Comparison of the spur, the cavity below the spur and hammer – the CZ P-07 on the left and the Duty on the right (Jiří Sedlačík)

By David Pazdera

The research and development program of the Česká zbrojovka Uherský Brod (CZ) company has added several alternate handguns to the classic CZ 75 series since the mid 1990’s. But none of them was launched into production. That situation changed after the arrival of a substantially simplified Omega trigger mechanism.

The breakthrough in Omega’s fate came in the winter of 2006, not long after the appointment of the new general manager of CZ, Ing. Lubomír Kovařík, whose priorities focused on the earliest possible addition of a technologically more efficient and a “tender” SA/DA pistol (Tender means offering to larger bids and contracts). The Omega mechanism offers such potential. The development process was given a go and CZ’s designer Ing. Ivan Filko poignantly summarised the efforts as follows:

“We wrapped the trigger mechanism with a pistol.”

That was the birth of the CZ 75 P-07 Duty model. However, the only immediate thing this polymer compact has in common with the initial Seventy-Fives is the operating principle of the trigger mechanism, the inner slide guide and the disassembly procedure. The rest of the design is based on what can be called the contemporary standard for service pistols. The frame of the Duty is made of Zytel polymer, free of fibreglass (used by CZ since the time of the CZ 100 striker pistol), fitted with a standardised mounting rail with three traverse notches, a large trigger guard for reliable shooting with gloves and a funnel-shaped magazine grip entry.

The initial version of the Duty had the walls of the polymer frame with slight bulges at the front of the insert. It had no impact on the operation and safety but it looked awful, and the knurled surfaces on the sides of the frame above the trigger fortunately provided a stylish camouflage. This feature was proven very useful in practice – not only for reliable “resting” of the index finger of the shooting hand off the trigger but also for reinforcing the grasp of the gun when held by both hands, when this knurled spot serves as a rest for the thumb of the other hand. That is why this feature has been preserved on the modernised CZ P-07 and its larger sister – the CZ P-09.

The polymer frame of the Duty houses two inserts manufactured by the MIM method. The top parts of these inserts are provided with notches to ensure the inner guidance of the slide. The rear insert is a container that carries the firing mechanism and its rear surface is provided with cogs to cover the back of the slide, the front insert is a container that serves for the fitting of the trigger and the slide catch axis runs through it, serving also as a connecting pin between the frame and slide assembly with the main and return springs. That is made of flat wire and it is fit freely onto a long plastic guide.

The Duty bets its success on the current and most common Browning system with an open quadrant comprising two hooks, locked by the square-shaped rear side of the barrel to fit the properly sized ejection port. The Duty further joined the systems locked in

horizontal position.

The Duty has been fitted with ambidextrous plastic controls and de-cocking levers. The hammer is provided with a classic round knurled thumb rest with a large relief hole.

Characteristic features of the CZ 75 P-07 Duty model include the slide with the large grooves below the rear sight and the markedly bevelled sides of the rear part to simplify drawing and re-holstering.

But one can never satisfy all demands of every user. Many shooters like to charge their pistols by grasping the front part of slide, which is quite problematic due to the bevelled section of the Duty. Testing under various conditions further revealed that the sheer lines of the slide and receiver are fairly sharp and may catch on clothes in case of swift drawing. Customers were also quite sceptical about the economical polymer sight. On the other hand, the new magazine was praised by everyone. It was developed by adaptation of the magazine from the CZ 75 Tactical TS and the manufacturer managed to achieve the same capacity as in the standard CZ 75, with a lower height.

The CZ 75 P-07 Duty model specification was initially for nitriding of the barrel and slide. However, this subcontracted surface treatment did not fully meet the expectations; the nitriding surface treatment turned out to be prone to scratching. The CZ finally opted for the surface protection of the barrel and slide on the Duty model with manganese phosphate coating, which improves the anti-corrosion and friction characteristics. The company processes this surface treatment on its own, using the automatic processing line purchased several years ago.

Reason for Modernisation

The development of the CZ 75 P-07 Duty was finished during 2007 and launched to retail shops in the spring of 2009. Nowadays, CZ admits that it needlessly hurried. Even though the pistol passed all the demanding tests performed in accordance with service standards, the launch of production and its practical use have demonstrated the need for fine tuning of certain details. But the initial stage of problems did not last very long and the new CZ “plastic” gun promptly began to make its way to both the service and civilian markets.

The launching of the Duty on the market was obviously associated with concerns about the material of pistol frame. Some customers perceived Zytel without fibreglass as being too soft and sensitive to temperature changes. The reality is that the fine tuning of the design has eradicated all operation problems and even proved the pistol as a potential rival to products of truly prestigious brands – the information available from the tender in Egypt show this pistol won the final stage, out-performing pistols from Glock and Beretta. Nevertheless, CZ resorted to substantial re-consideration of the polymer to be used for further expansions of its portfolio.

Looking at the fact that the CZ 75 P-07 Duty was originally designed as a “tender” pistol, it still lacked one important thing: the option to customise grip sizes by means of replaceable backstraps. Most shooters are impressed with the ergonomics of the Duty, so its development team had to tackle the actual need for the utilisation of this feature. The only problem here is that partial changes in the grip size have become one of the most observed conditions in tender proceedings over the recent years.

Having summarised all these facts, CZ reached a conclusion: the most convenient and fastest way forward is to modernise the CZ 75 P-07 Duty model. The same process was also destined for the high-capacity pistol unofficially called the “large Duty”.

Time for Changes

Following the appointment of the new general manager Kova?ík, CZ launched its ambitious scheme for the development and production of new service firearms and hired several ex-military personnel for product management positions in this respect. New product managers know the true needs and preference of their customers – as well as the things to be avoided, undesired or unusable.

The new pistols CZ P-07 and CZ P-09, both launched in 2013, have benefitted from a series of accurately aimed alterations to remove weak spots from the CZ 75 P-07 Duty: the features concerned are the sharp edges of the frame and slide, the smooth bevelling of sides on the slide front, the missing option to change the grip size, the dimensionally stable polymer used for frame manufacturing, the reach on the trigger in the DA mode, the plastic sights and the return spring fitted freely on the guide rod.

When it came to modernisation, the company needed to go lock, stock and barrel! That finally led to changes affecting the hammer with the aim to enable its easy and safe operation by harmonising the shape with a new, altered design.

Polymers reinforced with fiberglass are not absolutely flawless. Their high strength and dimensional stability regardless of temperature fluctuation are amazing. But polymers with fiberglass are fairly brittle. The problem arising on the Duty was with the spur and the trigger guard. Whereas this issue was solved by partially thicker walls, the alteration to the frame rear took the design engineer a lot longer – his aim was actually to preserve the existing rear container. He could not make it one hundred percent perfect anyway, strengthening the spur required both the reduction of its length and thicker walls, as well as a slight curving of the top part of the grip, and this solution employed a reduced original container insert instead of making a new one.

As for the replaceable backstraps, the design engineer was inspired by the proven solution on the CZ 75 SP-01 Phantom model: the backstraps are slid onto the grooves in checkering and secured by means of a cross pin holding the firing spring ramp as well. They are easy to replace, yet the manufacturer does not assume that these replacements would be very frequent, so the pistol is supplied without any special tool for removal of the pin – one can simply use anything of the right diameter. The CZ P-07 and CZ P-09 models are supplied with three replaceable backstraps as standard: S, M and L, where S is the smallest default one.

What Remains Hidden

The return spring preloaded on the guide mounted in the new CZ pistols can be spotted and definitely enjoyed by every user. On the other hand, the new design of the sights on the CZ P-07 and CZ P-09 will remain unnoticed by many. Those are made of steel, which improves the service life and durability. The new sights are provided with luminescent dots as standard, the product range also includes versions with optical fibre and tritium capsules.

During the modernisation of the Duty, the CZ has decided to use carbon nitriding in a salt bath (tenifer coating), specifically the process called Arcor. The procedure improves the resistance to corrosion and wear significantly. In for a penny: the Arcor surface treatment on pistols CZ P-07 and CZ P-09 is used not only on the slide and barrel yet also on certain inner metal parts.

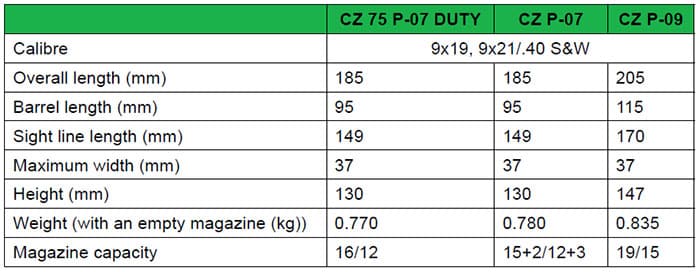

The last detail that not every user necessarily notices at first, is the alteration of magazine capacity for the CZ P-07 model. Its basic version contains 15 rounds in calibre 9×19, which is one less compared to the Duty. The basic accessories include a plastic bottom, which expands the magazine capacity by two more rounds without any significant increase in dimensions. The forty version even offers the impressive combination of 12+3.

Summary

The new polymer pistols CZ P-07 and CZ P-09 bring more than just a cosmetic improvement. The adoption of reinforced polymer and the implementation of the modern surface treatment on metal parts have brought rapid improvement to such crucial characteristics as reliability and durability under any weather conditions.

Both models are available in calibres 9×19 (9 mm Luger), .40 S&W and 9×21. The portfolio will be soon complemented by the compact version in “calibre 9 mm Browning short”. Armed forces can be supplied with adaptors to enable shooting both models with marking ammunition – Simunition/CQT. The product range includes the extended barrel with arrangements for suppressor mounting. For both models there are available the quality plastic holsters for concealed carry, made by the Hogue Company, alternatively also with the paddle and belt sling, as well as the service ones. Especially for the armed forces a variant of the holster with a thigh belt clip or MOLLE clip and safety (level 2) is available. Both pistols can be also provided with “a bodywork” in the RONI carbine conversion to enable more accurate, faster and more comfortable shooting.

| This article first appeared in Small Arms Review V20N1 (January 2016) |