By Warren Ferguson

EXCLUSIVE! Firing the unlocked rifle… dangerous to whom? The elusive story of the W.W.II German ‘People’s Rifle’ makes the weapon highly coveted.

Improvised firearm designs usually arise when a nation is faced with the threat of foreign invasion and formal weapons manufacture proves unattainable. Shortages of raw materials and a lack of elaborate manufacturing facilities during war create the kind of weapons that are typically very crude and unreliable. Yet some designs were effective, and that is all a grunt ever asked for. One such example is the Volksgewehr, or People’s Rifle, design from the German firm Gustloff Werke (Suhl), the VG 1-5.

Careful study of improvised and quickly manufactured weapons designs naturally brings the Volksgewehren and the Volkspistole (People’s Pistols) of World War II Germany into sharp focus. Material losses during the war combined with the need to arm domestic home guard units meant that manufacturers needed to produce great numbers of cheap and quickly built firearms. Several prototype firearms were developed under this program. Nearly all of these designs were crude and ugly, but they worked and were cheap and that is all that was required.

In the last few months of 1944, the German High Command urgently needed to replace the great volumes of weapons lost on the Eastern Front. There was a simultaneous demand for cheap firearms for irregular territorial defense troops, the Volkssturm (Home Guard) and others. At this stage of the War, most weapons plants could no longer cope with the demand for quality weaponry, such as the Mauser Infanteriegewehr 1898 rifle, the Walther P.38 handgun or the older Luger P-08. So various firms began to design firearms from the ground up which could be made quickly, simply and cost effectively. Critical to the design of any full-powered rifle or pistol was how to delay the opening of the breech long enough for the residual chamber pressure upon firing to lower to safe limits. This is not a problem in locked breech firearms like the Walther P.38 or those within the Browning family, since recoil unlocks the barrel from the slide assembly after the bullet leaves the muzzle. It is not a concern in a bolt action rifle or in a submachine gun either, the latter usually using bolt mass and spring strength to effect a delay. To solve this perplexity, various engineers began to look at something entirely new. They tapped a minute portion of the expanding gases of discharged ammunition to momentarily delay opening. On that account, the first gas-delayed blowback firearms came from the weapons factories of Nazi Germany.

Theory of Gas-Bleed Delay

The theory behind the ‘gas-bleed delay,’ is that part of the gas propelling the bullet seeps through ports in the barrel to impinge on the inner surfaces of the slide (or reciprocating cylinder). The breech stays closed until the bullet has passed from the muzzle, by which time, the pressure has dropped sufficiently to allow the breech block to move rearward in normal blowback manner. The breech block is not positively locked during the entire duration of the bullet’s passage up the bore. It is essentially a blowback system in which the rearward movement is momentarily delayed.

Several drawbacks of the design were identified early: first, the slide/barrel contact point required rather close tolerances or the gas would escape, making it blowback action, something it was not designed to be. Second, gas residue soon fouled the inner wall and plugged the gas port and needed frequent cleaning. Third, case warping and splits and rim separations occurred since there is a possibility of the bolt moving backwards while the case is still expanding against the chamber wall by gas pressure.

From an engineering perspective, overcoming the last problem is achieved by “fluting” the chamber, whereas thin grooves are cut longitudinally from in front of the case mouth to about one third of the case length from its base. Fluting is adopted to allow high-pressure gas to flow outside the case and thus ‘float’ it on a layer of gas and reduce friction during the initial movement of the bolt. The process prevents the cartridge case from sticking to the walls of the chamber on extraction but as a result, the mechanism is fouled to a black color after firing.

The evolved gas-delay system worked well in pistol form and could even function with the stout 7.92mm Pist. Patr. 43 ‘intermediate’ rifle round moving at 2150 fps! The German gas-delayed blowback VG 1-5 semi-automatic rifle was part of the Primitiv-Waffen-Programm of 1944 and was intended for the Volkssturm troops.

VG 1-5 Semiautomatic Carbine

The history of the VG 1-5, an arm made at Gustloff Werke (Suhl), is rather elusive because not many documents concerning it or actual weapon specimens survived the war. A letter to Suhl regarding the VG 1-5 exchanged hands many times before Elke Weiss, representative of the Suhler Jagd- und Sportwaffen GmbH weapons firm wrote:

“All materials about military guns and materials that were produced during the war in the Gustloff Werke were destroyed after the war. Since 1948 hunting guns and rifles have been produced in the former Gustloff Werke – now Suhler Jagd- und Sportwaffen GmbH so that we do not have a close connection with (the) military.” There ends the official trail.

What is known is that the VG 1-5 can be termed in various ways: “Selbstladegewehr”,“Selbstladekarabiner”, “Volkssturmgewehr 1-5”, “Volkssturm-Maschinenpistole45”, “Gustloffvolkssturmgewehren”, “Volkssturm-Selbstladegewehr, Gustloff-Werke”, “Selbstlader mit Kurzpatrone 44”, as well as the “Versuchsgerat 1-5.” [EDITOR: The ‘a’ in the last word, gerat, has double dots over it, an ‘umlaut’.] Note that the Volkssturm weapons were never adopted or assigned official nomenclature. The simple term “Volksgewehr” was used by the Germans as a general reference and the various other names were applied after the war.

At the time, perhaps about 10,000 of the semiautomatic carbines were manufactured for civilian resistance use. Today, the VG 1-5 is exceedingly rare and is primarily found only in noted arms museums. It is not known how many remain in private collections. What is known is that a VG 1-5 Title 1 deactivated war trophy was recently advertised in this magazine for $8200 – certainly not a cheap piece. Originally, the Volkssturm drew the bulk of its weapons from materiel captured by the Wehrmacht, but soon that supply was exhausted. In response, German industry showed remarkable resourcefulness by manufacturing serviceable weapons from basic materials and eminently simplified production techniques. Machining and heat treating was kept to an absolute minimum and steel tubing and pressed metal with welding, pins and rivets were used for component assembly. The alternate weapons program was initiated to field basic shoulder arms chambered for both the 7.92x57mm long cartridge and the 7.92x33mm short (Kurz) cartridge. The designs included single-shot and magazine-fed bolt-action rifles and semiautomatic carbines. Participating weapons firms included Appel, Berliner-Spandau; Bergmann KG, Velten; Gustloff Werke, Suhl; Walther, Zella-Mehlis; Deutsche Industrie-Werke AG, Berlin; Rochling, Wetzlar (Coenders); Berliner-Lubecker Maschinenfabriken; ERMA, Haenel, Hessische Industrie-Werke, Mauser, Rheinmetall-Borsig, Ruhrstahl, Spreewerk and Steyr.

Early development efforts climaxed during the autumn of 1944 and the weapons were demonstrated to Adolf Hitler during November 1944, according to Albert Speer’s writings. Among the models demonstrated to the Fuhrer “leader” [EDITOR: Fuhrer always has an umlaut (double dots) over the u] was a retarded blowback self-loader for the Kurz cartridge, with a 30-round magazine, a model from the Gustloff Werke, Suhl.

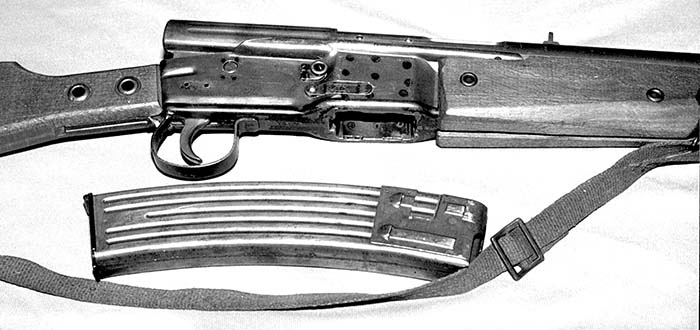

Karl Barnitzke, the chief designer at Gustloff Werke, designed the VG 1-5 to feature a barrel permanently assembled to the receiver. A sheet metal design, the receiver was formed in separate halves and then welded together. Surrounding the barrel and extending behind it over the receiver is a thick-walled, machined operating cylinder (.175-inch-thick, 15.5-inch-long steel tube, approx. 1.420-inch in diameter.) At its front, the cylinder is closed by a long cylindrical collar. To the rear, a half-cylindrical bolt is pinned directly to the long cylinder and a recoil spring is mounted around the barrel. The operating cylinder reciprocates and carried the bolt with it. Upon firing, normal blowback action begins until combustion gas escapes through four radial gas ports in the barrel 2.5 inch behind the muzzle to act upon the forward cylinder collar. This gas is trapped in the space formed by the operating cylinder collar and the barrel. The gas pushes forward against the collar and rearward against a shoulder on the barrel, thus retarding the opening of the action. After one-inch rearward travel, the ports are exposed and normal blow-back continues. Loading is achieved by the returning recoil spring.

After examining each firearm, Hitler rejected all single shot models and indicated that the VGs should have a magazine of about 10-rounds to facilitate prone position shooting. The longer 30-round MP 44 magazine was not to be used. The Gustloff self-loading model was snubbed by Hitler due to its expense, excessive ammunition consumption and because the MP 44 was already in production with about the same use of material and cost.

Indeed, while workable, the VG 1-5 was never highly regarded compared to the MP 44. There is no reliable information concerning the field performance of the VG 1-5, but it is assumed that it suffered from the most typical problem of gas-delayed blowbacks – fouling. Since it was machined to somewhat close tolerances, unless the surfaces were habitually cleaned and carefully lubricated, the combined effect of accumulating gas residue and barrel expansion would occasionally cause the weapon to jam. Yet the VG 1-5 did work and it is likely that Allied Intelligence reports would have declared that it was “presumed to be effective.”

Post-War Developments

Much has changed since some of the first German designs were field tested. Today the wartime method of breech locking, using expanding cartridge gas to delay a blowback action, has become accepted by several noted military and police forces.

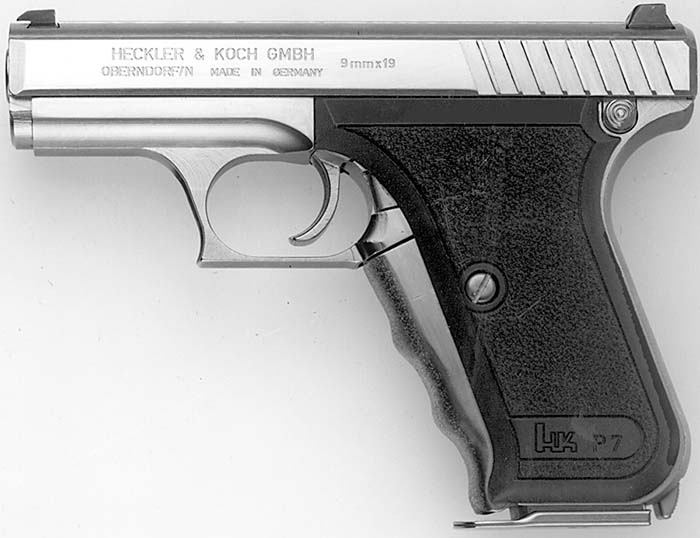

Following the war, gas-delayed rifles were mostly abandoned but other forms of mechanically delayed blowbacks were attempted, all of which used W.W.II German technology and experience in one form or another. Early post-war variants of the delayed blowback system included the Spanish Fusil d’Assalto Cetme Modelo 58 7.62x51mm NATO, the French AAT modele 52 7.62x51mm machine gun, and the Swiss Sturmgewehr Modell 57 7.5x54mm rifle. To illustrate how war-time innovation carries on to date, take a look at the French 5.56x45mm FAMAS “bullpup” rifle. It is a delayed blowback that uses a fluted chamber, and the same can be said about the German G3/HK33/MP5 family. Since the War, the gas-delayed blowback pistol design has continued with several modern entries. They have overcome the aforementioned drawbacks of gas-delayed designs in various ways, including fluted chambers, an insistence on jacketed ammunition (never lead bullets), and precise, quality manufacturing. In fact, the manufacturing practices and standards for gas guns are the same as those for conventional designs. The newest gas guns are both reliable and generally inexpensive to produce, something the original German engineers vigorously sought after.

These include the Austrian Steyr Model GB, the German Heckler & Koch P7 variants, Network Custom Guns’ M1911 drop-in gas gun conversion kit, the Heritage Manufacturing Stealth pistols, and the South African Du Plessis ADP pistols. These designs will safely fire 9x19mm subgun ammo and the newer and hotter .40 S&W rounds. Indeed, so successful has been the P7 entry that it has become standard issue to several military and police units including the armed forces of Germany and the New Jersey State Police. Further, the P7M13 (high capacity version) was initially a candidate for the Joint Services Small Arms Program in the early 1980s as a replacement for the older .45 ACP service pistol. That is, however, another story.

The VG 1-5 gas guns certainly started out on the drawing board as a cheap improvised design, but it has nevertheless earned its place in weapons history. Its collectability is as unquestioned as the certainty that firing this rifle with its unlocked breech would have been infinitely more dangerous to our GIs than to its user. Author’s note: I would like to thank Z. Frank Hanner, Andrew Phillpotts, Steve Galloway, Elke Weiss, Randall Sinclair and Peter Kearns for their considerable help in compiling graphics and data for this article and for its critique.

Editor’s note: Warren Ferguson is a former Weapons Technician with the Canadian Army’s Electrical Mechanical Engineers and is now a freelance writer. He can be contacted at: wfpaddy@hotmail.com.

References

Hogg, Ian V. and Weeks, John. Military Small Arms of the 20th Century, 5th ed. DBI Books, Inc., Northfield, IL, 1985. Markham, George. Guns of the Reich: Firearms of the German Forces, 1939-1945. Arms & Armour Press, London, U.K., 1989.

Senich, Peter R. The German Assault Rifle 1935-1945, Paladin Press, Boulder, CO, 1987

| This article first appeared in Small Arms Review V3N3 (December 1999) |