By William R. Bishop

One of the most iconic firearms of the Cold War was the diminutive Vzor 1961 (Model 1961) submachine gun made in the Czech city of Uhersky Brod by the firm of Ceska Zbrojovka. More properly classified as a machine pistol than true a SMG, the Vz61 was named the “Skorpion.” This unusual Combloc firearm, of which only a few post-86 dealer samples are currently in the United States, seemed to naturally find its way into the hands of Red Brigade terrorists, Central American assassins and assorted bad guys who opposed American interests.

Skorpion parts kits are available in the US and now, for the first time, a lower receiver made here in the US is available for sale and is specifically designed for direct “drop in” of a Skorpion parts kit. It has just received ATF approval for sale as a receiver which “is not readily convertible” to full automatic. You can now legally possess a Skorpion that is as close to the actual Vz61 as our government will allow without some form of NFA provision.

The Company Behind the Skorpion

RT Manufacturing is the creator behind this US-made Skorpion Vz61 receiver. Co-founded in 1999 in Wauconda, Illinois, by Jack Koziol and a business partner, it was purchased outright by Jack in 2000 and has continued under his management since that time. Employing four full time machinists, it is a general job shop which has several major customers, one of which is a huge entity in the medical precision equipment field.

Jack and his family have been in the machinist trade for many years. After completing a four-year formal apprenticeship program in the machinist field (and winning a VICA “National Machining Championship” in the 1990s), over a 15-year career, he taught himself CAD/CAM designing and its integration with CNC machining. This became key to the Skorpion project.

Aggressively looking for more work in early 2001, he introduced himself to a neighboring firm in Wauconda – Krebs Customs – and started performing subcontractor machine work for them. Krebs is nationally known for quality AK parts and RT Manufacturing began making their muzzle compensators, Picatinny rail fore-end, front sight gas block and other precision AK parts. As Jack had never worked with firearms before, he became increasingly fascinated with their design and manufacture. It was at this point the Skorpion concept emerged.

With RT Manufacturing looking for more projects in the firearms field, Mr. Krebs threw Jack a huge challenge in mid-2003….build a Skorpion lower receiver which can pass ATF muster as a legal semiauto pistol when fitted with a parts kit. Krebs had been very interested in the Vz61 for years but simply did not have the time to properly design and build one themselves given their AK work.

There was only one problem with this. RT Manufacturing had literally no idea what a Vz61 was or looked like. Further, Jack now laughingly admits he did not even know there was a “K” in the Skorpion name instead of the Americanized “C”. For this reason his first Internet searches turned up no information. Not admitting failure, Jack made the October, 2003, pilgrimage to Knob Creek and purchased his first Skorpion parts kit. Though he had the parts kit, he still did not know what it should look like.

Designing the Lower Receiver

Throughout late 2003 and early 2004, Jack carefully examined every piece of the Vz61 parts kit being very interested in how the Czech’s had machined the lower receiver. Fortunately, the kit included the four torch-cut receiver pieces. By examination of their machining marks, he determined their sequence of cuts and the kinds of tools used. He also realized this was not an easy project and why Mr. Krebs had directed it his way.

The Skorpion lower receiver was a true jewel of the machinist’s art. The Czech’s are internationally recognized for their industrial skills and the Vz61 was proof of that reputation. Designed by Miroslav Rybar in 1959 when CNC did not exist and the Communist regime had literally thousands of skilled machinists and many tons of machine tools, the receiver was truly “old school” in both design and execution. During its production run of 1961-1976, the Skorpion was manufactured by manually-controlled equipment. RT Manufacturing could not economically apply this extremely labor-intensive practice to create a new Skorpion. A new receiver could only be profitably cut by CNC.

Jack began reverse-engineering the receiver by using the parts kit itself as the starting point. The overall dimensions of the new receiver were easily captured by the upper receiver from the parts kit. The front of the lower receiver was determined by the takedown pin hole. The rear of the lower receiver was established by the back of the upper receiver where it must snap into place. The magazine well area was defined by the proper lockup of the magazine, while the trigger area was brought into relationship by the rivet hole of the trigger guard. In short, Jack was able to arrive at a fairly accurate starting point for the dimensions of the lower receiver. But that was the starting and not ending point.

Using these initial dimensions, Jack then began using CAD/CAM software to design the first version of the Vz61 receiver. It was a laborious trial and error process in which iterative test cutting was done on blocks of 6061 aluminum. With each passing block the parts kit would fit better. By the 15th block the parts kit simply “dropped in”…with just one problem to overcome.

The front pin hole

Try as he might, Jack could get everything to routinely fit except for the front pin hole. It seemed that one time the parts kit would fit as expected while another would have trouble getting its upper receiver to mount with the front takedown pin and then slide into the rear of the receiver. He even considered making the hole larger to accommodate all possibilities, but, that could lead to a sloppy fit. Finally, by moving the hole a few thousandths of an inch at a time, Jack got it precisely where needed. The temporary loan of a post-86 dealer sample Skorpion ultimately validated the dimensions by allowing direct comparison of the new lower receiver to that of an original. This also facilitated minor cosmetic corrections such as the depth of lightening cuts, etc.

It was now mid-2005 and time to machine a steel Vz61 lower receiver and get it to ATF’s Tech Branch for validation as a legal semiautomatic receiver. Almost two years of work was now coming to this final step.

Manufacturing the Lower Receiver

The receiver is manufactured out of billet 4140 pre-hardened steel. This starts life as a 6.75 lb “hunk of metal” that measures 1.5 x 2.5 x 6.75 inches and is precisely machined down to three-quarters of a pound, an incredible 89% reduction in weight. To achieve this result, RT Manufacturing uses MasterCam CAD/CAM software which is directly connected via RS232 cables to two machines: a Haas VF2 and Hurco vertical machining centers.

While each machine can easily carve a complete Skorpion lower receiver by itself, so much time is consumed to make a receiver that it takes two machines running simultaneously to output a profitable production run. One machine simply could not mill a receiver fast enough.

The MasterCam software produces almost 15,000 lines of G-code to define a Vz61 receiver. In turn, this code controls each machining cut so that every steel billet requires almost five hours of dedicated machine time – and seven separate setups – to be converted into a receiver. Every single internal and external surface on the receiver is touched in some fashion by a carbide cutting tool. Each side of the receiver of this intensive machining takes approximately 45 minutes to make. There are six sides.

After the CNC work is done the lower receiver is still not completed. RT Manufacturing must still perform over 30 minutes per receiver of hand deburring with an air tool to remove all sharp edges. It is then tumbled in ceramic media for another 45 minutes to ensure all internal edges are truly finished. After that….the entire receiver is glass bead blasted to finalize the surface preparation.

Each receiver is then quality checked on a granite surface plate which allows readings to one millionth of an inch. However, for a firearm, this level of tolerance is unnecessary and in fact would lead to an unreliable and far too costly weapon. RT Manufacturing holds the Vz61 receiver production tolerances to +.0025” and for the critical pin holes to +.0005”. These are tighter tolerances than original Czech receivers. But there is still one more “real world” inspection to pass. Will the new receiver accept a Vz61 parts kit? RT Manufacturing verifies this by taking a kit and test fitting the mag well parts into the receiver. A factory mag must correctly lock up with minimal movement. The upper receiver is then slid into place to ensure no lateral deviation and also must smoothly mate with the rear of the lower receiver. Finally, the front takedown pin is snapped into its pin hole and must properly lock up. Upon passing all these inspections the new receiver is stripped and shipped for final finishing.

This final surface finish is a deep black oxide finish that goes well with either blued or powder painted parts kits. The firm which does this is a full time finishing service and has worked with RT Manufacturing for years. Thus, their processing quality and delivery schedule are a known quantity. However, if requested, RT Manufacturing will at no cost leave the receiver in-the-white if the customer wishes to finish it themselves.

ATF Certification of the Lower Receiver

After milling the first receiver in June of 2005, it was sent to ATF’s Tech Branch for examination and validation as a semiauto firearm. This is the single step that has caused more problems and concerns for so many manufacturers. However, Jack’s Vz61 lower receiver passed the first time through in just two months.

ATF issued their approval on 25 August 2005 and confirmed that any receiver which RT Manufacturing made to the specifications contained in that letter would be classified as a semiautomatic firearm. Jack had done his research very well and now had the formal government documentation to validate his work. While the specific internal modifications made to gain ATF approval are proprietary, a copy of the letter will be shipped with each Skorpion lower receiver to assure the end user of a legal firearm. Externally, the RT Manufacturing Vz61 Skorpion receiver appears to be an exact duplicate of the real thing. Side by side, other than the required US manufacturing markings and no folding stock dovetail, you cannot tell the difference.

Building the Skorpion Semiauto Pistol

The absolute first thing to do is obtain a parts kit. Prices have gone higher and availability is getting tight. SILLC of Nevada imported 200 Vz61 kits in the late 1990s and an additional 200 in 2003. These kits were “as new” when decommissioned and first class in all respects. SILLC is importing another group of 130 Vz61 kits but, after that, US government regulations may have shut the door. At a minimum, kits which might come in will not have barrels remaining intact. Yugoslav-made Skorpions, known as the M61(j), are still being produced but their availability is unknown. There are probably less than 550 Czech Vz61 parts kits currently available in the US. So, getting one is the first order of business.

Handling about 20 parts kits over the past six months, it appears that two slightly different variations of Skorpion were imported: One group was made in 1965 and contains all blued parts, while the second type was made in 1975-76 and has a tough, dark grey-blue powder paint finish. Both kits are exactly the same with regard to quality of manufacture and ease of assembly. Each kit comes with a 10-round magazine, lanyard, leather holster and cleaning kit. A special magazine deal is available where you can get two high capacity, factory 20-round mags and leather pouch for about $40.

The Skorpion as delivered from RT Manufacturing arrives in a sturdy cardboard tube and contains the receiver, a slave pin to ease trigger assembly, a trigger axis pin to replace the one in the kit and a small button-head screw which replaces the trigger guard rivet. After cleaning and laying out the parts, the sequence to build the Skorpion is:

- Bolt hold open, magazine catch and ejector assemblies.

- Trigger guard, pistol grip screw, rate reducer and bolt stop assemblies.

- Trigger mechanism and safety selector.

- Hammer and spring cover assemblies.

- Bolt assembly and upper receiver.

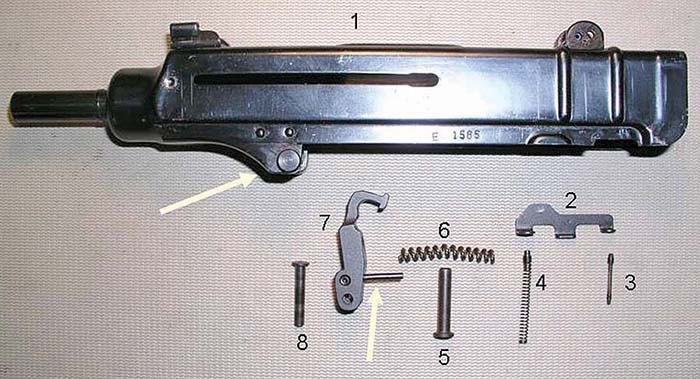

Construction starts with removing all parts from the kit’s torched central section which contains the bolt hold open, magazine catch and ejector assemblies. Use a 1/16 inch punch and push down on the small detent pin that is at the rear of the ejector. This pin is spring-loaded so once you push it down, carefully slide the ejector forward and remove it; the detent pin and spring are now free to be taken out.

This ejector detent pin also cleverly retains the bolt hold open and magazine catch assemblies. Once this detent pin comes out, these two assemblies will pull out easily. Make sure each of their springs comes with them as these could inadvertently remain hidden inside the torched section due to congealed grease or metal movement from the demil procedure.

Reverse the process to insert them into the new Skorpion receiver. The order should be the bolt hold open, mag catch, and ejector assemblies. To verify all is correct, insert a magazine to ensure it locks up and releases correctly. The Skorpion has a tight well and you will have minimal magazine rocking.

The trigger guard, pistol grip screw/rate reducer and bolt stop assemblies are now installed into the new receiver. The original Skorpion had a riveted trigger guard while the new receiver uses a 4-40 buttonhead screw. Some trigger guards were slightly bent during demilling and thus, depending on yours, it may fit perfectly or require some slight bending/cutting to line the holes up. If the small curved tang on the trigger guard must be removed to obtain proper hole alignment, then do so as it does not affect functioning or looks. You must also enlarge the trigger guard rivet hole with a 1/8 inch drill bit to allow clearance for the screw. Finally, use a drop of blue Loctite and a 1/16 inch allen wrench to install the front of the trigger guard onto the receiver.

Insert the pistol grip screw/rate reducer assembly into the wooden grip, then through the large hole at the rear of the trigger guard. Screw this assembly into the receiver until it seats the wood grip into place. Insert a 1/8 inch punch into the two holes on the bottom cap to further tighten it. You could use blue Loctite but this is not necessary since a wave washer is holding it in place.

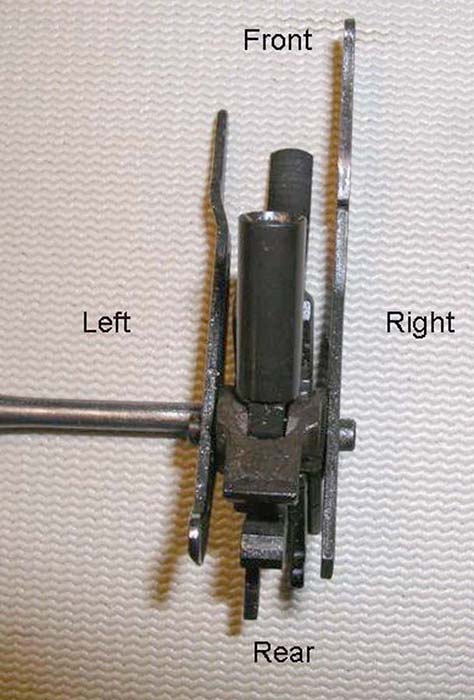

Next is the installation of the bolt stop assembly. Insert the “hat shaped” axis pin into its hole in the left side of the receiver and push it all the way through while capturing the rate reducer lever and bolt stop. Make sure the bolt stop has its detent pin assembly in place before doing this otherwise it will not cycle correctly.

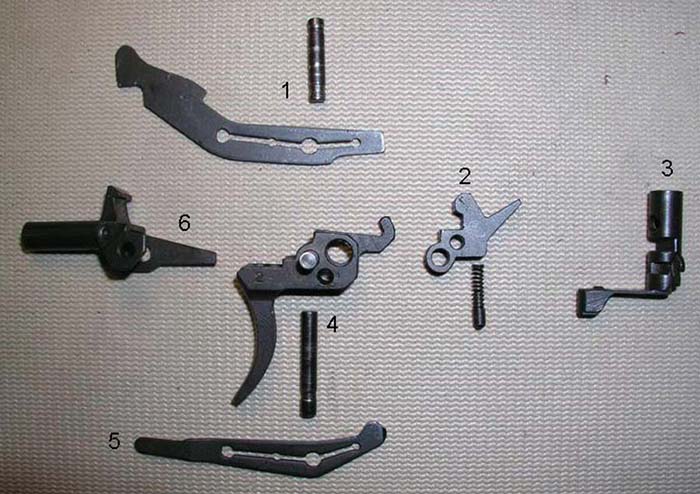

The trigger mechanism is relatively easy to complete with a bit of patience. Using a 1/8 inch punch, tap out the original axis pin and remove the full auto controlling lever (aka the “FA sear”) on the right side of the assembly and bolt hold open connecting lever on the left side. Discard the FA controlling lever as it will no longer be used on this semiauto pistol; however, set aside the bolt hold open connecting lever as it will be reutilized. Next, insert the provided slave pin through the axis hole on the right side of the receiver, then through/capturing the remaining parts of the trigger mechanism, and into its corresponding hole on the left side, to temporarily fix it into place.

Now, slightly withdraw the slave pin back towards the right and drop the connecting lever back into place on the left side of the assembly. The forward tip of this lever must fit into the hole on the back of the bolt hold open button. Line everything up and tap the new axis pin into place from left to right. This will push out the slave pin while keeping all parts aligned. The single groove on this new axis pin must be on the left so the connecting lever can snap into it. Once again, the single groove on this new trigger pin must be on the left side.

Now, take the safety selector and insert it into position from left to right and rotate counterclockwise into place. You will have to depress the bolt hold open button to mechanically lower the connecting lever in order to give the safety selector enough entry clearance. To validate its proper installation, flip it back and forth from “0” to “1” several times. When installed properly you will see the bolt hold open go up and down.

The hammer assembly is installed by inserting the main spring into the main spring guide. This guide is the cylindrical housing attached to the front of the trigger assembly. Then, insert the main spring strut into the spring and slide the entire hammer assembly down into the receiver. Insert the flathead axis pin from right to left and you are complete. The hammer stop pin is then inserted through the receiver from left to right. Finally, drop the large and small detent pin assemblies into their holes on the bottom of the receiver and slide the spring cover over them. Make sure the pins fully snap into their respective holes in the cover.

To attach the upper receiver you use a small needle or dental pick to push in the tiny detent pin which is found on its left mounting arm. Push it in just enough so you can rotate the takedown pin and force the detent further back into its hole. Then, withdraw the takedown pin just enough (about 1/8 inch) to allow the upper receiver to be installed onto the mounting lug of the lower receiver. Push the takedown pin into this lug and then rotate it until the detent snaps back into position. The upper receiver is now locked onto the lower receiver.

Insert the complete bolt assembly into the upper receiver, drop into place the two cocking knobs and then slide it all the way forward. Swing the upper receiver down onto the lower receiver, push it back 1/4 inch until it stops, then snap the takedown pin all the way home. Congratulations, you have just built your Skorpion pistol.

Obtaining the Skorpion Lower Receiver

RT Manufacturing has invested many man-hours of time and research into this ATF-approved semiauto Skorpion receiver. It is the first one of this quality, and the first ever, to come onto the US market. With five hours of CNC machine time per receiver, an additional two hours for hand deburring, inspection, test fitting, tumbling, plus the black oxide finish, it is a high quality product.

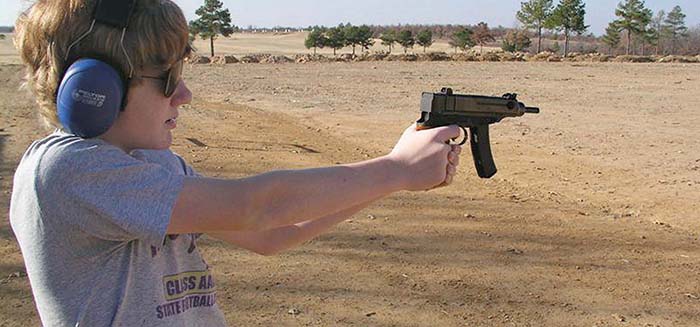

The current retail price from RT Manufacturing is $645 and includes insurance and delivery to anywhere in the United States. Volume purchasers will receive pricing discounts and should contact Jack for more specifics. Add to this the cost of an original Czech Vz61 parts set and for less than $1,000 you have an iconoclast of the Cold War which will truly enhance a small arms collection. More than that, it is just pure fun to shoot with widely available ammunition.

Mods and Sods

The .32 ACP ammo that the Skorpion fires is a light recoiling cartridge. More importantly, the common 71-grain FMJ projectile is easily subsonic at approximately 900fps. This means the Skorpion is an excellent candidate for suppression. But, there are currently no suppressors being built in .32 ACP by the leading manufacturers such as Gemtech, SWR, etc.

RT Manufacturing is addressing this gap by optionally installing an H&K-style three-lug adapter to the muzzle of the Skorpion barrel and allowing a standard 9mm snap-on suppressor to be mounted. Though the 9mm aperture is inefficiently large for a slug measuring 7.65mm in diameter, it is dealing with substantially less expanding gas and the sound signature remains very quiet. Thus, for those owners who already have a 9mm suppressor of this type, there is now an additional weapon which can use it. RT Manufacturing will sell/install the adapter for a nominal charge and this option should really be looked into by the enthusiast.

Another option being investigated is a .22 conversion kit. While still in the initial planning stage, this possibility could greatly reduce the cost of firing the Skorpion. Since the factory barrel is pressed and then pinned into a steel trunnion, some form of .22 barrel liner is being looked at as a viable solution. Of course, the issues of magazine modifications, bolt, offset firing pin, spring rates, etc. must all be dealt with. This option is clearly further down the line but not outside the capabilities of the firm.

Finally, for those who possess the proper NFA authorization, RT Manufacturing will sell a fully automatic version of the Skorpion as a post-86 Dealer Sample firearm. This has already been tested and works as reliably as the original Skorpion. In fact, of the first production run of 50 Skorpion lower receivers, 15 of these are already spoken for as post-86 versions. As before, contact Jack for additional information on this option.

Conclusion

Rare, unusual, hard to “quite-really-define” what category it fits into, the Czech Vz61 Skorpion has been an enigmatic firearm since its shadowy introduction over 45 years ago. Ostensibly designed for armored vehicle crewman who needed a small and efficient firearm in their cramped quarters, it typically found its way into terrorist, police, insurgency and other paramilitary hands. Other than a handful imported into America, this situation has been clearly remedied by RT Manufacturing.

Their ATF-approved semiautomatic Skorpion lower receiver is a superbly designed piece of the machinist art. Externally it is an exact duplicate of the original version and is cleverly built to accept the drop-in of a Vz61 parts kit. Made of proper 4140 pre-hardened steel and cut on modern CNC milling machines to the highest tolerances, it is a delight to own and fire. RT Manufacturing has certainly done their homework on bringing this Skorpion to America.

Sources

RT Manufacturing Company Inc.

Attn: Jack Koziol

1000 Rand Road, Unit #212

Wauconda, IL 60084

(847) 487-7562

SILLC

631 N. Stephanie Street, #372

Henderson, NV 89014

(702) 564-0521

surplusllc@aol.com

www.sillc.com

| This article first appeared in Small Arms Review V9N11 (August 2006) |