By Robert Bruce

“The purpose of an under barrel shotgun is to reduce transition time from your primary weapon to your under barrel shotgun and vice versa. That’s what it’s doing now and we’re refining it to make it an even better product. The fact that it can also be used as a stand-alone, two or so pounds lighter than a Mossberg or a Remington, more advantageous to the soldier than carrying (those) around. Also the fact that … the XM26 Modular Accessory Shotgun System …is more portable and enables the soldier to move through tighter areas than carrying (a standard pump shotgun) along with an M4.” Thomas Vass, XM26 Product Director, US Army Program Manager Small Arms

SAR has been following development of the XM26 MASS (Modular Accessory Shotgun System) for several years, dating back to when it was still called LSS (Lightweight Shotgun System) in military documentation.

The first working prototype was created early in 1999 by C-More Competition’s Ira Kay based on his proposal that had been submitted in response to an Advanced Concept and Technology (ACT II) Program solicitation issued by the US Army. It has remained essentially the same in form and function through the years as small quantities have been acquired by cutting-edge military organizations for purposes ranging from formal testing to urgent combat fielding.

Now, a bit shy of a decade later, Kay’s compact, light, magazine fed, manual straight-pull 12 gauge is slated to be the US Army’s first really new standard-issue shotgun in more than 100 years since John Moses Browning’s iconic pump-action Winchester Model 1897 entered the inventory during the Philippine Insurrection.

Key words here are “really new + standard- issue.” Yes, SAR knows that plenty of other pump shotguns, bearing familiar names like Savage, Stevens and Ithaca, have been in widespread Army issue with the most current notables being Remington 870s and Mossberg 500s. Not “really new” because they’re all based on Browning’s slide action.

Various scatterguns in semi and even full auto have been acquired by the Army for testing and sometimes limited issue during the 20th century. The selective-fire HK/Olin Close Assault Weapon System and its radical flechette ammo almost made it to the finish line back in the 1980s. More recently, the semiauto HK/Benelli M1014 Joint Service Combat Shotgun, developed by the Marine Corps with the goal of standardization throughout Department of Defense, is in Army use only with 75th Ranger Regiment.

But, if things stay on track for type classification and full rate production, Remingtons and Mossbergs will give way to the M26 Modular Accessory Shotgun System beginning in 2008. Readily convertible at individual soldier level as under barrel or stand alone weapons for a full range of shotgun applications, the basis for issue is currently set at two per squad, for a total currently set at 22,000 guns.

So, what’s the gun like now in its pre-production configuration?

SAR asked for it and the Army delivered big time.

Public Affairs Officer Debi Dawson of Program Executive Officer Soldier has laid on an extraordinary opportunity for our readers to be the first outsiders to get a close look at the latest version of a weapon that is on track to be the Army’s first really new standard issue shotgun in over a century.

It’s a frosty but sunny winter morning at the historic home of the Ordnance Corps, where the energetic and personable Ms. Dawson has more than a dozen military and contractor personnel standing by, including the weapon’s stalwart inventor and the director of the Army’s program to perfect and field it.

That is pretty impressive VIP treatment for such a relatively small magazine and definitely not taken for granted.

It might be because SAR is closely tuned to the “muddy boots military;” the grunts doing the tough, dangerous and grinding combat missions 24-7 in the Global War on Terror. Infantry weapons are our specialty and we take pride in recognizing the good people who are responsible for developing and fielding the world’s best and most effective battlefield hardware.

Behind The Fence

So one lone reporter, personally escorted by Dan Terek, Aberdeen Test Center’s (ATC) earnest young Test Director, joined a convoy of government vehicles cleared to pass through a high-security gatehouse and venture into the secret land “Behind The Fence.” This deceptively bland phrase describes miles of forbidding, barbed-wire topped barrier separating main post from ATC’s vast domain of ranges, impact areas and hushhush facilities.

The trip to Soldier Systems Test Facility Outdoor Range covers several miles, revealing an amazing variety of activities that, of course, Terek is not at liberty to comment on. But we’re allowed to look and over on a manmade mountain they’re doing rough terrain testing of an unusual armored gun platform. Then, there appear to be preparations for some live fire engineering measurements of a large caliber gun system not recognized from current inventory. And who knows what’s going on inside the many cavernous buildings set in neat rows or others conspicuously apart and surrounded by multiple rolls of razor tape…

Range Control

Arriving at our destination, we climbed stairs to the second floor of what appears to be a new blockhouse, efficiently configured as Range Control. Enormous windows of thick double glass provide the Rangemaster and visitors a commanding view of a wide and seemingly limitless distance for extreme small arms shooting. The spacious and blessedly warm observation area easily accommodates this relatively large group with plenty of room to spare.

Tables and comfortable chairs, used in numerous on-site meetings of program and contractor personnel during year-round testingoperations, complete the arrangements for a near perfect venue to conduct the planned demonstration and related activities.

As the range would not be cleared to go hot for about an hour or so, the first order of business was to get some detailed photos of the weapon itself, normally a no-sweat task. However, security requirements prohibit visitors from bringing their own cameras so Susan Hagen, APG’s friendly and efficient Public Affairs Specialist, arranged for an official staff photographer.

Luckily for SAR, Jim Aguiar drew the assignment. This former Navy lensman proved to be interested, enthusiastic, proficient, and proactive, quickly picking up on what needed to be done despite this correspondent’s very poor attempts at direction.

How It Works

Army Sergeant First Class Donald Moore, NCOIC (Non-Commissioned Officer In Charge) of ATC’s Small Arms Systems Division, was the day’s designated XM26 shooter. He graciously agreed to assist with the routine photos as well by assuming the role of an instructor, teaching us the basics of the weapon’s mechanical characteristics and operation. By mutual agreement this was conducted inside, much to the relief of those participants who had neglected to wear long johns.

About this time we were joined by Ira Kay, the weapon’s outspoken, iconoclastic inventor and head of C-More Competition/C-More Systems. As Moore went through field stripping, Kay provided essential details on the design of various components in a rapid-fire delivery that commanded close attention. A case in point is the rotating elevation adjustment assembly on the shotgun’s forward mounting bracket, allowing precise zero to the host weapon’s sights.

As may be seen in the accompanying photos, this collaboration worked very well with Aguiar snapping away as Moore went step by step through field stripping, reassembly, then safe handling and firing preparations. Kay’s insights cued the all-important closeups that provide SAR’s technically minded readers with engineering details that words inadequately convey.

Ballistic Breaching

But there was precious little time for photographic niceties. With the range scheduled to go hot in just a few minutes we were invited outside to the concrete surfaced firing line where an elaborate doorway mockup had been positioned. There we met Nathan Beavers, one of ATC’s contract “shooters,” who was formidably armed with the stand-alone version of the XM26 and soon to be clad in ballistic protective gear from head to toe.

Beavers showed us how he was going to extend the cage-like standoff muzzle device and insert the barrel of the stubby, stocked shotgun through saucer sized holes in clear Plexiglas (protects against splash back of lead and debris) to blow the door’s locks and hinges. Safety rules required all others – photographer included – to be inside, so we were shepherded upstairs to view this dramatic demonstration through the observation room’s picture windows.

Special M1030 Breaching Rounds weren’t needed. The door fell on cue after single rounds of OO Buckshot were unleashed in each of the designated spots. We dutifully filed outside once again for a close look at the damage that nine pellets per cartridge at point blank range are capable of inflicting on wood and steel.

By this time in late morning the sun was flooding the firing line with thin but welcome warmth and the cutting wind had died down. Who could ask for more in February?

25 Meter Demo

We all gathered around on the hardstand at a safe distance as SFC Moore prepared an M4A1 Carbine with under barrel XM26 for the second demonstration. This, he explained, would be multiple rapid shots from standing position at a pair of standard E type silhouettes, a representation in size and shape of an adult male torso and head. As with the breaching demo, ammunition would be standard OO Buckshot, 2-3/4 inch loads, followed by a few finned non-lethal rounds.

The targets were placed 25 meters downrange on servo-motored carriers that automatically react to hits by sensing vibration and dropping the target backward. Depending on the scenario programmed into the Rangemaster’s control console, these will stay down until the exercise is completed, or quickly return the target to standing for multiple engagements in variable sequences. Such immediate feedback is very satisfying to competent shooters and a computer counts hits and misses for accurate scorekeeping.

XM26 accuracy test standards for this load at this distance call for a minimum of two of the nine pellets from each round to hit the target when “shoulder fired, using a bench rest….” Moore was shooting offhand but neither of the pair stood a chance against his rapid but methodical marksmanship.

After the last of several five-round magazines had been emptied and the weapon was confirmed clear, a few of us slopped downrange through the mud from recently melted snow. We were gratified to note multiple perforations, comfortably totaling in excess of the two per shot standard. Good shooting!

Hands-On Reporting

Philosophers caution us to “be careful of what we wish for because it might come true.” Well, this correspondent’s insistence on having the opportunity to shoot the XM26 had been officially blessed and now it was showtime – in front of the whole crowd.

The stand-alone version was selected, based on reasoning that its tubular buttstock and pistol grip make it closer in configuration and handling characteristics to semi-familiar riot guns of recent experience. Its MIL-STD 1913 accessory top rail sported a prominent front sight post to go with the large rear sight, cleverly consisting of a white dot inset on each wing of the rear attachment collar, somewhat more user-friendly than much smaller ones on the M4 carbine/shotgun combo.

Having paid some attention during the photo-session “lesson” and then observing several iterations of Moore’s loading and aiming drills, these essential make-ready functions had smoothed the way to a semblance of preparedness.

First, poke a finger into the action lock plunger under the receiver so the charging handle can be pulled rearward and the crossbolt safety engaged. SAFE comes with thumb pressure pushing through left to right so that the red ring is hidden. Next, insert the magazine AK style by locking in the forward lip and rocking the mag back and up until it snaps securely in place. Then, firmly push the charging handle forward to chamber a round and lock the action. The shotgun’s beefy mag serves perfectly as a foregrip with finger grooves molded in, and is properly spaced from the rear pistol grip for comfort and control.

Settling into a semi-crouch the index finger easily finds and pushes the safety through to FIRE (red warning ring now visible) and a passably good sight picture was attained on the left of the two silhouettes. Uh oh, it looked oddly smaller from an across the top of the weapon perspective. No fault of the sights, just the stressed shooter.

Breathe, sight, squeeze, boom, ouch! A sweatshirt and thin photo vest are no substitute for a flak vest or padded shooting jacket. Also, lacking the 7.5 pounds of recoil-absorbing mass that comes with an attached M4 carbine, the stubby little four pound standalone kicks like a mule. Yes, even with the relatively wimpy 2-3/4 inch Buck loads. Slugs? 3-inch Magnums? Uh, no thanks.

Fortunately, the first silhouette dropped immediately, drawing attention away from the grimacing shooter. Tighten up and drive on.

Resisting the natural tendency to grasp the charging handle to cycle the action, it’s time to try the demonstrated technique calling for knocking it back with the top edge of a flat palm and a fast flip of the wrist. This works as advertised, allowing immediate repositioning of the forward hand in grasping the magazine.

OK, we settle in again, this time on the right side target. Pulling the gun tighter into the shoulder proved useful, of course, and the second shot did less damage to the shoulder while managing to drop the target. Or maybe the Rangemaster did it manually from the control console….

Thankful that the weapon’s five round magazine had been loaded one short, there remained only two shots to endure. Get it over with quickly. Let’s see how fast two shots can be fired and hope that nine pellets per round will spread out enough over 25 meters to get a hit.

First target down, a flat palm bolt cycle done with clumsy inexperience, and a hasty final shot. As the smoke wafts away the second one is arrogantly standing there, testifying mutely but eloquently to the consequences of faulty aiming and trigger-jerk flinching.

Everyone was polite enough to pretend not to notice and, as most of the participants gathered at the splintered door frame for the obligatory group shot, there was time for a bit of reflection on some of the morning’s lessons:

- Any new weapon requires a lot of practice to attain proficiency.

- Shotguns are not magic blasters. Principles of marksmanship must be employed.

- Mass dampens recoil. Light weapons deliver more kick. Body armor negates the problem, but the planned addition of a highly effective new recoil buffer is welcome.

- Ira Kay’s invention will be a handy new addition to the US Army’s arsenal, particularly appreciated by breachers when attached as intended to their M16/M4 family of weapons.

New and Improved

The weapons shown and shot at the ATC press preview are close to, but not quite, what will be standardized/type classified and go into full rate production. Both Kay and Thomas Vass, the Army’s XM26 Product Manager, were careful to note a number of planned improvements based on soldier input and formal testing.

Seems this correspondent has a bit of company in being recoil-averse to the stand alone configuration, which, Vass said, garnered negative comment from one GI in formal review following testing. This was apparently enough and Kay told us that he has contracted with Enidine to include a version of their new ShotShock buffer in a redesigned telescoping buttstock that will also be fitted with a soft recoil pad.

Kay explained that, while liking the quick and easily manipulated crossbolt safety, some soldiers were inadvertently jamming the mechanism by putting the weapon on SAFE when uncocked, then retracting the bolt. Now, same as the M16/M4, the safety can only be engaged when the shotgun is cocked.

Similarly, the somewhat clunky add-on iron sights for the stand alone gun will be replaced with clever pop-ups positioned on the MIL-STD 1913 rail. Folded down and stowed out of the way when attached to a host weapon, they will be immediately available for use when reconfiguring for stand alone applications.

Vass told us that environmental testing – particularly in simulations of arctic cold and desert heat – revealed some problems with the polymer components. Production shotguns will feature tougher and more temperature- stable magazines, pistol grips and other nonmetallic parts.

So, the Army says to all you breachers, CQB specialists, sentries, MPs, and other practitioners of pump shotgunning – hang on a little while longer. A smaller, lighter, simpler, faster firing, faster reloading, more versatile tool is on the way.

Find Out More

C-More Competition and C-More Systems are best known for competition gun sights – www.cmore.com

1. After clearing the M4A1 Carbine use an index finger to depress the action lock release. This allows the bolt to be retracted fully to the rear. Carefully examine the chamber to ensure no round is present.

2. Depress the magazine release tab and remove the magazine.

3. Use the charging handle to return the bolt/carrier assembly to a forward position, stopping before the action locks.

4. Using a suitable tool or the point of a bullet, push the small end of the front mounting bracket takedown pin (left to right) to release the shotgun from the bracket. The takedown pin remains captive to keep it from getting lost.

5. While supporting the carbine with one hand; slide the shotgun forward until the rear mounting bracket assembly is able to come free of the M4’s barrel.

6. With the shotgun upside down so the bolt/carrier can be observed through the magazine well, use the charging handle to move the bolt/carrier into position where the charging handle retaining plunger access slot is visible. Using the nose of a 5.56mm bullet or other suitable tool, retract the charging handle retaining plunger. This unlocks the charging handle, allowing it to be partially withdrawn.

7. Rotate the trigger guard downwards.

8. Pull the charging handle rearwards to dislodge the recoil plug, then remove it.

9. Withdraw the charging handle.

10. Remove the bolt/carrier assembly from the rear of the receiver.

11. A view of the bolt/carrier assembly in proper relationship to the receiver.

12. Separating the bolt from the carrier allows easy access to clean the firing pin mechanism without further disassembly. Important: Do not pull the trigger or allow the hammer to fall if the bolt and carrier are not installed in the weapon!

13. Separating the bolt from the carrier allows easy access to clean the firing pin mechanism without further disassembly. Important: Do not pull the trigger or allow the hammer to fall if the bolt and carrier are not installed in the weapon!

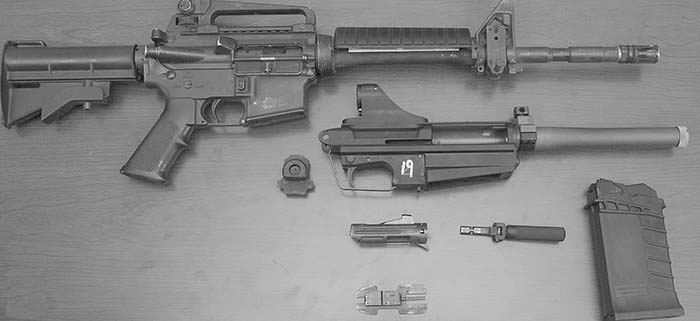

14. Field Strip Layout (top to bottom, left to right): M4A1 Carbine, recoil plug, receiver and barrel group, bolt assembly, charging handle, magazine, bolt carrier.

Program Executive Soldier oversees an extraordinary range of weapons, ammunition and equipment in support of America’s Armed Forces. Visit their website at www.peosoldier.army.mil with a link to Program Manager Small Arms, directly responsible for the XM26 MASS and other exciting weaponry.

| This article first appeared in Small Arms Review V11N2 (November 2007) |