Already in the early stage of World War II, the German troops on their advance encountered landmines of all kinds, some of which were laid over large areas. They did not always have the time to laboriously search for the individual mines by hand in order to defuse or blow them up. During an ongoing attack it was necessary to break through the mine fields quickly and to clear paths for advancing infantry and vehicles.

In the course of time different methods of mine clearance were developed and tested. A quick clearing of larger areas was to be achieved by machines. For example, armored vehicles specially converted for this purpose pushed massive cylindrical clearing devices in front of them, which detonated the mines without causing any damage to the vehicle itself. In impassable terrain or areas with heavy vegetation, however, this method was usually ruled out. In these cases, portable mine detectors had to be used. The mines were marked with a warning flag after detection until the time was found to dig them out by hand. During an attack, possibly still under enemy fire, this kind of search was hardly feasible.

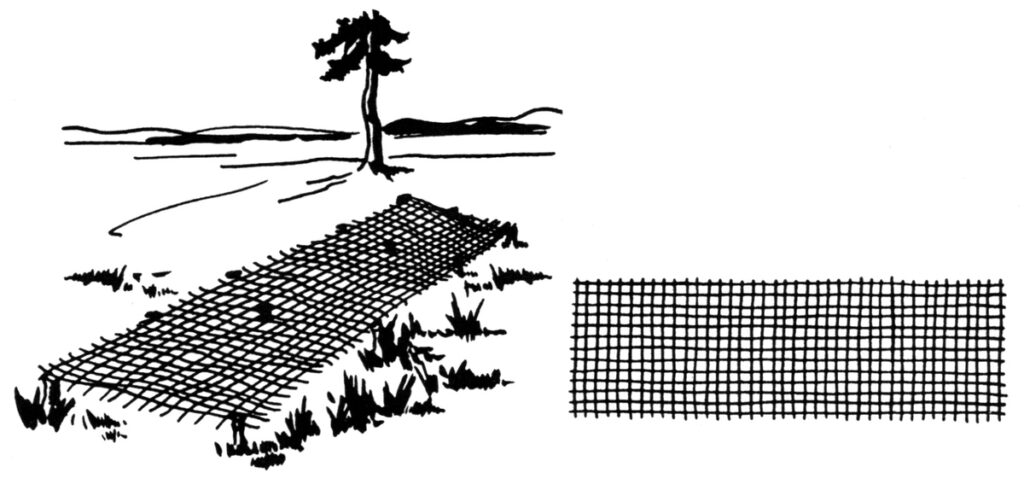

In early 1940, the idea therefore arose to detonate laid mines by means of a so-called “Knallteppich” (literally translated as “bang carpet”). Sometimes it is also referred to as a “blasting carpet” or “blasting net”). This net was made of explosive igniter cord and could be laid over a detected minefield. When ignited by a fuse, it detonated, and the blast wave was sufficient to detonate the mines below it.

The Waffen-SS also showed great interest in this development and on 4 September 1941 a meeting took place between representatives of the Heeres-Waffenamt and the SS-Waffenamt. SS-Gruppenführer Hans Jüttner, as head of the SS-Führungshaupt- und Kommandoamt, received a protocol of this meeting that shows the technical details and the still unsolved problems.

Due to the positive assessment by the Pi.Lehr-Btl.2 in Dessau-Roßlau, 3,200 “Knallzündschnurteppiche” (blasting cord nets) were ordered and delivered to the troops. However, at this point in time there was no feedback. The carpets delivered had a length of 10 meters, a width of 7.5 meters and a mesh size of 10 to 15 centimeters. The weight was about 0.5 kilograms per square meter. The nets could be laid next to each other to cover areas of any size. It was not necessary to connect them, but they should overlap by about 10 cm to ensure a proper activation. If necessary, such carpets could also be made provisionally by stretching igniter cords over a slatted frame. When laid out, the carpets were insensitive to rifle ammunition (including tracer ammunition), but extremely sensitive to shrapnel, which caused an immediate detonation.

According to a leaflet of June 1942, the easiest way to unroll the rolled net was by two men using a rod inserted into the roll and, to the surprise of the opponent, preferably at dusk or in the dark. The loud bang of the exploding nets was to be camouflaged by simultaneous fire of the artillery. So far so good, but from this we can already see the disadvantages: to roll out the net, the two soldiers had to walk through the minefield themselves. And this, as far as possible, in the dark! Furthermore, it turned out that the nets worked very well with anti-tank mines, but almost not at all with anti-personnel mines. Trials with treated, meshless fabric (nitrated cotton cloths) brought no success.

As an alternative to the dangerous rolling out by hand, the use of line-throwing devices was tested and found to be useful. A rope was attached to an anchor, with which the net could then be pulled over the minefield. However, the method only worked in unobstructed terrain, otherwise the carpet tore when pulled over rocks or vegetation. Another idea was laying the nets from the air and so together with the Luftwaffe, they tested dropping the nets from airplanes. The success was moderate. A helicopter was a better option, but this would not have made much sense due to the danger of getting shot down while hoovering so close to the front line.

Another development called automatic net-layer did not get beyond the planning phase. A light vehicle, steered from a safe distance by cables, would have rolled out carpets 3-meters-wide over the minefield. It was controlled from a PzKpfw II, which protected the operating crew from spall. The Talbot wagon factory in Aachen had produced a prototype, but shortly afterwards the order was cancelled as “not decisive for the war”.

Although the idea with the blasting nets was well-intentioned, it failed due to the rigors of reality. No type of net or laying device was actually introduced by the Heer or Waffen-SS.