By Janne Pohjoispää, Photos by Tuomas Mäkelä

Likely inspired by the German MG34 and MG42 general purpose machine guns they encountered during WWII, Soviet designers started to develop their own version of a portable, belt-fed multi-purpose machine gun during the Second World War. While many attempts were made to replace their aging Maxims, since the 1930’s no satisfactory design had been found. A brainchild of Vasily Degtyarev, the DS-39 medium machine gun was issued to the Red Army just before WWII, in 1939. It was quickly discovered that the DS-39 had an improperly engineered belt feed mechanism which damaged the cartridge cases while stripping them off from the belt. Tested in the Finnish-Russo Winter War (1939 – 1940), the DS-39 was found to be too complicated and liable to malfunctions, especially in cold and dusty conditions. The DS-39 was withdrawn from service.

The next step was the SG-43 (followed later by an improved variation known as the SGM) designed by Petr and Mikhail Goryunov. Goryunov’s machine gun was far more reliable than the DS-39 and lighter than the old Maxims. Mounted on a wheeled carriage or tripod it served well in the medium MG role, and was converted into a coaxial MG as the SGTM. For infantry the SG43/SGM was just a medium machine gun like the DS-39 or Maxim, however, shortly after WWII, a belt fed version of Degtyarev’s DPM light machine gun, the RP-46 was adopted as ‘the company machine gun’. The RP-46 was lighter and more maneuverable than its predecessors, but poorly suited in roles other than as a light machine gun.

The RPD light machine gun firing an intermediate 7.62 x 39 mm M43 round was considered for the GPMG role. The 7.62 x 39 mm M43 cartridge was already standardized for the AK-47 assault rifles and SKS semi-automatic carbines. One caliber for all infantry small arms would have been an ideal situation, but the 7.62 mm M43 seriously lacked both the penetration and effective range needed in a GPMG. It was dropped and interests were turned for developing a whole new GPMG, firing the more potent 7.62 x 54 R caliber round.

In the early 1950’s two Soviet designers, Grigory Nikitin and Yuri Sokolov, started to design a belt fed machine gun chambered for the 7.62 mm rimmed round, while the renowned Mikhail Kalashnikov worked with his own design. Both Nikitin-Sokolov and Kalashnikov weapons were gas operated having rotating bolts and quite similar external appearance. Tests arranged in 1960 revealed that Kalashnikov’s design, the PK (Pulemyot Kalashnikova) was more reliable. The PK was also less expensive to manufacture, and it was selected over the Nikitin-Sokolov design. The time for Nikitin and Sokolov would come ten years later. In 1972 the 12.7 x 108 mm NSV heavy machine gun designed by Nikitin, Sokolov and Vladimir Volkov was adopted to replace the DShK and DShKM heavy machine guns-but that is another story.

In 1961 the Kalashnikov-designed PK-series was adopted as the standard GPMG of the Red Army. Eight years later, in 1969 a product improved version called the PKM (Pulemyot Kalashnikova Modernizirovanniy) was introduced. The PKM can be easily recognized because of its lighter, unfluted barrel and a hinged shoulder strap on the buttstock. The PK/PKM series has changed into four configurations:

The PK/PKM is a basic LMG version with bipod.

The PKS/PKMS (PKS – Pulemyot Kalashnikova Stankoviy) is a tripod mounted PK/PKM. Every PK or PKM can convert to a PKS/PKMS while it is placed on the tripod.

The PKT/PKMT (PKT – Pulemyot Kalashnikova Tankoviy) is a solenoid-fired armored vehicle coaxial machine gun, which has no pistol grip or shoulder stock. The PKT is the standard machine gun in recent Russian armored vehicles including the T-72 and T-80 main battle tanks and BMP infantry fighting vehicles.

The PKB/PKMB (PKB – Pulemyot Kalashnikova na Bronetransportere) is a vehicle flex mount MG, and externally quite similar to the SG-43 and SGM. It has no shoulder stock or pistol grip, but is fitted with the spade grips and butterfly trigger.

General purpose machine guns chambered for the 7.62 mm rimmed cartridge are quite scarce. However, in addition to those mentioned below, there exists (or have existed) a few other GPMG’s chambered for the 7.62 x 54 R cartridge. Czechoslovakia didn’t adopted a Soviet machine gun, but fielded the VZ 59 GPMG of their own design. The VZ 59, also produced in the 7.62 mm NATO caliber, has not been distributed widely outside the borders of former Czechoslovakia. During WWII, famous Finnish arms designer Aimo J. Lahti designed the L-41 “Sampo” general purpose machine gun chambered for the 7.62 x 54 R round, which was used by the Finnish Army in a limited capacity during the Second World War. The L-41 didn’t stay in service after the war. In addition to this, there was the 7.62 x 54 R caliber variation of German MG42 developed and built in Finland. The 7.62 x 54 R caliber MG42 never went beyond the prototype stage.

During the Cold War, the PK-series machine guns were widely distributed to Soviet ‘friendly’ nations all over the world and fired in anger in many communist-backed conflicts. PK-series machine guns have been manufactured or are still in production at least in Former Soviet Union/Russia, Bulgaria, Hungary, Rumania, mainland China Type 80 (Export only), Yugoslavia (M84) and probably in Poland and the former East Germany.

The brand new PKM acquired for SAR evaluation was manufactured in Hungary. It came with an extra barrel with the same serial number, several belts and belt boxes, tripod, padded sling and blank firing attachment, all packed in a heavy wooden transport chest.

Construction

Like all other true machine guns, the PK fires from an open bolt. Despite that, the basic operating principle follows the familiar Kalashnikov pattern. The PK has a rotating bolt with two locking lugs, similar to the AK bolt. The PK bolt is larger and more robust; it has a larger face to accept a 7.62 mm rimmed round and a single claw extractor similar to the AK assault rifles. Because the PK fires from an open bolt, the firing pin is temporarily fixed on the bolt carrier. The firing pin can be removed with the bolt, but while the bolt is rotating along its bolt carrier guideway, the firing pin stays locked on the bolt carrier. It will project and strike a primer while the bolt rotates to engage on the locking lugs. The PK’s bolt carrier is somewhat similar to the AK slide, except it is turned upside down, it is bigger, heavier and has a less complex shape. The PK is gas-operated with a long stroke piston i.e. the gas piston is permanently mounted on the bolt carrier and moves with it. The gas piston and its rod are chrome-plated for better corrosion resistance and pivoted on the bolt carrier. The hinge allows for a slight bending of the carrier/gas piston while it is removed/installed. Not all PK series machine guns have a slide buffer, but the Hungarian and Yugoslavian made ones do. If you have examined buffers in other machine guns, the buffer may be a fancy name for a 1/4 inch thick plate of fiber-reinforced reddish plastic placed at the rear end of the recoil spring guide. It will reduce recoil by preventing a straight contact between the bolt carrier and the receiver, and it also helps with removing and installing the recoil spring guide. The PK family has the gas piston and tube mounted beneath the barrel. The gas tube is fixed on the receiver by a spring steel latch, and it can be separated for cleaning.

The gas block is mounted permanently on the barrel, and connected to the gas tube via the gas regulator. The infantry versions have an exhaust type three-position regulator. Position “1” is a basic setting, which is used with a clean gun, and the positions “2” and “3” are used while the action gets more dirty. The gas regulator can be adjusted by using a cartridge or empty case as a tool. Theoretical cyclic rate is 650 rpm, according to Russian literature. Because the PK action has no proper buffering device, which is required for higher cyclic rates, increasing the cyclic rate with regulator settings is not recommended, because it increases the wear of the receiver and operating parts, and will reduce service life of the gun. The PKT and PKB type machine guns have a different “Venturi” type gas regulator, which doesn’t exhaust fumes to the vehicle interior.

The receiver is a U-section stamped from 0.06 inch (1.5 mm) sheet steel and assembled by riveting and spot welding. The receiver has double walls made from two 0.06 inch plates welded one upon another. The receiver top cover is stamped from sheet steel and hinged at the front to the receiver and locked at the back with a spring loaded latch. The ejector is similar to the AK’s and riveted inside the receiver. The PK ejects empty cases through the ejection port located at the left side on the receiver. The ejection port has a spring-loaded dust cover. With proper gas selector setting, the ejection cycle is not as violent as the AK cycle and the PK won’t damage ejected cases. The PK expels empty cases straight to the left at a distance of about 3 ft (1 m).

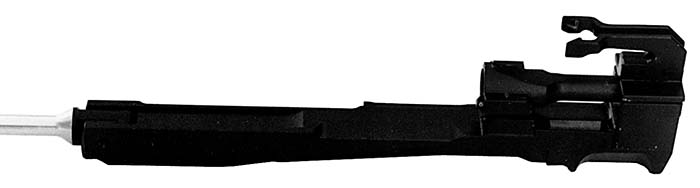

The barrel extension is riveted on the front of the receiver in the AKM manner. The barrel extension mounts the gas piston tube and includes the quick-change barrel locking mechanism borrowed from the SG43/SGM machine gun. The barrel extension has a straight boring to accept a cylindrical mounting piece of barrel, and two indexing studs to keep the barrel in the correct position. A horizontally sliding locking latch fixes the barrel to the receiver.

The barrel is the easiest way to distinguish the PK and its modernized variation, the PKM. The PK has a heavier, fluted barrel, while the PKM barrel is lighter (it weighs 2.35 kg (5.2 lbs.) and has no longitudinal grooves. The armored vehicle variations PKT/PKTM and PKB/PKBM have even heavier barrels, better suited to the sustained fire role. Like most other small arms of Com-Bloc origin, the PK family barrels have chrome-plated bores and chambers. The PKM bore has four grooves with a right-hand twist of one turn in 9 inches (225 mm). The barrel length is 23.7 inches (602 mm), which doesn’t include the flash hider. The muzzle has a left-hand metric M18 x 1.5 thread to mount a flash hider or a blank firing adapter. There is an AK-type spring-loaded plunger to hold the muzzle device in the correct position. There exist at least two different PK-series flash hiders. The earlier and most common type is similar to the M14 flash hider with five longitudinal slots. The more recent model is shorter and conical, also having five slots. The PK series blank firing adapter is a scaled up AK-design. Barrels have a pivoted handle, which can be used as the lever to crank the barrel out from its housing.

The trigger housing is mounted permanently underneath the receiver, and it includes the trigger guard. This trigger mechanism, very similar to the RPD, is simple, and also very similar to many submachine guns firing from an open bolt. The rotating safety catch located on the left side of trigger housing has two settings: safe and full-auto. There is no provision for semi-automatic fire, which is, after all, generally considered useless in General Purpose Machine Guns. The trigger mechanism cannot be separated, and it is difficult to clean after extensive firing.

The PK/PKM machine guns will usually appear with a skeletonized buttstock made from laminated wood. However, there is no rule without a few exceptions: some examples of Bulgarian-made PK machine guns have appeared with plastic buttstocks, the Chinese Type 80 has a skeletonized buttstock, but made from solid wood, and the Yugo M84 also has a solid wood buttstock. The PK and PKM have steel buttplates with a trapdoor compartment for cleaning gear. The PKM has a steel shoulder strap. The integral oiler is located in the buttstock. Pistol grip and barrel handle grip plates are usually made from reddish brown, Bakelite type plastic material.

Like most other small arms of Soviet and Warsaw Pact origin, the PK series machine guns will usually feature a black baked enamel finish. Some other examples have a blued or manganese phosphate (parkerized) finish.

Feed mechanism

The belt fed machine gun firing a rimmed ammunition has a more complicated feed mechanism than a counterpart chambered for a rimless cartridge. The Russians/Soviets have used the rimmed 7.62 x 54 R cartridge for more than 100 years, so they have a lot of experience in designing belt-fed mechanisms for rimmed cartridges. Russian-designed belt-fed ground machine guns, chambered for the 7.62 mm rimmed round include Degtyarev-designed DS-39, the RP-46 based on a magazine fed DPM light machine gun, Goryunov-designed SG-43 and SGM to name only those entered in service. There was also a series of fast firing, belt fed ShKAS (Shpitalniy-Komaritsky) aircraft machine guns with a noteworthy 1800 rpm rate of fire.

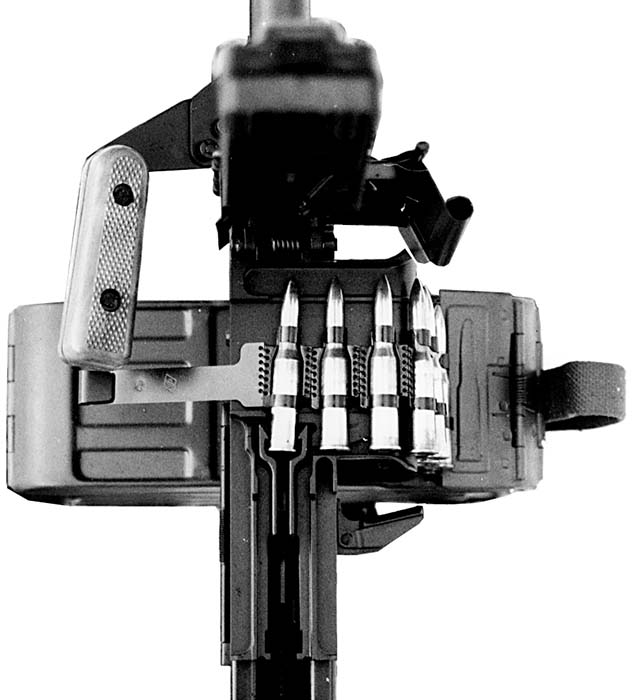

The PK series belt-feed mechanism, which is located over the breech block, includes some similarities to the RP-46 and Goryunov designs. The double hooked cartridge gripper is similar to one used in the SG 43 and SGM machine guns. Double receiver covers, the feed cover which includes the feed tray and the top cover, are also similar to the Goryunov’s. The spring-loaded depressing arm is a take-off from the RP-46.

The PK family utilizes a non-disintegrating, closed pocket metallic belt. Actually it is the same as used with the Soviet Maxims, the DS-39, RP-46 and SG43/SGM machine guns. The PK belts will usually appear in three lengths; for 100, 200 or 250 rounds. The 100 round belt is used with a small belt box that can be snapped beneath the receiver. In light machine gun configuration, the 100 rd belt with that assault box is usually employed. The 200 rd and 250 rd belts will fit in the bigger belt box, which is the same as is used with the Goryunovs. The 250 rd belt box is a logical choice if fired from the tripod, and it can be readily mounted on the tripod. Both Russian belt boxes are stamped from sheet aluminum. The 250 rd type is all aluminum, while the 100 rd box has an aluminum frame with a steel cover. Both types have canvas carry handles.

Pull-out type belts are usually used with machine guns chambered for rimmed rounds, but that is not the only way to go. The most ingenious feed system for rimmed rounds that I have seen was designed during WWII by Aarno Lahti of Finland, brother of the famous small arms designer Aimo J. Lahti, for the 7.62 x 54 R caliber version of the MG42. The 7.62 x 54 R caliber MG42 used a “push-through” type belt, which allowed the use of a standard MG42 fed mechanism. Few prototypes were converted from German-made guns, but license-production never started. The 7.62 x 54 R caliber MG42 was left as a technical curiosity.

The PK series belt feed mechanism works as follows: The belt comes to the feed tray from the right side of the PK. The feed tray is located over the chamber, and cartridges are pulled out from the belt to rearwards. While the bolt carrier starts to withdraw after a shot is fired, the cartridge gripper pulls the next cartridge from the belt, and bolt carrier movement activates the feed pawl to move leftwards to pull the belt inwards. After traveling about 3.5 inches (9 cm) backwards the cartridge stops at the feed cam mounted on the top cover, and is dropped over the feed lips of the feed tray by a spring-loaded depressing arm. Just before that the ejector expels an empty case through a spring loaded ejection port on the left side of the receiver. The bolt carrier continues to withdraw for about 1.6 inches. When the forward motion begins, the bolt pushes the fresh round towards the chamber, and bolt carrier movement forces the feed pawl to move back to the right. A holding pawl located on the top cover retains the belt.

Sights

The PK series machine guns (except a coaxial version PKT, which has no sights) have fully adjustable iron sights. The front sight is similar to the AK assault rifles. The post-type front has curved protective ears, and like the AK’s front sight, the PKM front sight is adjustable for both windage and elevation. The tangent-type rear sight has an open, U-shaped notch, and it is similar to ones used with the RPD SAW and RPK LMG, and it is adjustable for both windage and elevation. The PKM rear sight is graduated from 100 m (109 yds) to 1500 m (1640 yds) with 100 m (109 yds) increments and 300 m (328 yds) battle sight setting. The sight picture is identical to the AK assault rifles and RPK light machine guns.

Our test specimen has no provision for mounting an optical sighting device, but recent PKM GPMG’s will accept the four power 1P29 daytime sight (a copy of British SUIT) or the second-generation 1PN51 passive night sight. The scope mounting rail is located on the left side of receiver.

Bipod and tripod

The PK and its modernized version are issued with a folding bipod, which is mounted on the gas tube. The bipod non-adjustable legs are stamped from sheet steel, and it is somewhat similar to the RPK bipod. The bipod stays automatically in it’s firing position by use of a spring-loaded hinge. While folded, the legs are kept together by a stamped hook. The three-piece cleaning rod is stored on the bipod right leg.

The PK machine gun was originally introduced in 1961 with a tripod designed by Evgeniy Samozhenkov. Samozhenkov’s tripod weighed 17 lbs. (7.7 kg); almost half the weight of the SGM tripod, and it converted easily to both ground fire and anti-aircraft configurations. When the improved the PKM pattern was introduced in 1969, it was issued with a new and remarkably lighter tripod designed by Leonid Stepanov. The Stepanov mount can easily be described as a “light” tripod. Made almost entirely from steel stampings, it weighs only 4.5 kg. It has no buffering mechanism of any sort, and the cradle, which mounts the gun, is connected directly on a traverse and elevation mechanism. The Stepanov light tripod can be easily modified from the ground fire role to AA-configuration.

Each tripod leg can be folded for transport or adjusted for proper height or finding equilibrium in rugged terrain. While folded for transport, one man can easily carry the tripod into the field. Like any other tripod, the Stepanov light tripod requires sandbags for maximum stability.

The Stepanov tripod issued with our test gun was manufactured in Kovrov (marked with an arrow inside oval ring) in 1977. It appeared to be unused. The tripod was clean and dry; apparently stored 20 years ago by wrapping it in paper treated with corrosion inhibiting agent and putting it in a sealed container. During these years all the lubricants had dried and frozen most of the moving parts. It required some muscles and lots of gun oil to get all the hinged parts to operate properly. Please note: if you are handling wrappings etc. treated with Soviet/Warsaw Pact corrosion inhibiting agent, bear in mind that it is very poisonous.

In addition to the mounts described above, there exists a flexible vehicle mount, which accepts a standard PK or PKM.

Test firing

The Hungarian-made PKM was fired from both tripod and bipod rest, and my first impression was one of good controllability. Even an inexperienced operator can fire short bursts (three or four shots) from the bipod rest and keep the gun completely in control. From the tripod, firing longer burst with an acceptable accuracy up to 985 – 1100 yds (900 – 1000 meters) is possible. On this point accuracy doesn’t mean sniper grade accuracy, as the machine gun is an area weapon, not a point target weapon.

For test firing we used two different types of 7.62 x 54 R ammunition: Lapua-made training ammo fitted with a 123 gr. (8 g) FMJ bullet (in fact just the same as used with the 7.62 x 39 mm caliber ball) loaded to about 2950 fps (900 mps) velocity, and the military-type ball ammo fitted with a 200 gr. (13 gr.) FMJBT bullet, duplicating the Finnish D166 heavy ball, having muzzle velocity of c. 2300 fps (700 mps). The PKM cycled reliably with both types, but the feed mechanism didn’t like cartridges with light bullets. Since the depressing arm and gravity together are intended to turn the cartridge to the correct position, the bullet should be long and heavy enough that the center of gravity would lie far enough from the base, and the cartridge would easily go into the chamber. With the D166-type ammo, the PKM operated without malfunctions.

There exist a lot of people in this world who can’t read or write, but they know very well how to handle Kalashnikov assault rifles. Operating Kalashnikov’s belt fed machine gun is almost as simple as operating Kalashnikov’s assault rifles. To load the PK series machine gun, first make sure that the gun is not cocked and then set safety to “ON”. Then open the top cover and place the belt over the feed tray so that the first round’s base sets in the gripper claws. Holding the belt, close the top cover. Cock the action, and return cocking handle manually to front position. Turn the safety “OFF” and the PK is ready to fire.

A third generation of the PK machine gun?

In 1993 a new member of the PK family chambered for the unique 6 x 49 mm round was introduced. Called the Unified Machine Gun (UMG), it is basically similar to the PK/PKM, but has a shorter receiver, apparently with a simplified feed mechanism. The UMG has a longer barrel, while overall length (45.3 inches or 1150 mm) is approximately equal to the standard issue PK/PKM. This new Russian machine gun is relatively light in weight, as it weighs only 14.3 lbs. (6.5 kg) with a bipod. The revealed prototypes have no iron sights, but were fitted with an optical sighting device. In addition to the improved PK machine gun, the SVD based sniping rifle and AK assault rifle chambered for the 6 x 49 mm cartridge are also being developed.

Presumably inspired by the U.S. Army SAW research, the Soviets started developing the 6 mm ammunition primarily intended for infantry machine guns and sniping rifles in about 1980. The first type revealed was the 6 x 53 mm, which launched an 80-gr. (5.2 g) bullet with a muzzle velocity of 3770 fps (1150 mps).

About ten years later the 6 x 49 mm cartridge was introduced. It has a rimless case with approximately the same rim diameter (0.449”/11.4 mm) as a classic 7.62 x 39 mm round. The 6 x 49 mm round has muzzle velocity equal to the 6 x 53 mm, it is also extremely hot having higher chamber pressures than the 6 x 53 mm. While there is a risk for case separation, the case has a circular groove formed near the extractor groove to allow case stretching without risk of separation. For reliable operation, adequate headspace is critical in self-loading firearms. On the other hand, high pressure ammunition will require tight headspacing to be safe. Controlled case stretching as used with certain aircraft cannons allows use of workable headspacing, yet the gun is also safe to fire.

While not so prolific as Mikhail Kalashnikov’s assault rifles, his belt fed general purpose machine gun is really an outstanding design. Not the least because it fires a complex rimmed round, but also because it is reliable, easily controllable and easy to operate. It will serve to the foreseeable future in existing forms or firing a new rimless cartridge, which might be a less complicated choice for belt fed weapons.

SAR would like to thank Peter G. Kokalis for his help in editing this article

| This article first appeared in Small Arms Review V1N8 (May 1998) |