most effectively at. Aluminum softens and begins to sag near 900 degrees, depending on the alloy. That means, when the next blast of gas hits at that temperature, an aluminum baffle has the strength of a warm chocolate chip cookie, and the center will blow out from the impact. I’ve seen this happen to the center of a piston in an outboard engine, and I’ve seen it on suppressor baffles. It’s OK for .22 rimfires and pistol-caliber subguns, but aluminum won’t take the heat blast and powder peaning from high-intensity rifle cartridges. We make 9mm & .223 M16 cans for law enforcement entry teams, and most of them are either all-steel, or have steel shells and end caps. When a team breaks through a door and a member has to physically shove a perp onto the floor with his rifle, the can on the end of that rifle could bend and crush like a cardboard tube if it is thin aluminum. I’m told that a weapon shouldn’t be used like a battering ram, but in the rough-and-tumble atmosphere of a forced entry an officer uses what is in his hand at the time. I believe strongly in short, thick barrels and massive threaded joints.

SAR: Are all your units sealed?

Mark: They are now. We started with cans that came apart, but customers would take them apart and not be able to cram all the pieces back in as tightly as we had. So things would not go, or they would work loose. So now most our cans are steel or stainless, and welded together as a unit.

SAR: Why are they welded?

Mark: Because welding is more efficient, lighter, stronger and more permanent than threading or gluing. You have to remember that I taught welding for over 25 years, and have a lot of experience with industrial metal fabrication. If your only tool is a hammer, all of your solutions will look like nails. My tool is a welder.

Initially I did everything with a stick welder, then invested in a good TIG setup. All the baffles are machined from solid bar stock or heavy steel because I want the holes in the baffles as axially centered as they can be. The extreme geometric shapes I want can’t be achieved with stamped material. I’ve worked very hard to have no dead spots, no closed cells, no areas where crud will be encouraged to build up and pack in, and not have any reason why it won’t wash out with solvent.

The cans are designed to be sealed units, and to be cleaned by immersion in paint thinner or in an ultrasonic cleaner, and then blown out with an air hose. One of my customers had an integral MK II pistol that he stuck a bronze bore brush in, and form-fived it to me for repair after 6,000 rounds. When I finally got it apart the inside was almost perfectly clean. Cans always pack up in the rear first, yet the rear end was very clean. He had been soaking it and blowing it out after every thousand rounds, and this gives me hope that the system is working.

SAR: Do all your customers clean their guns like that?

Mark: Almost no one cleans. They fire their weapons until they absolutely refuse to function. Then they run a can of spray carburetor cleaner at the action to hose it out, hit it with a light touch of Break-Free, and continue on. On a rare occasion someone will take the time to shoot a little carburetor cleaner or light oil into the chamber of the firearm, but that’s about it.

SAR: Does that bother you?

Mark: It’s a fact of life. That’s why I designed the Millennium Can, to be of a large enough volume to handle all that waste and debris, and keep on working.

SAR: The Millennium Can is a big can for a .22 LR. I’ve seen much smaller cans for a .22 that worked.

Mark: But they don’t work nearly as well, nor as long without choking up.

SAR: What inspired you to design the M-Can?

Mark: I kept getting calls from dealers who wanted one can that an entry-level customer could put on both a rifle and a pistol. I resisted for eight years because I refused to turn perfectly good barrels down to thread to a small diameter. I knew that the end result would be a weak joint and a barrel that had lost its accuracy. I would get calls from customers who had had other manufacturers turn and thread their barrels to tiny 3/8 and 1/2-inch stubs, messing up the accuracy. They wanted me to fix mistakes perpetrated by others, and they weren’t fixable because the mistake was in the design of the small diameter, threaded system, which causes the bore to expand at the worst possible place. Eventually I discovered that I could take a heavy barrel and thread the muzzle internally to make a joint between the barrel and can that I could live with. Later I experimented with accurizing concepts and developed the short, thick, ported barrel welded to a short, fat can that we call the MONOLITH. We plotted velocity curves for different barrel lengths to find out just how long a barrel had to be to keep generic ammo subsonic. We experimented with different crowning systems. We played with barrel twists to determine accuracy parameters for bullets of different weights. We developed porting systems to enhance accuracy out of short barrels. I like original research, and enjoy the experimentation involved with making a product more accurate and more dependable. In spite of all that has been written about accuracy, there is no book available that can tell us what we need to know about making a weapon quieter, more accurate and more compact. Much of what we need to know has to come from original research, and it continually surprises me that I learn more by accident than I do on purpose.

Both the M-Can and the Monolith Cans are huge and heavy, but they work on both the 10/22 rifle and the bull-barreled MK II pistol, very effectively. Of course they are obvious, but I’d rather have an honest attempt than something that looked good but wouldn’t perform. I am reminded of the slimline muzzle brakes that are designed to be the same diameter as a barrel’s muzzle. In order to do that the builder has to thread the barrel’s muzzle to a diameter that leaves the wall of the bore almost paper-thin. That makes it fragile, and may also affect accuracy. If they would make the brake larger in diameter it would be more effective, and shorter. It would be an honest attempt, rather than a compromise between effectiveness and disguise. If a customer wants a low profile I’ll be happy to build him an integral MK II pistol with a tube that resembles a bull barrel. More and more of our customers are animal control people, and they need accurate, dependable weapons that can be relied on to do a job. They don’t care what the weapons look like. They don’t want a fine, shiny finish. They just want the weapons to deliver very quiet, accurate, reliable fire when they pick them up off the floor of their pickup.

Our Millennium and Monolith Cans (the Millennium screws on, while the Monolith is welded onto a short, heavy, ported barrel) got excellent sound reductions at the SAR Suppressor Trials. Al Paulson fired a 10/22 with one of our long Monolith Cans and was quite surprised with its level of silence. Out of all the 10/22s he’s ever tested, that was the only one that was so quiet that he could actually hear the recoil spring ringing. After all the heavy construction and chainsaw noise I’ve been exposed to, my hearing is hosed, but others with better hearing tell me they can hear the spring noise, so I believe them.

What most people don’t realize is that .22 ammo is really filthy, and an integral can on a semi-automatic weapon will dump much of that filth into the action. And that action will choke up and fail to function in very short order. The Millennium and Monolith Cans capture most of the crud at the muzzle, so the action stays cleaner longer. And the weight and damping action of almost a pound of metal on the muzzle does wonderful things for accuracy on either a rifle or a pistol.

SAR: Do you have to use subsonic ammo with the M-Can?

Mark: On a pistol with a 5-1/2-inch barrel you really only have about 4-1/2-inches of acceleration, which isn’t enough to get most rimfire bullets supersonic. The Monolith uses a similar short barrel welded to a long can, so most of the ammunition run through it is subsonic as well.

SAR: You work with a lot of different weapons. What are your favorites?

Mark: One of the best designs is the Ruger MK II. It first came on the market 50 years ago and had a few problems, most of which have been worked out. I do hundreds of these a year and I’ve never had one that wouldn’t function easily and well. I like the model with the 5.5-inch bull barrel because it is the most accurate, and because the M-Can interfaces easily with it. I have a customer who likes to shoot rimfire pistols a lot. He’s an excellent shot, and will easily shoot three to five thousand rounds on a weekend. He has owned and worn out over thirty MK IIs. Of all the brands of pistols he’s owned, he says the Ruger MK II stays accurate and functions the best before it finally wears out. He had us build and mount an eight-inch Monolith Can on his newest MK II because he said it was built like a MK II. He is able to easily hit shotgun shells lying in the dirt at 100 yards, offhand, with that pistol.

SAR: Do any other weapons come to mind?

Mark: The Colt 1911 and the M16, both of which have been in U.S. service longer than most other weapons. These are both far more complicated than they need to be, but their modularity make them a joy to work with. Those who are around me a lot will eventually hear me talk about the air-cooled Volkswagen engine being a flawed concept, brilliantly executed. The 1911 and the M16 are similar. They have been around so long and messed with so much that some examples of both are capable of being incredible performers. The locking system, barrel mount, and the straight-line aluminum action of the M16 are brilliant concepts, brilliantly executed. Having the gas tube dump filth into the action is a flaw. When mated with a short, heavy barrel the M16 is far more accurate than it has any right to be. It is very easy to mount a can on, although I prefer to use my own left-hand, large-diameter threads to do that.

SAR: Would you change anything on the M16?

Mark: My ideal weapon would have a short, heavy 16-inch barrel. It would be semi-auto only, have a short, fixed stock and a flat-top receiver to take a 10-power scope with a fat 30mm or 40mm tube. The bayonet mount would go. The weapon would have iron sights that could be deployed as a backup. If the weapon were to be used as a sniper rifle I would mount a seven-inch can on the barrel with heavy, 11/16-inch, left-hand threads to pull it up against a shoulder. If the barrel were thicker I would use even heavier threads. The joint between barrel and can is as critical for accuracy as the joint between receiver and barrel. While I like short, light weapons, I have learned that a stiff barrel is the most accurate. You will note that almost any variation of the M16 one could want is available today, right off a shelf. If I were going to change anything it would be to do something about the gas tube dumping into the action, which is a problem greatly accentuated by a suppressor.

SAR: What are your most popular products?

Mark: The M-Cans outsell everything else we make. They are now made in .22 LR, .223, .308 and 9mm. They are designed to be both effective and economically mass-produced. As a result they are reliable and affordable. The M-Cans and the integral MK IIs are what we do best. They deliver very quiet, very accurate fire at the highest velocity possible. These items constitute about 90% of our sales.

SAR: Why does the M-Can have such rounded ends?

Mark: It’s a small thing, but I’ve always been annoyed with cans that have square corners and razor sharp ends. They’re easy to get cut on, look amateurish, and they resist being shoved into a padded case. When I machine the end caps I cut deep grooves for fillet welds. As the end caps are jigged and welded in place I melt the steel down into those grooves with the tip of a TIG electrode, and then later carefully round off and smooth out the profile in a lathe. Other manufacturers now round off some of their cans in a similar profile, although they still use threaded connections.

SAR: Do you often share ideas with other Class II manufacturers?

Mark: We don’t live in a vacuum. Others in the business have shared some techniques with me, and I have given them some of my ideas. While I don’t bare my soul to everyone, there have been some people in the industry who have helped me, and I don’t mind returning the favor. If a customer calls asking for a can that I don’t make I will refer him to an industry associate who puts out a good product. This is a big field and it’s getting bigger. A little consideration and cooperation go a long way.

SAR: Have you changed the basic design of the M-Can to handle the .223?

Mark: The basic design is similar, except for the use of all-steel components to take the heat. The new .223 M-Can weighs twice as much as the .22 LR M-Can. The 7-inch long .223 can was optimized for roughly 30-grains of gas at a greatly increased pressure level. While a .22 rimfire may uncork as low as 700 psi, the .223 dumps its gas at pressures as great as 10,000 psi, in some situations. We’ve used dedicated rimfire conversion kits in M16s suppressed with our .223 M-Cans, and they work very quietly with subsonic ammo, especially with Aguila’s 60-grain SSS. The reason the non-dedicated units don’t work so well is that the soft lead bullets reach velocities approaching 800 fps before they finally hit the rifling, after being accelerated in the free-bored .223 shell insert. That usually strips the bullets in the rifling, leads the barrels, plugs the gas ports, etc. Very few rifles fitted with those conversion kits are accurate, which is why a dedicated upper unit with a proper chamber is so much more effective.

SAR: Have you had any problems with the .223 can?

Mark: There are two that come to mind, and both are induced by ignorance or carelessness on the part of the shooter. The first has to do with heat buildup. The smaller .223 entry cans are made to go on a short M16 barrel and have minimum bulk. The more effective a can is, the hotter it will get with each shot. On a weapon with an 11.5-inch barrel our little 1.5 by 5-inch cans will increase in temperature considerably every time the piece is discharged. Fire three shots on a warm day and you will burn your hand badly trying to unscrew the can. If someone slams a 100-round Beta C-Mag full of military ball ammo into the weapon and dumps most of it downrange in one continuous burst it will raise the temperature of the can to at least 1,500 degrees F. Since steel becomes plastic shortly after reaching red heat, the primary expansion chamber is going to get hot and bulge under the heat and pressure. Usually one side bulges more, and that will warp the can.

SAR: What happens then?

Mark: If they continue to fire a round could lodge in the can, which usually rips the can from its threads and sends it down range. It happens so fast that an unaware or careless person could ruin both the can and the barrel in seconds. The smaller and more efficient the can is, the greater the problem. And the pressure is on from law enforcement customers to make their cans as compact as possible.

We tell shooters to limit full-auto fire to a single 20-round magazine, but obviously some people just don’t care. We tell them that a meltdown is their responsibility and their problem, not ours. With the use of a machine gun that fires a high-intensity round like the .223, and with a small, highly efficient suppressor, should come the operator knowledge and responsibility to use the weapon with care and moderation. A silencer increases the level of operating pressure, which is capable of boosting the cyclic rate to at least 1,200 rounds per minute under the right conditions. A tremendous amount of damage can be done to both the barrel and the can in as little as 6 seconds. I would prefer it if the fire selector would only allow semi-automatic if a can were installed. In that regard a semi-auto rifle like the AR15 encourages more responsible use than a machine gun like the M16. I have always felt that single, aimed shots are more effective than spray-and-pray, in any event.

SAR: What’s the second problem?

Mark: Water. Every time a weapon is fired water is generated during the combustion process and trapped inside the can. The can has to be unscrewed and allowed to vent after firing or the barrel, the threads (or QD couplings) and the can itself will rust. Cans rusted to barrels are quite common in this business, even with the use of QD couplings and stainless steel. I fired a newly manufactured can just once and then cut it apart to see what the inside looked like. There was no single area that wasn’t totally covered, absolutely saturated with powder residue. Since sulfuric and nitric acids are used in the manufacture of gunpowder, that stuff becomes embedded in every pore of the metal. Add water to that and you will get corrosion. Guaranteed.

SAR: How effective are your .223 cans?

Mark: Initially they were just average, but one of my law enforcement dealers, kept asking me for a more effective can in a smaller package. He had an HK53 (.223) with a 7” barrel that was really vile to shoot. He’d fire a few rounds of military 55-grain ball ammo at a LE demo and the team leader would tell him to put it away. It was that bad. I made a 5-inch long can for that weapon that allowed one to fire it without ear protection. He said “If you can do that for the short-barreled ’53 you need to be making smaller cans for the M16.” So during the week I would make up a few experimental cans with slightly different components and proportions. He would come by on the weekend and we would fire a few rounds through the experimental cans. I would save the best of the lot from that batch and make more like it for the testing the following weekend. I made a lot of unusual experimental stuff that simply wasn’t effective, but eventually developed some features and concepts that were worth concentrating on. The .223 is a very intense, high-pressure round. It responds well to baffles that trap high-pressure gas. It is gratifying to make a 6-inch long .223 can that allows comfortable shooting without ear protection.

SAR: Does the sonic crack of the .223 bullet bother you?

Mark: Any sonic crack is loud, but there’s a way around that. When I built my shop I had the bulldozer operator pile the overburden into a hill. We shoot into that big pile of dirt and clay from about three feet away, and usually there is not enough room for a sonic crack to develop. So we get a pretty good idea of what the can is doing without the distraction of a loud sonic boom. I am told one can shoot a silenced .223 up to 10 feet on some days, under the right atmospheric conditions, and not create a sonic crack. Hit squads have used that phenomenon to good effect for years. We’ve learned quite a little about proportion and baffle spacing from experimental research. We’ve improved the efficiency about 40% over what we used to have, but the changes are primarily subtle changes in proportion — shaving a little off here and adding a little there. I try a lot of concepts that don’t pan out. Occasionally I will gather up a bunch of our newest products and drag them out for testing in front of a number of industry gurus. We feel that every firearm should be suppressed, and strive mightily to do our part.

SAR: Tell us about your 10/22 Pocket Rifle.

Mark: That was a project inspired by a group of federal wildlife control officers who had spent a lot of money on suppressed weapons from another manufacturer. They had cumbersome equipment that was noisy and wasn’t performing for them. One of them had seen my suppressed bullpup prototype at the Atlanta SHOT Show, and asked if it would work for them. I told the group that it wasn’t ready for production yet, but that I would make a short 10/22 that would be accurate, quiet, much cheaper, and almost as compact. This happened about the time that Aguila came out with their 60-grain, subsonic rimfire ammunition. A lot of people were excited about the ammunition, but the bullet was long and wouldn’t group accurately in existing rifles. I had been fooling with fairly expensive, fast-twist barrels and was getting pretty good accuracy out of the SSS ammunition. The fact that this wildlife control was a federal operation meant that they didn’t mind the rifle being a double [tax] stamp gun, since the transfers were free to their institution.

I described the weapon, but they were lukewarm on the project. Once it was built and they actually got to test it, they were very enthusiastic. They couldn’t believe that a short barrel would deliver the power and accuracy required. The long barrel myth has been pounded into us since grade school, and it’s hard for people to believe that firearms have changed that much in the last three hundred years. The first pocket rifle was just thrown together on a pre-ban Choate folding stock, with an old action and a short, lightly ported barrel, with a short, fat Monolith can. The piece was quiet, reliably accurate, and folded into a package about 19-inches long. They used it on deer and feral hogs with good success, as long as their only shots were head shots. The heavy SSS bullet penetrates well, and then bends and turns sideways, so it has good terminal effect without overpenetration. They told me that my rifles were the only weapons that would shoot the SSS accurately, which I attribute to several months of experimentation with different barrels and accurizing techniques. What I learned here would have been useful forty years ago, when they had problems stabilizing M16 rounds in cold climates. It is much more than rifling twist and bullet shape that must be dealt with.

SAR: What is your next book about?

Mark: I’m currently under contract with Paladin for a book on the 10/22 rifle. The book is titled THE ULTIMATE RUGER 10/22 MANUAL AND USER’S GUIDE, and is currently in production.

SAR: Thanks for sharing your thoughts with our readers.

Mark: You are quite welcome.

| This article first appeared in Small Arms Review V3N8 (May 2000) |