By Leszek Erenfeicht

For years on end it was but a legend. With just a few words about it and even fewer photographs known thereof, two were repatriated; then a gunsmith from Poznan started to manufacture replicas of it. The Maroszek self-loading rifle was resurrected at last.

The uncertainty of even the very existence of such a rifle ended in 1974 when a letter arrived at the Polish Army Museum in Warsaw from an Arizona-based American gun collector containing several photographs of a rifle nobody had seen before – but some had heard of. The sender was the late Robert Faris, and the photos were showing an unknown self-loading rifle, s/n 1048, of his collection. He bought it from another gentleman with the understanding that this was a Czech weapon for the description on top of the receiver said “Zbr.2” like ‘Zbrojovka’ and there were stamps showing a ‘Z in circle’ all over the rifle – exactly like Czechoslovak stamps. Then Mr. Faris undertook research in Dr. Miroslav Sada’s book on Czechoslovak small arms, published in Prague in 1971, and found not a sign of any weapon similar to that. When after a year or two he found similar ‘Z in circle’ stamps all over the Polish wz.35 anti-tank rifle, a thought finally dawned on him – ‘What if that one is Polish as well?’ And so he wrote his letter to the museum on the other side of the Iron Curtain to find out.

For more than a year he didn’t get any answer for the addressees were no less at a loss than he was. They then contacted the Warsaw-based historian of Polish interwar armament industry, the late Mr. Leszek Komuda, and finally he had the answer: ‘That looks like the Maroszek rifle, but let me ask Mr. Maroszek.” Józef Maroszek, the designer of both the wz.35 anti-tank rifle and the wz.38M self-loading rifle was still alive then, retired from his teaching career at the Warsaw Technological University, and Mr. Komuda got to know him while preparing an article about the anti-tank rifle. Several days later they met at the museum, and the American rifle was finally identified: ‘Yes, that’s definitely one of my self-loaders. See that ‘Zbr.2’ on the receiver? That’s Zbrojownia Nr 2 (No.2 Armory) in Warsaw, where we had them made in 1938.” Also, the ‘Z in circles’ proved to be not Czechoslovak stamps after all – they were ‘2 in circles,’ Zbrojownia’s control stamps. Only then an answer could be sent. Mr. Faris told this author in 2000 upon meeting him that he had long lost hope of receiving an answer after so long a silence.

Five or so in the World

For many years this was the only Maroszek SLR officially known to exist in the world – but it turned out it was not the only one as the Polish Army Museum’s vice director was to discover several years later, and much closer to Poland than Arizona. In Moscow’s Central Red Army Museum he found another one, s/n 1027, but it took more than a decade to repatriate it, just before the whole Eastern Block came crumbling down. At the very last moment, in 1989, they were able to swap it for some Soviet memorabilia, and finally a Maroszek rifle, or rather what was left after it was viciously deactivated when it arrived home in Poland.

In subsequent years several more cropped up, but still only five are known to exist for sure, as photos showing serial numbers are known: 1014 in Germany, 1019 in U.S. (recently repatriated to Poland, now exhibited at the Warsaw Uprising Museum), 1027 (in Polish Army Museum), 1030 and 1048, both in private collections in America. Additionally, two other rifles, s/n 1017 (Germany) and 1054 (USA) are rumored to exist, but no photos are in evidence to corroborate that as of yet.

The SLR Contest

Józef Maroszek (1904-1986) was born to a peasant family at Boglewice, near Grojec, in Mazovia (40 miles south of Warsaw). The family sent him to be educated in Warsaw, and encouraged by his physics teacher, who discovered his technical gift, he enrolled into the Warsaw Technological University in 1923. There he quickly joined the Armament Section – a joint academy-military probe to find potential future engineers for the then-organizing Polish armaments industry. The Section’s member allowance greatly alleviated the financial burden carried by the family, paying his stipend and then leaving some change. Membership carried with it other perks: it greatly enhanced chances of a solid, stable, government-paid employment. In 1930, he wrote his final thesis on Technological Improvements in Current Service Rifle, which was a Mauser 98-based wz.29 carbine. He did not limit himself to the improvements of production methods, but instead designed a simplified Mauser rifle. That made quite an impression and he was given a temporary job at the Warsaw’s Rifle Factory (the FK for Fabryka Karabinów) to build and test prototypes. These were tested in 1932, found promising, yet requiring too much time and effort to perfect. But it put his foot in the door and he was hired by the ITU (Armament Technological Institute) in Warsaw.

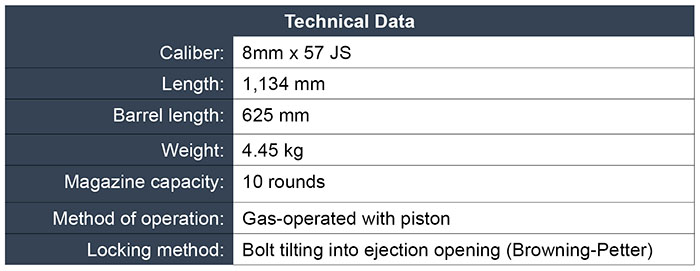

On March 14, 1934, two weeks after his simplified rifle was finally rejected, the ITU announced a contest for a self-loading rifle for the Polish Army. The requirements were: weapon chambered in the service caliber (7.9mm Mauser), not heavier than 4.5 kg, with a magazine capacity of 10 rounds, barrel length equal to the service wz.29 carbine (600 mm), easy to operate, simple in design, reasonable number of parts and manufactured with simple production methods. The deadline was 31 December, 1934. Nine rifles were proposed, but unfortunately most are only known by the codenames: 14895, ABC-34, BK, Celer, ES, Gajos, Samopal, SKS and Turniej.

The jury, under ITU commander Lt. Col. Czeslaw Kunart, selected on 8 January, 1935 three rifles for further development: SKS by Engineer Stefanski (unfortunately the given name is absent from all correspondence), ES by Edward Szteke and Turniej by Józef Maroszek.

The Stefanski SKS rifle was a gas-operated weapon with the gas cylinder on top of the barrel. During development the original SKS got ‘thoroughly redesigned’ into kb.sp. wz.34 but the details are missing. In 1938 due to no progress evident in subsequent testing it was discontinued.

Edward Szteke’s ES rifle was a lever-retarded blowback recoil-operated weapon, with fixed barrel; somewhat along the lines of the HK G3, but with kidney-shaped levers instead of rollers. It was patented in Poland, Europe and the U.S. in 1933-1937. Mr. Chinn may be right on many things in his monumental series of books The Machine Gun, but how he managed to find in it a predecessor of the MG 42 is a mystery. Perhaps he mistook MG 42 (short recoil gun, roller locked with recoiling barrel) with MG 42V, Vereinfacht, or Simplified, prepared to be introduced into the Wehrmacht’s inventory as the MG 45 – a retarded blowback with fixed barrel, like the ES…

Maroszek Rifle

The Maroszek ‘Turniej’ was a gas-operated weapon, but the details of his original design, especially the lock, we cannot ascertain for lack of documents. Polish ordnance archives were pretty thoroughly sieved, vetted and dispersed, first by the capturing Germans and Soviets in 1939, then by Germans re-capturing them from the Soviets, and then in 1945 by the British, American, French and Soviets, capturing them once again from the Germans.

Szteke’s rifle was judged the best while Maroszek placed third. Regardless, he was too busy designing his AT rifle, which was given much higher priority, and so he was given a respite, while ES and SKS were toiled upon.

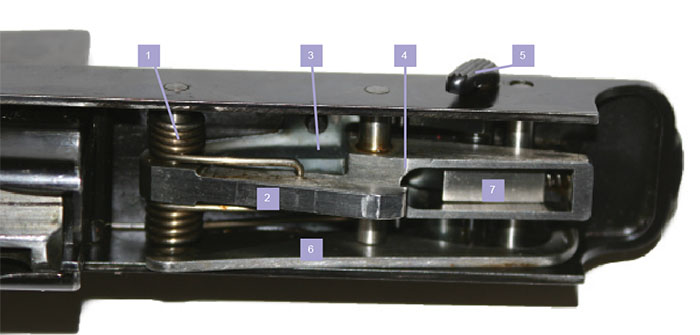

In 1936 the rifles were progressing steadily, but as the AT rifle was then ready for production, the SLR board requested Maroszek to submit a prototype. Meanwhile, he had an epiphany as to the locking system of his rifle, and instead of starting to build his original rifle, he turned it inside out to accommodate his new idea of tilt-locking the bolt into the ejection opening of the receiver – what we now call a Browning-Petter locking, generally associated with handguns. The new receiver was much shorter, with no need for barrel extension. The return spring is similar to the BAR – but the original M1918, not the wz.28 Polish one – being stored inside the bolt-carrier and gas piston. The new ideas seemed plausible enough to grant him six weeks deadline extension in which to redesign the rifle from scratch. In mid-1936 at the No.2 Armory at 2/4 Szwedzka Str. in Warsaw’s Praga district, a three-man team which last year cooperated with Maroszek in preparing the AT Rifle production set to manufacturing parts for his second design for the Polish Army, now re designated the ‘kb.sp. M’ (kb.sp. is an abbreviation for ‘karabin samopowtarzalny’ or self-loading rifle, the SLR, while M stands for Maroszek). The finished rifle was tested at the Ballistic Research Center in Zielonka, and evaluated positively. The only fault was the firing pin, which accounted for nearly all of the jams, triggered by the tip breakage.

Arrested Development

The first time the FK’s Bureau of Studies budget indicated expenditure towards the Maroszek SLR was in FY 1936. The rifle’s development was funded to the tune of zloty 10,314.42 (of which Zl 7,409 was paid to Zbrojownia Nr 2 for manufacturing the functional model and five prototypes). [Polish Zloty exchange rate to USD at that time was Zl 5.14 to $1]. The real costs were certainly higher as some of the development was paid for from the Zbrojownia Nr.2’s own budget, while Maroszek was the ITU employee, so he was paid only a salary for his work. This sum was more than already was paid for the ES rifle over past two years (Zl 9,918.64 zl) – but still half of the cost incurred by the Stefanski’s SKS rifle over that same period – Zl 20,096.24. It was not that the SKS was that much worse – simply Stefanski was an outside man, so all his costs were paid directly from the Bureau of Studies budget. On the other hand, Szteke was employed by the FK, so the cost of his prototype work was paid from their budget – hence the difference.

In 1937, five pre-prototypes were subjected to military testing, and another round of improvements was introduced. The Stefanski rifle program was terminated with the end of FY 1937, with kb.sp. M substituting for it. In May of 1938, a complete set of manufacturing drawings were ordered from the State Armament Works Central Laboratory in connection with the planned ordering of 72 rifles for military testing from the Radom Fabryka Broni (FB). FB, however, politely declined – it was already fully busy with orders for wz.29 carbines and still saddled with wz.35 (Vis, the Radom pistol) orders, already two years in arrears. The order was then extended to the FK in Warsaw, with the same answer – thanks, but no thanks. Finally, it was the latter’s experimental establishment, Zbrojownia Nr.2, which accepted the order on 13 July, 1938. However, it was reduced to just 55 rifles with delivery date extended to 1 January, 1939. Lacking the barrel-making facilities, Zbr.2 ordered 63 barrels from FK. The order was worth Zl 277,000.

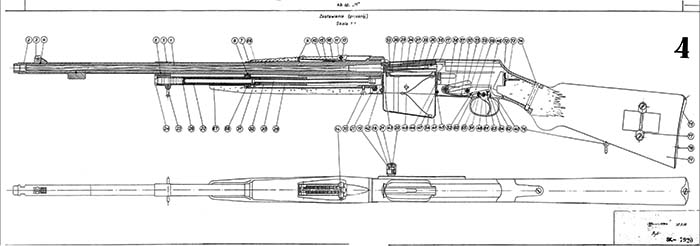

The final wz.38M SLR is a semiautomatic, gas-operated weapon with a tilt-locked bolt, fed from a 10-round fixed internal magazine. The rifle had 68 parts, which was quite reasonable against the background of the contemporary designs: the SVT-38 numbered 63, the G41(W) 66, but the M1 Garand only 55. For cleaning it can be broken down into just four components: barreled action with buttstock, gas cylinder, bolt carrier with return spring and bolt.

This was not the end of the road neither for the Maroszek rifle, nor for the SLR for the Polish Army. The contest was still hot, the Szteke’s kb.sp. wz.37S (former ES) was also still under development and tested in November 1938, where during the durability testing it still did not reached the goal of 10,000 shots, having failed (receiver hairline crack discovered) after 8,000. This was the final failure, but earlier on the 37S chewed through three firing pins (after 300, 550 and 1,800 shots), extractor (859 shots), and bolt bumper (4,923 shots). Despite all that the project continued with new, improved 3rd Gen prototypes ordered for further testing in 1939. On 26 February 1939 one each ‘enhanced accuracy’ wz.37S and wz.38M rifles were ordered for a shoot-off to determine which rifle would serve as a basis for a sniping rifle. This is unfortunately the last paper trace left by either of the rifles.

As the delivery deadline for the 55 rifles was 1 January, 1939, and no trace of any further barrel orders was found so far, it is safe to assume that not more than that number of the wz.38M rifles were ever manufactured. All serial numbers known so far are contained within the 1001 – 1055 range, corroborating the quantity.

Maroszek Redux

This author had the opportunity to handle, strip and examine in detail the Maroszek rifle, s/n 1048 that was owned by Bob Farris in the U.S. but unfortunately firing it was not possible as it had a familiar Maroszek ailment: the firing pin point was broke off. Regardless, it was different from the one we had in Poland – with just one cross-bolt, instead of two. Later on, two other Maroszeks were found in America, both of a single cross-bolt variety, while another two-bolt rifle was found in Germany. With no hard documents to prove it, one can only assume that this might have been a last-minute addition, perhaps a result of the spring of ‘39 troop-testing, perhaps to reduce the lower receiver wobble. So, perhaps the 1014 and 1027 were prototypes for the new series-production model? How significant, that one ended up in Germany, and the other in Russia – two hoodlums conspiring against Poland in 1939… We’ll never know.

Or do we? Once at the Museum, I met a gunsmith from Piotrowo near Poznan, Mr. Ryszard Tobys, whom I knew as the Guinness’ Book of Records world’s largest cap-and-ball revolver manufacturer. He was planning to build a shooting replica of the Maroszek rifle. He was taking some measurements to reverse engineer some small bits, which in reality looked quite different from the blueprint. It transpired that Mr. Maroszek’s nephew in Bialystok inherited a set of production blueprints for the wz. M rifle. This was the penultimate version of it – those five prototypes of 1937, so several changes were introduced later, which he was then analyzing comparing blueprints with the real thing.

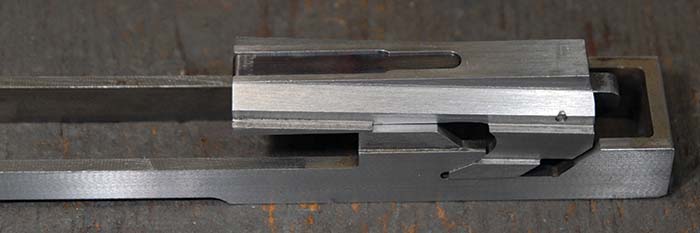

In November 2013 rifle s/n RT001 was ready, and I’ve been the first journalist to see it, handle it, and shoot it. The first rifle was more of a test-bed than show-piece, but I’ve seen three barreled actions in various stages of manufacture, so there would be better and prettier ones once all the bugs are ironed out of the first. The price tag would be enormous as the project already cost thousands upon thousands of hours of hard work, but fortunately Ryszard’s two sons, Blazej and Remigiusz can program his CNC machines for free, so he can avoid the most costly part. At first, the components were machined in aluminum and brass to check if they fit together, then real parts were made and fitted. This seems to be a really nice, well balanced, and smooth to shoot rifle – given it’s chambered in 8mm x 57JS Mauser.

| This article first appeared in Small Arms Review V18N6 (December 2014) |