By Christopher R. Bartocci

The introduction of the 5.56x45mm M16 rifle in the early 1960’s changed the outlook of the modern battle rifle all over the world, including behind the iron curtain. Within the Soviet Union studies were ongoing at the Tsnii Tochmash small arms ammunition bureau at Klimovsk under direction of engineer Viktor M. Sabelnikov and his design team. Depending on who you interview, some claim that the early development of the 5.45x39mm cartridge was underway prior to the release of the 5.56x45mm by the United States. But looking at the timeline, clearly the combat performance of the 5.56x45mm in Vietnam influenced the 5.45x39mm adoption by the Soviet Union. The time period of development from 1964 to 1970 spawned the prototype 5.6x41mm round. This cartridge was a necked down 7.62x39mm cartridge case. During the development of the cartridge the diameter of the cartridge case was reduced as well as the overall length resulting in the final Model 74 (M74) 5.45x39mm cartridge.

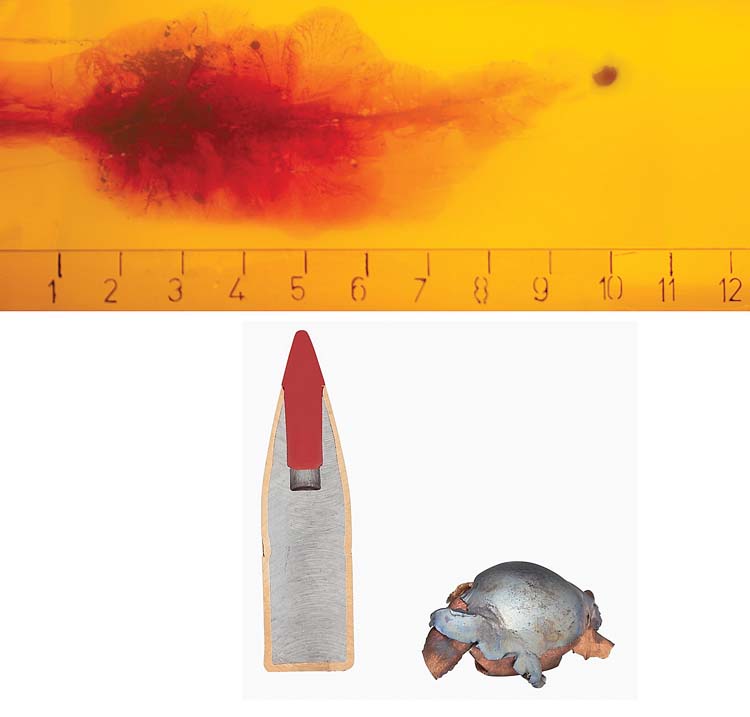

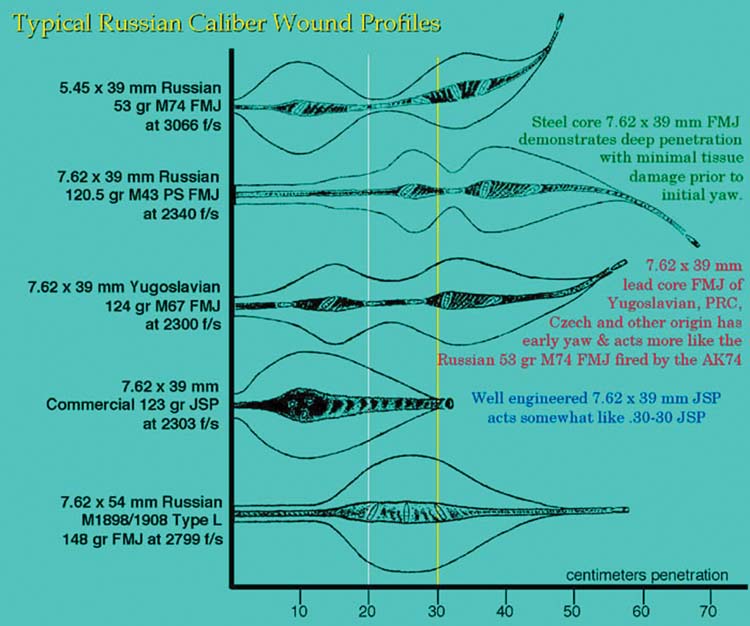

In terms of ballistic capabilities, the 5.45x39mm is the least powerful military cartridge on the modern battlefield. The old saying about how size does not matter – it is how you use it; fits the description of the 5.45x39mm cartridge perfectly. The muzzle velocity of the M74 cartridge is 2,952 feet per second with muzzle energy of 1,365 joules. This is less than the 5.56x45mm, as well as the previous 7.62x39mm, however, the construction of the projectile puts it on a level playing field making it out-perform its predecessor, the 7.62x39mm. Due to the dynamics of the 5.45x39mm round, the rim of the cartridge case had to be thicker and stronger to deal with the higher extraction force of the round. The projectile is not seated as deeply in the cartridge case as a standard 5.56mm round and the projectile is significantly longer as well. Like its 7.62x39mm counterpart, the 5.45x39mm projectile consists of a steel jacket, steel penetrator core, lead alloy around the sides and on top of the steel penetrator. However, there is an empty space between the tip of the lead and the tip of the projectile. What this does is greatly increase its terminal performance over that of the 7.62x39mm cartridge. When the projectile hits tissue the lead core shifts in the tip causing the projectile to yaw in about 4 inches consistently opposed to the 7.62x39mm projectile beginning to yaw at nearly 10 inches in depth. In many cases that could be thicker than a body it strikes. This is consistent and repeatable. The length of the projectile and keeping the center of gravity in the rear of the projectile, plus the velocity, keep this performance repeatable and reliable. Additional benefits of the 5.45x39mm round are that its trajectory is much flatter than that of the 7.62x39mm allowing the 5.45x39mm to be able to hit targets out to 400 to 500 meters. The 52 grain projectile is fired from a 16.3 inch chrome lined barrel with 1 turn in 9.25 inches giving the projectile nearly 3,830 revolutions per second.

The weapon development ran concurrently with the design of the rifle. The Soviets like proven designs that do exactly what they are designed to do. However, every soldier wants a lighter weapon that is more accurate, has less recoil and is more lethal than what they currently have. The development of the AK74 gave the Soviet soldier just what they asked for. The 5.45x39mm round decreases recoil significantly, making the AK74 more effective on automatic fire.

The AK74 has many changes from the AKM and throughout the service of the rifle changes have been made to further improve the performance of the rifle. The AK47/AKM is world famous for reliability under terrible conditions. The AK74 is even more reliable. The bolt carrier to bolt ratio is 5 to 1 on the AKM, the AK74 has a bolt carrier to bolt ratio of 6 to 1. What this does is with the heavier bolt carrier to bolt ratio provides more inertia to chamber a difficult round. This increased ratio also increases rearward velocity which in turn increases extraction force. This is a great benefit but it prematurely wears the extractor so there was a new improved stronger extractor designed for the AK74.

Starting at the rear of the rifle, the original stocks were manufactured from plywood to increase strength. You will also notice a groove in each side of the stock; this was done to decrease weight according to Mikhail Kalashnikov. A metal buttplate was added to the rear with ridges on it to make the butt less likely to slip off the shoulder of the shooter. The AKS74 eliminated the less comfortable under-folding stock for a side-folding stock. This stock folded to the left side of the rifle so there would be no interference with the function or manipulation of the bolt and selector lever. There is a stock catch on the left side of the receiver just behind the handguard and the release is located on the left side of the receiver. In 1991 the metal side-folding stock was replaced (AK74M) with a folding high strength black polymide side folding stock. Original rifles utilized plywood stocks and handguards. Pistol grips were manufactured of wood and quickly replaced by polymide grips which were found in maroon, plum and finally black in color. Handguards were manufactured in wood and later the late 1980’s were replaced with plum color PA6 polymer butt stocks and handguards. In 1991 the plum color stocks were replaced with black polymide ones on the AK74M rifle.

Early Russian AK74 rifles utilized the AKM reinforced receiver cover (ribbed). This was later in 1993 changed back to the standard smooth receiver cover. The rear sight base is modified for the trajectory/drop of the 5.45x39mm cartridge. The slope was not as steep due to the significantly more flat shooting projectile.

The bolt carrier was changed as well to accommodate the 5.45x39mm bolt. The hole in the carrier that the bolt rides in was decreased in diameter to accommodate the smaller diameter bolt. This additional material left in the bolt increased the bolt carrier to bolt ratio from 5 to 1 to 6 to 1 as previously stated. The shape of the cocking handle also evolved over time. It should be noted the Romanian AK74-type rifles have a charging handle that curves upward. This is a very unique to Romanian rifles. The piston of the Russian designed rifle was change as well. The original AK74 gas piston, like the previous AK47 and AKM had two circular grooves in the piston; in 1989 these grooves were eliminated for ease of production. There was no real purpose for these grooves.

The gas block is another major change in the change in calibers. The standard AK47 and AKM rifles use a gas port that is drilled at a 45-degree angle. This is very identifiable in the shape of the gas block; there is more of a slope on the front of the gas block. It should be noted that an angular gas block does eliminate many issues related to gas port erosion. When the barrel was chambered in the 5.45x39mm caliber it was found that the higher velocity projectile was experiencing sheering of the jacket material as the projectile passed the gas port. To prevent this, the gas port was drilled at a 90-degree angle. This change was made in 1977. All AK100 series rifles use a 90-degree gas block regardless of their calibers.

The front sight base is quite different from that of the AKM. The front portion of the block is threaded to accept the 24mm muzzle brake. The threads are 24×1.5mm right hand as opposed to the 14x1mm left threads of the AK47/AKM which it replaces. Sight adjustment of the front sight is the same as its predecessors. The threading of the front sight post was altered to adjust for the adjustments of the 5.45x39mm cartridge. There are two mounting studs on the front sight base. The one closest to the muzzle is for attaching a bayonet. Due to the use of the muzzle brake, the bayonet front attaches to the front of the muzzle brake and the rear locks into the stud on the front of the front sight base. The rear stud is for mounting accessories such as a grenade launcher. Also the front sight base is the guide for storage of the cleaning rod.

The most notable feature of the AK74 series weapons is the unique muzzle brake. Unlike standard muzzle brakes/flash suppressors which were attached to the threads on the muzzle, the AK74 muzzle brake is attached to the front sight base. The muzzle brake screws in place and is locked by a plunger pin on the front of the front sight base and it locked into a notch on the rear rim of the muzzle brake. There are two chambers in this design, one in front of the muzzle inside the muzzle brake and the other right outside the main body of the brake, connected by two bridges at 12 and 6 o’clock. The half moon brake was in production from 1974 until 1979. In 1979 the zigzag brake was introduced and was in production till 1983. This differed in that there were zigzag shaped slits on both right and left sides of the brake. This was more expensive to produce and was cut by an electro-discharge machine (EDM). The 3rd and current design of the muzzle brake is another two piece design and has two crescent shapes. This brake is much less expensive to manufacture due to not machining or laser cutting the slits. A baffle plate was pressed into the muzzle brake main body and the shapes were provided on each side of the baffle to allow high pressure gasses to vent from the muzzle brake. The bridges were made significantly stronger as well. This design muzzle brake not only reduced recoil but muzzle blast as well as noise levels. This muzzle brake was so effective that the recoil of the AK74 is reduced by nearly two-thirds of the 7.62x39mm AKM.

Around 1968, the Soviet Union began replacing the heavy steel magazines with a new lightweight fiber reinforced AG-4S phenol plastic being orange in color. Metal feed lips were molded into the plastic body. These magazines were primarily manufactured by Tula and Izhmash factories in Russia. Only prototype magazines in the Soviet Union were manufactured of steel. The production AK74 magazines would be made of the same material as the 7.62x39mm polymer magazines. It should be noted that steel magazines have been manufactured in large numbers by Romania and Poland. The Soviet magazines are equipped with two grooves on the rear of each side of the magazine which allow a stripper clip guide to be inserted. The ammunition was issued in 15-round stripper clips. The orange color tended to be problematic due to the way it stood out and also the way it could reflect light. The magazines were later manufactured in plum color and then finally black. The plastic magazines have a capacity of 30 rounds but also have a 45-round magazine for the RPK74 light support weapon. A magazine has also been developed which holds 60 rounds and stores the ammunition in 4 columns of 15 rounds. The polymer magazines have been manufactured in various colors by several countries. Bulgaria has manufactured them in brown.

The final design of the AK74 spawned a new rifle with an effective range nearly 2 to 2-1/2 times that of the AKM. The use of low impulse high velocity ammunition coupled with an excellent muzzle brake made a more accurate rifle as well as a more controllable automatic rifle. This all adds up to a more effective soldier. The soldier can carry double the ammunition for the same combat load of 5.45x39mm ammunition than the heavier 7.62x39mm ammunition.

The AK74 would not wait long to be combat tested as the Soviet Union invaded Afghanistan on 27 December 1979. At this time the rifles were first being fielded. Western intelligence would learn of this new rifle from a Soldier of Fortune journalist Galen Geer in September of 1980. Initial intelligence reported that this cartridge was only in use by Soviet Special Forces and later that proved to be incorrect. The Soviet Union was completely replacing their entire 7.62x39mm fleet with the new AK74 family of weapons. The AK74 earned a reputation for its destructive wounding capability and was very respected and feared by the Mujahedeen. The rifle has gone on to be the standard Soviet infantry rifle to present day Russia.

It was thought that the reign of the Kalashnikov rifles was coming to the end in 1994. In 1994 a new rifle was adopted to replace the Kalashnikov rifle called the AN94 or Avtomat Nikonova Model of 1994 designed by Gennadiy Nikonov. The AN94 is chambered in the M74 cartridge (5.45x39mm) and uses a new operating system known as blow back shifted pulse, a combination of gas and recoil operation. The rifle has selector settings for safe, semiautomatic, 2-shot burst and fully automatic. Due to the method of operation the rifle has two cyclic rates. The first two shots fire at 1,800 rounds per minute and subsequent rounds fire at 600 rounds per minute. The 1,800 round per minute 2 shot burst gives the shooter the feel of one impulse for two shots. When the rifle fires, the projectile is launched down the barrel and passes the gas port, gas is bled off into a gas port entering a gas block pushing the piston to the rear simultaneously the receiver/barrel moves rearward. When firing on automatic the first shot sets the receiver in motion as well as the bolt carrier cycles independently. A special cable and pulley mechanism loads the next round onto a special feed tray due to the fact the bolt never over travels the magazine. When the second round is fired the receiver comes to its full rearward position. For the third round and any continuous rounds in a single burst the barrel reciprocates once for each shot. When the trigger is released and pulled again the first two shot again fire at 1,800 rounds per minute and then down to 600 rounds per minute. The only parts in common with the AN94 and the AK74 are the pistol grip and the magazine. As advanced as this new rifle is, Russia has not been able to procure them in significant numbers and Russia is still taking shipments of the AK74M.

Krebs Custom AK74 Rifle

While doing some research on the AK74 for a foreign weapons training class for a deploying unit from the 10th Mountain Division to Afghanistan, I had a conversation with John Miller, who probably has forgotten more about military weapons than I will ever know. He told me I needed to talk to Mark Krebs, of Krebs Custom out of Wauconda, IL. With an endorsement from John, I did just that.

Krebs manufactures some of the finest and most advanced versions of the AKM/AK74 available anywhere to military as well as commercial customers in the United States. At first Marc Krebs started by doing “general gunsmithing.” After several years he shifted focus to specialize in building custom .45 1911 pistols. Even while working on these competition .45s (which, according to Marc, were always pushing the edge of reliability); Marc always respected the AK platform, and saw its potential. About 13-14 years ago, he shifted his focus to the AK platform. Although a small shop, Krebs Custom can manufacture approximately 600 weapons per year. These are each and every one custom manufactured from the bare receiver to the final inspection.

The great majority of the firearms Krebs Custom produce start out as Russian Saiga sporting rifles and shotguns, usually purchased directly from the importer. The rifles are stripped to their barreled receivers and then “built out” and “blueprinted” from there. They use the Russian Saiga receivers, and the original Russian hammer-forged, chrome-lined barrels. The trigger guards are removed, modified, and then re-installed in the proper position. The rest of the rifle is built according to the particular model they want to produce. They re-crown the barrels, straighten & align the sights, and eliminate any magazine problems (when necessary). For 922(r) compliance they usually install three U.S.-made trigger parts (Tapco G-2 parts that they have re-machined to Krebs standards), use U.S.-made fore-end furniture and buttstocks, and Krebs U.S.-made AK-74-style muzzle brake. While being built, all of the sharp edges of the rifle are smoothed. After the rifles have been industrially tumbled, they are ready to be bead-blasted to bare metal. They are then carefully painted, using Krebs locally-made, industrial-grade, flat black synthetic alkyd paint. After being cured for 10 minutes, the parts are then baked for 30 minutes to harden the paint and bond it to the metal.

Their most popular rifle configuration is their AK-103K which is a 7.62x39mm caliber rifle that has the outward appearance of an AK74. Although the 5.45x39mm caliber is very popular for Krebs (35%), the 7.62x39mm is by far more popular (65%). Krebs does do SAIGA shotguns as well and have the capability and is licensed to do selective fire weapons for law enforcement and military applications. They do not export any rifles or parts outside the continental United States with exception of State Department orders as well as orders to APO’s or FPO’s.

Krebs rifles are not cheap commanding price tags from $1,200 up to $2,185. This author could fathom an AK-type rifle being more than $500 – and that would be high. That was until the box was opened. The test and evaluation rifle sent was a 5.45x39mm caliber catalog number 74 rifle. The rifle has excellent fit and finish and it is Russian. The rifle benefits by being mostly manufactured by the factory that built the first models of the AK74 back in the early 1970’s. All of the updated changes have been made on this rifle including the 90-degree gas port and smooth receiver cover. The hammer forged chrome lined barrel insures this rifle will have a long service life. The gas piston is the Russian military type with the two cuts removed. Several Russian proof marks are visible on the receiver along with Krebs logo. The proper Russian style front sight base is installed with an American made duplicate of the Russian muzzle brake. To satisfy 922(r) there are several American made parts including buttstock, pistol grip, handguards and trigger group.

Anyone familiar with AK-type rifles knows that the selector levers are loud and clunky: not this one. It has been hand tuned to be smooth and quiet. Inspection of the trigger mechanism showed clear signs of polishing to sear surfaces. The trigger pull was incredibly smooth. Not to heavy but just perfect for a combat rifle of high quality. There are no sharp edges to speak of. The rifle was blemish free and just plain tight. The bolt and carrier is Russian and extremely well made. The piston rod is held in place by a peening process rather than a pin which is another current Russian manufacturing process to speed up the production time and decrease cost without sacrificing quality and reliability.

The rifle was shot with ammunition provided by Wolf Ammunition. This was perfect ammunition for the rifle. The ammunition was 100% reliable and defiantly combat accurate. The 5.45x39mm ammunition had a steel fully jacketed projectile in a steel case. There was no primer/bullet sealant on this particular target shooting grade ammunition. That is available on the Wolf Classic Military line of ammunition. The rifle was tested with German, Russian and Bulgarian polymer magazines. In 700 rounds the rifle experienced no malfunctions and produced 2- to 3-inch groups consistently off of a sand bag at 100 yards. Unlike any of the other AKs I had available to me including Chinese and Romanian 7.62x39mm rifles, the Krebs AK74 had consistent 100% hits on a silhouette target at 300 yards. I had another AK74 to compare the Krebs rifle to as well – a customized Romanian AK74. Comparing the two was literally apples and oranges. Quality of the Krebs rifle significantly surpassed it. The Romanian rifle clearly had early Soviet characteristics including the early piston rod and ribbed receiver cover. The muzzle brake on the Romanian rifle was slimmer and longer and there were no “zigzag” vent holes in the face of the first chamber on the brake. The barrel was not nearly the quality of the Russian, however in actual firing the accuracy was nearly the same with the lead on the Krebs rifle.

The AK74 has and always will be an enhancement to the previous 7.62x39mm rifles. Accuracy is significantly enhanced due to a much flatter trajectory of the 5.45x39mm cartridge as well as the low recoil making it much more controllable on automatic fire. The high velocity projectile is more lethal than the heavier and much slower counterpart. Although debate will go on about the high velocity lethal round versus the brick busting slow heavy round, there is a rifle for whatever side you stand. However, there is no question of the lethality of the 5.45x39mm round, it proved itself terrifying to the mujahedeen in Afghanistan. The rifle also made the Soviet soldier more efficient on the individual as well as platoon level. More accurate, longer range, more lethal and lighter combat load than what they had before and if you believe the math, a more reliable rifle than the rifle they had – not that there ever was a reliability issue with an AK.

Krebs Custom puts out an AK for the serious AK aficionado as well as the soldier who likes the AK platform. Krebs continues to improve upon the system with better iron sight options, quad rails, improved selector/safety levers, excellent triggers, telescopic stocks and much more. Mark Krebs undoubtedly makes the finest AK this author has ever seen and I have seen hundreds of them from various countries over the years. As previously stated, this author could not imagine a $1,200 AK, but I did. I bought one for my personal collection replacing my Romanian AK74. It was worth every penny.

| This article first appeared in Small Arms Review V16N1 (March 2012) |