By Jean-François Legendre

Rigid feed-strips

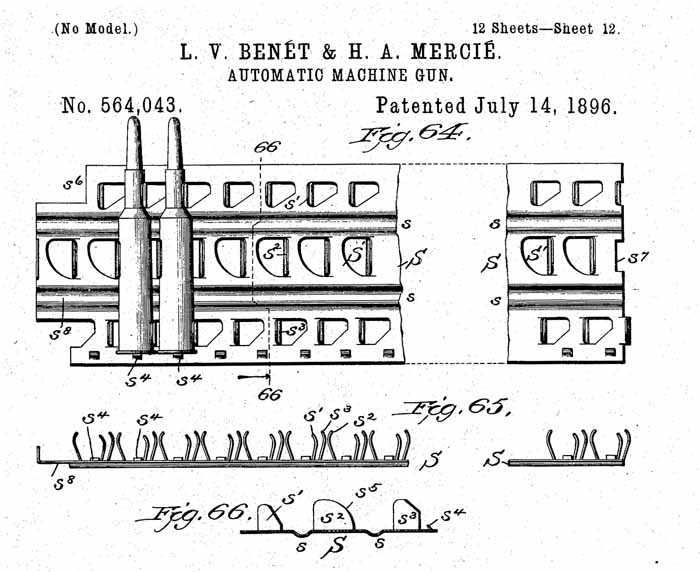

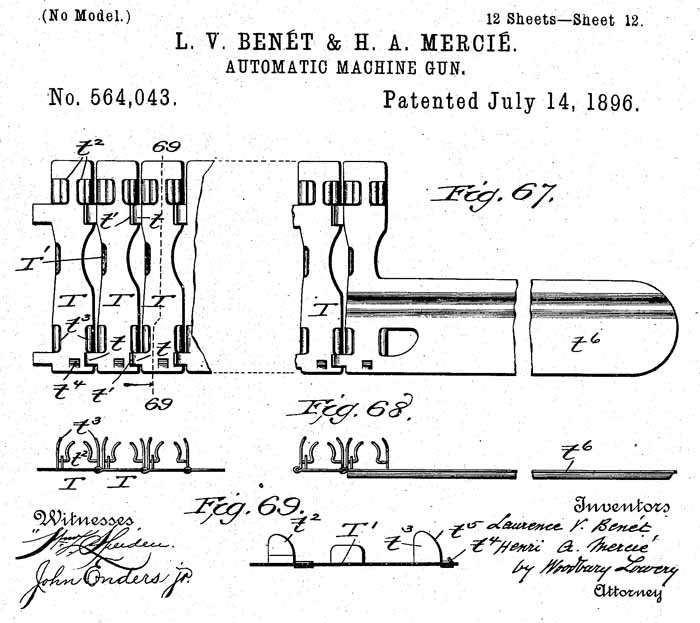

The improvements and new features of the Hotchkiss machine gun were thoroughly described in US patent No. 564-043 granted on July 14 1896 to L. V. Benét and H. A. Mercié, assignors to the Hotchkiss Ordnance Company Limited, London. Among many other features, this patent fully describes the original designs of both rigid feed strips and articulated belt. All relevant features incorporated into the rigid feed-strip design are described in the patent. The following paragraph is fully excerpted from the patent:

“The feed strip S, figs 64 to 66, consists of a narrow sheet of brass, tin, or other elastic material and may be of any convenient length, containing in general from twenty to fifty cartridges. Longitudinal ribs s are formed to give it stiffness. Three rows of clips s’ s² s3 are formed, as shown, to hold the cartridges. The front row of clips s’ embraces the cartridges at the neck from the right, the middle row s² holds the body of the cartridges from the left, and the rear row s3 holds the cartridges near the heads from the right. Small projections s4 are thrown up in line with the cartridge-heads and prevent withdrawal of the cartridges to the rear. The opening S’, formed in the strip when the clips s² are thrown up, are so formed that the front sides are spaced to the pitch of the feed-wheel P5, the teeth of which engage therein, as shown in figure 60. Also the rear edges of the clips s² are rounded, as shown at s5, to aid in raising the head of the cartridge to the level of the chamber. To the rear, the strip is cut away at s6 to permit the lever arm r of the lock R, Fig. 15, to rise when the last cartridge in the strip is in the loading position. The abutment s7 is formed on the front of each strip to engage the feed-wheel on the introduction of the strip into the feed-table and the tail s8 on the rear to accomplish its ejection.”

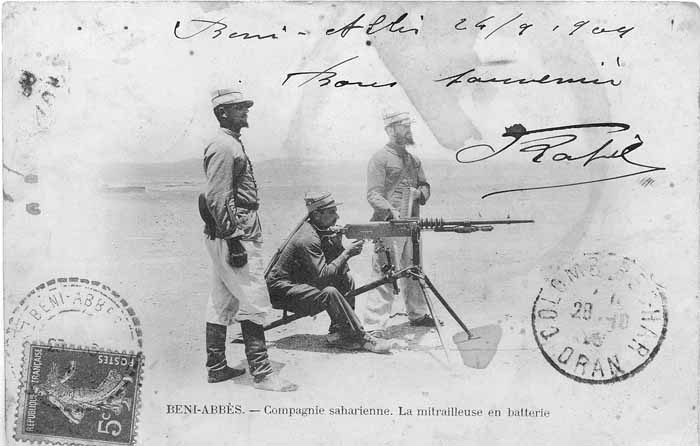

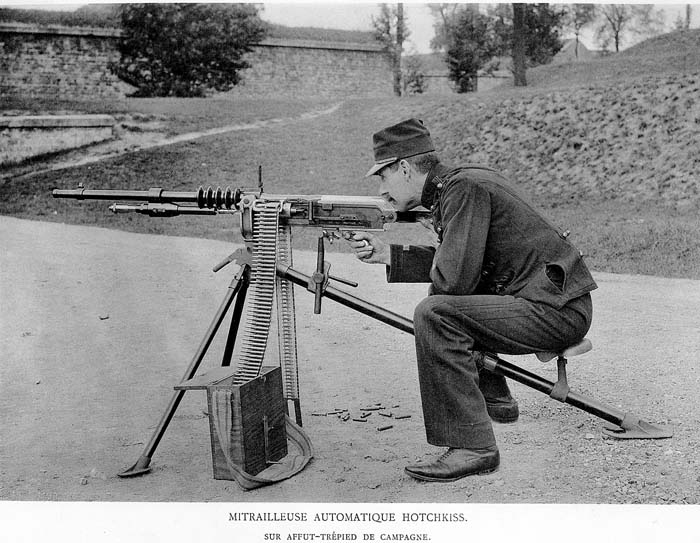

The first Hotchkiss machine guns chambered for the French 8x50R Lebel cartridge were acquired by the French Army in 1899. By 1904, around 400 Hotchkiss machine guns, officially referenced to as Mitrailleuse Hotchkiss Model 1900, were fielded for testing within several Cavalry Regiments, Alpine Mountain Troops and Saharan Desert Units.

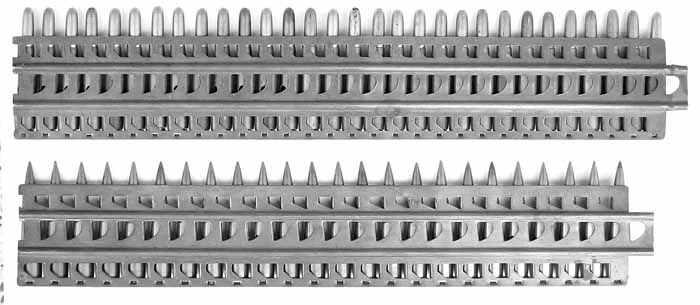

Hotchkiss machine guns contemporarily offered for export in various calibers (6.5×55 Swedish, 7×57 Mauser, 7.65×54 Mauser, .303 British, etc.) for many different customers were usually fed with 30-round rigid strips and sometimes with articulated belts. The standard pitch between 2 adjacent cartridges was chosen at ~13.5mm, which corresponds to the rim diameter of .303 British cartridges. Accordingly, the .303 cartridges can be seated with the rims exactly in contact with each other while any other rimless cartridges would then also be able to fit the same strip since they have a smaller cartridge base. The total length of the standard 30-round strips is ~418mm (16.46 in.). The ammunition chests intended to carry the feed-strips were designed accordingly with regards to the total length of the strip.

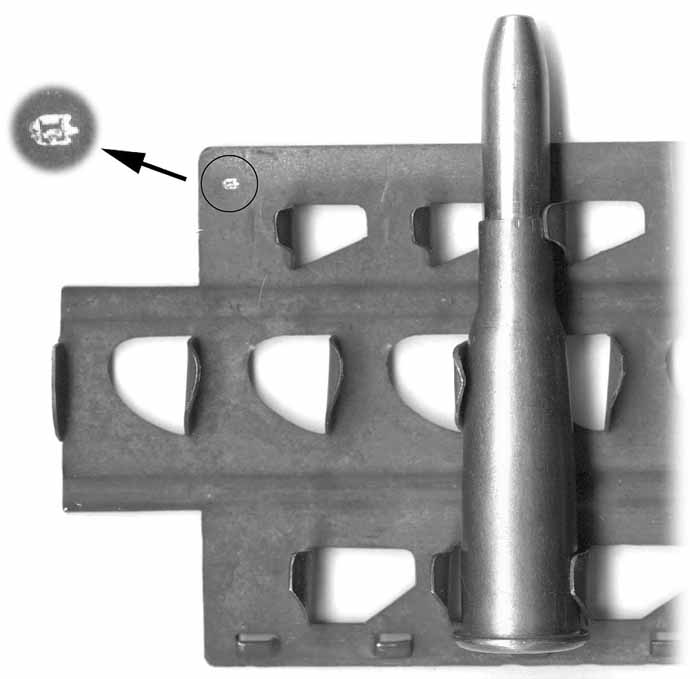

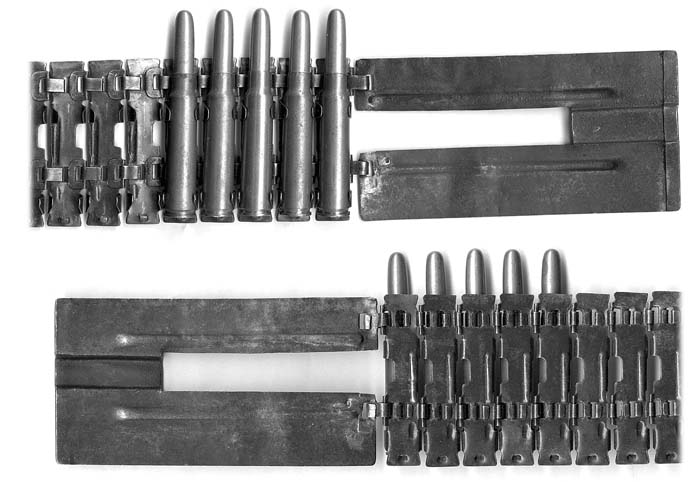

The French Hotchkiss Model 1900 was chambered for the rimmed 8x50R Lebel cartridges. The rim diameter of that cartridge is 16mm which, accordingly, is larger than the pitch of the standard 30-round feed strips and therefore cannot be accommodated in these. This feature necessitated the design of a dedicated strip for 8mm Lebel rounds with increased pitch. The pitch chosen for the new strip was 16mm that corresponds exactly to the rim diameter of the 8mm Lebel cartridges and therefore the rims are exactly in contact with each other when the strip is properly filled. Since the standard ammunition wrappers contained 8 rounds, the total capacity of the strip was set at 24 rounds so as to expend exactly three ammunition wrappers to fill one strip. These 24-round feed strips are ~395mm (15.55 in.) long. As they are slightly shorter than the standard 30-round strips they can also fit into the same standard ammunition chests. The 24-round Model 1900 strips are made of brass and bear a very tiny marking representing a shield with a letter inside. So far, no definitive identification of the meaning of this marking has been discovered though it is suspected that this might probably be an inspector’s mark rather than a manufacturer’s logo. Thus, a brass strip with a capacity of 24 rounds only can be clearly identified as for the Hotchkiss Model1900 in caliber 8mm Lebel.

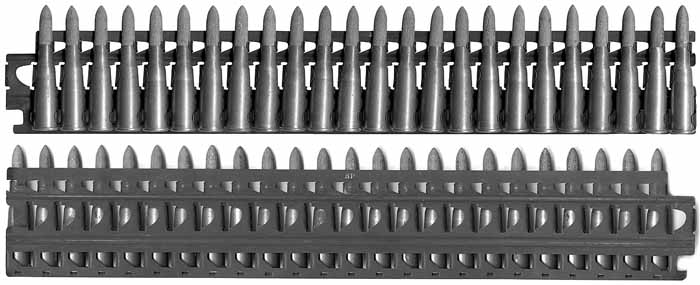

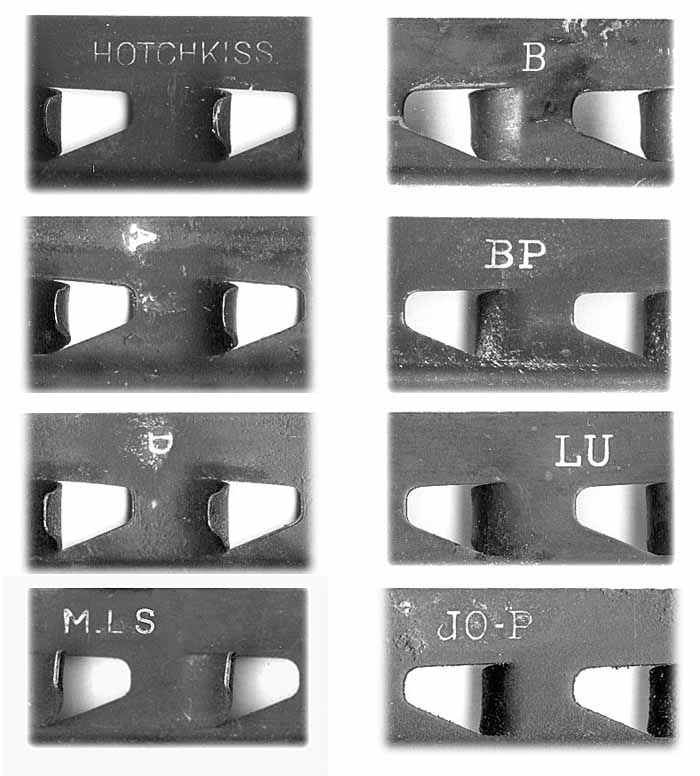

After several important improvements, a modernized version of the Hotchkiss Model 1900 was subsequently adopted by the French Army as the Model 1914. It remained fed with 24-round rigid feed strips. However, in order to enable repetitive reloading and increase durability, the feed strips were made of steel with an improved design of the stamping pattern of the base of the clips holding the cartridge cases. The design of these strips remained unchanged until the very end of service life of the Hotchkiss Model 1914. The early strips were blued (dark black color) whereas those produced since the end of the mid 1930s were phosphated. The strips usually bear stamped manufacturer’s initials although some productions are unmarked.

During WW2, the Hotchkiss Model 1914 remained in service being used by the German Army to equip second line troops and units installed all along the French coast on the Atlantic wall. Whereas 8mm Lebel ammunition specifically intended for Hotchkiss machine guns were still produced for the use and under control of the German occupation forces, it remains unknown whether production of Hotchkiss feed strips was also resumed during the German occupation. So far, no original 24-round feed strips with German WaA inspection stamp or any out-of-pattern markings have been observed by the author.

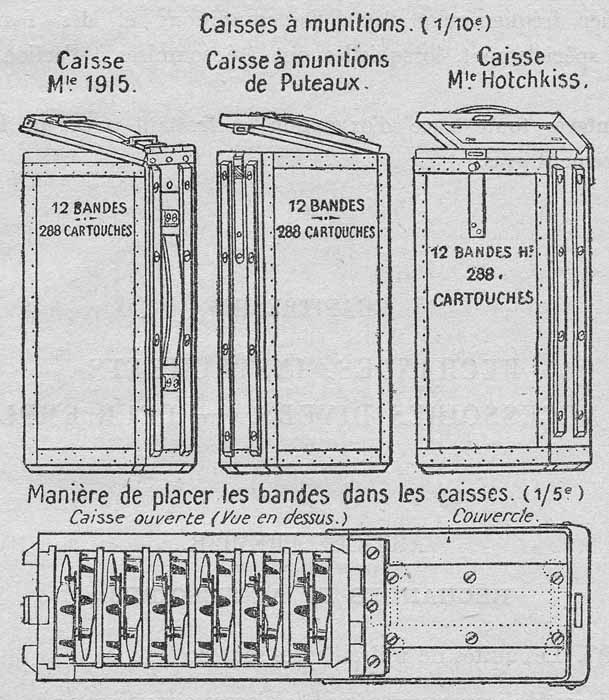

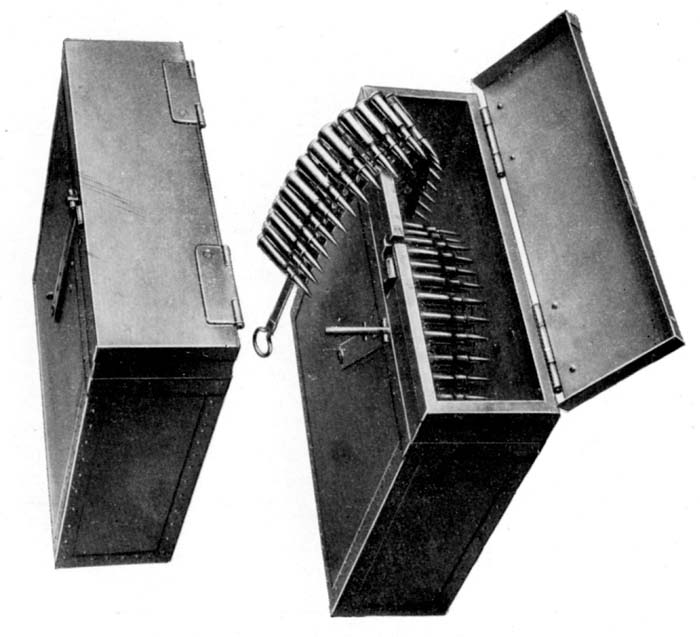

The rigid feed-strips were carried in different types of ammunition field chests mainly made of wood with some steel reinforcing parts. These field chests accommodate 12 rigid strips, which represents a total of 288 rounds. The chests are divided into 6 compartments with each containing 2 strips arranged tail-to-toe. Three different models of chest are used: Model Puteaux, Model Hotchkiss and Model 1915. The same chests were also used simultaneously to accommodate 12 strips for the St-Etienne Model 1907 machine gun. The Hotchkiss and St-Etienne strips are totally different and cannot be used interchangeably.

The total number of cartridges contained in the chest is the clue to readily take apart the type of strips contained in the chests. The chests for the Hotchkiss guns are marked with paint “12 bandes 288 cartouches” (12 strips 288 cartridges) and sometimes also a large letter “H”. For the chests containing St-Etienne 1907 feed strips, the markings with paint is “12 bandes 300 cartouches” according to the capacity of the feed strips of 25 rounds.

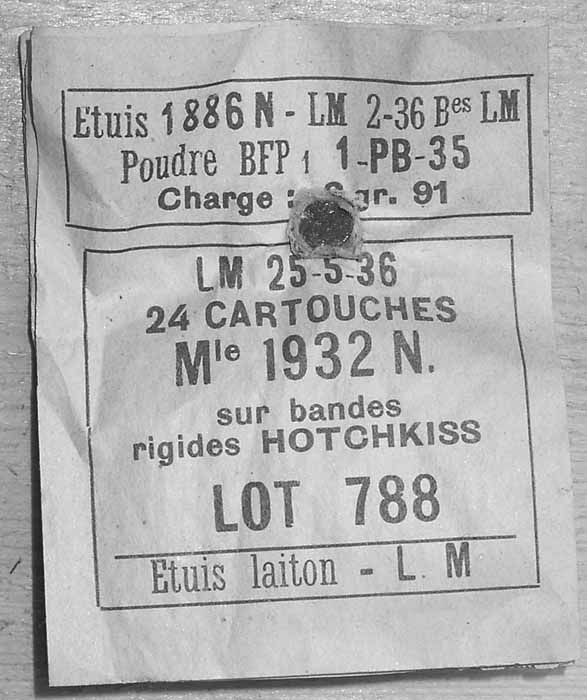

When first issued to the troops, rigid feed strips were usually supplied pre-loaded from the ammunition depots or directly from the ammunition factories. After the original ammunition content was fired, the strips were repeatedly reloaded by the troops in the units. A total of 1,872 rounds fitted on 78 strips were shipped in wood ammunition crates “N°6 mle. 1908” and later “N°6 mle. 1908-1923” with zinc inner liner. Loaded strips were wrapped with paper either individually or by pair arranged tail-to-toe. Paper wrappers were sometimes printed with the content designation. Usually, standard practice was to provide in each ammunition shipping crate a stack of small loose labels describing all the details of the ammunition. When the strips were taken out of the ammunition shipping crate to be loaded into the field chests containing 12 strips, one of these labels was inserted in the field chest to keep track of the details of the ammunition content. Such small labels are today very scarce collector’s items.

Articulated Feed Belts

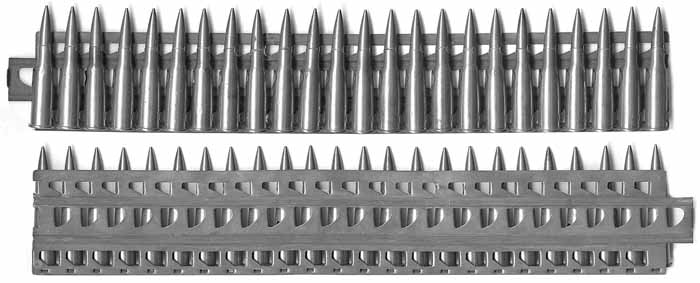

The design of articulated feed belts for Hotchkiss machine guns appeared as early as 1896 together with the rigid feed-strips as shown in the US patent No. 564-043 already described at the beginning of this article.

The most accurate description of the features of the articulated belt is excerpted from the patent as follows:

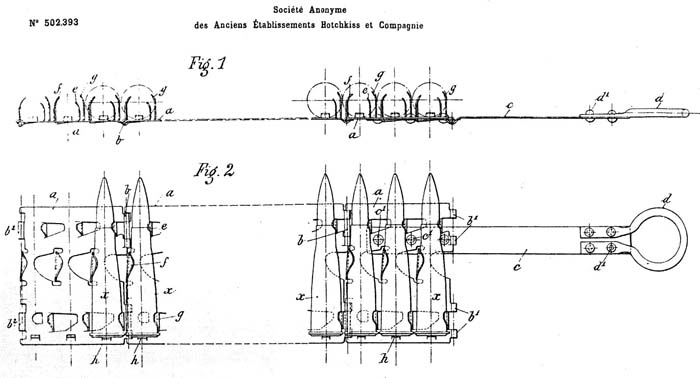

“In place of the elastic cartridge-strip S (shown in Figs 64 to 66,) we may employ a flexible band, as shown in Fig. 67 to 69, which consists in a series of links T, jointed together by hooks and eyes t and t’, formed in the links. Each link has formed upon it the clips t² and t3, which hold the cartridge at the neck and near the head, respectively, and the bearing t4, which prevents the cartridge from being withdrawn to the rear. The clip t3 is rounded at t5 to raise the head of the cartridge when it is forced into the chamber by the breech-block. The bearings T’ are formed to engage with the teeth of the feed-wheel P5 and are spaced to the pitch of this latter. The tongue t6 is formed on the first clip of each band to facilitate the introduction of the latter into the feed.”

It readily appears that rigid strips and articulated belts exhibit very different patterns of the clips holding the cartridges. Articulated belts were commercially offered for sale all around the world and a few customers (at least Belgium in caliber 7.65×54 or Sweden for caliber 6.5×55) adopted this accessory, sometimes for use in static positions like fortress mounts or in armored vehicles. So far, the author has not found any reference to a French Hotchkiss Model 1900 being fed with an articulated belt prior to WW1.

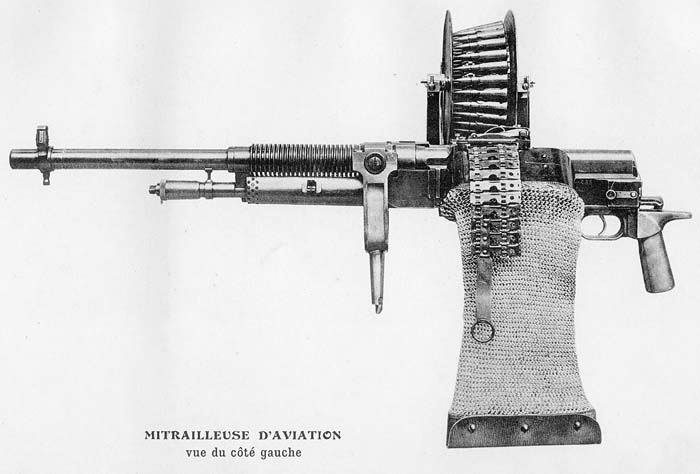

The first Hotchkiss articulated belt for 8mm Lebel ammunition identified so far was designed for the Model 1909 Light Machine Gun (Mitrailleuse Portative). A 100-round articulated belt was developed at the beginning of 1915 to feed this lightweight machine gun installed aboard early military aircraft. The belt was rolled around a spool attached to the weapon. The design of the individual links are similar to the commercial models exported to Belgium and Sweden for example but are only enlarged to cope with the wider 8mm Lebel cartridge. Extremely scarce surviving specimens of this articulated belt for airborne Hotchkiss Portatives show evidence of manual fittings rather than large scale industrial manufacture.

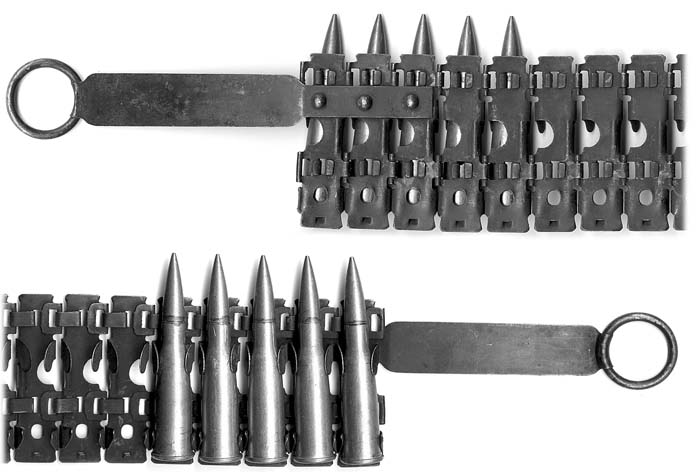

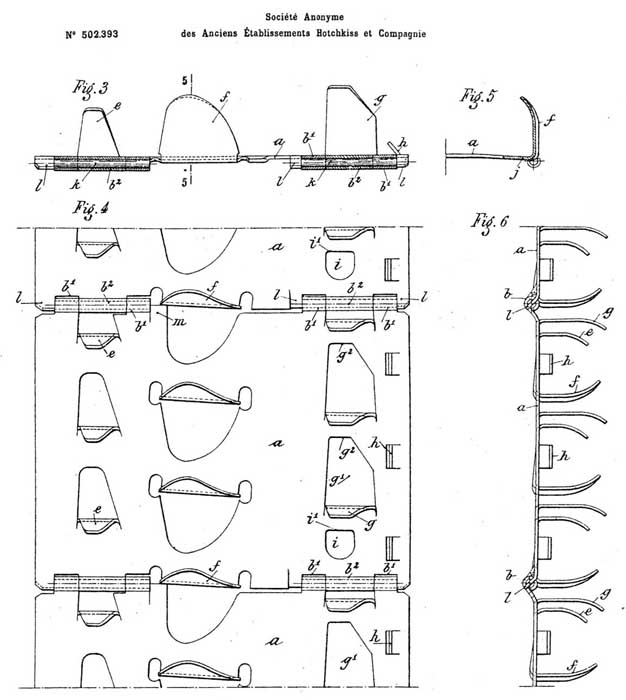

Soon after the outbreak of WW1, the need for articulated belts for sustained fire with the modernized Hotchkiss Model 1914 weapons in ground use also arose. The key requirement was for the weapon to be able to use either the rigid feed strip or the articulated belt. This was an issue since the force required to extract the cartridge out of the strip was very different between the rigid strip and the articulated belt. This comes from the pattern of the cartridges holding clips which are different between the two types of feed devices. For the articulated belt, the cartridges are retained by means of two pairs of clips whereas for the rigid strip the cartridges are retained by one clip on one side and two clips on the other. Adjusting the feed system of the gun to cope with a particular type of feed device was not a problem but readjusting in the field during combat was just not acceptable. This is why a new articulated belt for 8mm Lebel cartridge was developed in 1915 to deal with this requirement. A French patent for the corresponding design was applied for by the Société Anonyme des Anciens Etablissements Hotchkiss & Cie on July 15, 1915 and published in May 1920 with reference No. 502-393.

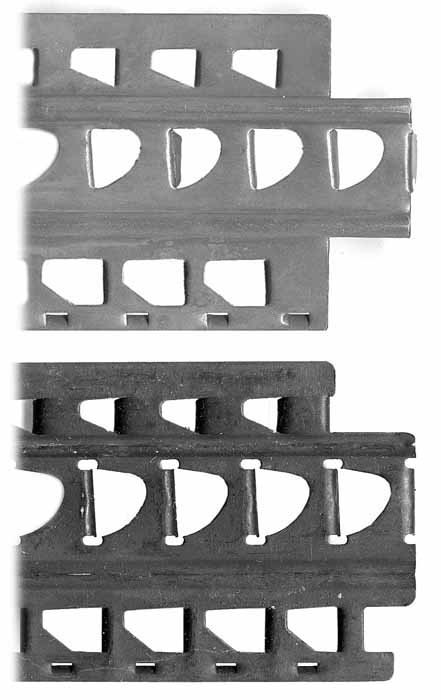

This patent describes the belt as composed of rigid sections containing three or more cartridges being hinged together. The design of the short rigid sections is similar to that of the rigid strips, in particular with regards to the cartridge holding clips. Therefore, extraction force required to push the ammunition out of the strip into the gun chamber is the same as that needed with the rigid strip. Furthermore, the patent also claims a better guiding of the belt into the feed tray than could be achieved with the former 1-round articulated belt. Finally, the patent also describes a starter tang used to facilitate the introduction of the belt into the feed system. The new articulated belt adopted for the Hotchkiss Model 1914 was based on a variable number of 3-round sections hinged together.

Up to four different total lengths of belts are officially reported depending on the number of 3-round sections involved. These different lengths were meant to deal with all different uses, namely infantry, fortress, vehicle, aircraft and even boats.

The most common length can accommodate up to 252 rounds and is composed of 84 sections of 3 rounds each. Although an official 1918 regulation prescribed an allowance of three 252-round articulated belts per field machine gun, these belts saw only limited use in the trenches during WW1. In the latter situations, those long belts were mostly used for anti-aircraft sustained fire. After WW1, although the articulated belt remained standard equipment for field guns, the great majority of the weapons remained fed with rigid strips. WW1 and Interwar photographs showing field guns fed with articulated belts are seldom encountered.

Another important potential use of the articulated belt in 1915 was for aircraft guns. In the 1915-dated patent, such possible use for aircraft installation was described with a capacity of 102 rounds (34 sections of three rounds). These belts were intended to replace the 100-round belt articulated every single link. However, when this new articulated belt became an item of standard issue, the Hotchkiss Portative weapon had almost completely disappeared from air service and replaced with Colt and Vickers machine guns. It is therefore doubtful that the 102-round version of the articulated belt saw extensive airborne service.

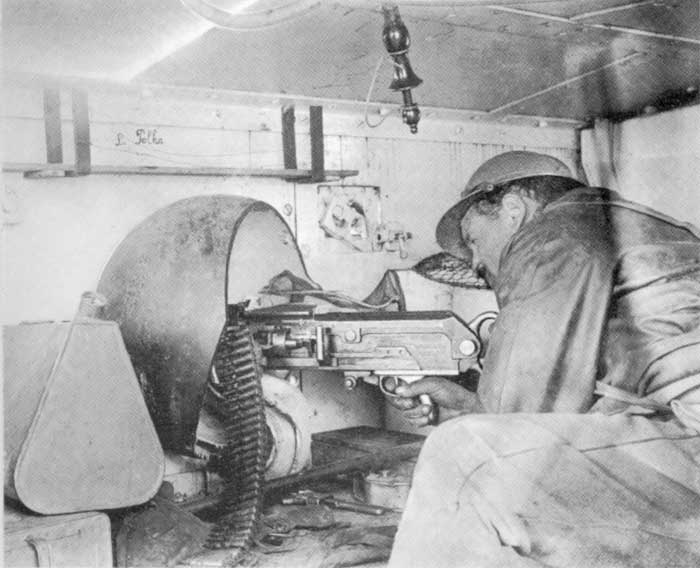

Articulated belts were especially used since WW1 in tanks and armored vehicles where space was so limited that it was sometimes impossible to feed the rigid strips. Depending on the space available in the various vehicles, three lengths are reported. For heavy tanks, the longer belt for 252 rounds was standard, whereas for smaller vehicles both 96-round (32 sections of three rounds) and even 48-round (16 sections of three rounds) were used. The use of the articulated belts in armored vehicles continued until the middle of the 1930s when the Hotchkiss machine gun began to be progressively replaced by the drum-fed Chatellerault MAC Model 31 as vehicle armament.

After WW1, the 252-round articulated belt was fielded in fortress positions like in some Maginot Line installations. After the invasion of France in 1940, large quantities of Hotchkiss Model 1914 weapons were captured by the German Army and many were subsequently fielded for coastal defense along the Atlantic Wall. Whereas the use of the articulated belts by the French Army is only rarely observed, pictures are more common showing the Hotchkiss Model 1914 fed with the 252-round articulated belt in the hands of the German Army.

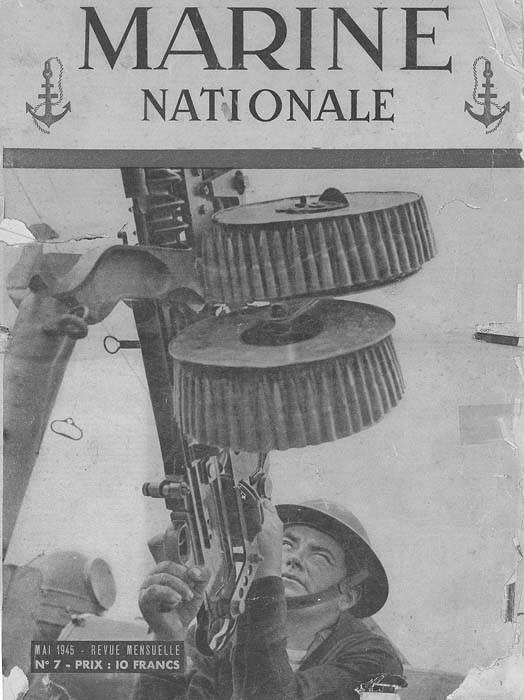

Since the mid 1920s, the Hotchkiss Model 1914 were also installed on ship decks for self-defense and anti-aircraft protection. The 252-round belts were used as standard for both single weapon mounts (CA mod. 1925) and twin weapons mounts (CAD mod. 1926). For some installations, the belts were fed from a spool attached to the side of the gun.

A complete 252-round articulated belt remains today a scarce collector’s item. WW1 and early post-war productions are blued (dark black color), whereas later productions are phosphated mat gray. The flat starter tang is marked with the manufacturer’s initials.

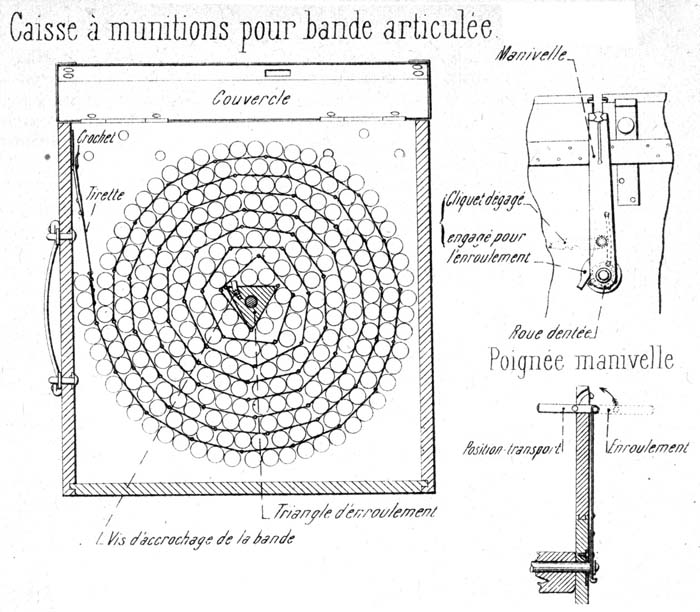

The chest to accommodate the 252-round belt is made of wood with steel reinforced corners and steel lid. The chest contains in its middle a triangular wooden axis around which the belt is reeled by means of a collapsible crank. This triangular wood axis is fitted with a prominent steel plug which is engaged into the very last cartridge pocket of the belt. This is the reason why, although the total capacity of the belt is theoretically 252-round (84 sections of three rounds), only 251 cartridges can be inserted in the belt since the last pocket must remain empty to engage the triangular reel axis.

Strip loaders

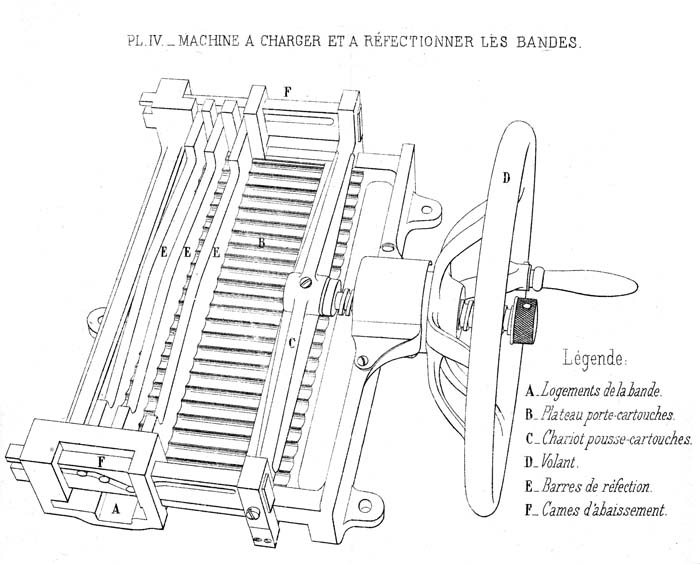

Among the numerous accessories provided with the early Model 1900 Hotchkiss, there was a very complex and cumbersome device intended to both load the strips with cartridges and resize the strips to their original shape. This latter operation was particularly important for the fragile brass strips were easily deformed or bent. This accessory was provided with every Model 1900 Hotchkiss machine gun acquired by the French Army. So far, the author has unfortunately not come across of any surviving specimen of such an early Hotchkiss loader.

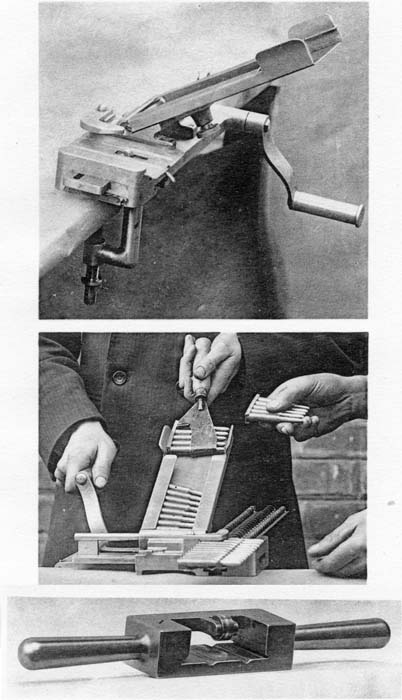

The Hotchkiss Company also offered for export a much simpler and very effective strip loader specifically intended for rimless cartridges only where the loose cartridges were fed from an inclined ramp.

A variant of this machine was also designed for the rimmed .303 British cartridge by using a hopper to feed the loose cartridges. However, when the modernized Hotchkiss Model 1914 chambered for the 8mm Lebel cartridge was fielded by the French Army during WW1, no such strip loader for the 8mm Lebel caliber was either available nor even asked for by French Ordnance. Only the small roller tool used to recalibrate the strips was adopted as standard accessory with the French Hotchkiss Model 1914.

During WWI, filling the Hotchkiss strips was carried out by hand. Instructions were specifically issued to require very careful filling so as to ensure cartridges were evenly and properly seated otherwise feed jams would doubtlessly occur.

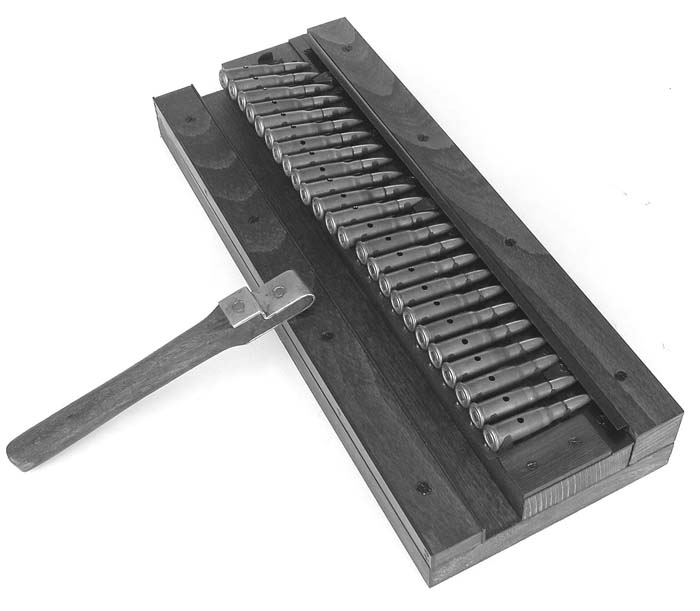

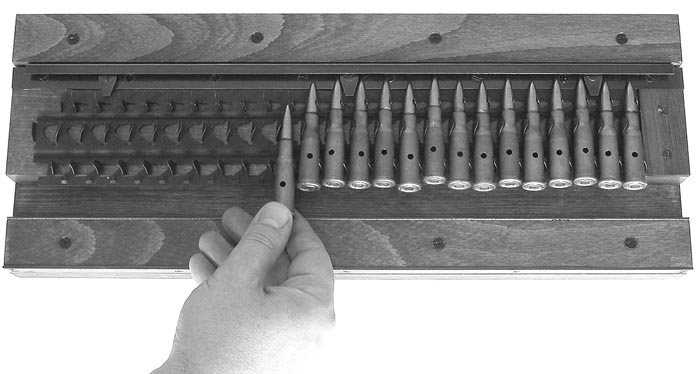

It is only after WWI that a new device was designed and officially adopted. This strip loader is referenced as Machine modèle 1924 à charger les bandes pour mitrailleuse Hotchkiss. This simple device was intended to be constructed directly within the regiment workshops and only the manufacturing plans were provided by the Ordnance Department.

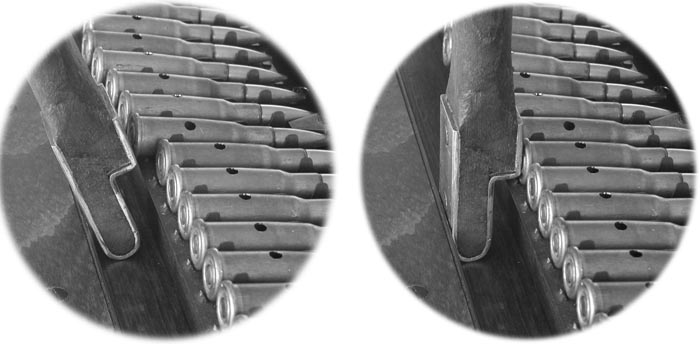

This loader is simply composed of separate pieces of wood assembled together with screws and fitted with very few simple steel sheets and filed spacers. The assembly basically provides a tray on which the strip is laid and a lengthwise groove in which a wood lever-arm takes its support. Once the strip is laid on the tray and held in position by three V-shaped spacers, the operator inserts by hand as far as easily possible the cartridges into the strip. The wood lever arm with its lower part protected with a thick brass sheet is inserted into the groove and is simply rocked to push a little bit forward the cartridge base so that to overtake the cartridge stop on the strip. According to the width of this lever, two cartridges can be pushed at once. The lengthwise groove is covered with a protective steel sheet on the side where the lever-arm takes support. Both 24-round rigid strips and articulated belts can be loaded with this device. For the latter articulated belts, the small wood positioning wedge at the far right end is simply removed.

This rugged device is really very effective and strips can be easily evenly loaded. This loader is however seldom mentioned in very few official instruction manuals only and it is most probable that it did not see wide use during the interwar years.

Ammunition

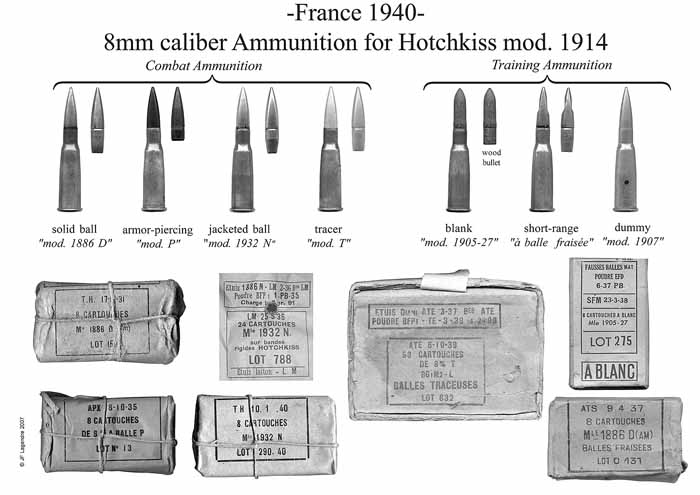

Standard ammunition issued for the Hotchkiss Model 1914 were solid bronze ball Model 1886 D and later the jacketed heavy ball Model 1932 N. Armour-piercing Model P and tracer Model T saw only limited issue. The heavy jacketed ball Model 1932 N with a slightly larger projectile diameter required the chamber to be slightly reamed. The barrels, either reworked to the standard 1932 N or newly manufactured to those new dimensions, were marked with a large N.

It should be emphasized that special purpose ammunition like armour-piercing and tracer did not have their trajectories matching with that of the ordinary ball. Accordingly, no instruction for belting sequence was ever officially issued to fill strips or belts by mixing standard balls with armour-piercing or tracers. On the contrary, instructions clearly indicate that only cartridges of the same type should be filled in the same strip, even when using special purpose ammunition. Therefore, when action against vehicles was expected, homogeneous strips filled with armor-piercing cartridges only were to be used. For anti-aircraft operation, instructions were given that some of the weapons in the group should fire strips loaded with tracers only in an attempt to deter the enemy pilot from flying too low rather than really expecting to hit him.

Short-range ammunition is based on a standard Model 1886 D solid bronze projectile with two flat surfaces milled on the side in order to increase the projectile drag in air and thereby reducing the maximum range. Blank cartridges were originally of Model 1905 with uncolored wood projectile which design was slightly modified in 1927 and was subsequently adopted as model 1905-27 identified by a wood projectile dyed blue. Dummy cartridges for machine gun are of the model 1907 with nickeled case and projectile.

The action of the lever-arm pushes two cartridges simultaneously. The rounds are at their right place when the bases have overtaken the cartridge stop on the strip. Note that lever arm is supported in the groove by a screwed steel sheet.

Operation of the lever arm.

Loading operation with articulated belts; ammunition displayed are of nickeled dummies Model 1907.

| This article first appeared in Small Arms Review V12N4 (January 2009) |