By Jean Huon

When World War I ended, peace returned: but it was fragile. A strong political anxiety existed in Germany, Central Europe and Russia and a minor incident could quickly turn into a major conflict. Military staffs throughout Europe were worried and, drawing from the conclusions from the war, decided to rearm.

The 1921 Program

France was quite conscious that the armament of its infantry was growing old and obsolete and embarked on a vast program relating to upgrading and modernizing its army. France initiated its famous program of May 11, 1921, which not only defined the characteristics of the weapons to be replaced, but also those of the new materials that remained to be created. These included:

- a semiautomatic rifle,

- a light machine pistol,

- an automatic pistol,

- a medium machine gun,

- a heavy machine gun,

- a tripod for machine gun,

- an anti-aircraft machine gun,

- two anti-tank weapons of small gauge (smaller than 37mm): gun half-automatic and machine gun also being able to be employed for the shooting against aircraft,

- a grenade thrower.

The characteristics of the machine pistol were defined as follows:

The machine pistol is to be light weight, using pistol ammunition and capable of providing a strong density of fire out to 200 meters.

The weapon will have the general shape of a shortened rifle. Its weight will lie between 3 and 4 kg.

Its ammunition will have to be the same as that model of the gun that will be selected by the Army. While waiting for that model to be selected, the weapons to be presented will have to fire the 9mm Luger cartridge. This cartridges can be obtained by the designers on request addressed to the Ministry of War (3rd Direction – 2nd Office – 4th Section).

The weapon will fire from a 25-round magazine or more.

It will be able to deliver single shot and full-auto. The rate of fire will be from 400 to 500 rounds per minute.

The weapon will be rustic and simple, and will be well protected from mud. The principle of an open bolt operation is recommended because of its simplicity.

Shooting at the distance of 100 meters, accuracy will have to be smaller than 70×70 cm in the full-auto shooting mode by burst fire from 5 to 6 cartridges, and smaller than 100×100 cm when shooting a complete magazine. The precision of shooting in the prone position will be tested and will be considered in the appreciation of the weapon.

The rear sight will comprise only of notches for 100 and 200 meters.

To facilitate shooting in the prone position, the weapon will have to be fitted with a bipod, whose weight will be included in that indicated above. The presence of this bipod will not obstruct the use of the weapon in the prone position when it is not used.

The program is signed by General Rémond, Director of Artillery to the Ministry of War.

Doctrines on Employment

Studies were conducted on the doctrines of use of the new machine pistols. It was observed that the Germans had employed in each company six machine pistols used by a team of twelve men. There were thus a gunner and an ammunition carrier for each weapon. The maschinenpistole was regarded as a collective weapon.

In the offensive, the elements of the mashinenpistole trupp were directed in advance on the points where the counter-attacks appeared most probable; or during the engagements they were placed at the disposal of the section heads by the captain leading the company. In the defensive, they were joined to the sections of which it was advisable to increase the means of resistance.

In the French Army, the light machine gun was used as a support weapon and there was no question of replacing it by the machine pistol. The machine pistol had to remain an individual weapon intended for close combat and could be used in the offensive actions as to react against an attack. In artillery and the tanks, the machine pistol would be used for the defensive.

One plan was to equip some NCOs and specialists not directly involved in combat in variable proportions according to the units with 64 guns in each company of infantry, 140 guns in each artillery regiment and 1 gun in a tank or motor vehicle.

Ammunition

Initially, the 9mm Luger cartridge was retained for the semiautomatic pistol and the machine pistol. The reasons for this choice are explained by the fact that this cartridge represents an excellent weight/power relationship between the various models of cartridges available on the market and whose calibre spread from .32 to .45. Additionally, there were considerable stocks of cartridges taken from the Germans.

As for the distance of employment, the figure of 200 meters, which had been looked upon at the time of the program of May 11, 1921, is called into question by the soldiers who consider the use of the 9mm submachine gun up to 600 meters.

Involved Models

Initially, various prototypes are made:

- that of the Section Technique de l’Artillerie realized in the workshops of Saint-Thomas d’ Aquin in Paris (a former convent),

- that of the Commission of Experiment of the Infantry to the Camp de Satory close to Versailles,

- another one from M.A.S. in Saint-Etienne.

STA 1924

The Section Technique de l’Artillerie (STA) worked since 1919 on the project of a submachine gun in association with the Saint-Etienne gun factory (MAS). It had no difficulties in achieving its project goals and, in October 1921, a prototype is ready. It is followed in 1922 by three other models: each one progressively improving their presentation by replacement of the V notches for shooting up to 100 and 200 m by a rear sight graduated up to 600 m, and, after having tested magazines of 32 and 40 cartridges, it is finally a model with 32 cartridges that is retained. To reduce weight it will be made out of duralumin. Another eight prototypes were presented in 1922: four with a bipod and four others with a monopod.

The Châtellerault gun factory made the magazines. Copying the curved Revelli magazine, it is inspired for that by the charger bent by the token entry Revelli, whose posterior groove was removed and replaced by three holes intended to check the filling. The use of duralumin was unsuitable and returned to the use of steel sheet magazines.

Other suggested changes were the installation of a dust cover for the cocking handle slot, fixed V notches to be replaced by a tangential rear sight graduated up to 600 meters, a barrel jacket and a selector switch for single shot. Only this last option was retained. The presence of the bipod is faulted and the possible presence of a bayonet is unanimously rejected.

Finally the STA submachine gun was put in production with 300 guns being made in 1924 and in September they are put under tests by various troops: 150 by infantry (146th Infantry Regiment), 40 by cavalry, 80 by artillery, 10 by tanks crews, 10 for experimentation, and 10 are kept in reserve.

The regiments were asked to come to a conclusion about the doctrines for use of the weapon, its simplicity in the service and the accessories. They ultimately asked for various modifications which were too applied under the designation of M1:

- the hook cocking lever is replaced by a round button,

- lips of the charger are redrawn and soaked,

- recoil spring is larger, which causes an increase in the rate of fire,

- bipod is definitively removed,

- other improvements relate to the ejector, the closing flap for the magazine housing, and the rear stopper.

Tested in July 1925, the STA 1924 M1 submachine gun proved satisfactory and was adopted on August 11, 1925. A ministerial dispatch shows an ordering of 8,250 weapons, which the MAS factory could immediately put in production.

But the weapon was not yet completely perfect and an order of ten specimens of the STA 1924 M1 was given to MAS in March 1926. A short time later, on July 9, 1926, the 1921 program was modified and new specifications were established. The future weapon would have to fire the .30 Pedersen long cartridge, which became the 7.65 Long cartridge. The career of the STA 1924 was finished.

Description

The STA 1924 submachine gun looks like a carbine with a stock and a short forearm. On the left side is a lug intended for the fixing of the sling. The oval buttstock is fixed by two screws and near the bottom an opening for placement of a cleaning rod.

At the rear of the frame is a key for take-down that resembles that which one finds on a shotgun.

The receiver frame is cylindrical and is sealed at the rear by a screwed stopper on which the stem-guide of the recoil spring is attached. On the lower part of the receiver is placed the trigger mechanism, which consists of a trigger and sear.

On the right side of the receiver is the cocking handle slot with the rear notched to put the weapon at safety when the bolt is in the rear position. A dust cover can be used when the bolt is at the forward position.

Also on the right is the ejection port. A cylindrical collar is installed at this location and its lower part receives the magazine housing. A flap can cover the magazine housing hole.

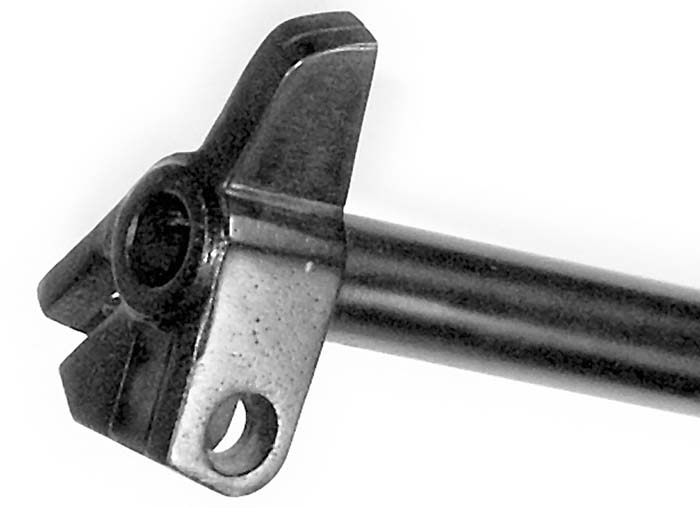

The bolt is directly inspired by that of the MP 18/1: a cylindrical main part with a hook cocking lever and a firing pin unit.

The barrel is 9mm calibre and has six right grooves. The muzzle end of the barrel is arranged in various manners according to the models. The front sight has two lower ears to receive the bipod on the prototypes. On preproduction models, a collar located before the front sight, receives the bipod and thread cutting is removed on the M1, because the bipod is discarded. On the prototypes, the bipod was made of stamped sheet metal. Later, the legs were telescopic and could be adjusted from 190 to 322 mm high.

The weapon is supplied by a curved magazine inserted in the bottom of the magazine well and holds 32 cartridges. The lips are arranged so that the cartridges of each column are presented alternatively. On the rear face of the magazine are three holes respectively marked 8, 16 and 32 to check the level of filling. A push through button retains the magazine.

The rear tangential sight has an eyepiece and is graduated from 100 to 600 meters by fractions of 100 meters.

The metal parts of STA 1924 are either blued or parkerized with black paint. Some specimens were zinc coated.

The marks on the weapon are the following: On the left side of the rear sight: STA 9m/m followed by the serial number. On the magazine housing, always of left side, M.A.S. – 1924. and on the barrel on a flat part machined in front of the chamber, the serial number.

The STA submachine gun is a simple weapon composed of only about sixty parts.

Operation

- Open the dust cover.

- Cock the weapon by pulling the lever to the rear.

- Open the magazine housing flap. Introduce a loaded magazine in the magazine housing.

- The gun is now ready to fire.

Disassembly

- Remove the magazine.

- Open the dust cover and clear the weapon.

- Turn the locking key to the right, which permits the frame and barrel unit to swing down.

- Unscrew the rear frame plug (1/8 of turn).

- Hold the plug as it moves to the rear, to help retard the recoil spring movement.

- Push the bolt unit to the rear.

- Remove the cocking lever.

- The bolt can be extracted from the frame.

- Remove the firing pin unit.

- Reassembly is carried out in the inverse order.

Accessories

- sling (is the same as the Mannlicher-Berthier carbine),

- cleaning rod, made of brass, it is carried permanently in the stock,

- crude leather cartridge pouches for soldiers contain three magazines. Each man who holds a submachine gun has to carry three magazine pouches (one on the right, one on the left and one on the back),

- crude leather cartridge pouches for troop, contains two magazines,

- Havana leather cartridge pouch for officer,

- gas cylinder brush for Hotchkiss machine gun was used to clean the barrel,

- oil can Model 1915,

- manual dated June 1924. (The manual examined carried the stamp of the colonel chief of the 146th Infantry Regiment and the handwritten date of reception: September 9, 1924.)

Eliminated from contention before it went into mass production, the STA 1924 submachine gun is an interesting weapon. It was the first one of long series of experimental weapons whose study is fascinating. Production did not exceed the 300 specimens produced and intended for testing by troops. The two specimens that we examined are held in military establishments and carry serial numbers 296 and 298.

It is possible that some of them were dispatched in Morocco, because their experimentation corresponds to the war in the Rif. Some others could have been kept in reserve and, perhaps, used in 1939-1940 when submachine guns were so scarce in the French army.

But these are only assumptions because no documents have been found that made it possible to find trace of their use in combat.

STA 1924

Operation: Open bolt blowback

Caliber: 9mm Luger

Overall length: 0.855 m (33.66 inches)

Barrel length: 0.226 m (8.9 inches)

Weight w/o magazine: 3.50 kg (7.73 lbs)

Capacity of magazine: 32 or 40 cartridges

Cyclic rate of fire: 350 rounds per minute

| This article first appeared in Small Arms Review V11N8 (May 2008) |