While many Class 3 enthusiasts may not recognize the name Max Atchisson, most have heard of, or possibly may own at least one of his many firearm or accessory designs.

Maxwell G. Atchisson was born on February 17, 1930 in St. Louis Missouri. He attended the University of Missouri and Kansas City Junior College. He then served in the U.S. Marine Corps as a machine gunner. His superiors soon noticed his firearm acumen, which earned him a new position as a weapons instructor, conducting classes in automatic weapons characteristics, maintenance and firing techniques. He was honorably discharged in 1952. Although not as well known as John Browning or Gene Stoner, Atchisson was a very talented inventor and designer of weapons. During his career he was granted twenty-four patents. Many of Atchisson’s ideas were ahead of their time, with several having commercial success. A close examination of Atchisson’s prototype weapons will reveal a compilation of components from existing designs. The idea behind this thinking was that his weapons could be manufactured from many existing surplus parts, and thus be inexpensively produced.

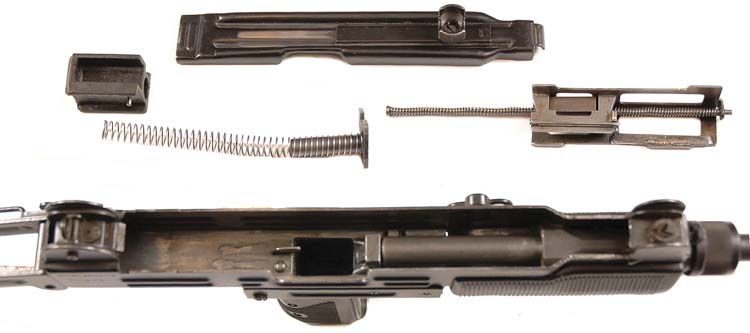

Max Atchisson studied many previous U.S. and foreign weapon designs and patents. While much of his inventing was performed on his own time, Atchisson worked for several large firearms manufacturing firms and contributed many ideas to experimental and production weapons. While employed as a mechanical engineer at the Hughes Tool Company, he designed a gas system and buffer group for the Hughes 5.56mm caseless rifle, and a new type of cascading sear for the open-bolt 20mm aircraft cannon. The new sear reduced the sear load from 100 to 10 pounds, thus allowing the system to utilize a smaller, lighter solenoid for remote operation of the weapon. After a brief stint as an engineer at the Bendix Corporation, Mr. Atchisson was hired as a project engineer for the Military Armament Corporation (MAC) in Marietta, Georgia. While at MAC he perfected his best-known product: the .22 caliber conversion kit for the AR-15 and M16 rifle. The kits were marketed world-wide by MAC, with Atchisson receiving a royalty for each unit that was sold.

During his employment at MAC, Atchisson was able to demonstrate many of his prototype weapons for U.S. and foreign customers at Mitch WerBell’s range near Powder Springs, Georgia. At MAC he worked with and became lifelong friends with Don Thomas, Gordon Ingram and John Foote. The men were among the few true “firearm enthusiasts” at MAC and spent many hours test firing weapons and suppressors together, both at work and during their free time. Before the eventual demise of MAC, Atchisson left taking his M16 .22 conversion kit to be distributed by other firms. First was Defense Systems International, a company formed by Mitch WerBell after being ousted by Quantum/MAC management who had taken over the company. After the DSI deal fell through Atchisson took his .22 conversion kit to WAK in Fairborn Ohio, then to Bingham International. Eventually, the improved Atchisson .22 caliber Mark III version, that allowed the M16 to operate reliably in both semiautomatic and full-automatic modes, was procured by Jonathan Arthur Ciener and are still manufactured and sold today.

Atchisson enjoyed the challenge of making semiautomatic and full-automatic weapons function reliably with .22 caliber rimfire cartridges, a round not easily adapted to work in automatic firearms. In addition to his AR-15, M16 conversion kit, Max Atchisson also developed .22 caliber rimfire conversions for the Reising, M1A1 Thompson and the Uzi submachine guns.

The C.R.A.C.K. Rifle

Another innovation was the Atchisson C.R.A.C.K. reduced recoil system or “Counter Recoiling Action Compensated Kick.” The weapon was designed to greatly reduce recoil and muzzle climb by using springs and other devices to counter recoil. Only one known prototype weapon was built. The rifle had an M1 Garand receiver, a BAR trigger group, and a straight-line stock configuration with raised sights. Atchisson claimed that the C.R.A.C.K. system reduced the felt recoil of firing 7.62mm ammunition from twenty-one foot pounds down to only three foot pounds.

Packer .22 Caliber Rifle

The Atchisson Packer rifle was designed as a low-cost .22 caliber rimfire firearm that could be inexpensively manufactured from metal stampings, including the receiver and bolt. The buttstock was made of two plastic “clamshell” halves that enclosed most of the receiver and the 17-inch long barrel. The rear sight was a flat piece of steel with an upright aperture leaf designed for fast and easy adjustment. The rear sight was sheltered from damage by large protective side ears. The Packer rifle fed from a removable box magazine in 15, 20, 22 and 32 round capacities.

Clamshell Rifle

Atchisson also designed several .223 caliber rifles with “clamshell” stocks similar to those used for the Madsen M50 submachine guns. Atchisson held several patents on the design.

The Curved Barrel Rifle

One of Atchisson’s more unique designs was the curved barrel .22 rifle. At first glance the rifle appears to have a very short barrel, but the legal-length 16-inch barrel actually extends to the end of the buttstock where it is loaded from the breech via a hinged buttplate. The barrel was slightly curved to fit into an ordinary appearing stock.

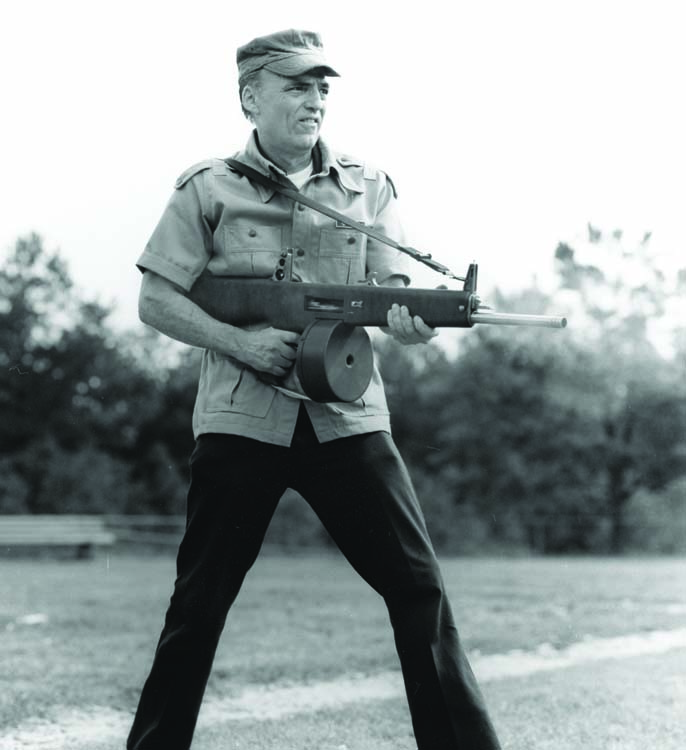

The Atchisson Automatic Assault Shotgun

The 12 gauge Atchisson Assault shotgun was fed from a twenty-shot drum or five-shot magazine. Designed to use 12 gauge 2-3/4-inch Magnum 00 buckshot, or rifled slugs, the full-automatic weapon could make consistent hits on a man-size target at a range of 100 yards. The blowback-operated shotgun was designed with a tubular receiver that formed part of the inline stock. The shotgun’s overall length was 39 inches, the barrel length 18 inches, and weighed 11 pounds unloaded. The shotgun’s drum magazine was fabricated from a Thompson submachine gun L-drum magazine, the box magazine was a modified BAR unit.

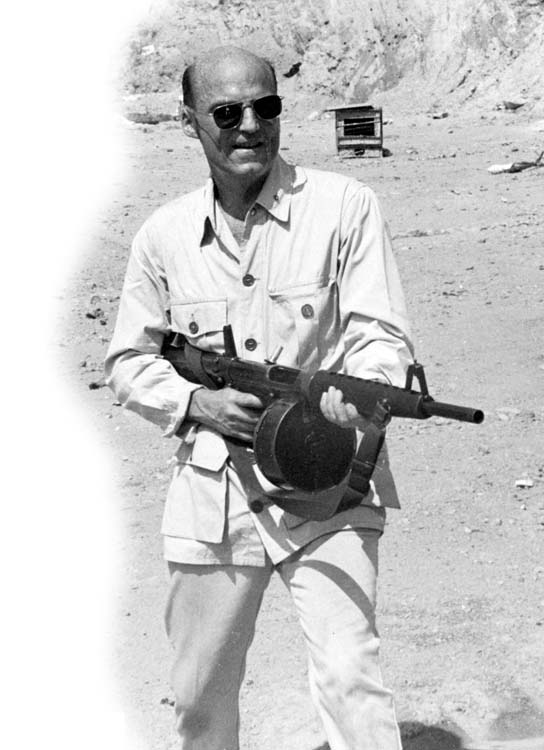

AA12 Shotgun

The AA12 (Atchisson Assault 12 Gauge) shotgun was yet another “clamshell” design with a two-piece nylon stock. The weapon evolved from the prototype shotgun described above. The select-fire weapon was manufactured in limited quantities in the U.S. and in Korea by Daewoo. In 1987, Max Atchisson sold the rights of the AA12 shotgun to Jerry Baber of Military Police Systems, Inc. Mr. Baber continued to improve on the original patented design and market the weapons.

Suppressors

Atchisson designed a built a number of unique suppressor designs like the adjustable-zero .223 caliber unit designed for the M16 rifle. The suppressor had an adjusting mechanism within the mounting clamp at the rear of the tube, allowing the shooter to zero his rifle with the suppressor attached. However, there was little interest and the unique suppressors were never put into production. One of his more unusual suppressors was constructed from a used propane cylinder.

The Atchisson Auto Connector: AKA The Lightning Link

One of Atchisson’s better known inventions, although his name is seldom associated with it today, was his device to convert semiautomatic AR-15 rifles to fire full-automatic, commonly known today as the Lightning Link.

Upgrades for the U.S. M16 Rifle

Mr. Atchisson designed many products for the U.S. M16 rifle, which allowed the weapon to fulfill many additional mission requirements. His upgrades required no permanent alterations, no special tools and often used existing parts.

The Atchisson Open-Bolt Firing Squad Automatic Weapon (SAW)

This innovation offered open-bolt operation, allowing sustained automatic fire, and reducing the possibility of cook-offs. To enhance accuracy, the SAW conversion also featured a heavy buffer to slow down the cyclic rate and a muzzle compensator. An automatic bolt release feature was activated by the magazine catch, allowing the bolt to move to a rear position, as soon as a magazine was inserted, making the weapon instantly ready to fire.

The Atchisson Tri-Mag

The Tri-Mag was an assembly of three standard M16 thirty-round magazines modified with the addition of an auxiliary magazine catch and retaining dimples. The device was specifically designed for his open-bolt SAW to offer 90 rounds of firepower. The Tri-Mag could also be used in the standard issue M16A1 rifle.

9mm M16 Submachine Gun Conversion

The Atchisson 9mm Parabellum conversion for the M16 was open-bolt, blowback operated, that used Uzi magazines. The weapon had a 10.5 inch barrel and Colt telescoping buttstock. Cyclic rate was 650 rounds per minute. Atchisson designed and perfected the 9mm/M16 concept years before Colt.

Suppressed 9mm Submachine Gun

The Atchisson suppressed submachine gun was based on the M16 with the 9mm conversion, but was hammer-fired operating from a closed bolt. The suppressor was designed to bleed off gas pressure to reduce the velocity of the supersonic 9mm rounds down to subsonic velocities. This feature allowed the use of standard 9mm ammunition. Progressive porting allowed the barrel to act as an obturator (pressure seal) eliminating the constant replacement of organic obturators (wipes).

M16 Night Sight

Atchisson designed a one-piece night sight to allow the soldier to fire accurately in low light conditions. The sight was a tunnel design that allowed the use of the standard sight, while the night sight remained attached. The sight used Promethium to illuminate the sight post.

M16 Cyclic Rate Reducer

The rate reducer was designed to enhance the accuracy of the M16 rifle when fired in the full-automatic mode. The device delayed the normal firing cyclic for 80 milliseconds, thus lowering the standard 750 round cyclic rate down to 375 rounds per minute. The device could be installed in less than two minutes using a 5.56mm cartridge as a tool. The cyclic rate reducers could be custom calibrated to whatever cyclic rate the customer desired.

The M16 Port-Firing Weapon

Also based on the M16, the Port Firing weapon was open-bolt, hammer-fired operated for sustained automatic fire. A heavy bolt and large diameter low rate action spring allowed a cyclic rate of 620 rounds per minute. An automatic bolt catch release moved the bolt into the sear position when a magazine was inserted, allowing the weapon to be fired immediately. A special spring was available to increase the cyclic rate to 800 rounds per minute if desired.

Atchisson M16 Variable Vector Muzzle Compensator

The device was designed to reduce recoil to allow accurate full-automatic fire. The brake featured deflector holes that were carefully positioned to divert muzzle blast forward, and was adjustable for right- or left-handed shooters. The brake was 3.875 inches in overall length and weighed .3 pounds.

Disposable Lightweight Grenade Launcher

The disposable grenade launcher was a lightweight, compact device designed to launch 40mm grenades from the M16 rifle. The basic idea was to provide every soldier the capability to launch grenades. The launcher was designed to mount beneath the barrel and be secured to the flash hider and bayonet lug. A hammer in the form of a spring was cocked by a pair of levers, which become disengaged so that the hammer and associated firing pin could fall and discharge the round. The launcher could not be cocked unless it was attached to a host weapon.

SWD and RPB

Some his later projects where made in association with RPB and SWD, including the semiautomatic operating system used in SWD’s very successful SM11/Nine pistol, the semiautomatic version of the M11/Nine submachine gun. Other products produced for RPB/SWD were the Atchisson throwing knives and the shirt tail holster.

Other Inventions

In addition to firearms and related accessories, Atchisson invented many other items to include a device to lock non-locking door knobs, a swimming snorkel that wouldn’t fill with water and a trigger for aerosol cans to name a few. Although he prided himself in living a lifestyle consisting of daily exercise and a healthy diet, Maxwell George Atchisson died of respiratory complications on February 15, 2003 at the age of 72.

| This article first appeared in Small Arms Review V15N4 (January 2012) |