By Mark Genovese

In October of 2003, Zastava Arms of Yugoslavia, whose factory is located in Kragujevac, Serbia, celebrated its One Hundred and Fiftieth Anniversary. SAR was there, along with many luminaries of the small arms community including General Kalashnikov. Their longevity surpasses even Beretta by twenty-five years. In 1853 the Kragujevac Gunfoundry cast their first six muzzle loaded bronze cannons under the watchful eyes of Duke Milos Obrenovic, founder of the Kragujevac Gunsmith’s shop- presently known as Zastava Arms. These were proudly engraved with the Serbian Coat of Arms. This amazingly resilient business managed to survive three major wars, several revolutions, and countless crises, both natural and man made. The binding force driving this dynamic company was and is the workers, who have strived to perfect the gun making tradition, and have handed this down from generation to generation.

In the period from 1928 to 1940 everything from artillery, mortars and hand grenades of German, French and British design, to sub caliber training devices, were manufactured. Modern caliber upgrades of the various small arms and rifles seized as war booty was also carried out. Machine gun calibers such as the French Chauchat 8x50R Lebel CSRG M15 light machinegun and the Austrian 8mm Schwarzlose were converted to 7.92×57 Mauser and the same was done to the Serbian 7mm M1909 and Bulgarian 8mm M09 Maxim machineguns. Domestic designs of the M33 universal machinegun tri-pod with anti-aircraft extension and optical scope are compatible with all 7.92mm machineguns that were developed.

By April 6, 1941 Kragujevac Gunfoundry, renamed Military Technical Works, was the largest industrial behemoth in Europe with 12,000 employees, 10,000 machine tools and working assets of 2 billion Dinars. Five days later on April 11, all that changed as elements of the 11th German Armored Division entered the complex and initiated their plan to absorb the firm into the German Military Economic Headquarters under the control of “Herman Goering Werke”. By August 1941, 2,500 qualitative machine tools were liberated/stolen in the name of the Reich and transported back to Germany; the rest were sent to the waste materials yard and the buildings were destroyed. Kragujevac was liberated on October 21, 1944 and the next day 300 former employees gathered amongst the destruction found 82 machines, formed working brigades and spent the next ten years reclaiming their destiny.

In 1954 the factory started the assembly of 162 American Willy’s jeeps and began production of 2,000 air rifles and 1,000 .22 caliber rim fire rifles; ready and eager for free market capitalism. In the following years a commercial line would emerge to include sporting rifles in calibers .22 LR to the powerful magnum loads, over-under, side by side and pump shotguns, the acclaimed CZ pistols and high end revolvers. New technologies continued to be introduced to the factory in the following decades. Barrels with hard chromium plating and zinc phosphate parkerizing were introduced in 1984. In cooperation with the Yugoslavian military and closely working with the Special Purpose Products Factory, they mastered the design of the semiautomatic rifle and a family of automatic Zastava (FAZ) weapons. Several generations of sniper rifles culminating with the outstanding M76, the long range 12.7mm ARM rifle and the M93 automatic grenade launchers are manufactured as well. A complete and in depth photo review of the Military program available through Zastava Arms can be found in Small Arms Review Vol.7, No.3, December 2003.

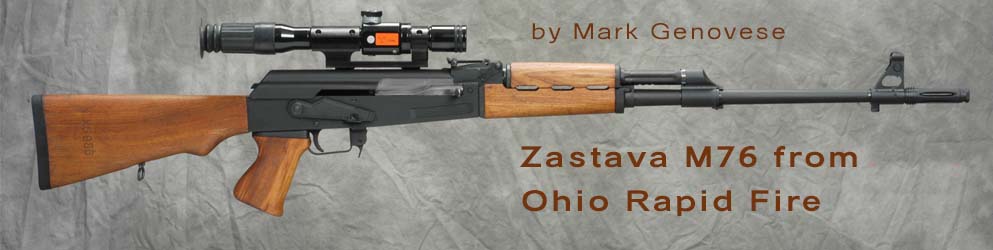

THE RAPID FIRE 8MM M76

Life started in the United States for the Zastava M76 as a stand alone import in 1986 when Mitchell Arms of California brought in and sold approximately 400 pre-ban rifles. More then a decade would pass before 2,000 more were imported by P.W. Arms of Redmond, Washington and then sold to SOG International of Lebanon, Ohio. Within twelve days these outstanding firearms sold out, a testament to their value and quality. Even though all the paper work was in order, a sample submitted and a form six import license granted, six months later the BATF declared it a machine gun as defined in 18 U.S.C. Chapter 44. It appears a third hole and pin in the receiver contained a safety sear. Consequently, all 2,000 firearms were returned torch cut to BATF specifications and the customers’ money refunded.

It was at this time that the young, ambitious and very talented Mr. Todd Grove, owner of Rapid Fire from Troy, Ohio would put his skills and newly acquired half million dollar ultra modern CNC machines to work on the first of the fifty original M76 kits. The new M76 started life as a twenty-six pound billet of 4140 and included several hundred meticulous machining operations that included a dovetail scope rail on the left side of the receiver (the original rail was riveted on). After a complete inspection of the completed machined receiver, it is heat treated to a Rockwell hardness of 40-45; a mandatory and logical step considering the power of the 7.92×57 Mauser cartridge and the Kalashnikov twin lug bolt design.

There are numerous dimensional differences between the M76 8mm and a conventional Kalashnikov 7.62×39. The 8mm receiver is 11 inches and the 7.62×39 at 10-1/4 inches; the 8mm gas tube is 8-3/4 inches and the 7.62 at 7 inches; the 8mm bolt carrier is 8-1/2 inches and the 7.62 is 7-1/4 inches; the 8mm gas operating rod, made by Rapid Fire, is 7 inches with three gas ring grooves and the 7.62 is 5-3/4 inches with two grooves; the 8mm bolt is 4-1/4 inches with two 2-1/2 inch lighting cuts while the 7.62 is 3-1/4 inches and the rather thin profiled barrel is 21-3/4 inches long and is not chrome lined.

The M76 trigger group, manufactured by Red Star Arms of Columbia, Missouri is completely adjustable with four Allen heads in strategic locations: one to limit the amount of travel between the first and second stage of the two stage trigger; one to adjust the weight/pull of the second stage trigger; one to adjust the disconnector engagement and one for over travel. Readers can find an in depth review of this wonderful trigger set-up in SAR Vol. 6, No. 11, August 2002, page 58.

There is a very effective recoil buffer that is attached to the rear of the recoil spring. The front sight base with bayonet lug appears to be machined from solid billet and is 4-3/4 inches long and includes the M14 style flash suppressor and adjustable sight post. Unusual is the MAC 10 style coarse, left hand interrupted threads at the base of the flash suppressor. With such a thin profiled long barrel and the size of the suppressor necessary to effectively lower the decibels of the Mauser round, it just didn’t make sense. A possible logical alternative would have to be some sort of blank firing attachment. The simple and finely machined gas bleed tower is fully adjustable with three settings. It functions as a cylindrical barrel within the gas tower and the operating rod fits within it. The cylinder has three gas holes marked 1, 2 and 3 (small, medium and large) and can be rotated to accommodate specific ammunition. Being a sniper rifle with only a ten round magazine, it is hard to imagine getting it so fouled one would need to increase the gas setting to allow proper functioning. If one does want to adjust it in the field, first the scope and it’s mount must be removed and a complete disassembly down to removing the gas tube is mandatory. All of the M76 components appear to be engraved, not stamped, with the firearm’s serial number. The wood furniture looks to be a light color teak with an oversized and very comfortable pistol grip and an effective rubber shoulder pad. Overall, the machining of the receiver, the parts kit used in its assembly and the finish to be of the highest quality.

The RFM76 was delivered in an outstanding Gun Guard of Arlington, Texas, roll around rifle case. Accessories included two ten-round magazines, a unique military rucksack to hold the magazines and the cleaning kit, a bayonet/wire cutter and sheath, a military fixed four power scope and solid aluminum mount specifically designed for this rifle and marked ZRAK 8344094 ON-M76B with it’s military style carry bag. Unfortunately, no manual for the rifle or the scope was included.

It appears that Zastava Arms offers two distinct M76 models. Their civilian glossy sales catalog lists an M76 with selected walnut stocks, blued, a completely different civilian type hunting scope, a less robust scope mount and no matching numbers. As delivered, my scope mount required considerable hand fitting before it was possible to fully engage the receiver rail though this does ensure a tighter fit over a factory loose unit. The Red Star adjustable trigger will require tweaking as well to individual requirements. Todd at Rapid Fire tests all M76s leaving the shop with a minimum of ten rounds and a maximum twenty rounds of PMC 170-grain pointed soft-point ammunition.

Test firing was at Ukumehame shooting range on the Lahaina side of the beautiful island of Maui, using 24 inch by 1inch thick square steel target at a distance of 235 yards. Ammunition used was 100 rounds of 1955 surplus Yugoslavian and 100 rounds of 1972 steel cased surplus Romanian. Occasional failures to fire with the 1955 Yugoslavian ammo was expected because of its rock hard and deeply set primers, with one out of thirty or so the norm. The 1972 Romanian was one hundred per cent sure fire. Out of the case with the scope set at zero and one notch before zero, this absolutely phenomenal military semiautomatic, using aged surplus full metal jacket, was consistently capable of 1-1/2 to 2 inch groups slightly high and slightly right. A paper target was set up at 100 yards to get a closer look at it’s performance and found the groups tightened up to 1 to 1-1/4 inches using just sand bags with a 2 mph off shore breeze and overcast. With the gas-bleed factory set at 2, this weapon violently throws the spent brass right and rear at least 30 feet and have since lowered the gas setting to 1.

A high-end Kalashnikov, this phenomenal rifle is a joy to own and operate and will satisfy the most discriminating shooter.

| This article first appeared in Small Arms Review V8N12 (September 2005) |