By Janne Pohjoispää Photos by Juha Hartikka

While machine guns were used in real conflicts since the Matabele War in 1893, followed by the Boer War (1899 – 1902) and the Russo-Japanese War (1904 – 1905), the First World War changed views on full automatic infantry weapons forever. Mobile warfare required portable automatic weapons, and to a great extent machine gun development mutated from tripod or wheeled carriage mounted water cooled machine guns, to lighter guns, which were air-cooled and magazine-fed. These new guns were called light machine guns or automatic rifles depending who was talking about them. The Danish Madsen light machine gun originally designed by Jens Torring Schouboe, was one of first LMG designs available at that time. It was followed by Lewis, Chauchat and a few others, which were all fired in anger during the Great War.

During the First World War, a serviceable machine gun was almost worth its weight in gold. If the machine gun was a highly prized war “booty” for major armies like the Germans, French and British, one can anticipate how smaller nations like Finland greatly regarded captured machine guns. After the WWI, a newborn Finnish Army had a limited number of machine guns and an even more limited number of man portable light machine guns. In the latter category the most common types were the German MG 08/15 and its less successful aircooled variation, the MG 08/18, both in original caliber 7.92 x 57 mm. The MG 08/15’s and MG 08/18’s were acquired from German expeditionary forces and purchased from France in 1919. Other LMG types including the Lewis, French Chauchat and the Danish Madsen were captured in small numbers from Soviet-Russian forces or Soviet-backed Finnish Red Guards. Some Lewis light machine guns, mainly in caliber 7.62 x 54 R, were imported after the war. To meet increasing needs for maneuverable warfare and to standardize a miscellaneous selection of automatic weapons, the Ordnance Department of Finnish armed forces selected the Danish Madsen LMG in 1920. Until 1928, the Finnish Army and National Guard purchased more than 700 Madsen light machine guns of various models from Denmark, mainly in caliber 7.62 x 54 R. Although in the early 1920’s Finns even aspired to license manufacturing of the Madsen, it was later considered too complicated and liable to malfunctions in the Finnish northern climate. However, it is also quite obvious that buying armament from abroad was quite hard for the economy of a young nation.

At this point, the L/S-26 light machine gun arrives on stage. In the early 1920’s young ordnance NCO Aimo Johannes Lahti (1896 – 1970) designed a submachine gun which later became the renowned Suomi M1931 SMG. At that point in time, the submachine gun wasn’t yet considered a serious military weapon. Therefore, his supervisors urged Lahti to develop a new light machine gun as the army was looking for a successor for the Madsens and MG 08’s. Lahti started to develop a light machine gun, first at his own expense, and after October, 1924, with an official assignment from Ministry of Defense.

In October of 1924, the Finnish Ministry of Defense established the Light Machine Gun Committee (Pikakiväärikomitea), to select a new LMG for the Finnish armed forces. While the LMG Committee was officially selecting a new weapon, it was quite obvious that they would all rather that the new LMG would be of Finnish design and manufacture as opposed to an imported one. Certain specifications, including that it should operate properly with the Finnish 7.62 x 53 R (*) service round, gave some advantage to a native design.

* The 7.62 x 53 R is a Finnish designation for the Russian/Soviet rimmed 7.62 x 54 R round. Despite a different name, the Finnish round is interchangeable with the 7.62 x 54 R.

Although Lahti had independently developed a submachine gun, to the bureaucrats he was only a self-educated inventor without any formal competence in small arms designing. Therefore lieutenant (later general-major) A.E. Saloranta was appointed as Lahti’s instructor and supervisor. Lieutenant Saloranta, who later became an important character in Finnish military small arms circles, had studied ordnance technology at the Royal Danish Military Academy. Perhaps due to this, it was quickly apparent that Lahti and Saloranta couldn’t work together, so Lahti continued his design work alone. While not close friends, Saloranta later helped Aimo Lahti to get sufficient compensation for his design, as Lahti had designed the L/S-26 mainly at his own expense, and the government at first refused his compensation. While the L/S-26 is a brainchild of Aimo J. Lahti, from the viewpoint that Saloranta worked on it, and helped Lahti with his government contract, it is justified that Saloranta has his name in that designation as well.

General-Major Saloranta’s career was a contradictory one. He was associated with the ill-fated “Lining Affair” (refurbishing worn-out Mosin-Nagant M1891 barrels by lining them using a so called Salerno-method) and the inoperative administration of the State Rifle Factory, which caused lengthy delay of issuing the first L/S-26’s to Finnish armed forces. Later he designed a military pistol which was, however, rejected in favor of Lahti’s L-35, and the Salobellum .22 rimfire conversion kit for the Parabellum pistol.

The first LMG prototype chambered for the 7.92 x 57 mm round was finished in the summer of 1925. In comparative trials arranged during the late part of 1925, the L/S-26 was fired against the Madsen, Swiss Ferrer MG 25, Colt-made BAR 1918, Anglo-French design Vickers-Berthier, French Hotchkiss and Italian Breda. After trials the L/S-26 light machine gun was found the most suitable type, and it was officially adopted on August 13, 1926, as “Pikakivääri m/26”, better known as the Lahti-Saloranta 26 or simply, the L/S-26.

As stated above, it took almost four years before the first L/S-26 light machine gun manufactured by VKT was issued to the Finnish Army in 1930. Established in Jyäskylä„ to manufacture the L/S-26 light machine guns, Valtion Kivääritehdas (State Rifle Factory) or VKT had serious administrative and technical problems with starting production of the L/S-26.

When production finally started in 1930, about 500 guns per year were manufactured. The last batch of the L/S-26 light machine guns was delivered to the Army in 1942. Altogether around 4700 L/S-26 light machine guns in caliber 7.62 x 53 R were fabricated for the Finnish Army. The main reason for ceasing production during WWII was that twice as many (around 10,000) Soviet DP light machine guns were captured from the Red Army. Nicknamed the “Emma” (*) by Finns, the gas-operated DP was highly respected by many first-line units, particularly due to its exceptional reliability in extreme conditions. The DP and its armoured vehicle variation known as the DT, became the standard weapons of the Finnish Army during WWII, and the Finnish arms industry started manufacturing magazines and spare parts for captured Degtyarev light machine guns.

* The Emma waltz was performed by various artists since 1929, and was one of Finland’s top hits in the 1930’s and during WWII, but why is the DP called “Emma”? The connection between a gramophone turntable and DP’s 47 rd flat drum magazine was obvious…

When Finland became involved in WWII in November 1939, the L/S-26 was the principal light machine gun of the Finnish armed forces. Virtually all existing stockpiles of the MG 08/15s, MG 08/18s and Madsens were sold abroad in the early 1930’s. The number of existing L/S-26’s was insufficient for a war-time army, but the situation became far better as Degtyarev LMGs captured from Soviet forces in large numbers during the Winter War (1939 – 1940), and the Continuation War (1941 – 1944) provided needed relief.

No commercial success

In early 1930’s Aimo J. Lahti developed an improved variation of the L/S-26 which accepted a 75 round drum magazine. Known as the L/S-26/31 it was originally intended as an observer’s machine gun for aircraft, but was soon adapted for ground use. The first models were designed to accept a 75 rd drum only, but very quickly they introduced a model which accepted both box and drum magazines. After minor modifications it was renamed as the L/S-26/32. The L/S-26/31 or the L/S-26/32 was officially adopted by the Finnish Army, while the few guns remaining at the VKT factory were put into service during the Winter War.

VKT invested a lot of money for marketing Lahti designs, but the improved models of the L/S-26 successors gained no significant commercial success. In the early 1930’s, VKT offered Lahti-designed machine guns and machine cannons to several European and South American countries, but without success. All that was changed in 1937, when the National Chinese government ordered 40,000 LS-26/32 LMG’s in caliber 7.92 mm Mauser. The first batch of 1200 guns was delivered to China in 1937. Soon after that the Japanese government asked the Finnish to cease arms sales to China. Although this single sale would have compensated all the establishment cost of the VKT factory at Jyväskylä, politics played a more important role. In addition to the 7.62 x 53 R and 7.92 x 57 mm caliber models, the prototypes were also made for the 6.5 x 51 mm Arisaka, 7 x 57 mm, 7.65 x 53 mm Argentine Mauser, .303 British and 8 x 56 R Solothurn (Hungarian) cartridges.

Recoil operated

The L/S-26 light machine gun fires from an open bolt and operates by the short recoil principle. The short recoil principle means that at the early stages of the recoiling stroke, the barrel and bolt engaged on the barrel will withdraw together for a short distance. Motion of the barrel discontinues, and the bolt continues alone on its backwards path. When the bolt comes back with a fresh round, it will chamber the cartridge and engage again on the barrel assembly. If the recoil operated gun fires from an open bolt, the striker will usually hit the primer before the barrel assembly is fully in the battery position. This principle is often referred to as “advanced ignition” or “floating fire”.

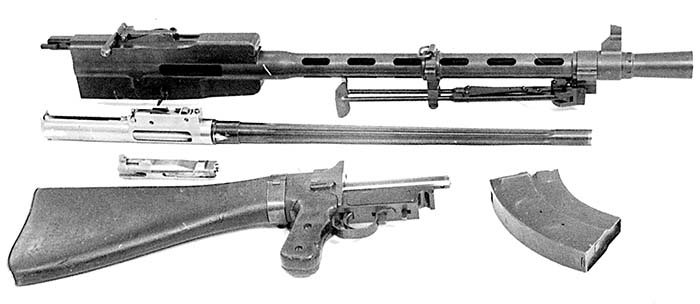

The L/S-26 works just that way. The upper receiver and barrel shroud permanently mated on the upper receiver, comprises the cradle for the barrel assembly. The upper receiver has bedways for the barrel assembly, and a guideway to control locking block movement. The muzzle of the barrel rests against the front of the barrel shroud, which serves as the bearing surface for the barrel. The L/S-26 barrel assembly includes a long, tubular barrel extension, which houses the bolt. The barrel extension has a tilting locking block that is connected on the receiver guideway via a pivot arm. The locking block will rise and fall according to the barrel extension movement. The barrel extension also includes an accelerator lever, which pushes the bolt backwards while the locking piece disengages from the bolt. The accelerator used with the L/S-26 also appears on other Lahti designed recoil operated small arms including the L-35 pistol. The barrel assembly weighs 5.11 lbs (2.32 kg), and the cyclic rate is moderate, 450 – 550 rpm depending on the ammunition used. The highest rates of fire in 7.62 x 54 R caliber weapons can usually be obtained with the Soviet silver tipped “LPS” light ball, which is usually judged the hottest service ammunition available for this caliber.

The upper receiver has a hinged top cover, which houses the cocking handle assembly. The cocking handle engages the bolt from above. It has no return spring, so it requires manually returning it to the front position.

Many gas-operated machine guns firing from an open bolt have fixed firing pins, which will hit the primer as the bolt goes to battery. Recoil operated L/S-26 employs a different and more complex system. The L/S-26 has a horizontally moving striker, which cocks as the bolt goes rearwards, and releases when the bolt goes to battery. The striker assembly is located inside the recoil spring capsule in the buttstock. The striker/recoil spring assembly is an Achilles’ heel of the system, and it is highly liable to jams while dirty or greased during the cold weather. Keeping the capsule absolutely dry and clean was a lesson learned the hard way during the early stages of the Winter War. The pre-War period Finnish Army regulations distinctly forbade disassembly of the lower receiver for all except armourers. The Winter War lessons were learned here, too, and regulations were checked. I have an army ordnance department manual printed in 1942, which gives instructions for disassembly of the striker/recoil spring assembly. However, those soldiers who received their advanced training with the National Guard (Suojeluskunta) knew well what was required to keep L/S-26 firing in the deep freeze of the Winter War.

The L/S-26 selective fire trigger mechanism provides both single shots and full auto fire. The sliding fire selector is located between the magazine catch and trigger guard. The selector has no markings, but it fires full auto on forward, and when pulled backwards it fires single shots. The safety is mounted just in front of the trigger guard. As the L/S-26 fires from an open bolt and employs a vertically moving striker, no hammer is required. The trigger mechanism has a tripping sear similar to most submachine guns. The L/S-26 trigger mechanism was nothing special, but in the pre-WWII era the construction of the trigger mechanism was classified as top secret. Revealing the construction details to foreigners, especially to those of the Soviet Union, would have been judged as treason.

The trigger mechanism, recoil spring and striker assembly are mounted on a separate lower receiver, which covers the receiver at the back and bottom. The lower receiver also mounts the buttstock assembly.

The L/S-26 has a heavy fluted and tapered barrel with a length of 19.7 inches (500 mm). The barrel is mounted on the barrel extension by means of a thread. The barrel assembly includes the barrel, barrel extension and bolt can be removed in the field, but as each assembly requires a specific bolt with correct, individually fitted headspace, it is not a true quick change barrel. Most L/S-26’s were originally issued with an additional barrel assembly carrying the same serial number. The spare barrel assembly, which is called the “Varamekanismi” in Finnish (the spare mechanism) was stored and carried in a scabbard made from leather or later from birchwood. As most L/S-26’s saw hard usage during WWII, spare barrel assemblies are currently scarce. Owning a gun and a spare barrel assembly with the same numbers is more than good luck.

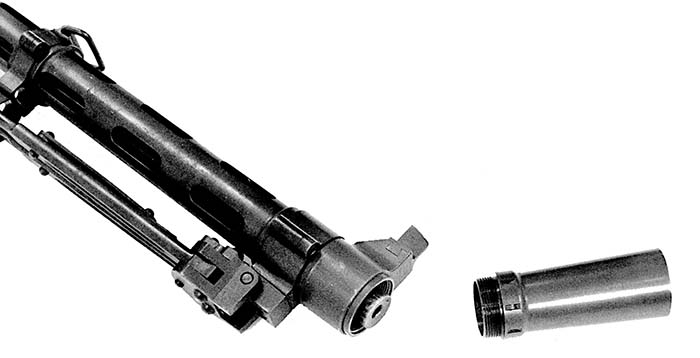

The barrel shroud has an internal thread, which mounts the flash hider and alternatively, the blank firing attachment. A separate blank firing barrel assembly, the “Paukkupatruunamekanismi” (blank firing mechanism) was used with the BFA. A spanner wrench was used for fastening/dismounting the flash hider and blank firing attachment. The spanner wrench is a part of a combination tool including wrench, hammer and screwdriver. Blank firing barrel assemblies were usually converted from worn-out or rejected parts.

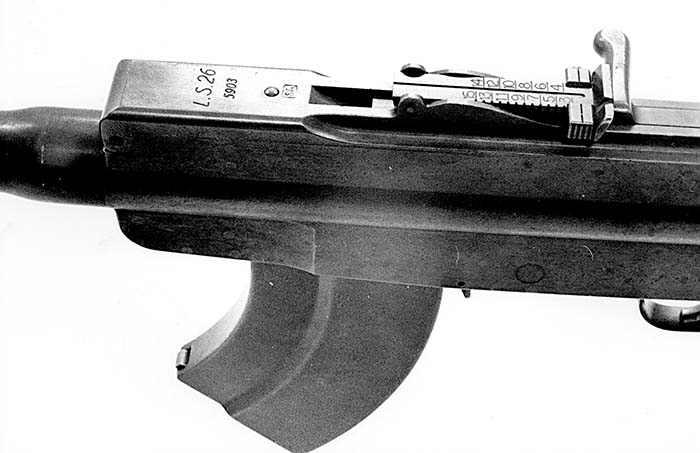

The magazine is mounted by the common method underneath the receiver. The 7.62 x 53 R caliber L/S-26 has a curved, staggered row 20 round box magazine. The L/S-26 box magazine has tapering lips so that it will feed from a single position at the middle of the magazine. Five to ten magazines were issued for each gun, varying by the date of delivery. Carrying the L/S-26 magazines in the field was accomplished with an issued olive drab canvas bag with a shoulder strap.

Two magazine filling tools were issued for the L/S-26 20 round box magazine. The most common type was a simple depressor crudely made from sheet steel. The other type was a sophisticated magazine filling machine manufactured by VKT. The magazine filling machine was better suited for arsenal use than for front-line use under fire.

The L/S-26/32 came into Finnish service during the Winter War. The LS-26/32 has a removable magazine well, which allows the use of both 20 round box and 75 round drum magazines. In the Winter War, most 75 round magazines were issued for the Finnish Air Force, who needed them even more desperately than the ground forces did. As the drum magazines were not available for the L/S-26/32, most guns had the removable magazine wells welded or pinned in place to accept 20 round box magazines only.

Sights are slightly offset to the left because of the wide receiver. The rear sight mounted on the receiver cover has a sliding tangent arm graduated from 300 meters to 1500 meters with 100 meter steps. The foresight is mounted on the tall post attached over the barrel shroud. Detachable anti-aircraft sights were also developed for the L/S-26.

Scoped L/S-26’s are not pictured in any books or included in public collections, but a few guns were converted, apparently on field level, to accept a prismatic sight taken from the 32/33 (Finnish Maxim) machine guns. These guns, as well as scoped Maxims, were used as counter-sniper weapons to eliminate Soviet snipers.

The L/S-26 has a folding bipod mounted near the muzzle. Similar to most other designs of its era, the L/S-26 bipod is machined from solid steel with fixed height legs, but with provisions for rotating and canting the gun while it is standing on the bipod. The bipod was not liked by many of those L/S-26 or DP gunners of the Finnish Army who were on long range patrols or otherwise involved in mobile warfare. The bipod was not considered necessary when the L/S-26 was fired at short distances in the forests, the gun was fired from an underarm carry position using the sling as a support, or it was alternatively supported over the gunner’s rucksack or a natural rest.

No tripod was developed for the L/S-26. Instead of that, the Army developed an anti-aircraft mount, which was constructed over the Army issue rucksack’s tubular metal frame. The AA-mount/rucksack was intended to be worn on gunner’s assistant while the gunner stood behind him and fired upwards. The L/S-26’s AA-mounts were never made in quantity.

The L/S-26 furniture, including the buttstock and pistol grip panels, are made from birchwood. The buttstock has a steel buttplate, and some examples were fitted with a hinged shoulder strap.

The manufacturing methods of the L/S-26 were both expensive and complex, similar to many other small arms of the same era. Most parts for the L/S-26 were laboriously milled from solid steel billets or forgings, with very close tolerances. In practice the tolerances are too close to expect that the gun would operate properly in adverse conditions. This became very clear during the cold days of the Winter War, when temperatures dropped below -40 degrees Fahrenheit. In these conditions it requires very careful maintenance and absolutely no oil. Properly prepared, the L/S-26 will cycle reliably in freezing weather. However, it got a bad reputation among Finnish troops due to problems with reliability, which were after all caused by improper maintenance.

The L-34 – an unsuccessful rival

From this author’s current viewpoint the recoil principle looks like too complicated an operating method for a mil-spec shoulder fired weapon, but in the early 1920’s it was an obvious choice. Many authorities were attracted by the reliability of the Maxim machine guns. Conversely, gas operated guns were usually judged as being more unreliable designs- like WWI-vintage French Hotchkiss machine guns.

In the late 1920’s some high-ranking army officials started speculating about adopting a new gas operated machine gun. Some early attempts were made to adopt the 1918 BAR, which was adopted a few years earlier by the Swedish Army as the Kulspruta m/21. However, the ordnance department suggested the creation of a domestic design. In 1934 Aimo Lahti was assigned to develop a new gas operated LMG. Lahti had already sketched a gas-operated weapon, so it took only one month to finish the new LMG, which was later known as the L-34 “Sampo”. The L-34 was an outstanding light machine gun, in different circumstances it would have been a serious rival for the Bren/Czech ZB-series. It has a gas piston mounted beneath the barrel, a quick change barrel and a top mounted magazine. In addition to that, the L-34 was more than 2.2 lbs (1 kg) lighter than the L/S-26. The L-34 would have been simpler and cheaper to manufacture than the L/S-26.

The Ordnance department seriously considered replacing the L/S-26 with the new L-34, so seriously that in 1935 production of the L/S-26 was almost ceased. However, all of the Army officials rejected the gas operated L-34, and the L/S-26 was placed back into production.

Later Lahti’s designs were mostly gas operated: L-34 heavy machine gun chambered for the French 13.2 x 99 mm cartridge, the 20 x 138 mm caliber L-39 anti-tank rifle and the 7.62 x 53 R caliber L-41 general purpose machine gun.

Production numbers of the LS-26 and its derivatives were limited. Altogether around 4700 LS-26 light machine guns were delivered to the Finnish Army in 7.62 x 53 R caliber. As described above a limited number (around 50) of 7.62 x 53 R caliber L/S-26/32 were used during WWII. Most LS-26/32’s were built in 7.92 x 57 mm for China.

The L/S-26 served the Finnish Army throughout WWII, and also during the post-war period until it was replaced in the early 1960’s with the 7.62 x 39 mm M43 caliber belt-fed KVKK 62 (KVKK = kevyt konekivääri – light machine gun). However, the L/S-26’s remained in FDF inventory until 1986. Some guns were destroyed, while others were sold to collectors.

| This article first appeared in Small Arms Review V2N2 (November 1998) |