By Frank Iannamico

The silencer (suppressor) business is booming (pun intended). In the last few years the sale of suppressors has increased dramatically. Suppressors have become so popular that many mainstream manufacturers are now offering their firearms with threaded barrels right from the factory. Sound suppressors have been around since the device was invented by Hiram Percy Maxim (son of machine gun inventor Hiram Maxim) in 1909. The original intent of the sound suppressor was to engage in sport shooting, without the associated muzzle blast. This was desirable before the widespread use of hearing protection. Sales of Maxim’s “silencers” were unrestricted; they could be purchased right over the counter at the local hardware store, or by mail order. Before long, the innocence, and original intent of the “silencer” was lost. Over publicized use of suppressors by criminals led the general public to believe that their only purpose was criminal and only criminals had them. Hollywood has perpetuated this myth by depicting the illegal use of “silencers” usually by assassins in the movies.

Why would anyone want a sound suppressor? A common question usually posed by those who are not firearm enthusiasts. There are a number of reasons: With the ever expanding urban sprawl there are less and less places to shoot without disturbing those in the surrounding areas. There is a far less chance of hearing damage for the shooter and bystanders. A suppressor is great for first time shooters, who are often intimidated by the loud report of a firearm and they are cool. To borrow a phrase often used by a certain group of motorcycle enthusiasts is; “If you have to ask, you won’t understand.”

As the interest in sound suppressors has increased, so has the number of companies springing up to provide them. In the end the winner is the consumer, as engineers and designers continually strive to improve their products to get one up on the competition. Modern suppressors are smaller, lighter and quieter then those made just a few years ago. Gone are the days of early suppressors that used “wipes” that lasted only a few rounds before needing replacement.

Up until recently many manufacturers concentrated on producing sealed, non-serviceable units. The reason was two-fold, for one it is not legal to possess any individual suppressor repair or replacement components, second an improperly assembled suppressor could result in damage to the unit and/or the shooter. However, due to customer demand many manufacturers have conceded and have begun to manufacture user-serviceable suppressors. Most manufacturers’ suppressor internals have been designed to be taken apart and reassembled with little chance of being put back together incorrectly. One caveat on suppressors that can be disassembled; if the suppressor is not routinely disassembled and cleaned according to the manufacturer’s recommendations they can be quite difficult, if not impossible, to take apart due to excessive carbon build up. This is especially true of .22 caliber suppressors.

First Round Pop

It doesn’t take long, particularly with subsonic ammunition, for the new suppressor owner to discover that the first round fired from his suppressed weapon is somewhat louder than subsequent rounds. This phenomenon is commonly known as “first round pop.” This will only register 2-4 decibels on a good sound meter, but since decibels are logarithmic rather than linear, the sound generated can be quite noticeable to the human ear. What causes first round pop? There are a lot of theories, but a plausible explanation is the presence of cool oxygen in the suppressor and the barrel. Once a cartridge is fired the oxygen is burned up and temperature in the barrel and suppressor is increased, thus subsequent rounds fired are quieter due to the lack of oxygen. Let the suppressor cool down and the first round pop will reappear. The cure: generally first round pop is not a serious concern to most shooters, but it can be substantially reduced by the introduction of an inert gas into the suppressor. The inert gas commonly used in most compressed air cans used for cleaning computer keyboards will work. A piece of tape placed over the end of the can will usually keep the gas inside the can for a time, but to be safe remove the tape just prior to firing.

Ammunition

For a suppressor to be effective the bullet’s velocity must not exceed the speed of sound. At an ambient air temperature of 70 degrees Fahrenheit the speed of sound is (approximately) 1,128 feet per second. The speed of sound is affected by temperature, at 30 degrees Fahrenheit the speed of sound is reduced to 1,085 feet per second. Some ammunition commonly used with suppressors is inherently subsonic, like 230 grain .45 caliber ACP and .380 caliber. Other calibers commonly used like 9mm are not, and special subsonic loadings must be used. Because of the increased popularity in .22 caliber suppressors there are now a growing number of manufacturers that offer special subsonic .22 caliber ammunition.

New Sounds

When firing a suppressed firearm for the first time the shooter will experience some unfamiliar sounds not previously heard: the sound of the bullet impacting the target, the action cycling and occasionally the sound of a bullet ricocheting. Firing a suppressed firearm will seem quieter in an open field than in an enclosed room or near buildings. If a bullet goes supersonic the sound of the bullet breaking the sound barrier will be heard.

“Wet” Sound Suppression

Introducing a small amount (5ccs or less) of a ablative material such as water, wire pulling gel, grease or similar coolant into the baffle stack of a pistol caliber suppressor will help cool the hot expanding gasses and make a suppressor more efficient (quieter), it may also reduce or eliminate “first round pop.” The down side is that it can be quite messy, and could damage the internal components. As always you should first consult and follow the suppressor manufacturer’s recommendations. Due to the high pressure encountered in rifle caliber suppressors firing them wet is usually NOT recommended.

Barrel Threading

To attach most suppressors to a firearm the barrel must be threaded to match the female threads on the end of the suppressor. Barrel threading involves much more than simply running a die over the end of the barrel. The problem is the bore of many barrels are not perfectly concentric with the outside diameter. This could cause the bore to be misaligned with the inside of the suppressor, resulting in a bullet striking the baffles and damaging the suppressor. To do the job properly the barrel must be set up and threaded on a lathe by an experienced gunsmith. A thread protector is also needed to prevent the threads from being damaged when the suppressor is not attached. There are also thread adapters available to attach a suppressor that may have different threads than your barrel is threaded for. However, be sure to be aware of the manufacturer’s ammunition recommendations and limitations for any particular suppressor model.

There are suppressors available made for just about every conceivable application from .22 caliber rimfire to .50 BMG caliber rifles. However, the most popular models are those designed for rifles and handguns chambered for the .22 rimfire round.

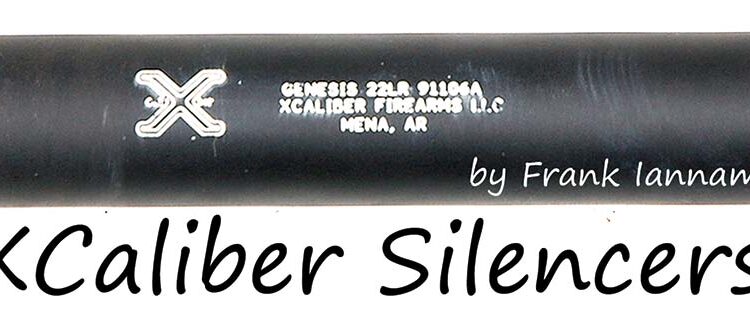

One of the latest entries in the popular .22 caliber rimfire suppressor arena is the XCaliber Genesis available in several configurations from the Silencer Store. The Silencer Store is owned and operated by the same folks that host the popular internet site www.silencerresearch.com that offers unbiased comprehensive suppressor testing and comparisons.

XCaliber Genesis All Stainless .22LR Silencer Line

XCaliber .22 caliber suppressors are designed to be easily disassembled for cleaning by the end user. They are also designed to have minimal or no first round “pop.” All suppressors come with a custom Battle Cloth pouch with belt loop and two disassembly tools. Currently there are three different models to choose from.

XCaliber Genesis Stainless .22 Caliber Suppressor

The Genesis All Stainless Silencer can safely fire a number of rimfire cartridges including .22 caliber Long Rifle, .17 caliber Hornady Magnum, .22 Winchester Rimfire Magnum, and the .17 caliber Hornady Mach 2. The stainless steel model is also full-auto rated for use on .22 caliber machine guns. The suppressor’s all stainless design allows for more aggressive cleaning methods than softer aluminum. Also, the stainless tube is less likely to be damaged if dropped or mishandled. According to the manufacturer, this model consistently measured 116-117dB on several popular hosts like the Walther P22, and Ruger MK3 pistols firing CCI Standard Velocity .22 caliber ammunition. CCI Standard is advertised as having a muzzle velocity of 1070 feet per second. Made of 300 series stainless steel, the Genesis stainless steel suppressor has an overall length of 5.5-inches and weighs 7.7 ounces.

XCaliber Genesis Aluminum .22 Caliber Suppressor

The Genesis Aluminum suppressor is manufactured primarily of aluminum for light weight. The internals are made of 7076T6 aluminum, with a 6061 aluminum outer tube. The rear endcap and blast baffle are made of 300 series stainless steel. The aluminum internal components are Type III hard-coat black anodized. This model is designed for use with .22 caliber Long Rifle, .22 Magnum and .17 Hornady Magnum cartridges. The suppressor has an overall length of 5.5 inches and weighs 3.9 ounces.

XCaliber Genesis Lightweight Micro Aluminum .22 caliber Suppressor

The Genesis Micro Aluminum suppressor endcaps and internals are manufactured entirely of 7076T6 aluminum. The outer tube is made of 6061 aluminum. All internal components are Type III hard-coat black anodized. The suppressor is also available with an optional stainless blast baffle. This suppressor also has virtually no first round pop and must be fired wet for maximum effectiveness. This suppressor is only 3.6 inches long and very light in weight at less than 2 ounces. The Genesis Micro suppressor is for those seeking the ultimate in compactness and light weight. Included with the unit is a bottle of UltraQuiet gel.

All XCaliber suppressors come finished with a durable flat black moly-resin finish at no charge. Colors available at extra cost are flat dark earth or OD green.

When cleaning suppressors and internal components be sure to always follow the manufacturer’s recommendations. Many of the popular firearm cleaning solvents available will damage materials like aluminum. Due to .22 caliber rimfire ammunition being inherently dirty, user-serviceable units are quite popular. However, some units can be very difficult to disassemble if neglected for too long.

In addition to their .22 caliber suppressors, XCaliber offers rebuild-upgrade services for some competitor’s suppressors, thread adapters, thread protectors, and AR-15 style receivers. XCaliber’s future plans include offering suppressors in 9mm and .45 ACP.

XCaliber firearms is based in Mena, Arkansas and is owned by Jonathan Lunsford and John Titsworth. Jonathan has over 20 years experience in computer numerical control (CNC) machining and manual machining. He is also the head machine tool technology instructor at Rich Mountain Community College. John Titsworth is also a trained machinist and firearms expert with many years of experience in firearms sound suppressors and testing. He currently owns and operates the website www.silencerresearch.com. The testing of hundreds of suppressors for the website inspired the design used in the XCaliber suppressor line. John also has several articles published with national magazines and has done consulting work for the military and other government agencies.

Visit the Silencer Store website for more product information and videos of their suppressors in action.

| This article first appeared in Small Arms Review V17N3 (September 2013) |