By Frank Iannamico

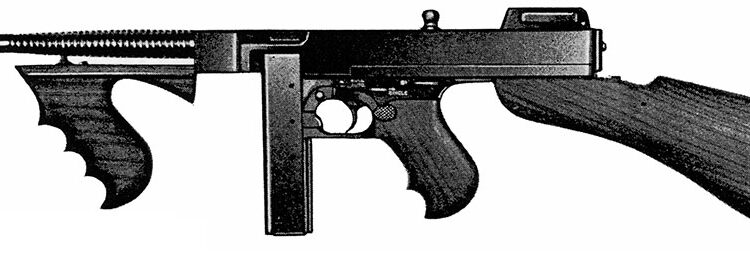

The Savage Arms Corporation, who originally developed the M1 version of the Thompson, had continued attempts to further simplify the design by experimenting with a fixed firing pin model they designated as the M42. The prototype M42 was originally fitted with an M1 bolt with a separate firing pin, but the pin was secured in the bolt in a manner that made it a non-moveable part. The firing pin was fixed in an extended or “in battery” position. The firing pin, spring, hammer, and hammer pin were omitted. Less than 100 M42s were produced before the “fixed” separate firing pin was completely eliminated and replaced by a projection machined directly on the bolt face.

In September of 1942, Aberdeen Proving Ground was instructed to test “A modified version of the M1 submachine gun, that eliminated the firing pin, firing pin spring, the hammer and hammer pin”. The four parts were eliminated from the design by making the firing pin an integral part of the bolt. Tests at Aberdeen indicated that the M1 submachine gun equipped with a fixed firing pin functioned slightly better than the standard M1 submachine gun. It was also noted that the fixed pin design saved considerable manufacturing time and that the bolt was strengthened by elimination of the deep drilling operation necessary to accommodate the firing pin and spring. The Springfield Ordnance District was notified that manufacture of a fixed firing pin bolt for use in the M1 submachine gun was authorized. In order to distinguish between submachine guns equipped with separate firing pins and fixed firing pins, the submachine guns fitted with the fixed firing pin would be designated as Gun, Submachine, Caliber .45, Thompson M1A1. It was also noted that the bolts with and without the fixed firing pin were interchangeable. The M1A1 Thompson was formally approved at an Ordnance Committee meeting held on 29 October 1942.

In 1943, Auto-Ordnance ordered from the Savage Arms Corporation under contract G-19, 100,000 Thompson Submachine Guns M42-M1A1 type without magazines, slings or other accessories. The contract specified “Savage agrees to manufacture said guns in accordance with the United States Government specifications which are identified as AXS-725 (revision 3) dated 7 January 1943 except each of the following parts are to be incorporated in the gun. These parts shall not conform to said government specification but to the Savage, Auto-Ordnance or United States drawing number placed after the part name”. All of the parts specified had been redesigned to require less labor hours in their manufacture. The design of the M1A1 along with the redesign of many other parts for faster production had reduced the time required to manufacture an M1A1 by 10.11 hours over the earlier M1928A1 model.

Early M1A1s were equipped with many parts that were originally manufactured for use on the 1928 and M1928A1 Thompson. These parts were generally used until the supply was depleted. An example of such parts usage was; the uncheckered paddle style rocker and safety levers, the milled steel mount for the foregrip and the M1928A1 type magazine release catch. When the Thompsons were being built there was little attention paid to getting “correct” parts in the weapons. Often a mixture of new and old design parts were used in the manufacture of the M1A1 Thompsons.

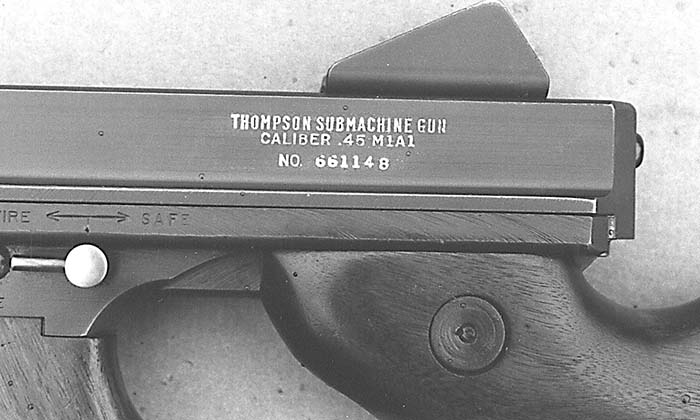

The M1A1 weapons that the Savage and Auto-Ordnance factories produced were identical in appearance and specification, and all parts were completely interchangeable. Unlike the 1928 Thompsons, the manufacturer’s initials, AO or S, were not used as a serial number prefix on the M1 or M1A1. To identify who made a particular M1 or M1A1 Thompson, the manufacturer stamped their code letters on the bottom of the receiver where the front grip mount is fitted. The letters used were S, which indicated Savage manufacture, or AOC for weapons made at the Auto-Ordnance’s Bridgeport plant. As on the previous M1928A1 model, the Auto-Ordnance Corporation name and Bridgeport address is present on the receiver’s right side, regardless of who actually manufactured the weapon. The patent numbers seen marked on 1928 and M1928A1 models were not stamped on the receivers of the M1 and M1A1 weapons. Another change noted in the M1-M1A1 Thompson was the spelling of the word caliber on the receiver. The word was changed from the early spelling of CALIBRE to the U.S. recognized spelling CALIBER.

Another method of identifying the particular manufacturer of an M1 or M1A1 Thompson is by the Army Inspector of Ordnance’s initials stamped on the receiver. M1 series Thompsons produced at the Auto-Ordnance plant in Bridgeport, Connecticut would have the acceptance stamp of the AIO of the Springfield Ordnance District. Very early M1s would have the stamp WB of Colonel Waldemar Broberg on them. Later production would be marked with the GHD stamp of Colonel Guy H. Drewery, GHD. The GHD initials were often stamped near the logo on the left rear side of the receiver.

Savage manufactured M1 and M1A1s would have been stamped with the Army Inspector of Ordnance’s initials of the Rochester, NY Ordnance District. AIOs of the Rochester District were Lt. Colonel Ray L. Bowlin using stamp RLB, and Colonel Frank J. Atwood using his FJA stamp. These were usually stamped near the magazine well on the left side of the receiver. A few early M1 models were stamped with Colonel Bowlin’s RLB stamp, while the majority of the Savage M1 and M1A1’s were stamped with Colonel Atwood’s FJA mark. While the Inspector of Ordnance’s initials appear on the weapons, subordinate officers and their team of inspectors conducted the actual inspection process. All Savage M1 and M1A1 submachine gun receivers and frames were also marked with the encircled GEG acceptance stamp of Auto-Ordnance’s civilian inspector George E. Goll.

Both the M1 and M1A1 models had their serial numbers roll marked on the left rear side of the receiver and a matching number was marked on the trigger frame. The trigger frame number is usually located on the bottom of the trigger guard. Like the 1928 and M1928A1 guns, the M1-M1A1 receivers and frame were originally matched and fitted at the factory, but purely for cosmetic reasons. A mismatched frame-receiver is fairly common and has no bearing on the proper functioning of the weapon. There have been many M1A1 trigger frames documented that did not have serial numbers stamped on them. The practice of placing a duplicate receiver serial number on trigger frames ceased in January of 1943 as per specification AXS-725. However, the practice of selective fitting of frames to receivers still was performed at the factories.

There are some interesting differences in the markings on M1 and M1A1 Thompsons that vary between the weapons manufactured by Savage Arms and those made by Auto-Ordnance, Bridgeport. On trigger frames of Savage manufacture, the words FULL AUTO are marked on two lines, while on Auto-Ordnance frames the words FULL AUTO are on one line. Some of the M1A1 Thompsons were marked US PROPERTY on the receiver just behind the rear sight. On Savage produced weapons the letters US are stamped on one line, and the word PROPERTY is on a second line underneath it. The US Property stamp was marked to be read from the rear of the receiver. On Thompsons of Auto-Ordnance, Bridgeport manufacture the US PROPERTY was roll marked on one line and was marked to be readable from the front of the weapon. Not all M1A1 Thompson guns had the U.S. Property stamp on them, the reason for this is not known for certain, but one possible explanation could be that those stamped with U.S. Property markings were destined for the Lend-Lease Program. One of the requirements of the Lend-Lease program was that the weapons provided through the program be U.S. marked. There were no early M1 models documented or examined by the author that were U.S. Property marked.

One other minor difference between the early M1 and later M1A1 Thompson’s is the configuration of the receiver. On M1’s the back end of the receiver was squared off and has somewhat sharp edges, while the M1A1’s studied had rounded edges at the rear of their receivers.

On many M1A1 Thompson guns manufactured at the Auto-Ordnance, Bridgeport plant the A1 designation appears to have been added by hand stamping. This has led many collectors to believe that these were originally M1 weapons, which is true in part. The Auto-Ordnance, Bridgeport facility had a difficult time when changing over from M1928A1 to M1 production, resulting in a several month delay in the start of their M1 production run. This delay was followed by another, when the weapons were rejected by the Springfield Ordnance District inspectors, because their full-auto cyclic rate exceeded the specifications. By the time the problems were resolved, and the Bridgeport plant M1 guns were finally being accepted by Ordnance, the M1 had been superseded as Standard by the M1A1 model. Most all of the receivers on hand at Bridgeport had already been roll marked M1, but were upgraded to the new M1A1 configuration by replacing the bolts. This necessitated the hand stamped addition of the A1 suffix on these weapons at the factory.

In January of 1943 the Ordnance Department announced to the Auto-Ordnance Corporation that the Thompson was going to be replaced by the newly developed U.S. M3 submachine gun. After the Ordnance Department’s official adoption of the M3 submachine gun, Thompson production was scheduled to be concluded in July of 1943. Plans were made to begin tapering off production of the weapon. In April 1943 62,948 M1A1 guns were built, this was reduced to 55,000 in May and 51,667 in June. This left only 5,000 guns remaining to be manufactured in July. Authority was then received from the Ordnance Department in June to procure an additional 60,000 weapons by the end of August. Before the end of August more orders for the Thompson were received from Washington. A total of approximately 119,091 additional Thompson M1A1 models were to be manufactured, providing continuance of production through December of 1943. At the end of December there were enough parts remaining to assemble approximately 4,500 additional guns. In January of 1944 authorization was granted to complete the remaining guns by 15 February 1944. Production briefly resumed in February completing a total of 4,091 additional guns. On February 15, 1944 the very last M1A1 Thompson Submachine Gun was accepted by the government against contract W-478-ORD-1949.

There were several manufacturing problems encountered with the new M3 that had caused Thompson production to be extended for several months until the M3 production difficulties could be solved. By the time of the last procurement of the M1A1 Thompson, the price charged to the United States government had been reduced down to $42.94 per weapon.

M1 and M1A1 Thompsons that were manufactured by Savage were originally assembled with parts produced by the Savage or Stevens companies. M1 and M1A1’s manufactured at Auto-Ordnance’s Bridgeport plant were assembled with parts supplied by a variety of contractors.

The Savage Arms Corporation manufactured an estimated total of 464,800 M1 and M1A1 model Thompsons, while the Auto-Ordnance Bridgeport plant turned out an estimated 249,555 M1 and M1A1s.

This article was partially excerpted from the new book “American Thunder, the Military Thompson Submachine Guns”. The book is now available from Chipotle Publishing 702-565-0746

| This article first appeared in Small Arms Review V6N2 (November 2002) |