When one hears the name Knight’s Armament Company (KAC) and/or their president’s name, C. Reed Knight, Jr., one automatically thinks of world class quality and ingenuity. The out of the box thinking has made KAC a defense contractor to be reckoned with; one that is known to supply our most elite special operations forces. The downside is that if you are not military, you waited a long time to get any of KAC’s high end weapons. When the company started out with its development of the renowned SR-25, development was funded through commercial sales. KAC has never mass produced any small arm as attention to detail and strict quality control prohibit this. Every SR-25 that leaves the factory is provided with a test target showing it fired less than 1 MOA prior to it leaving the factory. When news of a new 5.56mm rifle that KAC was introducing was released, it was anticipated that this weapon was going to be in a class all its own. Reed Knight was not just going to come out with a standard black rifle with his name on it – the rifle would be in a class by itself: and we were not disappointed.

As of this writing, the market is awash with black rifles. Nearly every major manufacturer has their own derivative of the black rifle with most M4-type clones with standard features. Relatively few of these weapons are combat grade weapons. Most are made specifically to cater to the commercial market where price is a concern amongst others. However, for those who stand ready to make combat reliable weapons, severe attention to detail, stringent quality control and relentless pursuit of ways to improve the weapon systems are constantly sought. Few manufacturers truly step up to the plate to build combat reliable weapon systems. The cost and facility needed to accomplish such a task are cost prohibitive for many manufacturers.

The SR-15 E3 is very unique in the world of black rifles from muzzle to stock. When designed, the concept was taking the best and making it better. Prior to release, KAC looked at existing weapon systems and looked at the critiques and took them into consideration. They examined the accessories operators were buying to make their weapons more effective and built many of them into their new rifle. With KAC’s involvement with Special Operations soldiers they understood the needs of the operators.

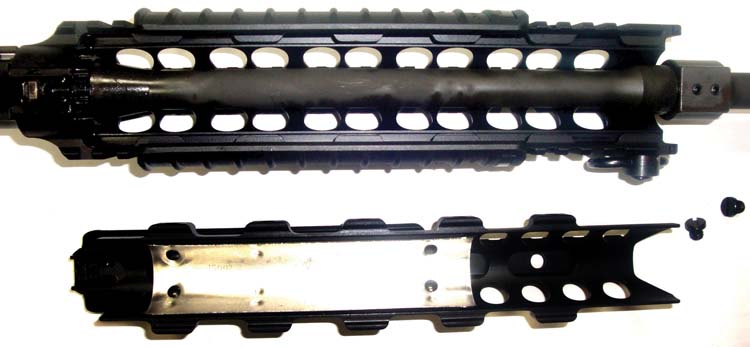

Starting with the barrel, the 16 inch barrel is chrome plated and hammer forged. Many within the SOCOM community feel that hammer forged barrels have longer service life than conventional button cut rifled barrels. They have the Mil-Spec 1/7 inch twist so the barrel will handle any projectile up to 80 grains that could be fed to it. The barrel is free floating in the KAC URX (Upper Receiver Extending) handguard. The URX has quad Mil-Std 1913 rails with a removable lower handguard. The lower handguard is retained by a plunger that is located at the bottom rear of the rail and can be depressed with a bullet tip or suitable tool. The lower handguard is secured (tightened) by two screws, one on each side of the rail. The two screws must be removed before depressing the plunger to remove to lower handguard. There are five integrated sling swivel mounds located on the URX. Two on the front side rails, two on the back side rails and one on the front of the bottom handguard. There are also numerous points that a KAC Sling Swivel Stud Assembly can be installed. Additionally integrated into the URX is a folding front sight. This Integrated Micro-Adjustable Folding Front Sight can be adjusted by hand by a dial. Neither bullet tip nor front sight adjustment tool is needed. The front sight is actuated by pushing inward on a button on the left side of the sight. The front sight post is very unique as well being extremely narrow and round. This is extremely beneficial and will increase accuracy by having a more precise aiming point. The sight is protected by “rabbit ears” to prevent damage. When folded, it has stop notches so optics or accessories can be attached over it.

The SR-15 E3 is provided with a 600 meter adjustable folding rear sight. This is one of the few Back-Up Iron Sights (BUIS) that are adjustable for windage as well as elevation. Of course, any BUIS can be used. Also provided with the rifle for examination was the new line of Micro Sight assemblies. The first is the 600 meter fully adjustable micro sight assembly (KAC part number 25650). This is a smaller and more compact version of the standard one (KAC part number 98474). The other is the 300 meter micro sight assembly (KAC part number 25475). This is a smaller and more compact version of the standard adjustable for windage only (KAC part number 97082). The micro sight assemblies were introduced at the 2009 SHOT Show.

The gas system has been altered from the conventional M4 carbine by utilizing a mid-length gas system. The gas port is placed in between the carbine and rifle gas tube lengths. This gives more dwell time (bolt remains closed longer allowing residual pressure to drop, which allows the cartridge case to contract more before extraction) thus increasing extraction reliability and durability. The URX used on the SR-15 E3 is specifically designed to accommodate the mid-length gas system.

The bolt carrier is a standard M16/M4 carrier with a well staked carrier key. Knights usually fully chrome plates the entire bolt and bolt carrier as their trademark. The SR-15 bolt carrier only had standard chrome plating on the inside of the bolt carrier and carrier key. The outside of the bolt carrier for the SR-15 is the standard Mil-Spec manganese phosphate finish.

The bolt on the other hand is all new. Knight’s were of the mindset to build an improved carbine and to do so would require actual improvements to correct deficiencies. This means the priority is on reliability and durability, not interchangeability. The multi-lug improved E3 bolt is just that. USSOCOM had complained of bolt breakage as the bolts would wear out and more than often they would break at the cam pin slot. Knight’s realized that the only way to increase that strength was to have more material in that area; so that is exactly what they did, by decreasing the diameter of the cam pin allowing more material on the bolt. There is a reduction in the diameter of the firing pin that was the result of creating a solid material recess for the dual extractor springs that astride the firing pin hole. What this adds up to is significant increase in service life of the bolt. Another issue addressed by SOCOM was failures to extract. This was mainly due to worn out extractor springs or lack of use of the newer generation gold springs. The solution was to add a rubber O-ring around the extractor spring assembly. Knight’s took an entire new approach. Rather than band-aid the problem, they created a completely new ejector. The extractor has a “lobster tail” configuration and utilizes two extractor springs instead of one – similar to Karl Lewis’ enhanced bolt. These differ by another major design change by Knights. They moved the location of the extractor pivot pin from the rear quarter to the center. Combine the two extractor springs with the leverage of having the pivot point in the middle you have a major increase in extractor force. A dirt groove was added right behind the extractor claw as well to give dirt a place to go rater than on the extractor claw. Additionally, the locking lug geometry has been changed. The corner edges from the lugs have been rounded off to increase the cross sectional area of the lugs, which increases the strength of the lugs. The bolt lugs are a common failure area of the conventional square lug bolt lugs.

The lower receiver has all been reworked as well. There are and have never been any “stock” weapons to come out of Reed’s factory. Starting at the rear, the LMT SOPMOD stock is used along with a 6-position receiver extension. The stock has a triangular cheek weld along with two removable battery compartments that are water resistant. Also, there are two Integrated Sling Swivel Mounts for the right and left side and a removable rubber buttpad. The lower receiver also has two Integrated Sling Swivel Mounds on the receiver right behind the rear takedown pin. This is a KAC innovation and has not been done in a lower receiver before. These points are preferred by those who like the one-point slings. Moving forward is the KAC ambidextrous selector lever that is not just for south paws as depending on your tactical position you may be holding the rifle in your left hand. Another major innovation by Knight’s is the ambidextrous bolt and magazine catch. The bolt catch is integrated into the lower receiver and is located just above and behind the magazine release button on the right side of the receiver. This enables a right handed shooter to be able to actuate and close the bolt with his trigger finger. Both the magazine and bolt release can be actuated by the trigger finger. The ambidextrous magazine release button is integrated into the lower receiver and is located on the left side right in front of the trigger guard. The ambidextrous magazine release button is easily actuated by the left handed shooters trigger finger. The trigger guard has been redesigned to accommodate a gloved trigger finger and is of Knight’s own design. Like the standard trigger guard, it can be hinged down by depressing the detent. The trigger itself is not stock either and is KAC’s proprietary two-stage trigger. The trigger breaks at 4-1/2 pounds and may be adjusted for as little or more creep and desired.

The sample rifle came with three KAC rail protectors, a vertical pistol grip and one Mil-Spec Okay Industry magazine was provided. That magazine was not stock either and was equipped with a new KAC magazine follower. The follower is identified by its white color and KAC written on the end. This is an anti-tilt follower, which is another reliability enhancement.

The fit and finish of the rifle was superb as what one comes to expect from Reed Knight. It weighed in at a light 6.75 pounds unloaded and measured at 33 inches in length with the stock closed and 36.25 inches with the stock fully extended. The lightweight was extremely surprising considering the enhancements from the basic design. The whole package came in a large black polymer case.

In testing the rifle a few things were added. There was only one thing left this author could think of to enhance the reliability of this rifle even more than KAC already has: that was to feed it with Magpul PMags. Based on this author’s experience, it is the finest magazine made for the black rifle. The PMags with the MagLevel (window) were used. The chosen optic was the Aimpoint CompM4 and 3X magnifier.

The ammunition used in test firing the SR-15 E3 was provided by Silver State Armory (SSA). SSA recently moved into a larger state-of-the-art manufacturing facility in Packwood, Washington. SSA is known for producing high quality match grade tactical and target ammunition and is also one of the few American companies that produce various armor piercing ammunition for law enforcement/military use. The particular ammunition used for this test was 300 rounds of their 5.56mm M193 Ball. This ammunition is actually 5.56mm and loaded in cartridge cases manufactured by Silver State Armory. Accuracy testing was done with Silver State Armory 5.56mm 77gr Sierra OTM (SSAA10075-77Sierra).

When one takes a Knight’s Armament Company weapon to the range, the bar is raised. High expectations are present and when firing the SR-15, there was no disappointment. The rifle was tested on a brisk winter upstate New York afternoon with a chilling 12º F. There were no malfunctions of any kind during testing. In all, more than 500 rounds were fired. The SR-15 shot continuous 1 MOA groups at 100 yards with both Silver State Armory 77 grain OTM and 55 grain FMJ ammunition. The Aimpoint CompM4 with the 3x magnifier worked out extremely well for this distance. Dialing the intensity of the dot down so it did not overpower the size of the bull’s-eye made all the difference. The rifle may serve well as a fighting carbine or a short range containment rifle. It has the reliability and the accuracy to accomplish both tasks.

Knight’s has put out a world class black rifle, one which sets a new standard as to where the black rifle can go and how much more can be done with this timeless design. After more than 40 years this family of weapons continues to evolve. With the talk of a new service weapon it really leads one to ask, “Why?” Properly made black rifles are light, accurate, reliable, user friendly, modular, adaptable and most of all, proven. Knight’s not to long ago was awarded the contract for the U.S. Army M110 sniper rifle system. This moved sniper rifles to another level in the U.S. armed forces. Traditional thinking of having to have a bolt action rifle for it to be accurate had been challenged. The M110 gives every bit of accuracy of the bolt action rifle with the semi-auto firepower allowing up to 50% decrease in engagement time over the current bolt action rifle. KAC is on the cutting edge of black rifle technology and will for sure be a company to follow to see the future of the black rifle.

| This article first appeared in Small Arms Review V14N6 (March 2011) |