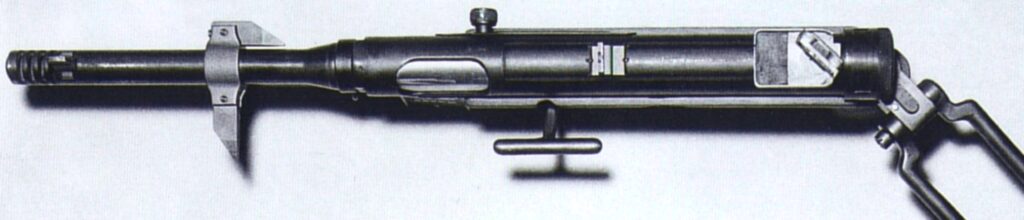

This Beretta model was used as “Maschinenpistole 1” (MP 1) by the Federal Border Guard (BGS) and the German Armed Forces. The triggers are marked in German with “E” (single fire) and “D” (continuous fire). The push-through button in the stock is the safety.

By Michael Heidler

The traditional German weapon manufacturer Carl Walther GmbH became famous for its pistols and sports rifles. The attempts to gain a foothold in other segments as well brought only limited success. Some developments remained only on paper, such as a folding stock with an aiming device for shooting around corners.

After World War II, the new German police and the Federal Border Guard (Bundesgrenzschutz / BGS) received an initial supply of weapons, vehicles and equipment mainly from stocks of wartime production. This included, for example, the Italian Beretta submachine gun, which was formerly manufactured under German occupation. A slightly modified version with a push-button safety incorporated into the wooden stock was adopted as the “Maschinenpistole 1,” or in short “MP 1.”

Like many other business owners, Fritz Walther, Carl’s son, fled from his hometown Zella-Mehlis in East Germany to the West Zone. There he initially manufactured civilian products such as calculating machines and tools before he was allowed to start manufacturing pistols again after Allied restrictions were relaxed in the early 1950s. During this time, a curious development also took place, of which only a few photos in the company archives are still preserved today.

Shooting at an opponent is one thing, but in a gunfight, the opponent shoots back. Therefore, it is generally advantageous to take cover and to expose as little body area as possible. As early as 1944, the Wehrmacht tested a curved barrel attachment for the Sturmgewehr 44, which allowed firing at the enemy from cover. A complicated prismatic sight helped with aiming. However, this device was too heavy, unwieldy to use, and the curved barrel quickly wore out due to the forced guidance of the projectiles. Series production and use in combat were never realized.

Walther now went a different way. Instead of a bulky, curved barrel extension, a special sighting device in combination with a laterally swivelling stock was to provide a remedy. For testing on a submachine gun, Walther used the Beretta which was in German service at the time. The wooden stock was sawn off behind the trigger, and a mount for a folding stock similar in design to the MP38/40 was attached. This mount could also be swivelled sideways.

This was the idea behind the pivoting folding stock: The spike on the barrel hooks into the bark of the tree and helps to aim without wobbling. The right hand holds the weapon by the T-shaped grip, so the shooter can aim from cover.

On the top of the receiver, near the end cap, a pivotable mirror was placed, with which the shooter could take aim via rear and front sights. The resulting higher sight line made it necessary to increase the height of both sights. On the photos it is not visible whether the mirror is connected to the stock joint and pivots synchronously. It would make sense, however. Otherwise the shooter would have to realign the mirror manually with every slight swivel movement of the stock.

Only the small silhouette of the weapon is visible to the opponent. The shooter stays completely behind cover, and only his fingers are exposed.

The posture in a shoot-around-corner firing position is uncomfortable and probably only intended for unusual situations or emergencies. The weight of the loaded weapon of approximately 9 pounds and the recoil forces strain the arm muscles and make accurate aiming difficult. The Walther engineers therefore attached a clamp with two spikes near the middle of the barrel. These spikes can be folded out on the left or right side as required, and the shooter can use them to hook the weapon into the bark of a tree, for example. The spikes, however, only serve as a support and are by no means able to bear the whole weight of the gun alone.

A T-shaped metal grip, which is mounted between the trigger guard and the magazine well, serves as a further aid for the shooter. It can also be swivelled to the left and right and allows the shooter to keep his front hand behind the cover. When not in use, the grip swings to the left side and rests partially in a cut-out in the wooden stock.

View from the top: Note the clamp with the two hinged spikes. The T-shaped grip is folded up on the left side when not in use.

Written documents about this development do not seem to exist anymore, and nothing is known about a trial or even a presentation to police or military officials. Therefore, only three photos remain in the company archive. This purely mechanical device for shooting around corners probably did not prove to be suitable for practical use, and Walther did not follow up on this idea. Today, thanks to modern technology, international development is already one step further. With a digital camera on the barrel and a small high-resolution color monitor on the swivel stock, shooting around corners has become more comfortable.

Special thanks to Carl Walther GmbH Sportwaffen, Ulm, Germany.

| This article first appeared in Small Arms Review V24N10 (December 2020) |