By Michael Heidler

45 mm of armor steel – that was way too much. With the arrival of the Russian T-34 tank at the front, the time of the German anti-tank rifles was finally over. Even the latest model, the Panzerabwehrbüchse 39 (Pz.B.39), was only able to deal with 30 mm of armor steel at 100 meters distance. In an experience report of the 88th Infantry Division it is mentioned: “The troop does not trust her and therefore she is mostly left back on the vehicles.”

The new Russian tanks were an unpleasant surprise. Besides the anti-tank rifles, the German infantry only had the rifle grenade launcher as well as mines and improvised devices available for combating tanks at the beginning of 1942. The development of the “Faustpatrone” (later called Panzerfaust) had just begun. Therefore, production of the Pz.B.39, starting in March 1940, ended in November 1941 with 39,232 weapons made.

In the efforts to give more effective anti-tank weapons to the infantry, in July 1941 the Army Ordnance Department (Heereswaffenamt) went up to the Westfälisch-Anhaltinische-Sprengstoff-Actien-Gesellschaft (WASAG) to increase the performance of the hollow-charge rifle grenade GG/P40. The designation stands for “Gewehrgranate zur Panzerbekämpfung Modell 1940” (rifle grenade anti-tank model 1940). It was a development of the WASAG specifically designed for the “Schießbecher mit Klappkorn” (spigot-type launcher with notch), a competitive model of the Air Force to the Army’s cup-style launcher. This grenade’s shaft was not put into, rather onto, the launcher. The wing-stabilized grenade could penetrate up to 35 mm of armor. Now the demand was for a penetration of 100 mm of armor at 75 meters distance and an accuracy of 100 meters. The grenade should also be as small and light as possible and the recoil should not exceed the endurability of the shooter. It was being considered to equip the outdated and ineffective anti-tank rifles 39 with a spigot-type launcher similar to the model GG/P40 for launching a new hollow-charge grenade. This saved valuable resources because most of the discarded anti-tank rifles were not scrapped.

On 9 September, a shooting test took place at the Kummersdorf proving ground with GG/P40-grenades with an increased amount of explosive and a steel layer in the hollow charge cavity. It showed an increase in performance, so that further experiments with different cavity forms and layers should be undertaken. The grenades were fired from model 98 rifles as the modified barrels for the anti-tank rifles weren’t ready in time. On 10 September, the official order was placed for the development of a “Panzerbüchsen-Granate”, in short “Pz.B.Gr.” (tank rifle grenade).

In November 1941, however, competition came into play: The Gustloff-Werke in Suhl received a development contract from the Army Ordnance Department for a reconstruction of discarded anti-tank rifles for launching grenades similar to the types of the Army cup launcher. In particular, the large spin-stabilized anti-tank rifle grenade with a penetration capability of 70 mm of armor promised acceptable chances of success in action.

What soon became an unpleasant experience was the wind sensitivity of the wing-stabilized GG/P40. Total penetration was only possible up to 50 mm of armour, providing that the grenade hit at all. In a letter to the WASAG from 1942, it is written: “The shooting on 10 April, according to General Lange, showed the utter uselessness of the current construction of Gg.P.40, because in gusty winds it was only with great difficulty possible to achieve 9 hits by 30 shots on a distance of 50 meters or less.” This act sealed the end of this development.

At the front, the time was pressing – but the development at the Gustloff factory went on slowly. Only 53 pieces of the now called “Kurze Panzerbüchse 39 (Pz.B.39 kz.)” (short anti-tank rifle) had been delivered for trial purposes to Kummersdorf proving ground until early July 1942, so that the planned start of mass production (1 July 1942) with 6,000 pieces/months could not be made. It was not until December when the production of the “Granatbüchse 39” (Gr.B.39) finally began. After the conversion to a rifle grenade launching weapon, the old designation “Pz.B.39″ was covered by a riveted metal plaque with the inscription “Gr B 39” and a newly assigned serial number. The company that did the conversion is not mentioned on the plaque. However, it is obvious that all the weapons were returned to Gustloff at Suhl.

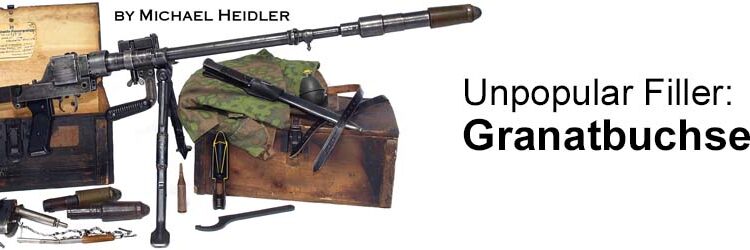

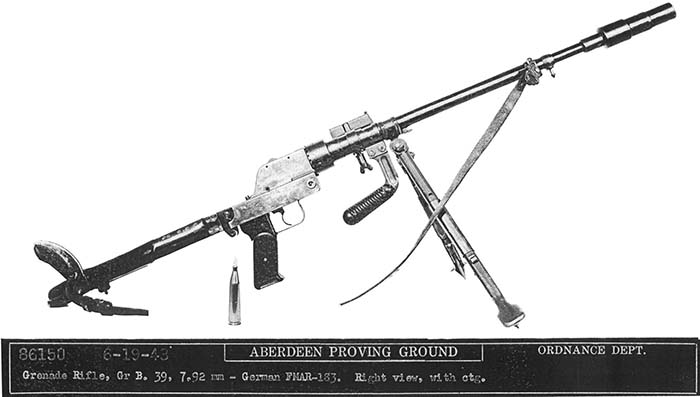

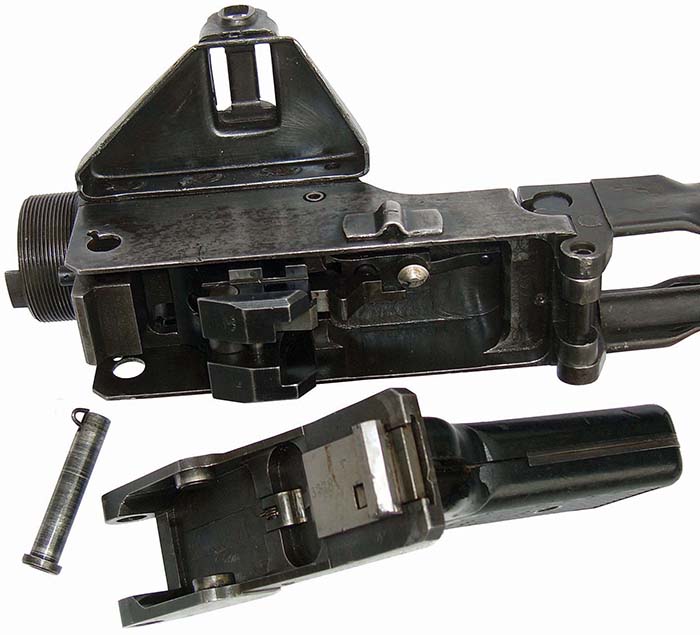

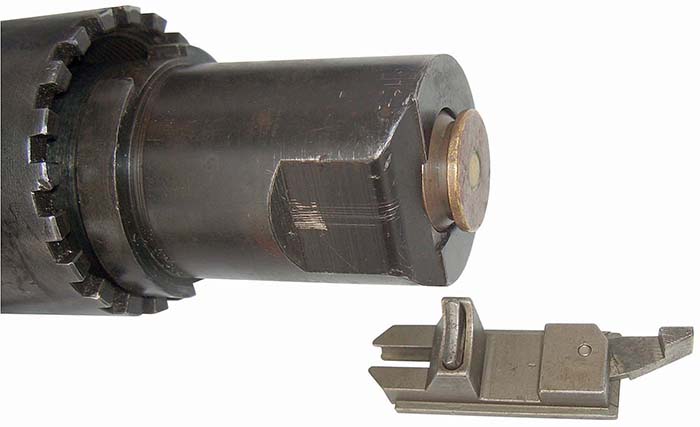

In the course of the conversion, the barrel was shortened from 1,085 mm to 590 mm, a new changeable front sight in a frame was mounted to it’s left side, the folding-stock was stiffened, the two-legs extended and a modified cup launcher was screwed onto the now threaded muzzle. The bipod is similar to the one on the MG 34 light machine gun. The weapon can be taken apart into two main components: the barrel with cup launcher, sight-frame and carrying handle and the receiver with stock, bolt, safety, rear sight and grip piece. A large castle nut ensures a stable connection. A spring-loaded catch serves as assurance that the bolt can only be released when the castle nut is fully tightened and the head presses against the catch; otherwise it rotates into the path of the breechblock.

The Gr.B.39 uses a vertically sliding breechblock, which is dropped down to open the barrel for reloading, and then rose up for locking before fire. The breechblock is designed with a loading tray. The trigger housing with pistol grip is connected to the forward end of the receiver by an axis pin. The rear of the housing is secured by a spring catch. The pistol grip was capable of a limited pivotal movement with respect to the trigger housing to operate the trigger housing spring catch.

A safety lever is installed on the top of the receiver just behind the bolt. It has two positions, one marked with a white “S” for “Sicher” (safe) and one marked with a red “F” for “Feuer” (fire). In the safe position, a part of the safety catch obstructs the sear and prevents its rotation.

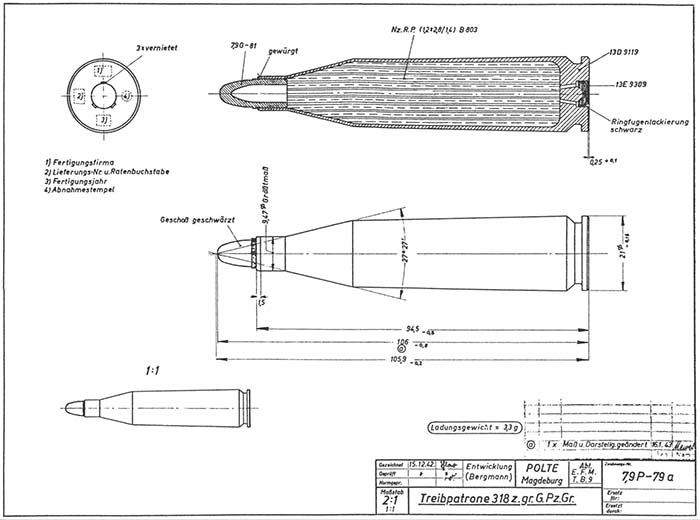

For loading the weapon, the pistol grip has to be pushed forward on its axis. The movement of the grip forces the trigger housing catch forward out of its engagement with the receiver. Continuing the forward movement of the grip, pulling it in a downward direction, the housing will pivot, drawing the breechblock downward until it is clear of the chamber. Now a “Treibpatrone 318” (launching cartridge 318) can be loaded. When pulling the pistol grip rearward, the breechblock rises and closes the chamber. During this action a ramp on the left side of the breechblock forces the extractor forward and the extractor slide toggle engages the groove in the side of the breechblock. The ramp above the breechblock then forces the cartridge fully into the chamber. The trigger can not be pressed until the trigger housing catch has re-engaged the receiver of the weapon.

The buttstock is connected with the receiver end. In contrast to the former Pz.B.39, the stock can no longer be folded downward over the pistol grip because it was reinforced for better stability by longitudinal struts. Two shoulder pads are fixed to the stock’s end. The lower one can act as a trail spade.

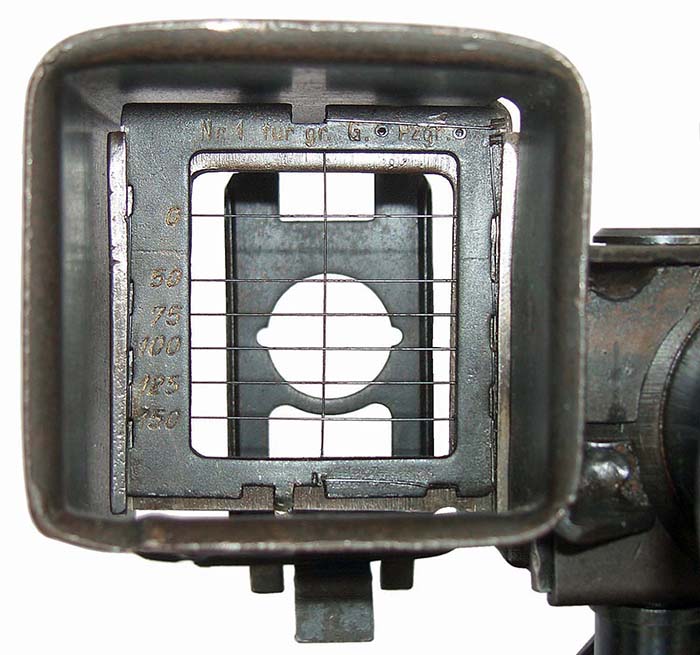

On the left side of the barrel a changeable front sight made of wires in a frame was attached. It is covered by a box-shaped housing. The distance scale is marked in white letters on the wire framework as “Nr. 1 für gr. G. PzGr.” (for the large rifle grenade). The changeability indicates that other rifle grenades were planned for use with the weapon, but it never happened and no other frame with a different scale is known to exist. The front side of the sight’s housing can be covered by a fold-down guard with an integrated auxiliary sight. When carrying the weapon through bushes the guard protects the wire framework. The auxiliary sight allows aiming at dusk or if the wires in the framework were damaged. When a target fills out the upper half of the sight, it is 75 meters away. On the right side of the receiver a small metal box with spring-loaded flap is fitted and contains a spare wire framework.

There was only one kind of grenade to be fired with the Granatbüchse 39: The “Große Gewehr-Panzergranate mit verbessertem Drallschaft” (large anti-tank rifle grenade with improved stem). The launching cartridge 318 looks like the blank cartridge differing only in the somewhat shorter wooden bullet. The rifle grenade with improved stem was the only grenade that was allowed to be used because all others could be destroyed by the enormous pressure caused by the strong launching cartridge 318.

In the spring of 1943, the development of a rifle grenade with increased penetration power especially for the Gr.B.39 began, but was shortly thereafter terminated.

This is not surprising because in April 1943 the end of the Gr.B.39 came. The weapon was too heavy (10.5 kg) and too long (123 cm) and did not exceed the performance of the standard Karabiner 98k rifle with cup-style rifle grenade launcher. This fact did not justify the production of another type of weapon.

In the five months of its production, a total of 28,023 Granatbüchsen 39 were made (1,416 pieces in 1942 and 26,607 pieces in 1943). In October 1944 an order was issued to all units to send back all Granatbüchsen 39 and other anti-tank rifles (including all captured weapons) for scrapping. Toward the end, the total stock of Granatbüchsen 39 was only 2,999 pieces. Of these only 116 pieces were still at the front. Today, the Granatbüchse 39 is a vey rare collector’s item.

| This article first appeared in Small Arms Review V17N2 (June 2013) |